4.3.2 Temperature Setting

Raise Temperature: Click “▲” button, the temperature will rise1℃, the LCD

will display the current setting temperature. If press the

“▲” button for at least 1s, the setting temperature will

rise rapidly. Loose the “▲” button when the value is up

to the required temperature.

Reduce Temperature: Click “▼” button, the temperature will drop1℃, and

the LCD will display the current setting temperature. If

pressing “▼” button not loosely at least 1s, the setting

temperature will drop rapidly. Loose the “▼” button

when the value is down to the required temperature.

4.3.3 Turn On / Turn Off the Sound

1. In the working state, press the “▲” and “▼” buttons simultaneously and

keeping about 3seconds. The sound will be turned on if the LCD displays

“”, and will be off if the LCD displays “OFF”.

2. When the sound is turn on (the sign displaying on the screen), it has sound

when clicking the button.

3. When the sound is turned on (the sign displaying on the screen), if the

difference in temperature between real temperature and set temperature is

bigger than ±20℃, it will sound to prompt.

4. If the sound is turned off (the sign don’t displaying on the screen), it is

soundless when clicking the button or the difference in temperature is bigger

than ±20℃.

3. After selecting the working mode, click “*” button to save and then return to

the parameter menu selecting interface.

5.5 Password Set

1. In the parameter menu selecting interface, click “▲” or “▼” button to select

the menu “-4-”, and then click “*” button into the password setting interface.

2. Once into the new password setting, the LCD displays “---”. After that, click

the “▲” or “▼” button, the 100’s digit is bright.

3. At the time, click the “▲” or “▼” button to select the 100’s digit, and then

click the “*” button when displaying the selected value of 100’s digit. After

that it comes into 10’s digit set. The setting methods of the 10’s digit and 1’s

digit are same with the 100’s digit.

1 2 3 4 5 6 7 8 9 0

4. If the setting passwords are not same with each other, it will return to the work

state directly, which means the password setting is not successfully.

5. If the setting passwords are same with each other, the LCD displays “ ”,

and then return to the parameter menu selecting interface, which means the

password setting is successfully.

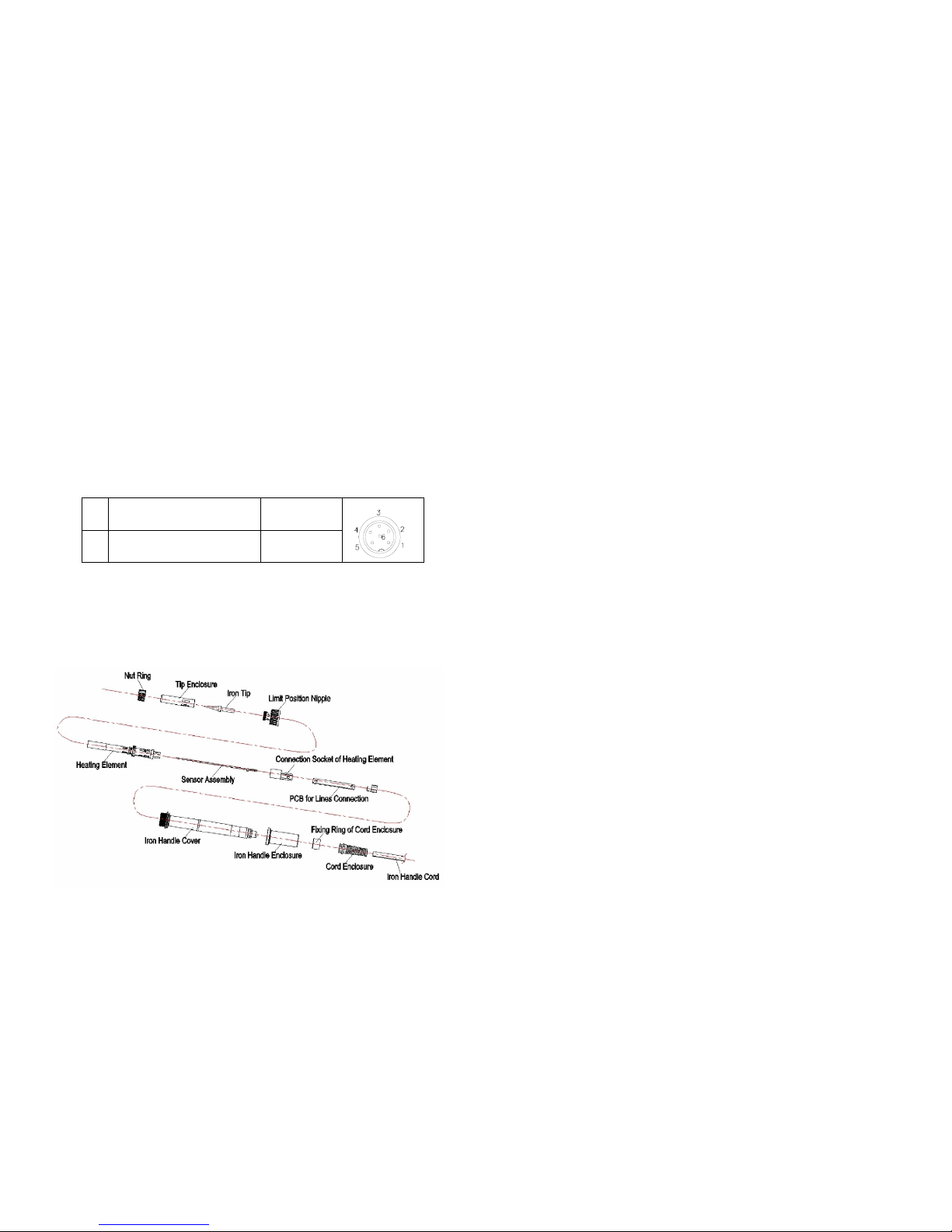

Ⅵ. Temperature Calibration

The temperature of the unit should be recalibrated every time if the handle, heating

element or soldering tip is replaced. The unit uses digital calibration.

Method of recalibrating temperature:

Use the thermometer to calibrate it and it is precise comparatively.

1. Set the temperature at a certain value.

2. When the temperature is stable, measure the tip’s temperature with

thermometer and write down the value.

Page 7 Page 12