SPIETH MSA Series User manual

Document

ba-msa-en2336

Page 1 of 10

Operating Instructions

MSA

The Operating Instructions are also available for download at www.spieth-me.de. In case of any questions, please

contact Spieth-Maschinenelemente GmbH & Co. KG directly.

Legal:

Spieth-Maschinenelemente GmbH & Co. KG, Alleenstraße 41, D - 73730 Esslingen

Phone +49 711 930730 0 - Fax +49 711 930730 7

E-Mail: info@Spieth me.de - Web: www.spieth-me.de

KG: Esslingen HQ, Stuttgart county court, company register sect. A 210689

PhG: Spieth-Beteiligungs-GmbH, Esslingen HQ, Stuttgart county court, company register sect. A 210636

Managing director: Dipl.-Ing. Alexander Hund

©Spieth

Proprietary

notice

ISO 16016

Previous document: ba-msa-en1815

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 15 Sep 2023/Fd

For any questions, requests or suggestions, please contact

Checked: 15 Sep 2023/Ax

Original version of the operating instructions

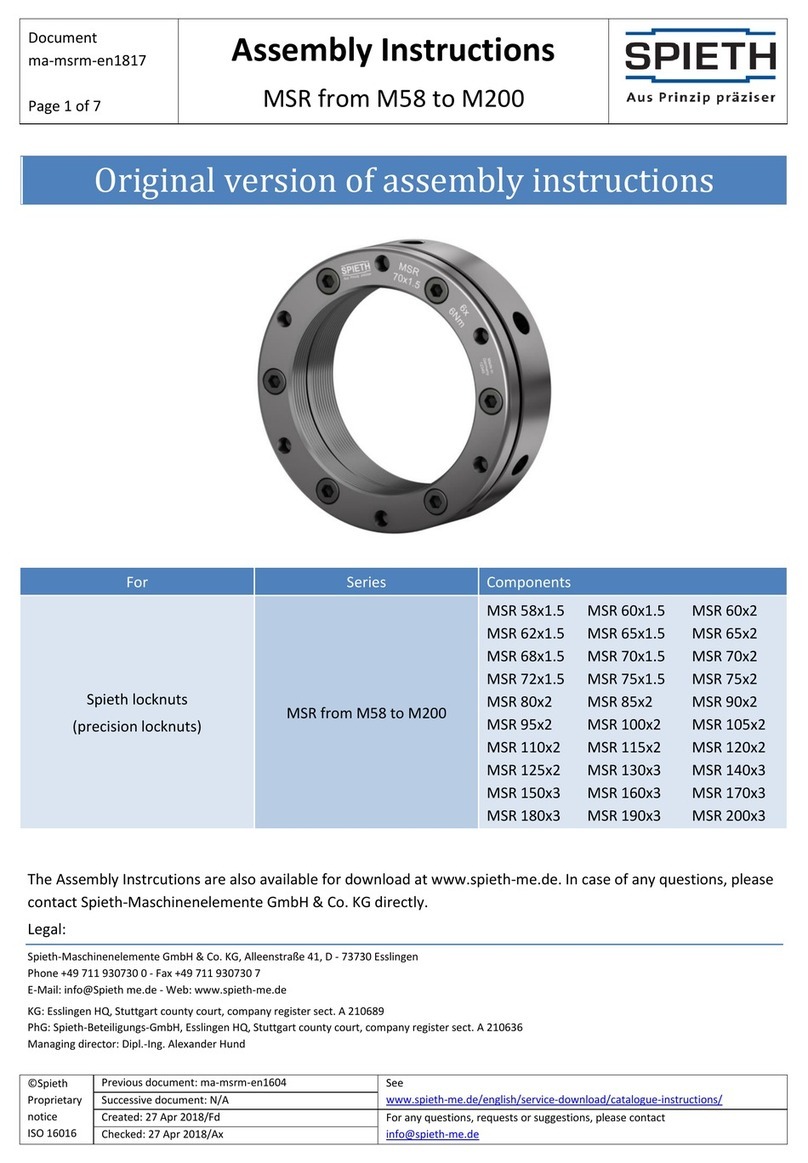

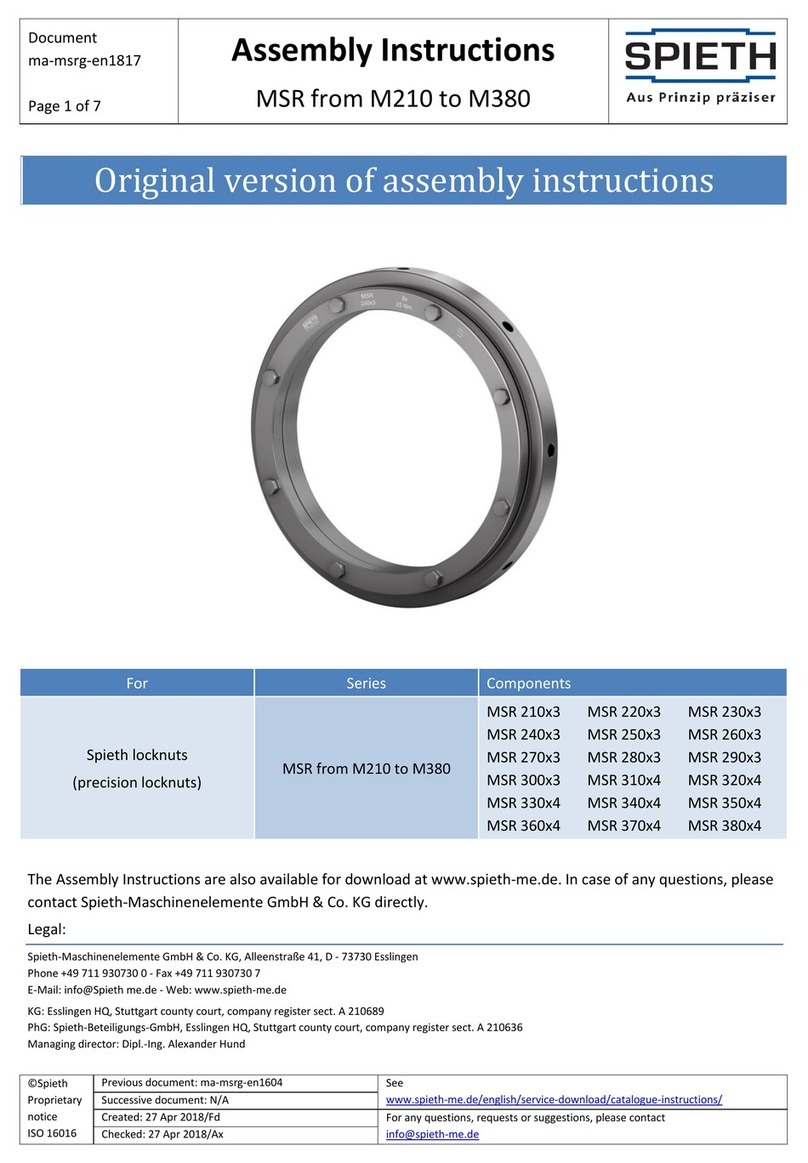

For

Series

Components

Spieth locknuts

(precision locknuts)

MSA

MSA 20x1 MSA 25x1.5 MSA 30x1.5

MSA 35x1.5 MSA 40x1.5 MSA 45x1.5

MSA 50x1.5 MSA 55x1.5 MSA 60x1.5

MSA 65x1.5 MSA 70x1.5 MSA 75x1.5

MSA 80x2 MSA 85x2 MSA 90x2

MSA 95x2 MSA 100x2 MSA 105x2

MSA 110x2 MSA 120x2 MSA 130x3

MSA 140x3 MSA 150x3 MSA 160x3

MSA 170x3 MSA 180x3 MSA 190x3

MSA 200x3

Document

ba-msa-en2336

Page 2 of 10

Operating Instructions

MSA

©Spieth

Proprietary

notice

ISO 16016

Previous document: ba-msa-en1815

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 15 Sep 2023/Fd

For any questions, requests or suggestions, please contact

Checked: 15 Sep 2023/Ax

About the operating instructions for Spieth Locknuts

These operating instructions enable safe and efficient handling of Spieth locknuts. Prior to performing any tasks,

ensure that your staff have carefully read and fully understood these operating instructions.

Notices

The basic requirement for working safely is compliance with all specified safety notices. They can be identified by

the following symbols:

Caution!

In addition to the notices in these instructions, local accident prevention guidelines and national health and safety

regulations also apply.

Table of Contents

1 Information about Spieth Locknuts ....................................................................................................................3

1.1 General information ...................................................................................................................................3

1.2 Safety notices .............................................................................................................................................3

2 Description of Spieth Locknuts...........................................................................................................................4

2.1 Structure.....................................................................................................................................................4

2.2 Mode of action ...........................................................................................................................................4

2.3 Intended use...............................................................................................................................................5

3 Delivery Contents and Storage of Spieth Locknuts.............................................................................................5

3.1 Delivery contents of the Spieth Locknuts ...................................................................................................5

3.2 Storage and shelf life of the Spieth Locknuts..............................................................................................6

4 Assembling Spieth Locknuts ...............................................................................................................................6

4.1 Preparing for assembly...............................................................................................................................6

4.2 Ambience/Environment .............................................................................................................................7

4.3 Assembly process .......................................................................................................................................7

5 Using Spieth Locknuts.........................................................................................................................................9

6 Disassembling Spieth Locknuts...........................................................................................................................9

7 Disposing of Spieth Locknuts............................................................................................................................10

Document

ba-msa-en2336

Page 3 of 10

Operating Instructions

MSA

©Spieth

Proprietary

notice

ISO 16016

Previous document: ba-msa-en1815

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 15 Sep 2023/Fd

For any questions, requests or suggestions, please contact

Checked: 15 Sep 2023/Ax

1Information about Spieth Locknuts

1.1 General information

Please read these operating instructions carefully, paying special attention to our safety notices. These operating

instructions are part of your product and must be kept accessible to the staff in the immediate vicinity of the

product at all times. The operating instructions are also available for download at www.spieth-me.de.

In case of any questions, please contact Spieth-Maschinenelemente GmbH & Co. KG directly.

Caution!

It is mandatory to comply with the recommendations and notices in these operating instructions.

Inform the end user about the contents of these operating instructions.

Spieth-Maschinenelemente GmbH & Co. KG assumes no liability for damage caused by (i)

misinterpreting or nonobserving the operating instructions; (ii) improper use; (iii) incorrect

installation or unauthorised structural changes; or (iv) incorrectly circulating or failure to circulate

the contents of these operating instructions to third parties.

These operating instructions apply on the assumption that the chosen product is valid for the use case. Please see

the related design guide (available at www.spieth-me.de) for specifications, characteristics, and information on

choosing the right Spieth locknuts.

1.2 Safety notices

Spieth locknuts are intended for use on threaded spindles. Please follow all relevant safety notices.

Caution!

Any work carried out with or on the locknut needs to follow the "safety first" guideline!

During operation, keep your hands away from the working area of the locknut!

Prior to any assembly work, switch off all machine drives!

Secure the machine against accidental power-up!

Prior to commissioning the machine, install all safety devices!

Only expert personnel are allowed to perform assembly work on Spieth locknuts. Using Spieth locknuts is only

admissible according to specifications. Spieth-Maschinenelemente GmbH & Co. KG assumes no liability for

violations of the operating instructions or safety notices. This also applies to incorrectly interpreting or circulating

these notices and to incorrect assembly or maintenance.

The locknuts described here are state of the art at the time these assembly instructions are printed. Subject to

changes based on evolved technologies. For international deliveries, follow the safety regulations applicable in

the target country.

Document

ba-msa-en2336

Page 4 of 10

Operating Instructions

MSA

©Spieth

Proprietary

notice

ISO 16016

Previous document: ba-msa-en1815

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 15 Sep 2023/Fd

For any questions, requests or suggestions, please contact

Checked: 15 Sep 2023/Ax

2Description of Spieth Locknuts

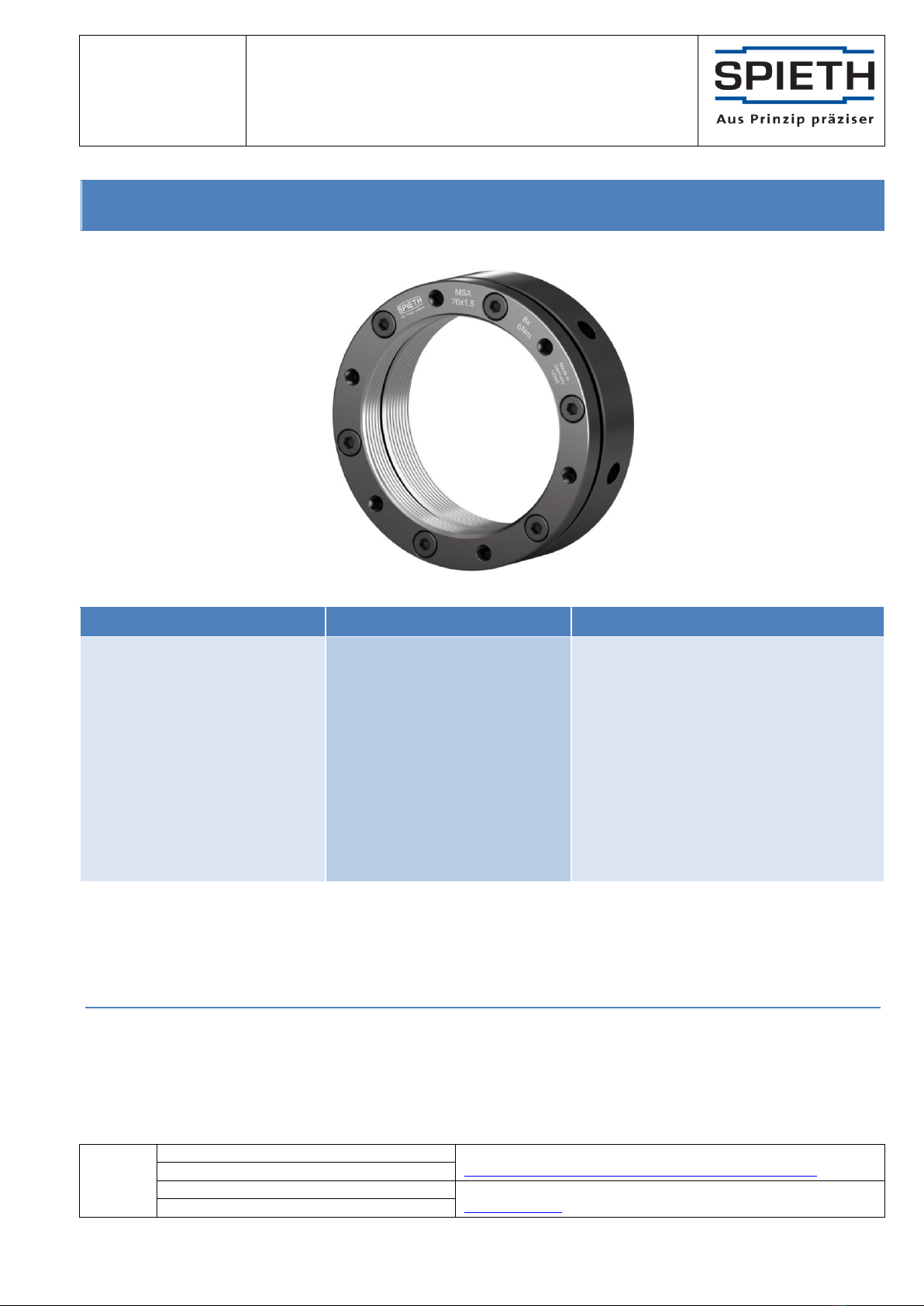

2.1 Structure

Spieth locknut bodies

Fig. 1: Schematic representation similar to

Spieth MSA series locknuts

Spieth clamping screws

Radial boreholes for pin spanner DIN 1810 - B

Axial boreholes for face spanner

Identifying features (for original Spieth locknuts)

Spieth logo

Name

Batch number

Locking torque MSfor clamping screws

Spieth MSA series locknuts are assemblies consisting of locknut bodies and clamping screws. The thread inside

the locknut body is interrupted by a groove, separating the locknut body into a load and a locking part. A

diaphragm connects load and locking part.

2.2 Mode of action

Spieth locknuts are precision locknuts. Due to their design they

provide a maximum of precision, combined with utmost locking

properties.

Spieth MSA series locknuts have been designed as all-purpose

precision locknuts (e.g., for locking high-quality fastenings, shaft

bearings, or spindle bearings).

Despite their compact design and the high axial loads occurring

here, Spieth-locknuts guarantee permanent pretension and a

rigid and precisely aligned contact with the bearing for an

immaculately supported spindle.

Fig. 2: Illustration similar to Spieth MSA locknuts

Spieth MSA series locknuts are frictionally engaged one-piece locknuts. Load part and locking part of the locknut

body approach each other purely along an axis via the elastic diaphragm. Actuating the tensioning / clamping

screws arranged in axial direction causes load part and locking part to approach each other purely along an axis.

Since the locking part has been designed as a stable ring, a 360° tessellation using several thread turns is used to

achieve a frictionally engaged clamping on the shaft thread. Tessellation converts the bolt force directly into a

contact force evenly distributed across the entire circumference. Owing to system characteristics, this

automatically aligns the end face at a right angle.

Document

ba-msa-en2336

Page 5 of 10

Operating Instructions

MSA

©Spieth

Proprietary

notice

ISO 16016

Previous document: ba-msa-en1815

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 15 Sep 2023/Fd

For any questions, requests or suggestions, please contact

Checked: 15 Sep 2023/Ax

2.3 Intended use

Spieth locknuts are recognised state of the art. They have been designed to permanently retain pretension and/or

a position on a threaded spindle using frictional locking in the thread. Any other usage is regarded as improper

use.

Spieth-Maschinenelemente GmbH & Co. KG reserves the right to technical changes. In case of any questions or

technical issues, please contact Spieth-Maschinenelemente GmbH & Co. KG.

Caution!

Only expert personnel are allowed to choose, assemble, operate, and service Spieth locknuts.

Use Spieth locknuts only according to product-specific specifications. To ensure proper functioning of the Spieth

locknuts, it is mandatory to comply with the specifications of the connecting components. Detailed information

on the above items can be found in the Design Guide. Operating conditions, e.g. speeds and temperatures at

which the Spieth locknuts are used must not exceed common standards.

Caution!

The user assumes responsibility for proper spindle thread design, for ascertaining the pretension

required for the bearings to be locked, for determining the operating loads and meeting permissible

operating conditions. In case of any questions or technical issues, please contact Spieth-

Maschinenelemente GmbH & Co. KG.

In case operating conditions change, it is mandatory to check if the locknut is still suitable for further use.

Spieth locknuts need to be handled with care, assembled correctly, and used as intended to achieve their full

functional potential. Prior to working with our locknuts, please read these operating instructions carefully. In

particular, please follow all relevant safety notices.

Caution!

It is mandatory to comply with the instructions for use and the general safety notices!

Handle locknuts with care before and during assembly and assemble them according to these

operating instructions. Use only stipulated tools for assembling locknuts.

Incorrect handling or the use of inadequate aids can severely limit, damage, or destroy the machine

element and/or the machine in its functionality.

Spieth locknuts are not meant to be repaired; if repairs are necessary in exceptional cases, only the manufacturer

is allowed to perform them.

3Delivery Contents and Storage of Spieth Locknuts

3.1 Delivery contents of the Spieth Locknuts

Spieth MSA series locknuts have been treated with a preservative. Within the component's packaging bag, a VCI

atmosphere is created providing additional corrosion protection for a certain length of time. Opening the cover or

This manual suits for next models

28

Table of contents

Other SPIETH Industrial Equipment manuals