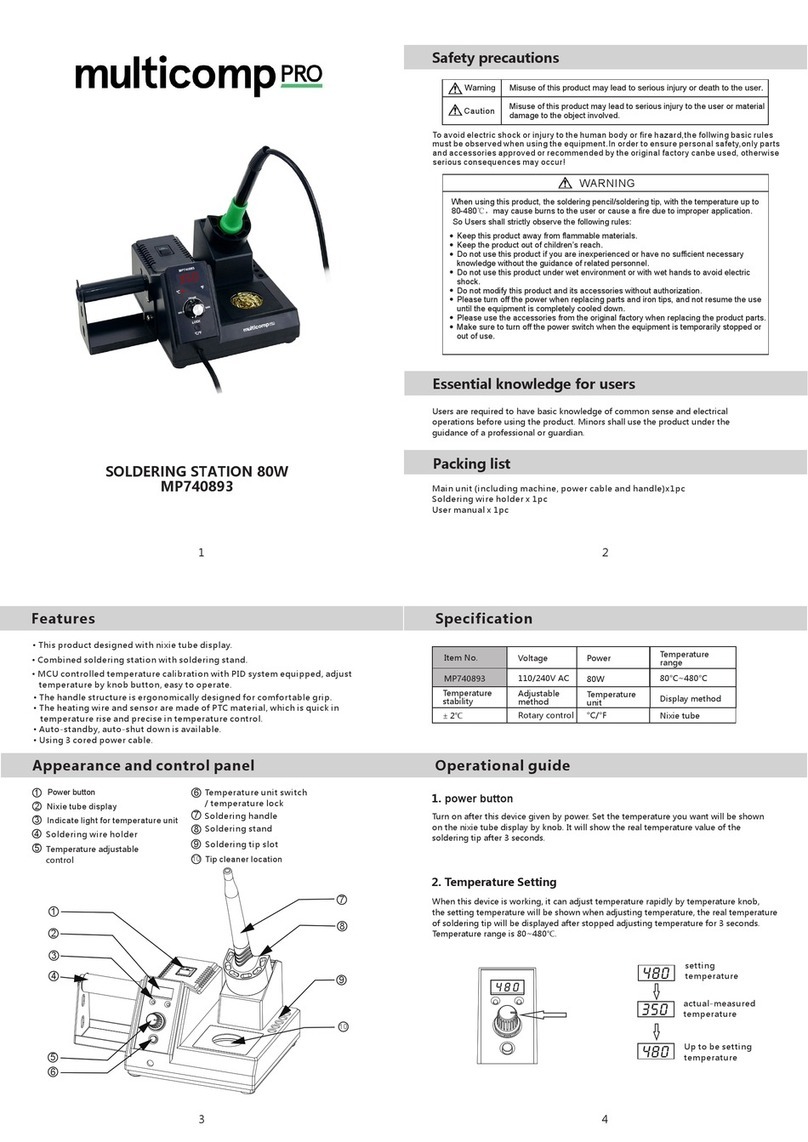

4

ENGLISH

OPERATION

LED lights

Red LED -ON- when lit, it indicates that the station is

plugged in the mains.

Green LED -READY- when lit, it indicates that the

system is ready and correctly set for working.

The green led light is on after a few seconds, is the

time needed to carry on the self-checking system.

The green light is pulsing when the desoldering iron

is in sleep mode.

If the green led is not lit, the reason why, will be one

of the following:

1. The desoldering iron is not plugged in.

2. The maximum available power has been

exceeded for too long - e.g. in a very thick

desoldering at the high repetition rates.

3. The desoldering heating element has a short

circuit or an open circuit.

4. Any other trouble preventing the system from

working properly.

The handpiece will reset itself automatically should

the cartridge short circuit or go open circuit.

Should the handpiece be subject to:

-An electrical surge or the cartridge has not been

fitted correctly.

Please turn the unit off and switch on again to reset.

When pressing the button of the desoldering iron

handle, one of the two leds in the area marked

SUCTION will light up:

Green light -SUCTION- indicates the correct

functioning of the desoldering iron.

Red light -SUCTION- indicates a blockade within

the vacuum circuit.

This can be caused by the following:

-The tip of the desoldering iron is blocked.

Sleep function

One of the Series Advanced features is that when

the desoldering iron is placed in the holder, the

temperature at the tip drops automatically to the

sleep temperature. This function is only

possible because of the quick response time

which does not make the user realise the

temperature rise to reach the selected

temperature. Also by this, the oxidation of the

tinning of the tip is considerably reduced and

tip life is extended.

To indicate that the desoldering iron is in sleep-

mode, the green led starts pulsing. These

parameters can be modified using the Console

AC 2600 Ref. 2600000.

In order to take advantage of the above

mentioned feature and as a security measure,

it is necessary to place the desoldering iron

on stand when the iron is not being used.

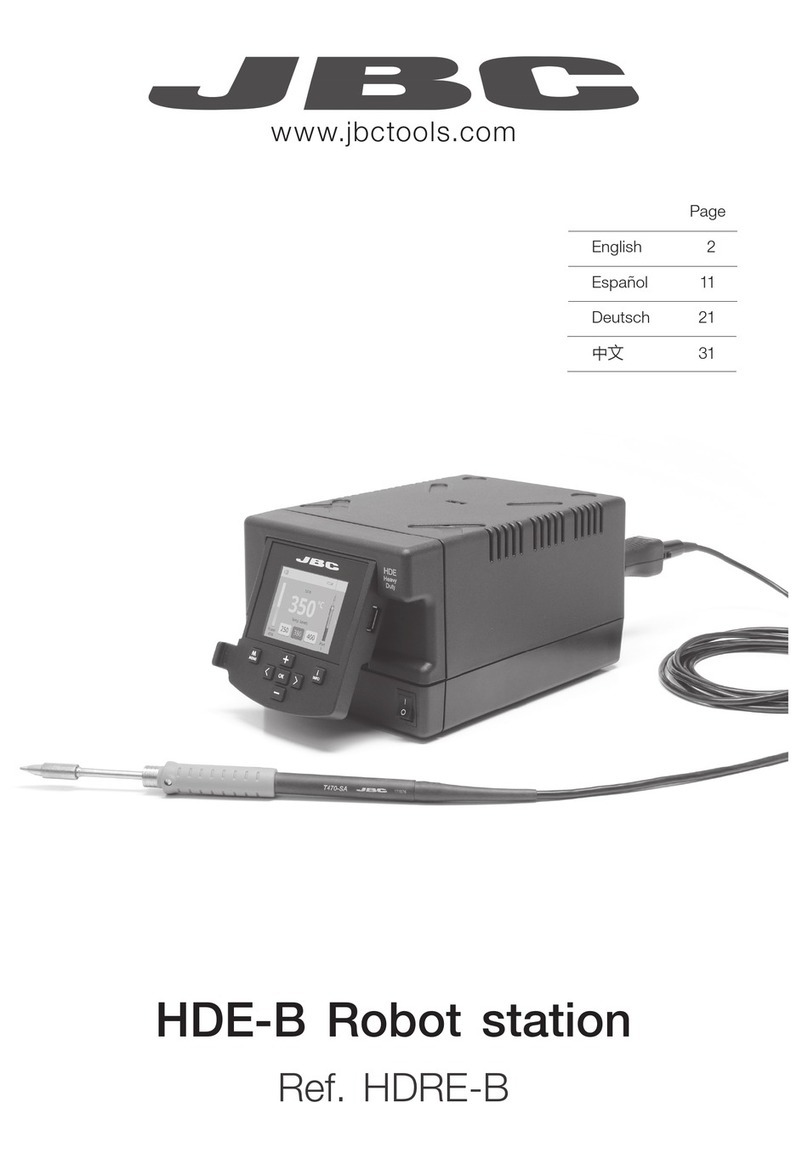

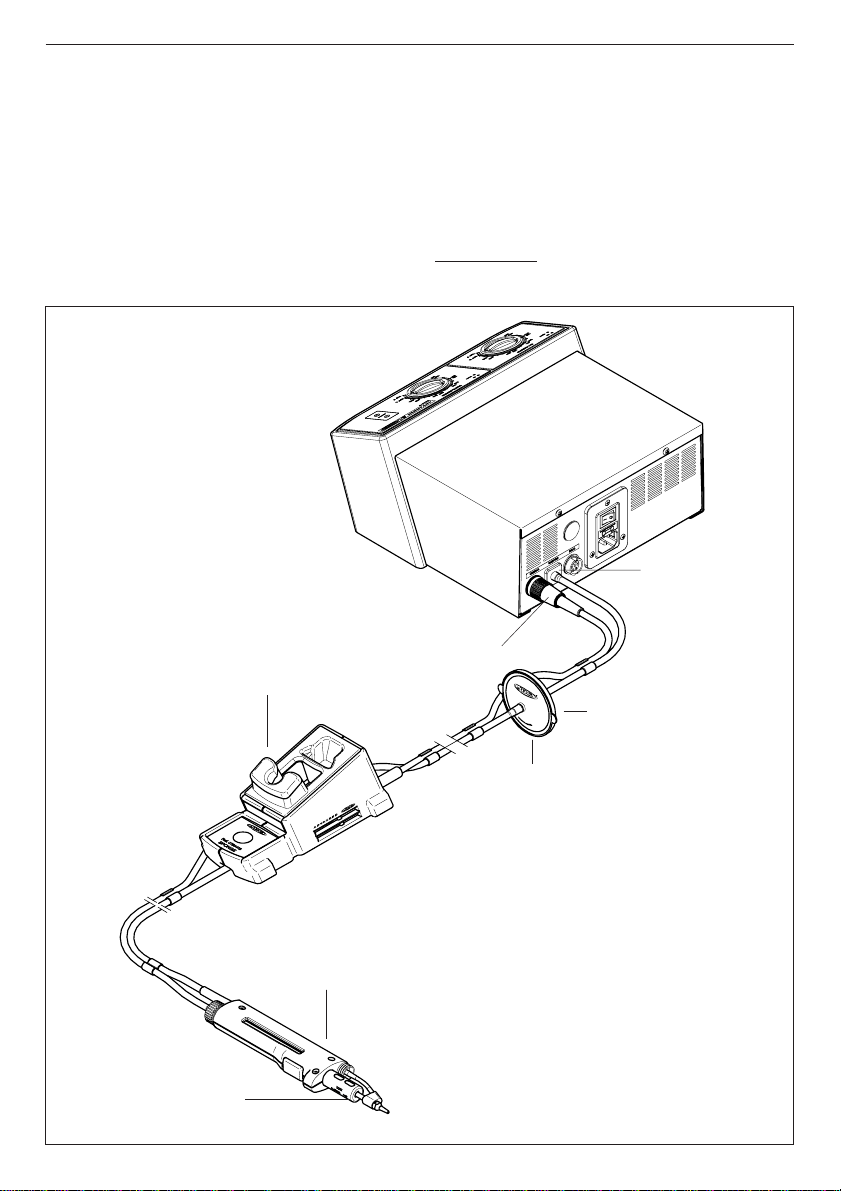

DR 5600 Ref.5600000

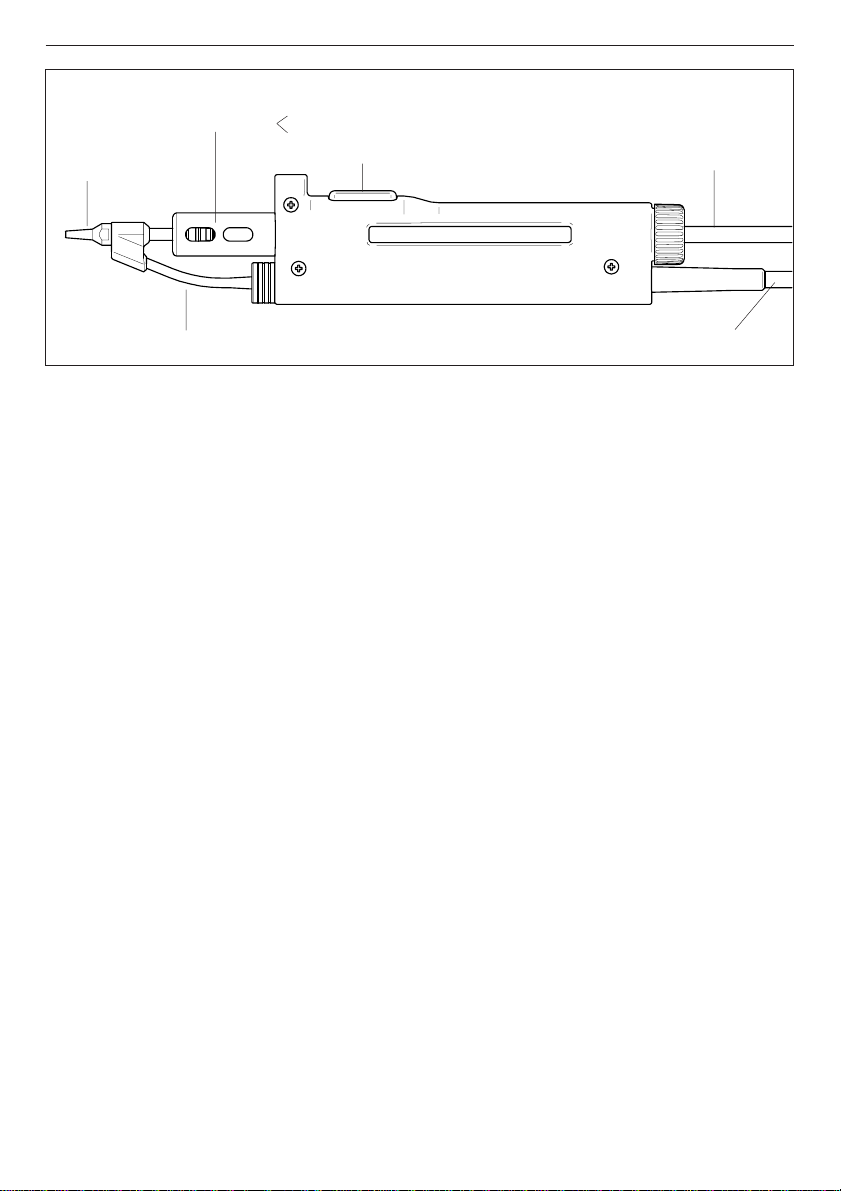

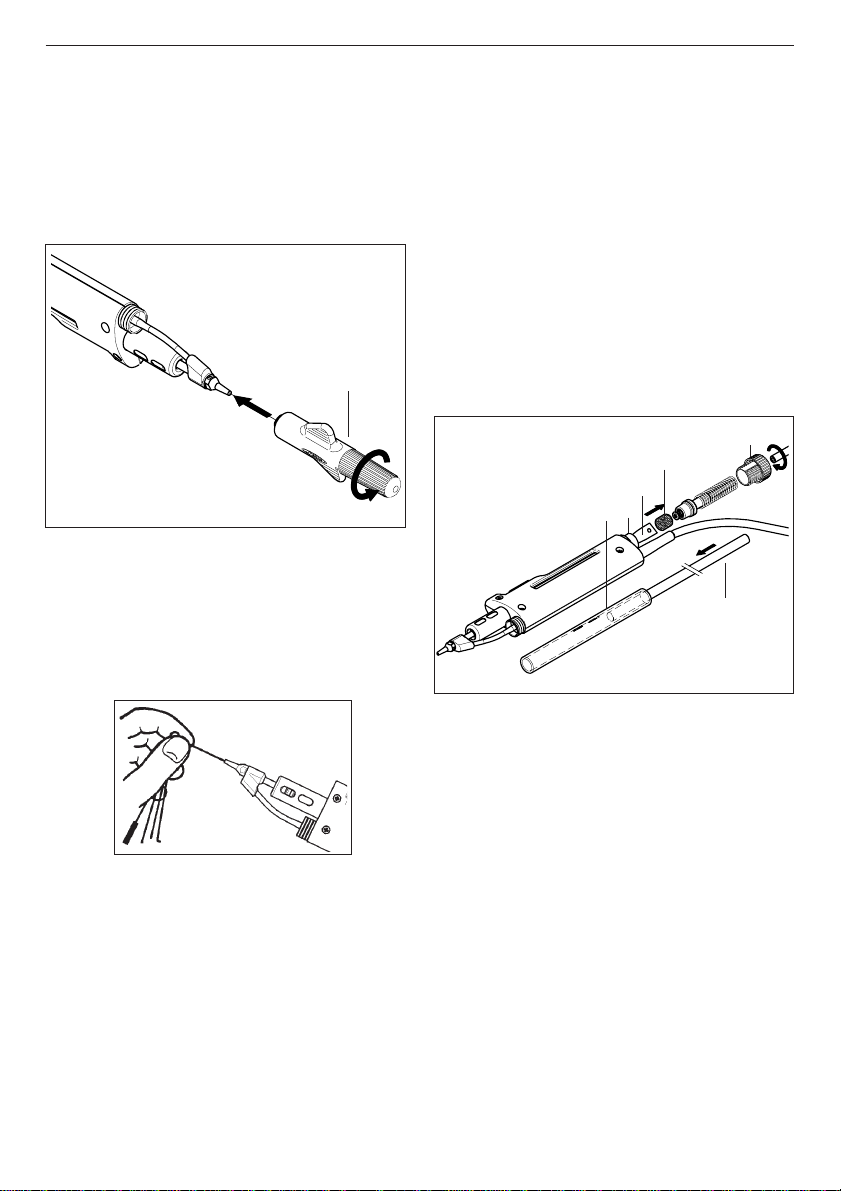

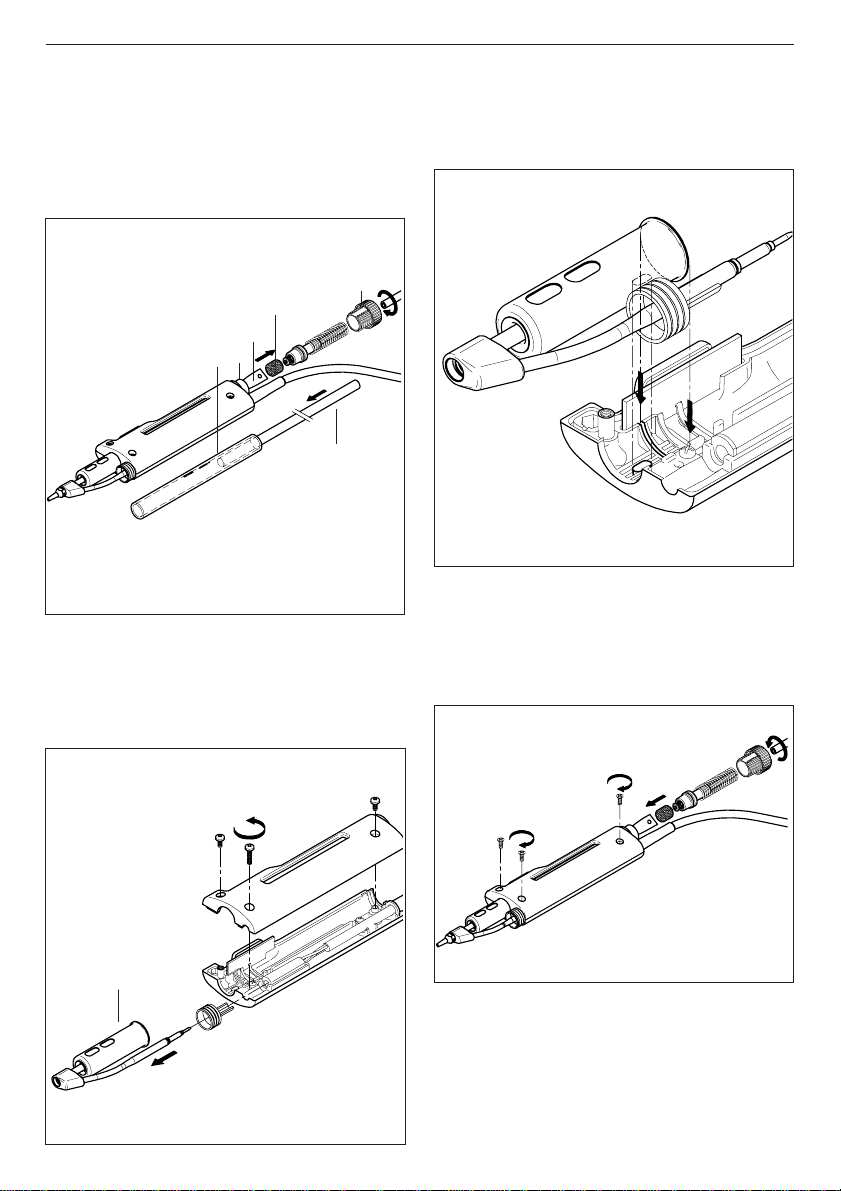

Desoldering tip

Heating element

Pushbutton vacuum pump Vacuum hose

Desoldering iron cable

Solder tin deposit Metal

Glass

-The solder tin deposit is full.

-The filter of the desoldering iron is dirty.

-The station’s external desoldering air filter is

dirty.

Only for users of AC 2600 console ref. 2600000.

If you lock the working temperature thanks to the

console, the green LED -READY- will remain on

while the dial is set at the locked temperature.

If the dial is not set at the locked temperature,

the green LED -READY- will be blinking. The

farther the dial will be set from the locked

temperature the slower the blinking pace will be.