TKR Group PNP 90 SNW-RIV User manual

Pneumatic, hydraulic

stamping and riveting tool

PNP 90 SNW-RIV

Instruction manual

83 43 2 158 708, Translation of the original instructions

2

All photos, drawings and other illustrations as well as the text and other content in this instruction

manual are subject to the copyright of both the TKR Group and the author involved. Reproduction,

processing or other use is permitted only with express written consent.

3

1. Information regarding this manual 4

2. Explanation of symbols 5

3. Labelling 6

1. Operating principles 7

2. Accessories and specifications 8

3. Noise and vibration values for PNP 90 SNW-RIV 8

4. Safety instructions 9

5. Fundamentals of riveting tool handling 10

6. Maintenance 11

1. Technical data - pump PNP 90 12

2. Technical data - rivet clamp SNW-RIV 13

1. Initial start-up 14

2. Riveting tool preparation and connection 16

3. Riveting tool operation 22

4. Hydraulic pump maintenance (oil change) 28

5. Riveting tool storage 30

1. Troubleshooting 32

2. Warranty 34

3. Declaration of Conformity 35

Other languages

To obtain this instruction manual in other languages, please visit

our download area on the Internet site:

www.tkr-service.com

1.

2.

3.

4.

5.

4

1.1 Information regarding this manual

Legislation stipulates that workers handling hydraulically-driv-

en riveting tools must be protected.

If desired, training can be provided at TKR in Gevelsberg or on

site at the customer.

In the interests of quality assurance, we reserve the unre-

stricted right to carry out technical modifications on the basis

of further developments in technology and product improve-

ments, without prior notice.

This riveting tool represents state-of-the-art technology. To en-

sure the functionality of the equipment, it must be operated in

a proper and safe manner.

Read the instruction manual carefully before using the riveting

tool.

All handling necessary to ensure correct operation is described

in the instruction manual.

No work method other than that expressly approved by the

manufacturer may be used.

In the event of a fault, the user or owner may only carry out

repair work for faults for which the relevant maintenance pro-

cess is laid out in the instruction manual.

Information

Technical

modifications

State of the

technology

Read the

instruction

manual

Handling

Faults

5

1.2 Explanation of symbols

In this instruction manual, some sections use internationally

known warning symbols, warning symbols and general in-

structional symbols.

The individual symbols are explained below.

Observe the instruction

manual

Observe the general

information

Wear face mask

Wear gloves

Warning

General source of danger

Warning

Hand could become

trapped

Warning

Finger could become

trapped

Warning

Danger of environmental

contamination

Warning

System under pressure

Follow all in-

structions and

safety rules

TÜV certification

Please note the following.

Arrow to clarify

pressing together

Arrow indicating direction

For further information

see chapter...

Audibly engage

A

F

B

C

D

E

1.3.1

1.3 Labelling

AName

BSerial number

CManufacturer’s details, date of manufacture

DMaximum permissible operating pressure (oil)

ECE mark

FSymbol to read the instruction manual

Stamping

and riveting

tool label

7

2.1 Operating principles

The pneumatically driven stamping and riveting tool, model

PNP90 SNW-RIV, is used to install rivets. This tool set is special-

ly designed to rivet sheet metal for the automotive industry.

Each tool set consists of a pneumatically-driven hydraulic pump

as well as the rivet clamp with hydraulic cylinder and the appro-

priate rivet mandrels and dies for the rivets in question.

The hydraulic pump is a pneumatically driven pressure intensifier

with an intensifying ratio of 1:100. This means that hydraulic

pressure is one hundred times the preset air pressure. If the preset

end pressure is reached, the pump automatically stops and

keeps this end pressure constant. The hydraulic pump has a

pneumatically controlled pressure relief valve.

The rivet clamp is connected to the pump with a hydrau-

lic hose. This hose is connected to the pump via a leak-free

quick release coupling. The coupling will only release from the

equipment when it is depressurised.

The two pneumatic control hoses must also be connect-

ed to the pump. Make sure that the black hose is attached

to the coupling that is marked for the black hose. Once the

high-pressure hose and the two control hoses have been con-

nected to the rivet clamp, compressed air can be connected

to the equipment.

The two control valves are installed on the rivet clamp, which

activates pump function. Riveting can only be started when

both valves are actuated. If one of the valves is deactivated,

riveting is interrupted and the rivet plunger automatically re-

tracts.

Never bypass either of the control valves or replace

them with other valves! Without the genuine two-hand

control operation, there is a danger of personal injury.

Pump PNP 90

Rivet clamp

SNW-RIV

8

2.2 Accessories and specifications

In the repair manual from the manufacturer recommended

rivets

Filling capacity 280 ccm

Hydraulic oil brand as per DIN 51524 and

ATF as per DIN 51562-1;

viscosity approx. 68 mm²/s at 40°C

Example: Shell Tellus TX 68, Dexron, Mercon, Hydroclear

6 bar / 87 PSI

Quality class 2 as per ISO 8573-1

5 – 50°C / 41 – 122°F

Protective gloves

Face mask

Emissions noise level: LPAI < 75 dB (A)

Vibration emission value: a < 2,5 m/s²

Permissible

rivet accessories

Permissible

hydraulic oil

Max. air

pressure

Compressed air

Ambient

temperature

Safety

2.3 Noise and vibration values

9

2.4 Safety instructions

Permissible

rivet accesso-

ries

Usage as

described in

instruction

manual

Chapter 4.3

Improper

use

The stamping and riveting tool must only be used for rivet-

ing with the approved accessory tools. Only use genuine rivet

mandrels and dies for the two rivet sizes. Note the information

list on the packaging.

Make sure that the riveting tool is problem-free and that it has

all functionality necessary to ensure safe operation.

The tool must only be used as a hand tool with two-

hand operation! Any modification of the tool or other

usage forms are the responsibility of the user.

Follow all health and safety regulations in the country of oper-

ation. Do not use any hoses or fittings that are not permitted

for the equipment’s operating pressure.

Protective gloves and a face mask must be worn during rivet-

ing as incorrect usage or a tool defect could cause parts to fly,

which could lead to severe bodily injury.

See also ANSI Z87.1-1989

Never wave the tool in the air or allow it to fall.

Never use the stamping and riveting tool for purposes other

than those intended and never allow untrained workers to

use the tool.

The riveting tool must only be used at ambient temperatures

between 5°C and maximum 50°C.

Never use the stamping and riveting tool in areas where there

is a risk of explosion!

10

2.5 Fundamentals of riveting tool handling

Route all supply lines in a manner that prevents people from

tripping over them. Correctly route and attach the compressed

air hose. If a compressed air hose whips around wildly, it could

cause severe bodily injury.

Before starting work, check the preset air pressure! In-

correctly set air pressure could cause equipment dam-

age or bodily injury!

Make sure that the maximum permissible operating air pres-

sure of 6 bar / 87 PSI is never exceeded. Check the setting of

the pressure regulating valve before each riveting operation!

Make sure that the pump is only supplied with clean and dry

compressed air. Moisture and contamination could cause

equipment malfunction and/or damage. Only use com-

pressed air of quality class 2 as per ISO 8573-1.

Always disconnect the riveting tool from pressure when leav-

ing the work site!

The manufacturer accepts no liability for damage or injury

caused by improper repair or use of foreign replacement parts.

Incorrect usage of the riveting tool that leads to equipment

damage invalidates the warranty.

Riveting tool PNP 90 SNW-RIV has been tested and manu-

factured in accordance with European guidelines. The Decla-

ration of Conformity has been included with this instruction

manual.

The compressed air supply must be disconnected from

the equipment before any adjustment or maintenance

work is performed.

Danger of

bodily injury

Max. air

pressure

Clean

compressed air

Warranty

Declaration of

Conformity

Chapter 5.3

11

2.6 Maintenance

Care and

maintenance

Chapter 4.4

The tool’s hydraulic system, pneumatic control systems,

hoses and couplings must all be kept free of dirt and

other contamination. Foreign bodies in the hydraulic

fluid or in the control air will cause the tool system to

malfunction.

All maintenance and service work on the pump must

only be performed with air disconnected and oil

drained.

Normally, pump maintenance only entails a regular oil change

(see 2.2 for permissible oils).

All other necessary maintenance work and/or repairs should

be performed by the manufacturer or properly trained per-

sonnel.

With normal use of the pump, hydraulic oil should be changed

every 80 operating hours or every 6 months. Make sure that

used oil is disposed of as required by national environmental

legislation.

Oil that is not properly disposed of could harm the en-

vironment.

The user must only perform the maintenance and repair

measures outlined in this instruction manual.

Maintenance and repair work not covered in this instruction

manual may only be performed by professionals with proper

training by TKR. For further information on servicing and train-

ing, please contact us at our Service address:

TKR Spezialwerkzeuge GmbH

Service

Am Waldesrand 9–11

D-58285 Gevelsberg (Germany)

Telefon +49 2332 66607-77

Telefax +49 2332 66607-51

E-Mail

support@tkr-service.com

3.1.3

3 .1.1 3.1.2

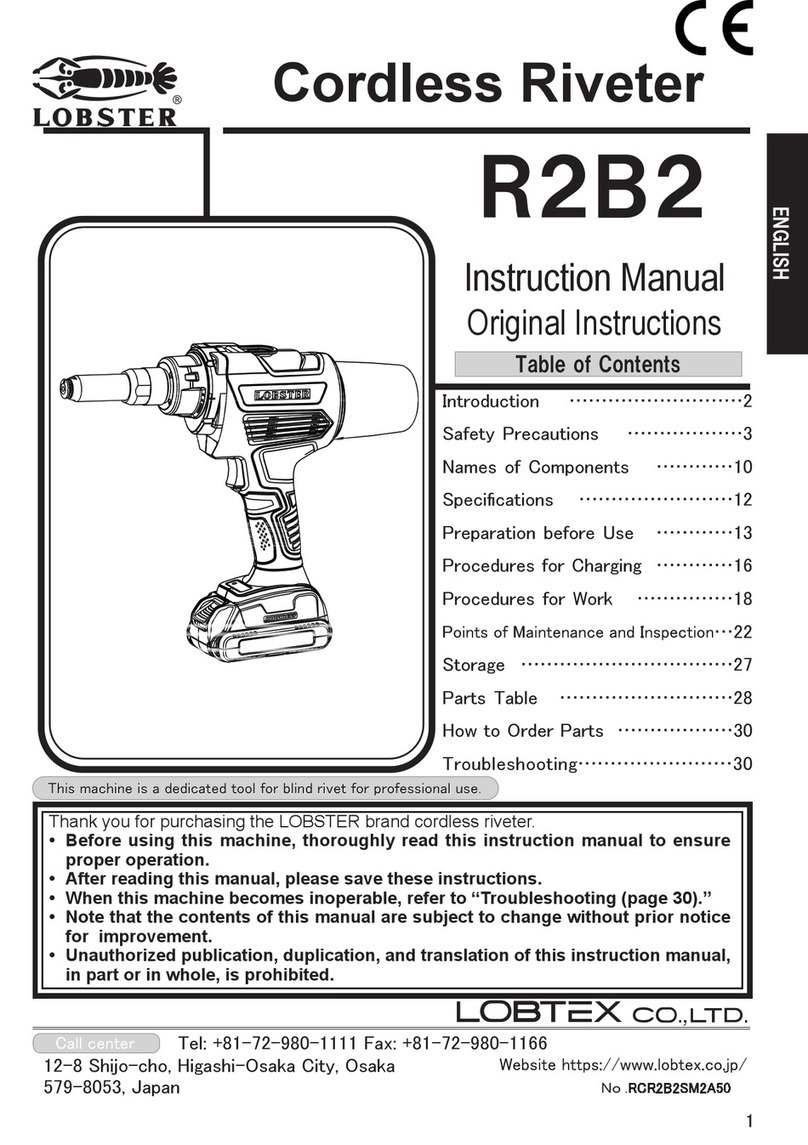

3.1 Technical Data Pump PNP 90

Length 330 mm

Width 230 mm

Height (incl. handle) 213 mm

Weight 7,665 kg

Max. Input pressure 6 bar

Max. Operating pressure 600 bar

3.2.1 3.2.2

3.2.3

3.2 Technical Data

Rivet clamp SNW-RIV

Length 340 mm

Width 60 mm

Height 275 mm

Clamp opening 78 mm

Opening depth 125 mm

Stroke 25 mm

Press force (6 bar) 55 kN

Weight 5 kg

Length and weight without hoses

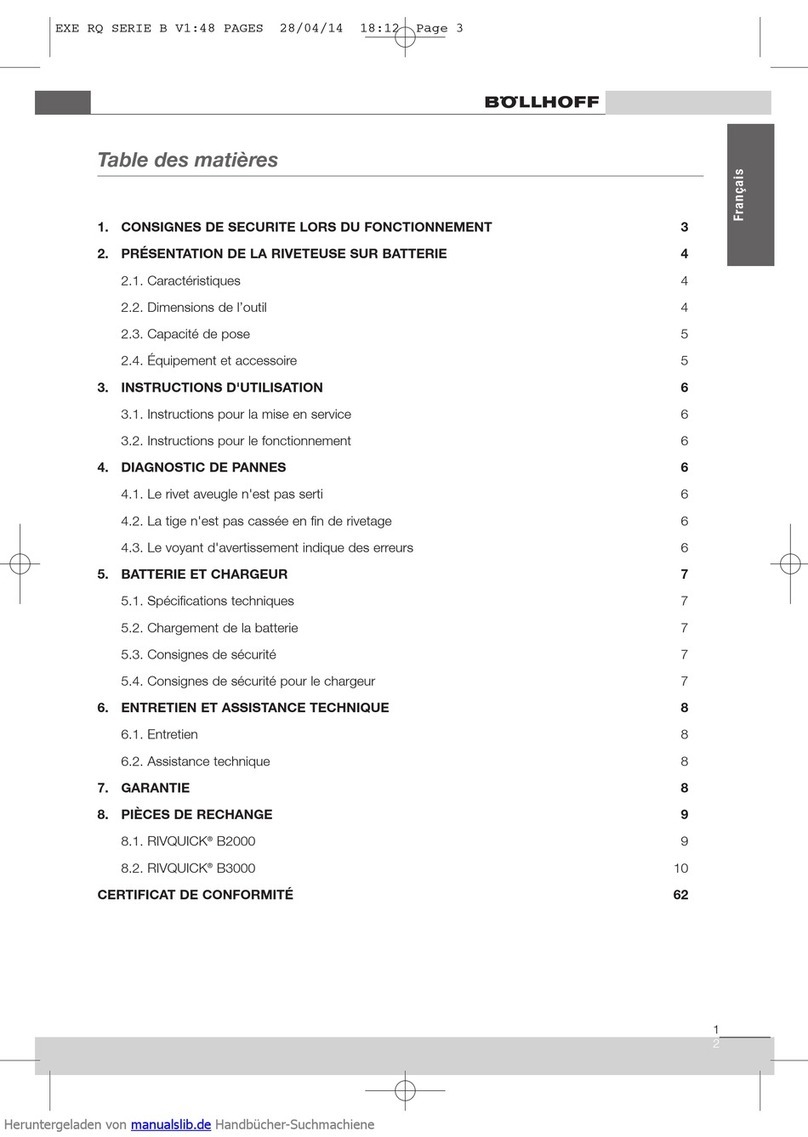

4.1.24 .1.1

G1/4“

4.1 Initial start-up

The equipment is delivered from the factory without a com-

pressed air connection. The pressure reducing valve has a con-

nection thread of G1/4“ (internal thread).

The pressure regulating valve is delivered with a cap fitted (Fig.

4.1.1). Remove the cap (Fig. 4.1.2).

4.1.3 4.1.4

R1/4“

Use a compressed air connection with R1/4“ thread and seal

(Fig. 4.1.3). Screw this onto the regulating valve (Fig. 4.1.4).

16

4.2.1

4.2.3 4.2.4

4.2.2

4.2 Riveting tool preparation and connection

Before using the equipment, check the condition of the

riveting tool and the hoses. Risk of severe bodily injury if

the pump or the rivet clamp is damaged.

4.2.64.2.5

In the event of any noticeable damage, the hydrau-

lic components must be replaced. Damaged hoses or

couplings could cause severe injury!

Incorrectly attached hoses could come loose and cause

severe bodily injury.

Check the hoses and couplings for damage.

Connect the high-pressure hose to the high-pressure pump

with the quick release coupling. Make sure that the high-pres-

sure coupling completely engages and locks (Fig. 4.2.4).

Connect the pneumatic hoses. Make sure that the black hose

is attached to the marked coupling (Fig. 4.2.5).

black

blue

18

4.2.9

4.2.7

4.2.10

4.2.8

4.2.11

4.2 Riveting tool preparation and connection

Insert the rivet mandrel and rivet die for

the planned riveting operation in the

rivet clamp and screw them into place

(Fig. 4.2.7 – 4.2.11).

During the entire process, always make

sure that the rivet mandrel and die are

firmly seated.

19

4.2.12 4.2.13

4.2.15 4.2.16

4.2.14

16

13

1 2 3

Make sure that both the correct rivet

mandrel and the correct die are used.

Check for the correct part numbers and

designations (Fig. 4.2.14 / 4.2.15 / 4.2.16).

* These parts are available directly from BMW via your normal parts ordering channels.

Riveting die Ø3, 81 43 2 209 938 B

Rivet bolt Ø3, 81 43 2 209 938 A

Set: 81 43 2 209 938*

Riveting die Ø5, 81 43 2 209 939 B

Rivet bolt Ø5, 81 43 2 209 939 A

Set: 81 43 2 209 939*

Elastomer ring, Wrench set,

06-00000112

BGR-TKR-00000239

Distance bolt, Set: 81 43 2 209 937*

1 = Bushing, 81 43 2 209 937 C

2 = Distance bolt, 81 43 2 209 937 B

3 = Spacer, 81 43 2 209 937 A

20

4.2.184.2.17

4.2 Riveting tool preparation and connection

Never use pressure over the permitted value of 6 bar or

87 PSI. This could cause damage to the equipment or

even bodily injury (Fig. 4.2.17).

Connect compressed air to the pressure regulating valve and

set the pressure (Fig. 4.2.16 / 4.2.17).

max. 6 bar / 87 PSI

Table of contents

Other TKR Group Rivet Tools manuals