spikenzielabs The Rainbow Light Show Manual

For the best outcome, follow each step in order.

We recommend reading this guide entirely before you get started.

The Rainbow Light Show

Hobby Electronics Soldering Kit

Instruction Guide

TM

v1.2

Tools required:

Soldering iron, solder, flush cutters, Phillips head and small flat blade screwdriver, safety glasses, masking tape.

Laser cut acrylic parts and hardware

Electronic components

Button

IC

Resistors

TCRT IR sensors (3)

DC barrel jack

3pin screw terminal Socket

220uf capacitor

0.1 capacitor Transistor

5v 2A Ac Adapter

16 LED Strip

PCB

Nuts

Screws

Stand

Under bezel washers

Bezel

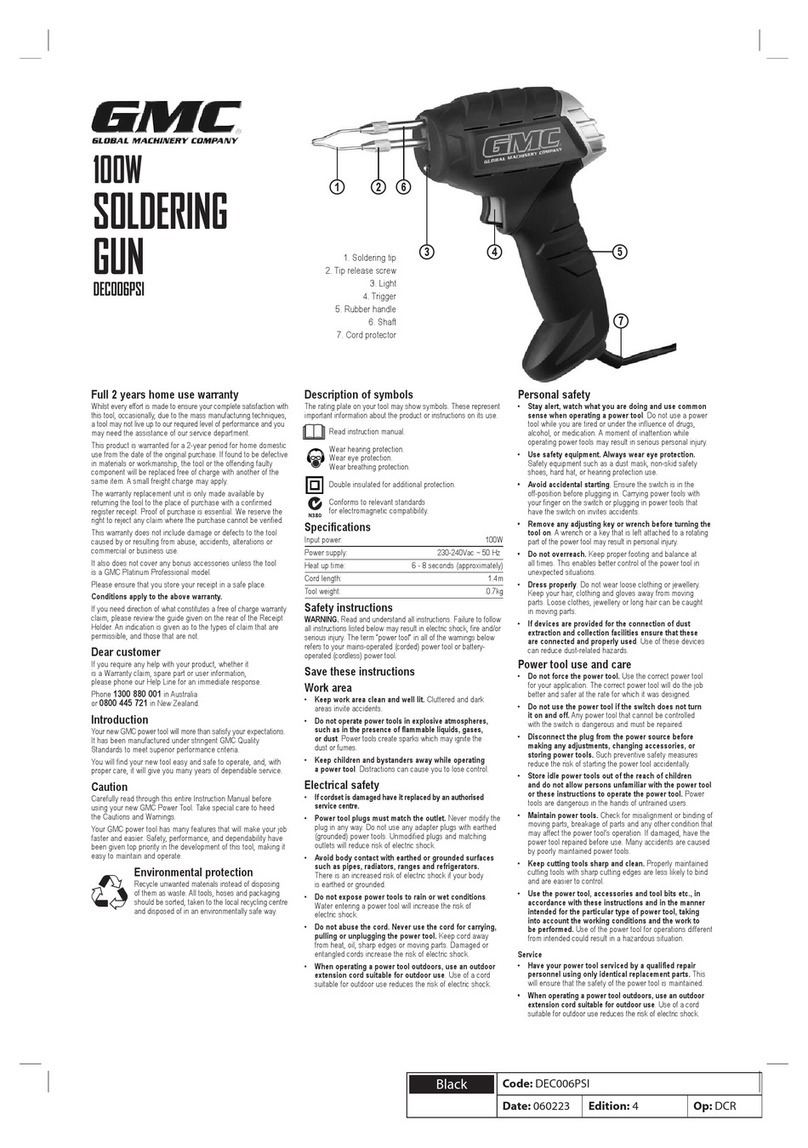

The Rainbow Light Show PCB will have most components soldered to the bottom of the board, as well some

on the top. In all cases, the component is soldered onto the side with a white printed outline.

Top Side of PCB

Bottom Side of PCB

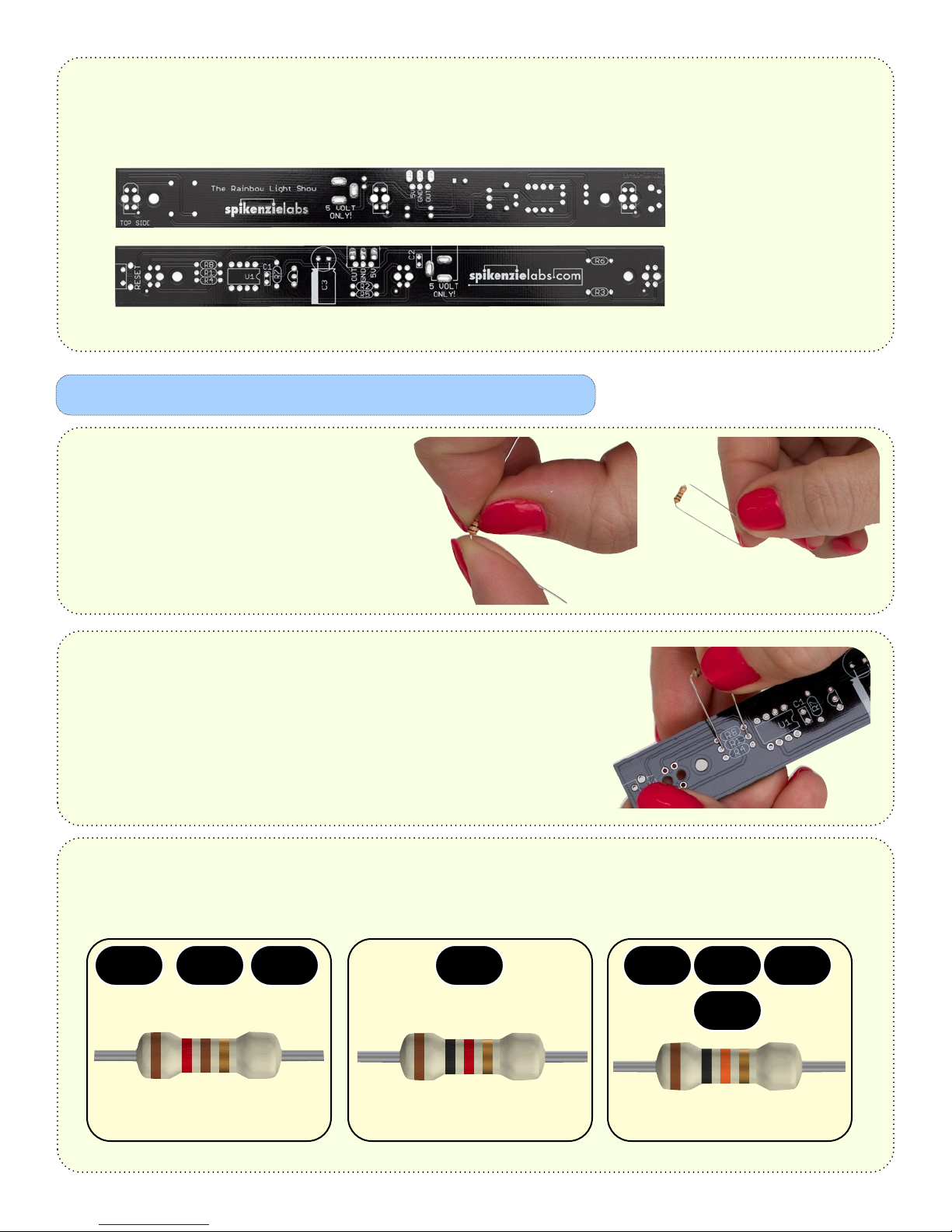

Resistor bending:

Bend each of the resistors like in these photos:

You want to have the bend of the leg

as close as possible to the body of the resistor.

Resistor preparation and soldering

It is important to place each resistor in the appropriate area on the PCB.

Prepare one resistor at a time, and insert it into the proper location on

the PCB.

Be sure to install the resistors on the bottom side of the PCB.

Use this chart to place the proper resistor in the right location on the PCB.

Note the R numbers printed on the PCB.

1k ohm [brown/black/red] 10k ohm [brown/black/orange]

Resistor graphics by samstechlib.com

120 ohm [brown/red/brown]

R1 R2 R3

R8

R7R4 R5 R6

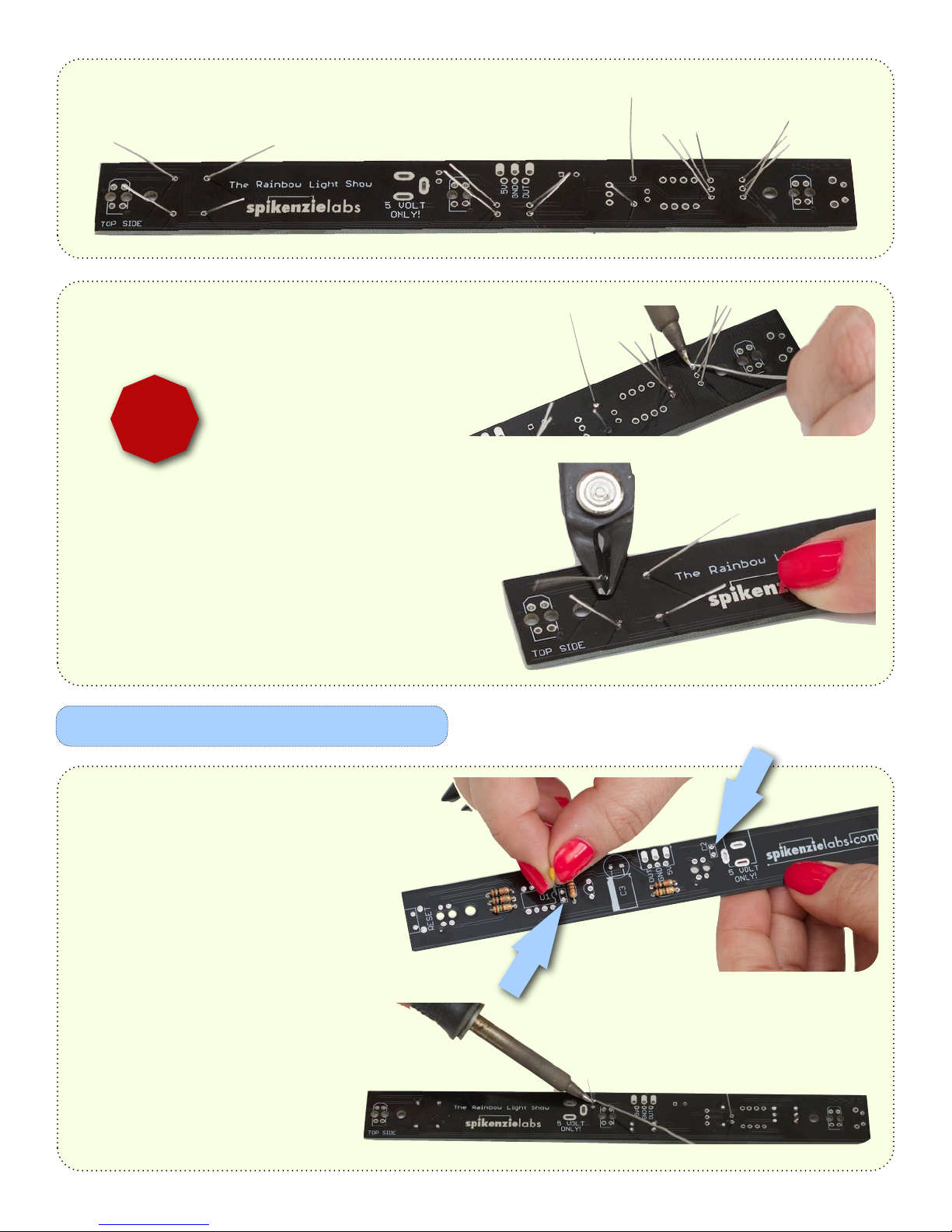

Flare out the legs to keep them in place. Be sure that the body of the resistor is flush against the PCB.

Solder the resistors in place. Make sure you don’t

forget to solder any of the legs.

Snip off the ends of the legs. Be sure not

to scratch the surface of the PCB. Keep

your safety glasses on!

Do this for each resistor leg.

!

Safety Glasses On!

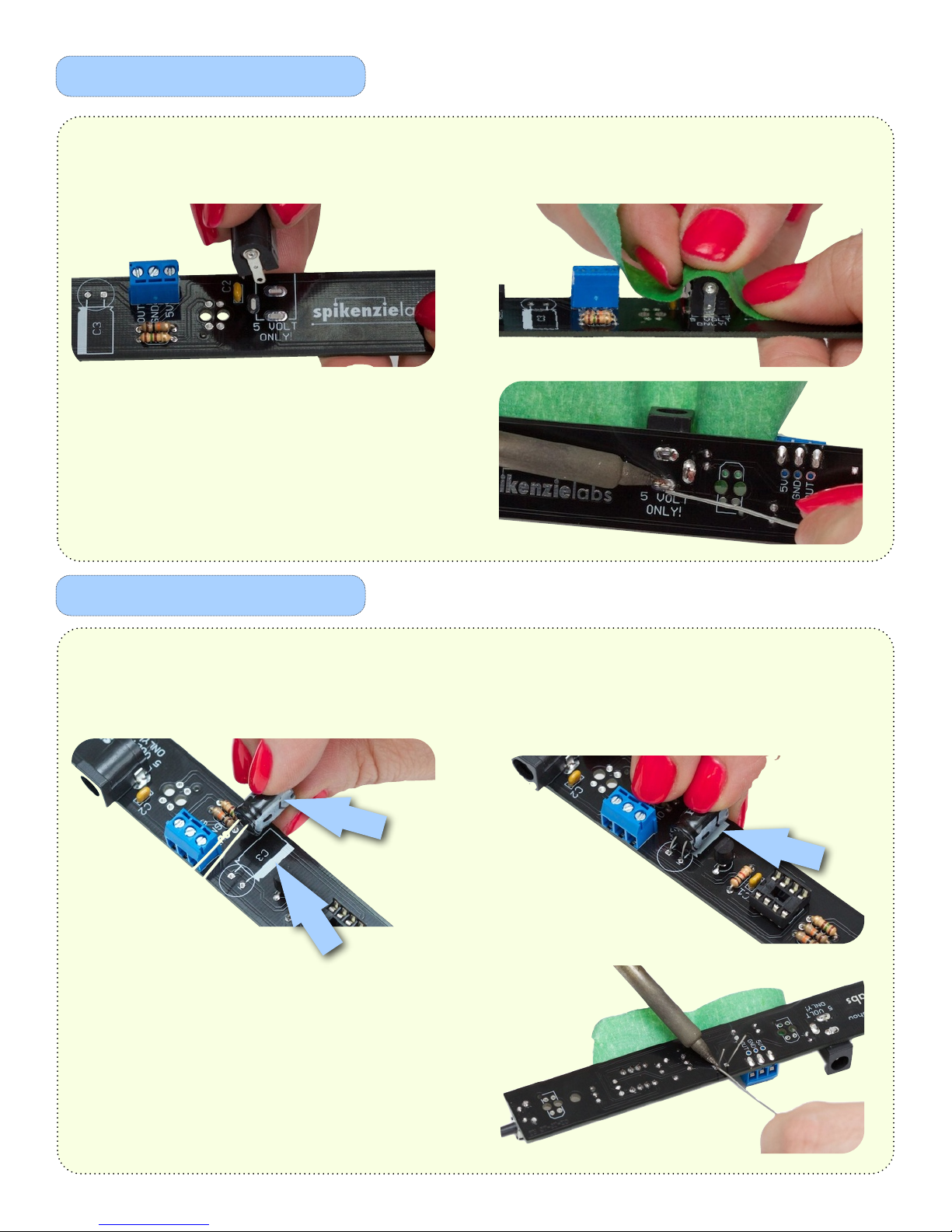

Capacitor preparation and soldering

Place the capacitors in the two locations

as seen in these photos. Marked as 0.1uf

on the PCB.

Orientation does not matter for these.

Flare the legs out as your did for

the resistors, and then solder both

capacitors in place.

Snip the ends of the legs.

The IC socket

Transistor preparation

The IC socket has a notch on one side.

The PCB has a printed notch. When

you are mounting the socket to the

PCB, make sure the notch on the

socket is lined up with the notch printed in

white on the PCB.

!

Mind the notch!

Solder the socket in place. You can use a

piece of masking tape to hold the socket in

place while soldering.

Cut the 3 leg transistor from the tape. Look at it, and note that there is a rounded

side as well as a flat side to the body. This is important for the next step.

Line up the transistor so that the flat side matches the

white printed outline on the PCB.

Solder the transistor in place.

The calibrate / wake button

Line up the button over the PCB. Mount the right angle button to the PCB.

Note: The button has 4 legs.

The button will hold itself in place. Make

sure the button to flush to the surface of

the PCB.

Solder the 4 legs, and trim the excess.

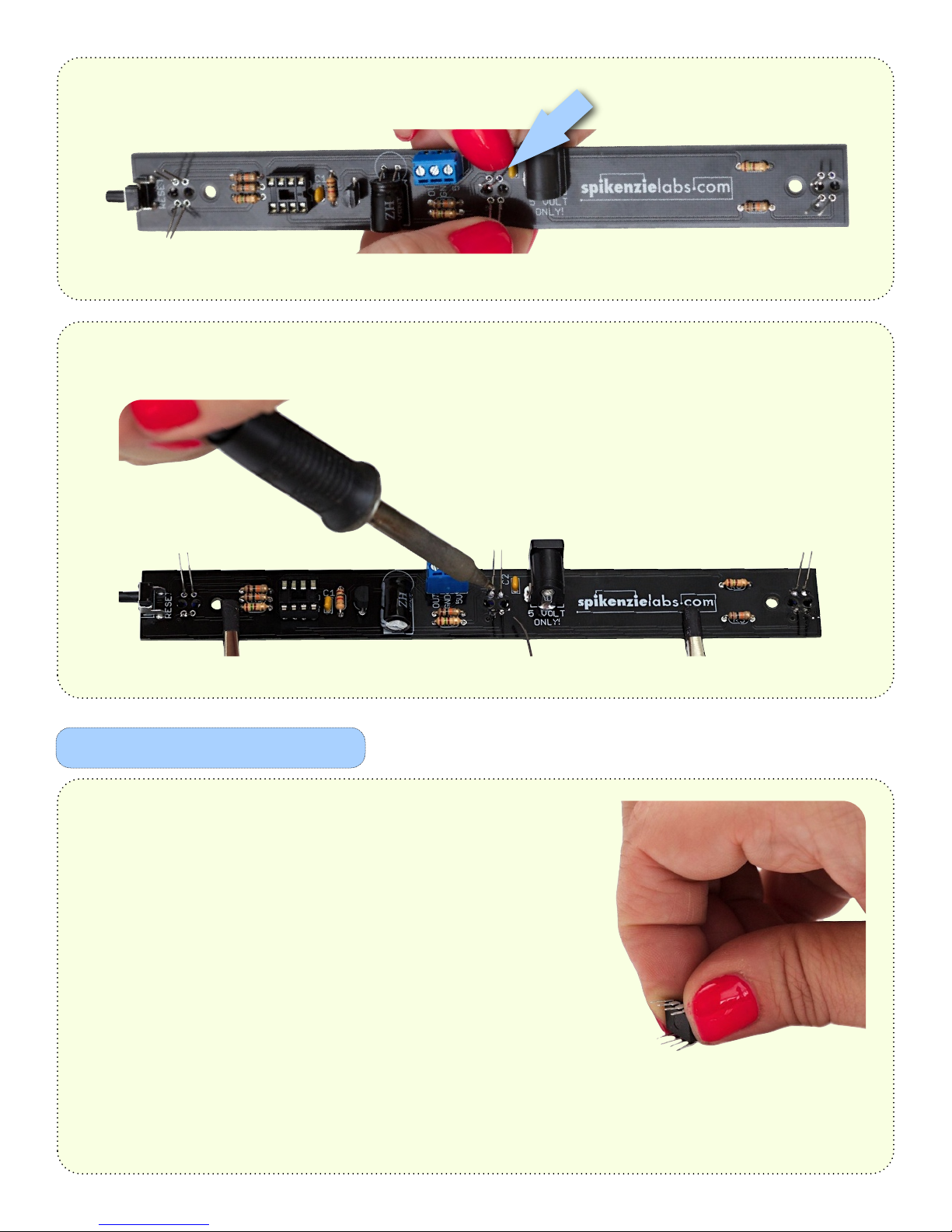

Screw terminal block

Place the 3 pin screw terminal block over the PCB.

Note the orientation of the wire connect holes.

Slide the 3 pins through the holes. Hold in place

with a piece of masking tape.

Solder the 3 pin screw terminal block in place.

DC barrel jack installation

220uf capacitor

Place the DC barrel jack over the PCB.

This can only be installed in one direction.

Slide the 3 tabs through the slots in the PCB, and

hold in place with a piece of tape.

Solder the DC barrel jack in place.

Line up the white indicator stripe on the body of

the 220uf capacitor. Proper polarity is important

for this component.

Insert the 2 legs, and lay the capacitor down like in

this photo. Note the white stripe on the capacitor

and the indicator on the PCB.

Hold the capacitor in place with a piece of tape,

and solder both legs. Trim the excess.

IR Sensors

The bottom of your PCB should now look like this:

Next you will be installing the 3 IR sensors on the top side of the board, and soldering on the bottom side.

Note the corner insertion pin on the sensor. It fits

inside the mount hole on the PCB. The body shape is

also printed in white on the PCB for proper installation.

Slide the 4 legs through the PCB, and push the IR

sensor all the way down. The insertion pin will

mate with the hole in the PCB.

!

Mind the notch!

Don’t press on the 2 LEDs. Hold the sensor

from the sides. If you press too hard on the

leds they may break.

A properly mounted sensor should look like this before soldering.

If the bottom of the IR sensor plastic housing

has a deformity that stops it from laying flat

on the PCB, trim the plastic with your snips,

or a hobby knife.

Flare out the legs of the IR sensor as you have in previous steps.

Solder and trim the 4 legs for each of the sensors.

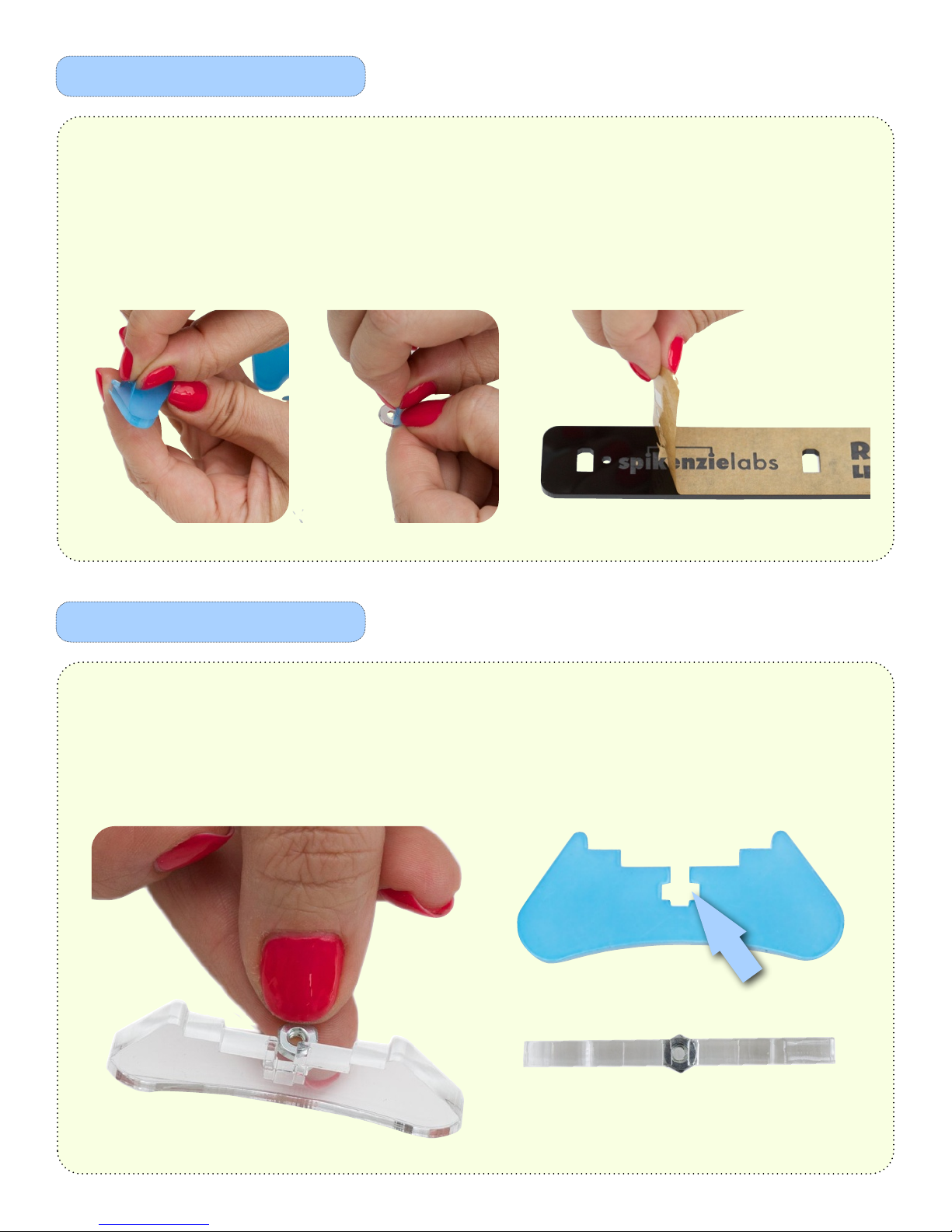

IC preparation

When manufactured, the legs are flared out slightly.

To be mounted to the socket, the legs need to be

closer to the body of the IC.

Remove the IC from the antistatic foam. Hold it firmly

on either end, and press the legs down on a flat hard

surface.

You can test fit it on the socket if you think you have

them straight enough.

Be Careful when soldering the sensors on the

already populated bottom side of the PCB.

You don’t want to accidentally burn any of the

components. You may need to rotate the PCB

to get a good angle for each of the 4 pins for

each sensor.

The IC, socket and PCB all have a notch indicating

the correct orientation for the IC. Make sure they

are all lined up. If you insert the chip in the wrong

orientation, it will not work.

!

Mind the notch!

Place the IC over the socket. When you see that all of the legs are lined up, gently press down until it is

seated flat against the socket..

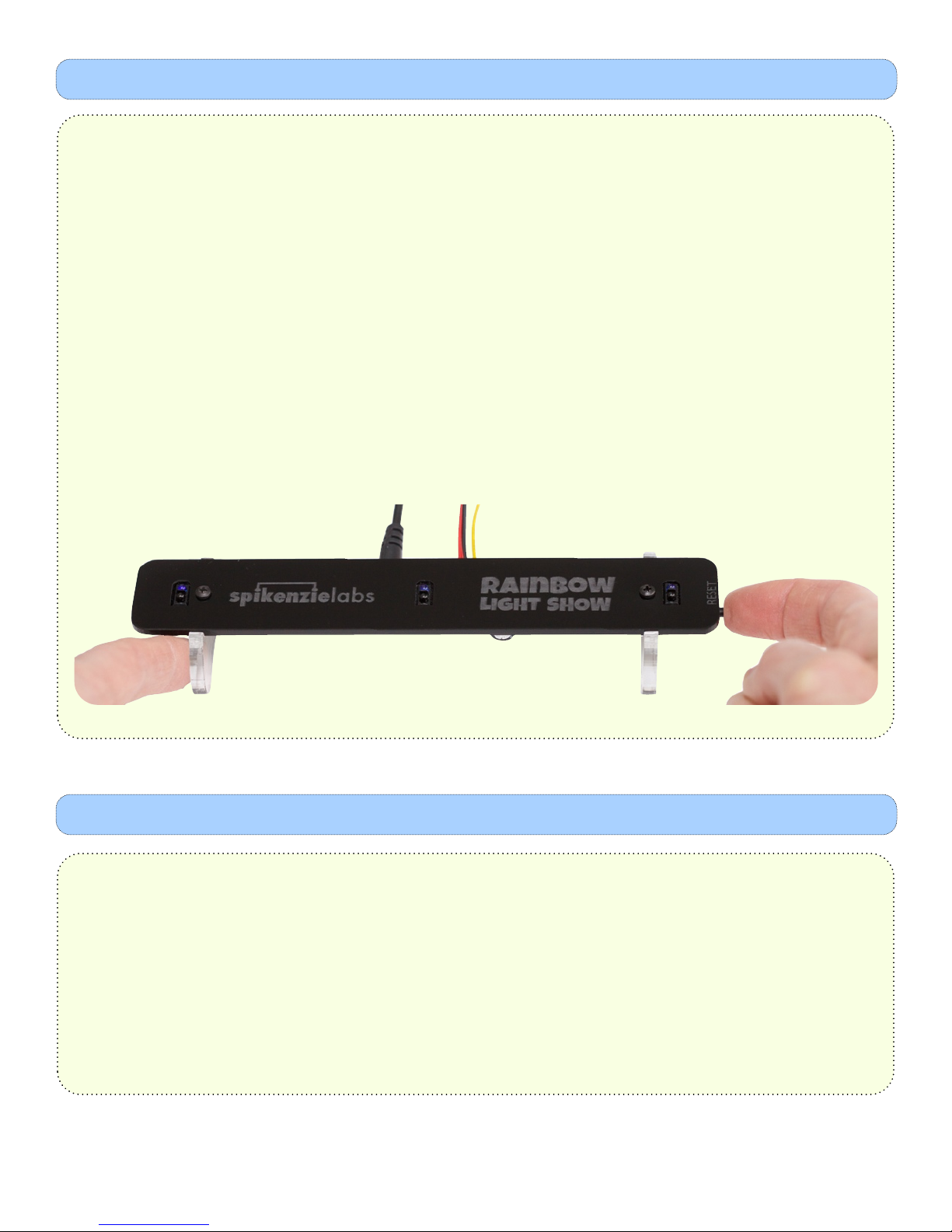

Preparing the acrylic parts

The stands

Peel the protective plastic and paper from the 2 stands, washers and top bezel. For the pieces of paper

that remain on the black acrylic, scratch at a corner with your fingernail, and then lift it away. Be careful

not to scratch, bend or flex the acrylic. If the surface picks up fingerprints, we recommend cleaning

acrylic surfaces with Windex, and a lint free cloth. Never use alcohol based cleaners on acrylic.

Slide a nut into each stand. If the nut keeps sliding out the other side, you can put a small piece of

masking tape on either side to hold it centered in place, until the screws are tight.

Place the fully populated PCB over the stands. Top side up. Center the screw holes directly over the center

of each nut.

Place a washer over both of the screw holes on the PCB.

Make sure that the nut has not slipped out. You will be

able to see it if you look directly through the hole, from

the top down.

Place the bezel over the PCB and washers.

The ‘reset’ side of the bezel, goes over

the button end of the PCB.

Slide a screw into each screw hole in the bezel.

Slowly tighten each.

Do not over tighten. You may crack the acrylic.

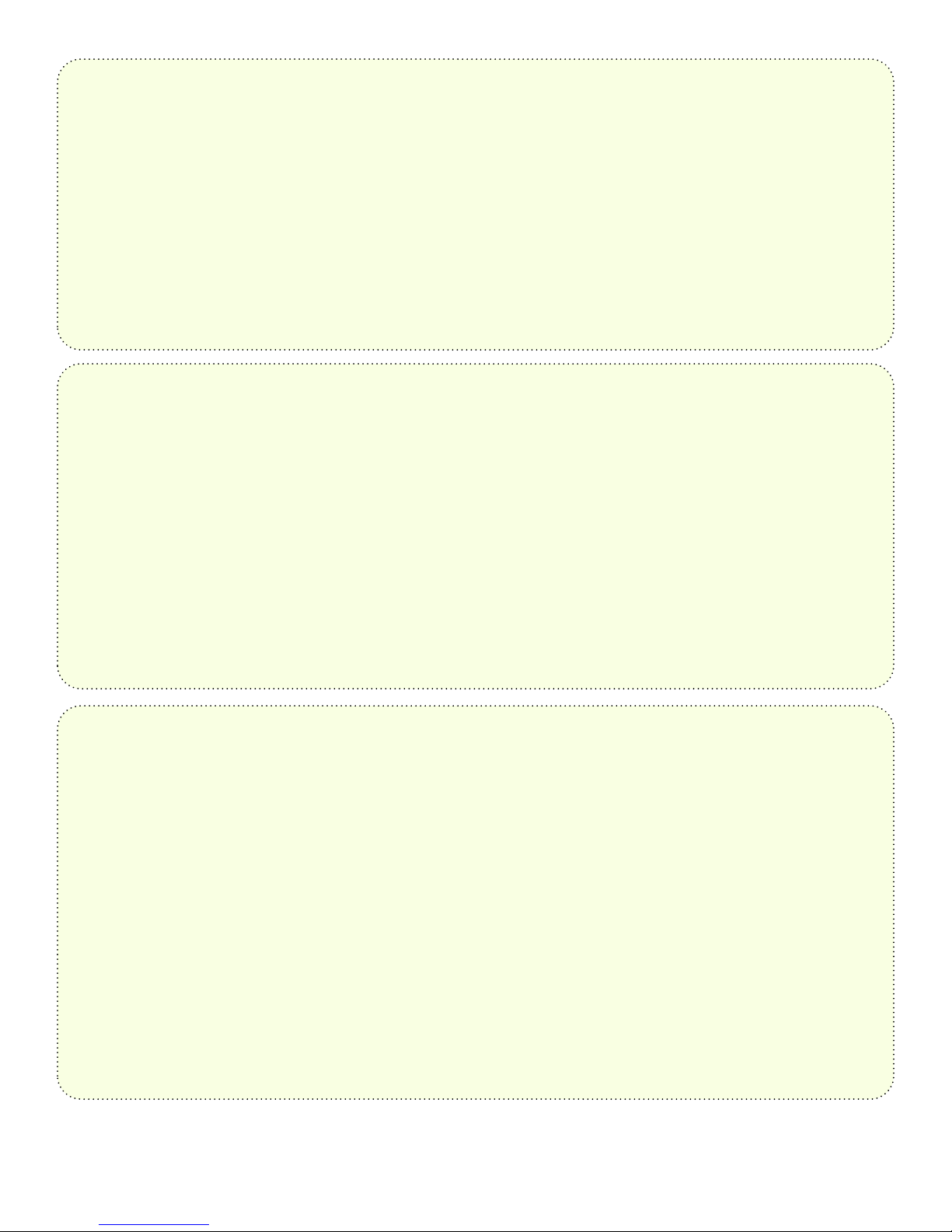

Loosen the 3 flat blade screws of the screw terminal,

about 4 turns each.

Line up the Red wire, with 5V.

Black wire with GND.

Yellow wire with OUT.

Double check to be sure this pattern is correct before

connecting the AC adapter.

Insert and screw down the Red wire.

Insert and screw down the Black wire.

Insert and screw down the Yellow wire.

Plug in the AC adapter in to the wall, and then

plug it in to the DC barrel jack.

ONLY EVER USE THE SUPPLIED AC ADAPTER

THIS DEVICE RUNS ON 5V DC ONLY

In order to allow the RLS to produce nice smooth color transition and avoid false triggers we added a calibration

function. When the RLS is first powered on (or awoken from sleep mode) the calibration function is run. At any

time if you see random LEDs lighting up, (even when your hands are not near the RLS) simply press the "reset"

button and the RLS will re-calibrate.

When recalibrating, do not stand too close to The Rainbow Light Show or put a hand over any of the sensors.

The best way is to place you left index finger to the left of the left stand and use your right index finger to press

the reset button on the lower right hand side of the RLS.

After 30 seconds of inactivity, The Rainbow Light Show will go to sleep. To wake it up, simply press the reset

button in the same way you would to recalibrate it.

Quick Start:

The Rainbow Light Show • How it works

What is the RLS?

The RLS is based on our SPLixel LED driver, that is, a microprocessor that is specially programmed to light up addressable RGB

(Red, Blue and Green) LEDs.

We modified the SPLixel programming for the RLS to read three sensors and use those readings to produce an intensity of red,

green and blue light on a LED. Using a shifting algorithm, the colors displayed from the first LED are shifted to the second and then

to the third and so on, all the way up to 64 LEDs.

How it works:

The RLS has three sensors. These sensors are IR (infrared) light proximity sensors. On each sensor there are two parts. The first part

is an IR LED, that is shining a beam of IR light upward. The IR beam is invisible to the naked eye. If you look though your phone's

camera you may be able to see it. The second part is a phototransistor. When the phototransistor is exposed to IR light it allows a

current to pass through..

Since both the IR LED and IR phototransistor are pointed upwards on the RLS, we need something to reflect the IR light back into the

phototransistor. This is where your hand comes in! When you bring a hand closer to the RLS's sensors more IR light is reflected back

into the phototransistor and more current passes through. The microprocessor then reads an analog (read a variable) voltage

produced due to the changing current flowing though the phototransistor. It does this for all three sensors and It uses these varying

voltages to decide how bright to light up the red, green and blue channels of each LED.

Calibration:

Did you know that your TV remote also uses IR light? So that your TV does not change channels by itself, TV manufactures use a

special type of phototransistor that only works when a specific frequency of IR light is received (typically 38 - 40 khz). The TV

remote is actually flashing an IR signal to the TV!

The type of IR proximity sensors used in the RLS do not have any special filtering. They can pick up stray IR light from other sources.

This will make a series of random colors flow along on your RLS LEDs. We chose not use IR phototransistors with filtering, since all

the models that we tested were either excessively expensive or did not work well to produce a nice smooth analog voltage.

In order to allow the RLS to produce nice smooth color transition and avoid false triggers we added a calibration function. When the

RLS is first powered on (or awoken from sleep mode) the calibration function is run and at any time if you see random LEDs lighting

up, (even when your hands are not near the RLS) simply press the "reset" button and the RLS will re-calibrate.

How to Calibrate your RLS:

As lighting changes or people move around causing both reflections or shadows you may have to recalibrate your RLS.

Remember, IR light is invisible to your eyes so even if you don't see the "light" changing, light on the IR spectrum may have

changed.

When the RLS does a recalibration, it turns off the three IR LEDs on the sensors and then reads the value of IR light coming in. It is

important the RLS be able to see all of the ambient IR light while it is recalibrating. So, it is important that you do not stand too

close to it or put a hand over any sensor while recalibrating. The best way is to place you left index finger to the left of the left

stand and use your right index finger to press the reset button on the lower right hand side of the RLS.

When the RLS does a recalibration it reads the intensity of IR light coming in. It then adds a safety cut-off value to this reading and

will then ignore any IR reading that is below this threshold. What these means for you, is that your RLS will work in many different

lighting conditions. It prefers to be used in areas that are not too bright. Also, when the RLS is calibrated in a bright area, the

threshold is set much higher, so in fact the RLS will be less sensitive to your hand. This means that your hand will have to be closer

to the top of the RLS before it starts to produce colors.

Table of contents