Speedaire 3CRH3B Instructions for use

Operating Instructions & Parts Manual EN

AIR RIVETER

Models 3CRH3B and 3CRH4B

PLEASE READ AND SAVE

THESE INSTRUCTIONS.

READ CAREFULLY

GNITPMETTAEROFEB

,LLATSNI,ELBMESSAOT

OPERATE OR MAINTAIN THE

PRODUCT DESCRIBED.

PROTECT YOURSELF AND

OTHERS BY OBSERVING ALL

SAFETY INFORMATION. FAILURE

TO COMPLY WITH INSTRUCTIONS

COULD RESULT IN PERSONAL

INJURY AND/OR PROPERTY DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE

REFERENCE.

PLEASE REFER TO BACK COVER

FOR INFORMATION REGARDING

DAYTON’S WARRANTY AND OTHER

IMPORTANT INFORMATION.

Model #: ___________________

Serial #: ___________________

Purch. Date: _______________

© 2015 W.W. Grainger, Inc.

All Rights Reserved

Printed in Taiwan

Version //201

BEFORE YOU BEGIN

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

See General Safety Instructions on page 2, and Cautions and Warnings

as shown.

1

Personal protection equipment

Unpack:

parts. Shipping damage claim must be filed with the carrier.

Contents:

UNPACKING

GENERAL SAFETY INFORMATION

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

2

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

"

area, and work with approved safety equipment, such as those dust masks

that air specially designed to filter out microscopic particle.

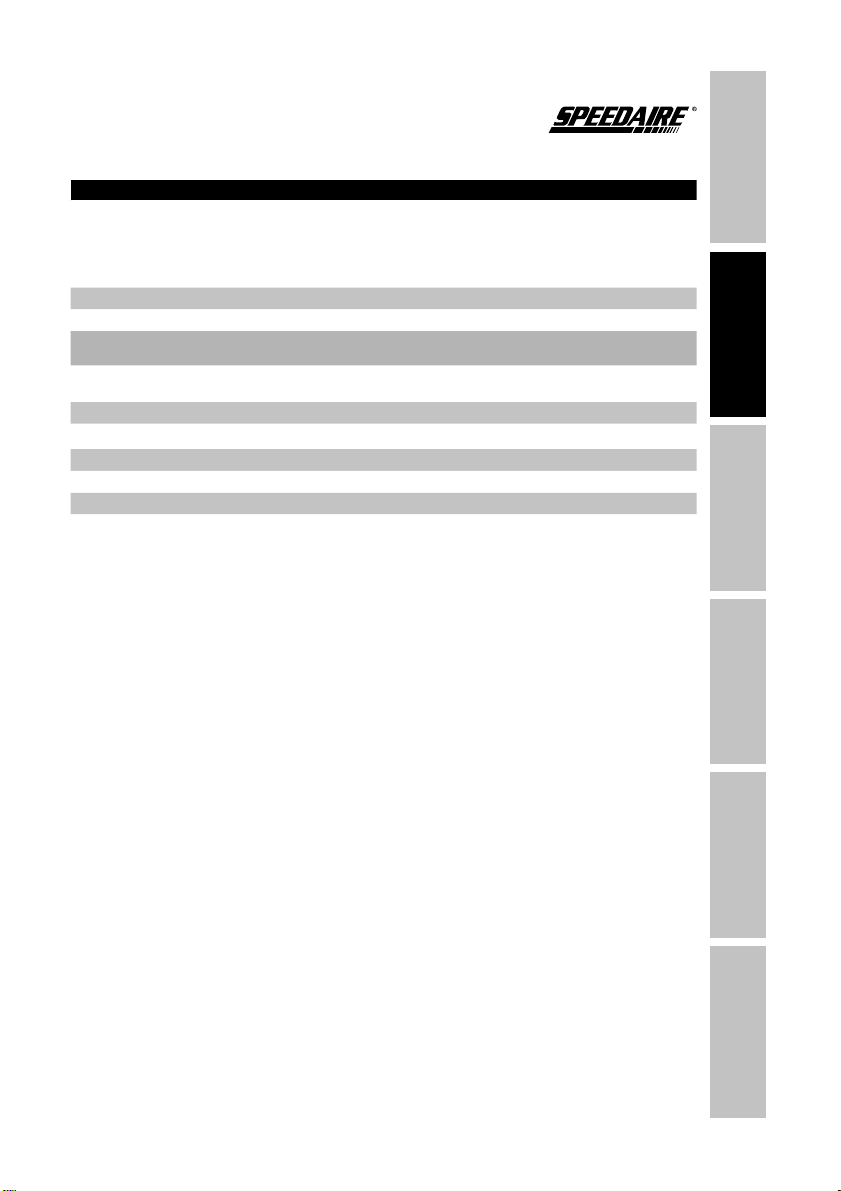

SPECIFICATIONS

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

3

3CRH3B 3CRH4B

Rivet Sizes or Rivet Nut Sizes 3/16”

5/32”

1/8”

3/16”

5/32”

1/8”

3/32”

Pulling Force (Ibs) 1983

Stroke

Maximum Air Pressure (PSI)

Air Consumption per Stroke

(CFM)

Air Inlet (NPT)

Recommended Hose Size 3/8” 3/8”

Hydraulic oil

Overall Length

Overall Height

Overall Width

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

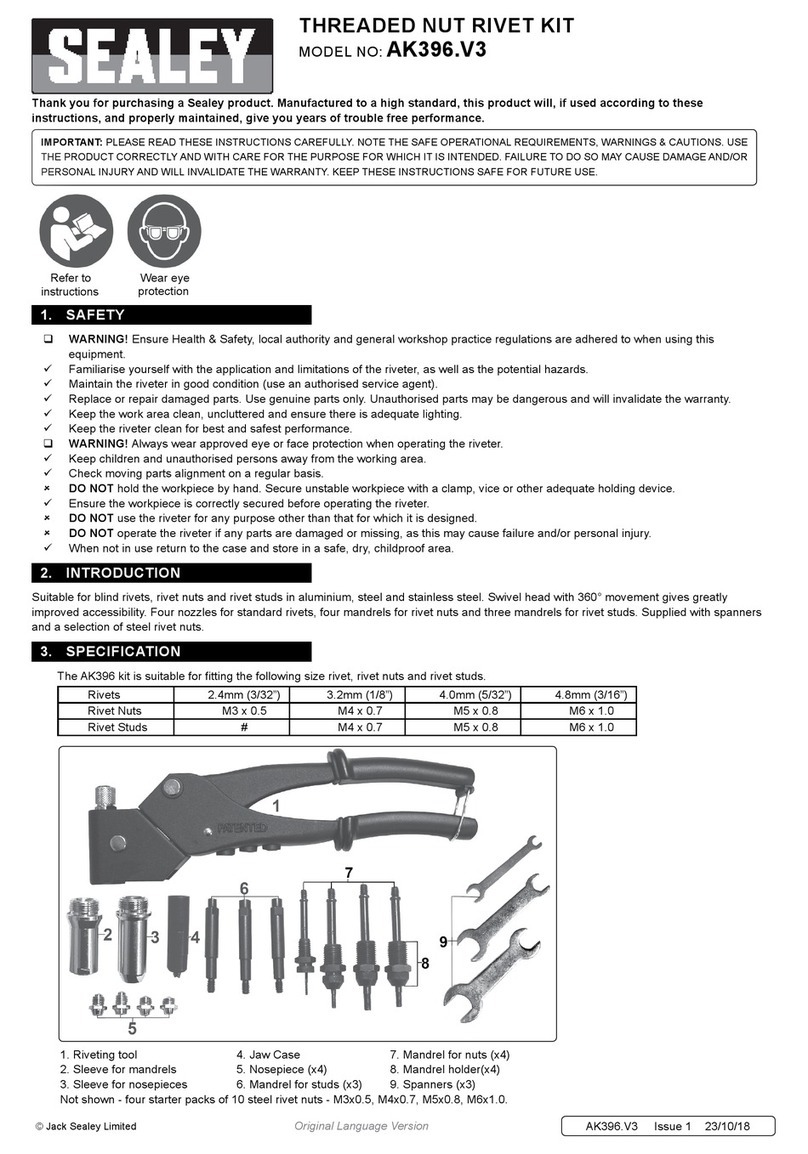

Loosen and remove the nosepiece from the frame head as

shown, and replace it with the desired nosepiece.

INSTALLATION INSTRUCTIONS

Figure 1

Figure 2

Inner Dia. of

Nosepiece

Outer Dia. of

Rivets Available

Nosepiece display

3/32”

1/8"

5/32"

3/16"

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

5

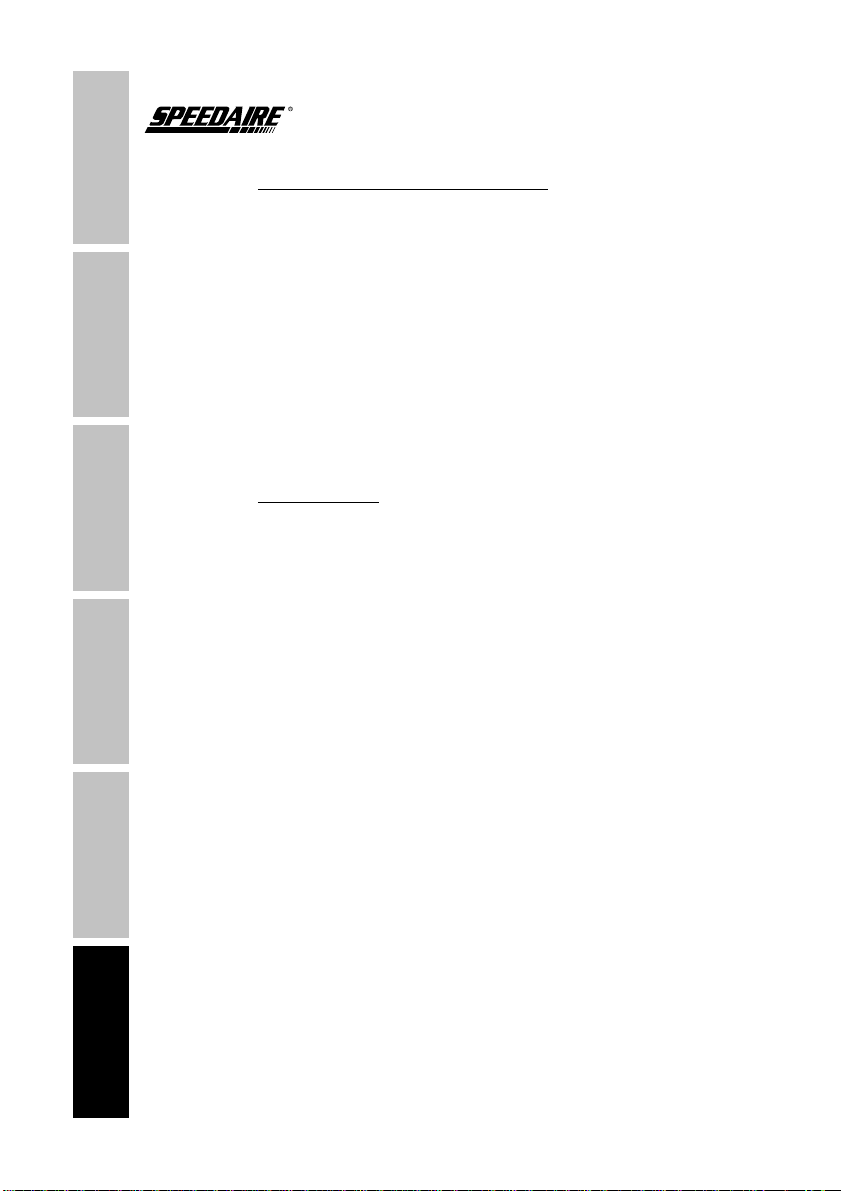

Loosen and remove the frame head from the frame, then loosen

and remove the front jaw case from the rear jaw case.

Take out the jaw and jaw pusher, and replace with the jaw and

jaw pusher that correspond to the nosepiece installed above.

Assemble the jaw housing and adjust its length using the spanner

gauge as shown.

Re-assemble the frame head and lock it with the corresponding,

previously loosened lock nut.

INSTALLATION INSTRUCTIONS

Figure 3

Figure 4

Figure 5

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

1. Select rivet size and ensure riveter nosepiece size matches.

See “Assembly” section for instructions for changing the nosepiece.

2. Insert rivet mandrel into nosepiece.

3. Insert rivet body into material to be riveted.

4. Squeeze the trigger to attach the rivet.

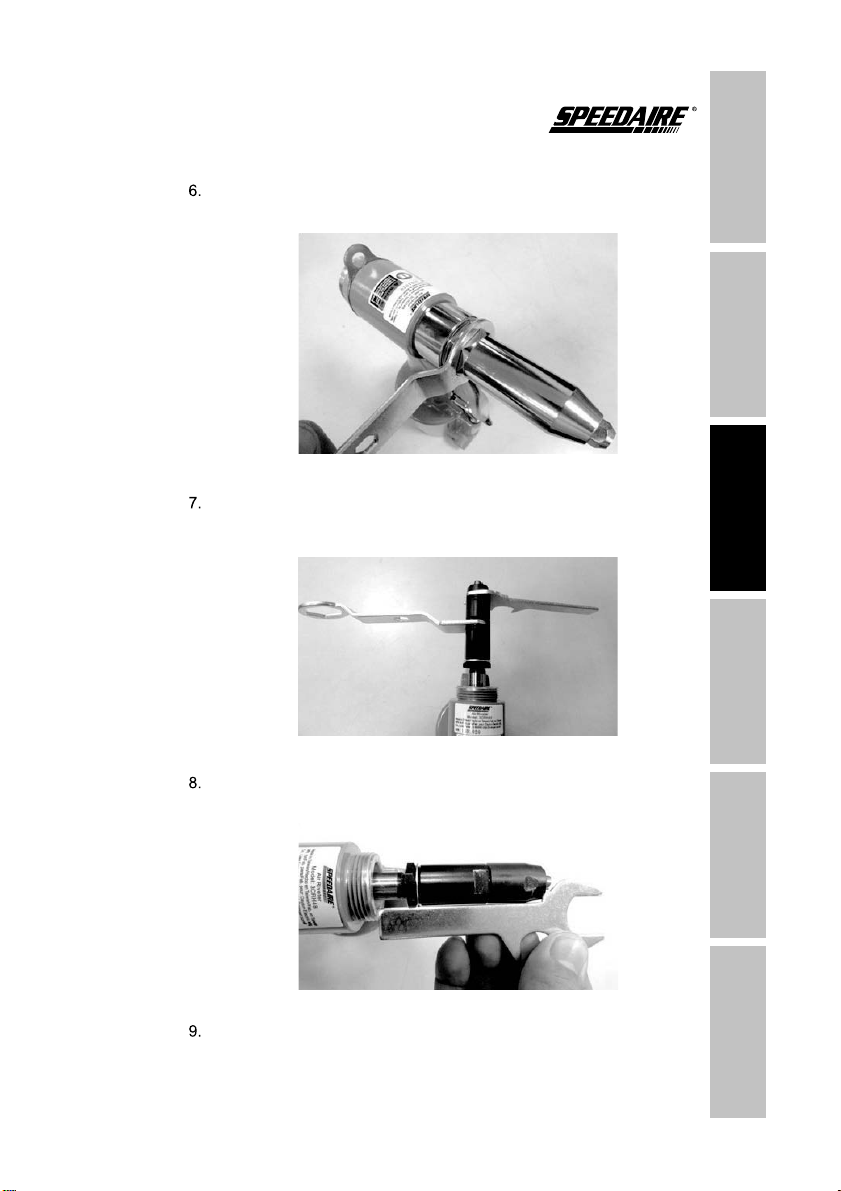

Figure 6

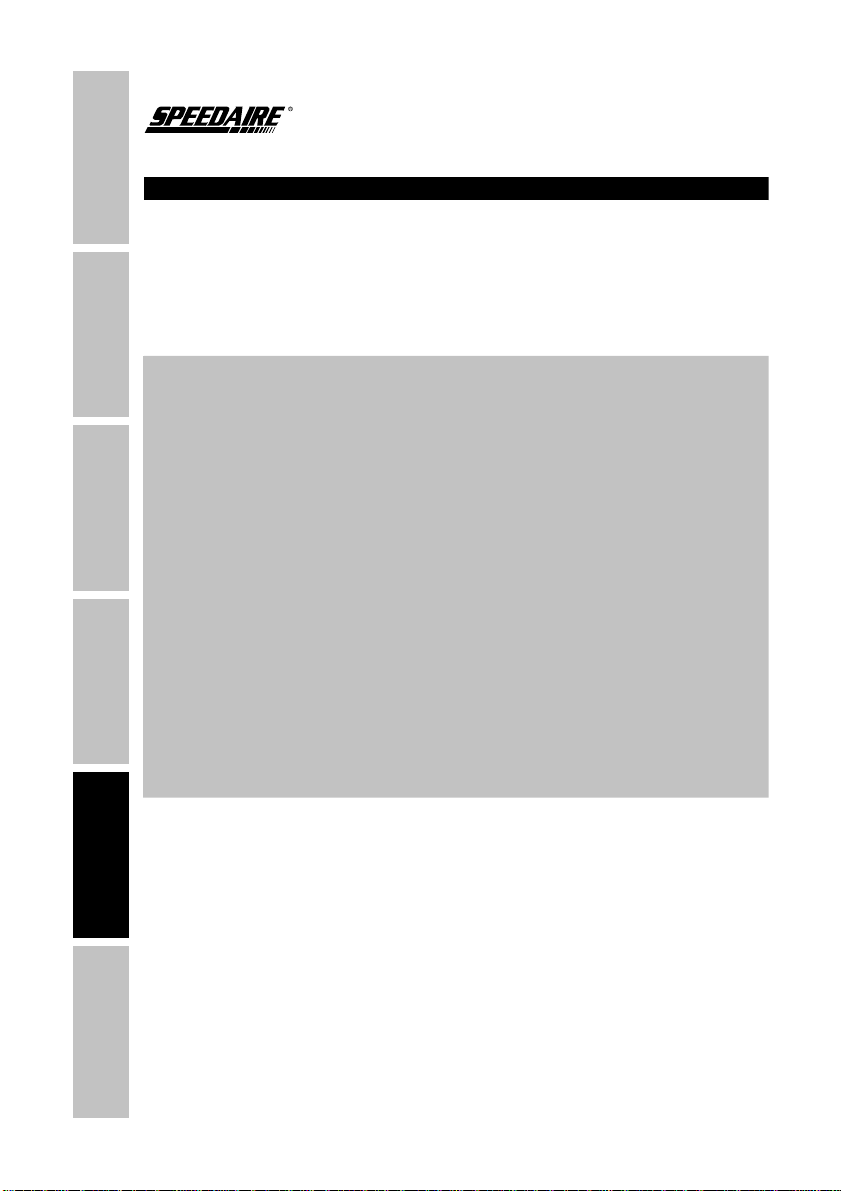

Figure 7

OPERATING INSTRUCTIONS

6

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

TROUBLESHOOTING

Symptom Possible Causes Corrective Action

j

f

cf h

isassemble the air cylinder, frame

and frame head.

Before adding oil, check if

the oil piston is at the bottom of its

stroke by hand pulling the front jaw

case away from the frame.

The oil piston should be at the

bottom of its stroke automatically when

removing the frame head.

WKHIUDPHWRWKHOHYHORI

WKHWRS

fh

FDVH

FQ

f

jh

spanner before

assembling frame head.

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

TROUBLESHOOTING

Symptom Possible Causes Corrective Action

FF

V

M

sc

IK

M

K

5HOR

rivet,

FKLSVFDQVWLFNWRWKHQRVHSLHFH

malfunctioning

tv

c

v

8

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

TROUBLESHOOTING

Symptom Possible Causes Corrective Action

V

36,

9

frame head/jaw housing/jaw/jaw pusher/

spring/jaw housing coupler

frame head/jaw housing/jaw/jaw pusher/spring

he mandrel bottle needs to be emptied when it is filled with

5 rivets' resideues.

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

MAINTENANCE

V

WKH

VWURNHE\KDQGSXOOLQJWKH

IURQWMDZFDVHDZD\IURPWKHIUDPH

EHDWWKHERWWRPRILWVVWURNHZKHQ

UHPRYLQJ

KDQGSRZHU

WKH

WKH

IUDPHWRWKHOHYHORIWKHWRS25LQJ

IRURLODSSHDULQJLQWKHDLUF\OLQGHU

R

Jaw Inspection and Replacement

Pneumatic Oil

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

MAINTENANCE

11

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

12

For Repair Parts, call 1-800-323-0620

24 hours a day – 365 days a year

Please provide following information:

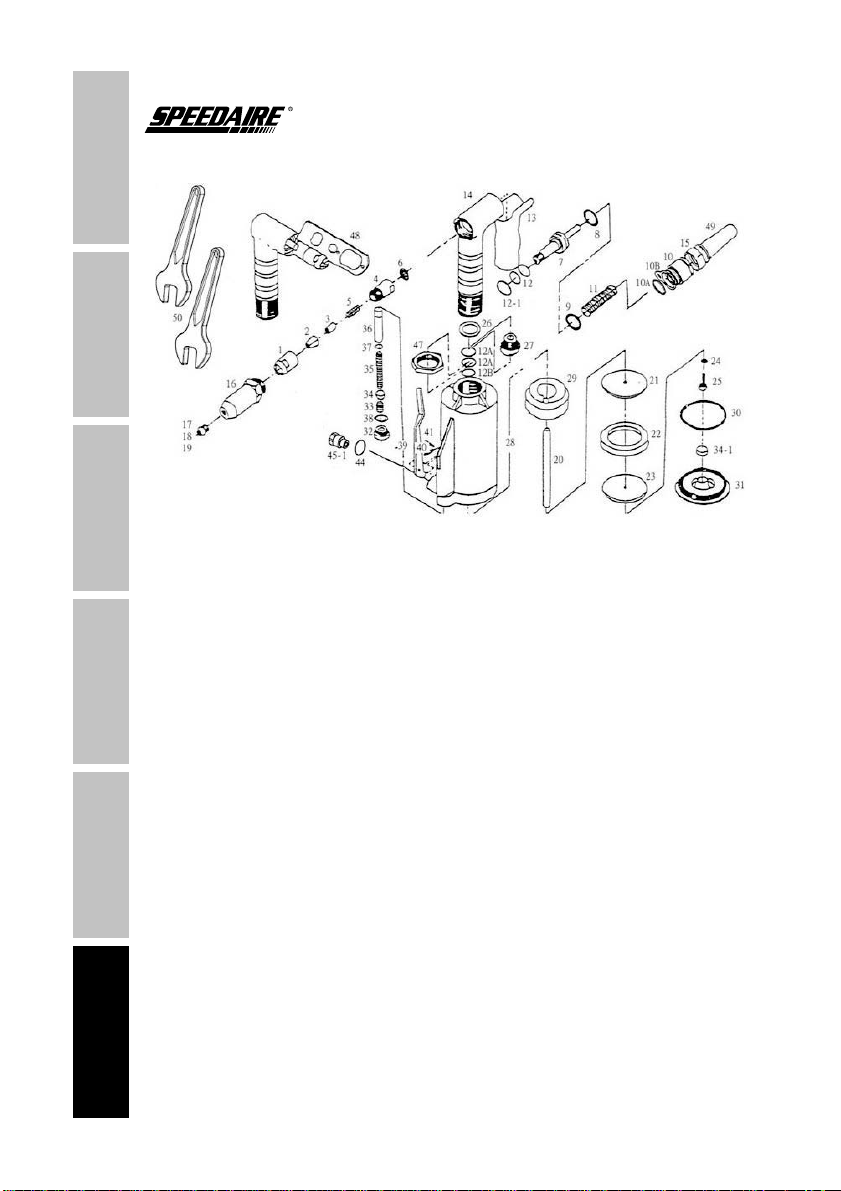

REPAIR PARTS ILLUSTRATION FOR 3CRH3B

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

Description Part No. Qty.

32 *** 1

33 *** 1

*** 1

*** 1

35 *** 1

36 *** 1

*** 1

38 *** 1

39 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 2

REPAIR PARTS LIST FOR 3CRH3B

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

15

NOTES

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

16

REPAIR PARTS ILLUSTRATION FOR 3CRH4B

For Repair Parts, call 1-800-323-0620

24 hours a day – 365 days a year

Please provide following information:

GETTING STARTED SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

REPAIR PARTS LIST FOR 3CRH4B

*** 1

*** 1

*** 1

*** 1

32 *** 1

33 *** 1

35 *** 1

Description Part No. Qty.

1

1

1

1D 1

*** 1

*** 1

02

*** 1

1

*** 1

*** 1

11 1

12 *** 1

13 *** 1

*** 2

15 *** 1

16 *** 1

*** 1

18 *** 1

19 *** 1

*** 1

21 *** 1

22 *** 1

23 *** 1

*** 1

25 *** 2

26 *** 1

*** 1

29 *** 1

*** 1

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATIONTROUBLESHOOTING

MAINTENANCE /

REPAIR

Description Part No. Qty.

36 *** 1

*** 1

38 *** 1

39 *** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

*** 1

51 *** 1

52 *** 1

REPAIR PARTS LIST FOR 3CRH4B

18

This manual suits for next models

1

Table of contents

Languages:

Other Speedaire Rivet Tools manuals