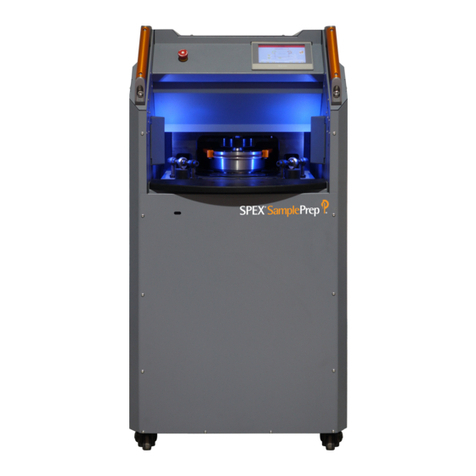

How To Operate 6875D Freezer/Mill

Set up the 6875D FM in a well ventilated, unconfined

space. The Freezer/Mill should be run on an open

countertop, in ambient air, with recommended

maximum relative humidity 70% from 5°C –31°C

(40°F –88°F).

When working with liquid nitrogen directly or

indirectly, the LN Tank valve or hose, or chilled

Freezer/Mill components, cryogenic gloves must be

worn to protect hands. A face shield is recommended

to protect eyes from possible splashing. Wear the

proper protection equipment (PPE).

Dual Pre-cooling

Chambers

Touching Edit will activate

a pop-up keyboard to edit

Control Panel, Saved Protocols,

and Resources can be accessed

On the Control Panel, select Mono

or Dual sample mode and Auto-Fill

or Manual to fill the mill with liquid

nitrogen. In auto-fill mode make

sure the unit is connected to a LN

Tank with the LN hose and the LN

valve is open. In manual mode fill

the tub with LN until the unit

sounds with a series “Beeps”

indicating the proper liquid nitrogen

level has been reached (approx. 2

inches below the rim of the tub).

From the Resources screen the run

history, technical support, accessories,

and training information (manual, etc.)

Touching the Home Icon returns

the user to the Home screen.

Step 1. Connect the powercord to the AC Inlet located at the back of unit. Power On the 6875D FM. “Please

Wait”appears on the screen during start-up as the software loads. After a brief animation, the screen

will switch to the Home Screen.

Step 2. Fill the tub with auto-fill connection or manually with liquid nitrogen to approximately 2 inches below

lip of the tub). Always close the lid slowly to avoid splashing of LN and latch down. It is normal

to see a visible vapor stream exiting the vent at the back of the unit. Do not block the vent.