Dimensions and technical information are subject to change without notice

102

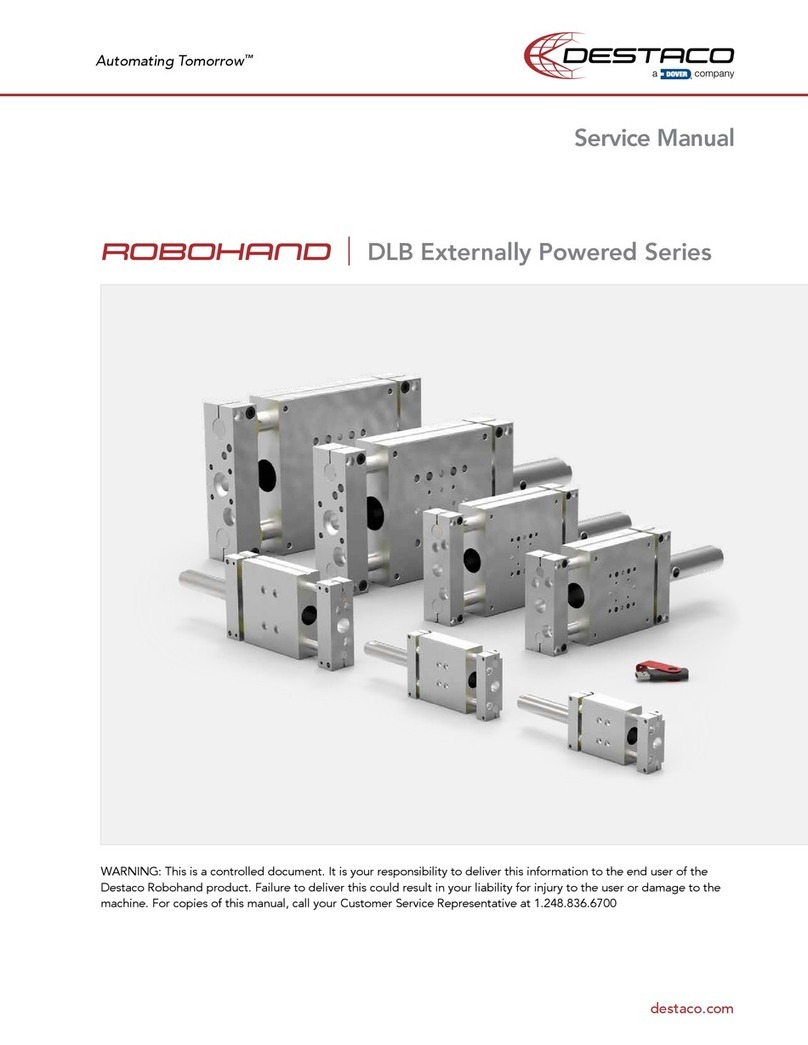

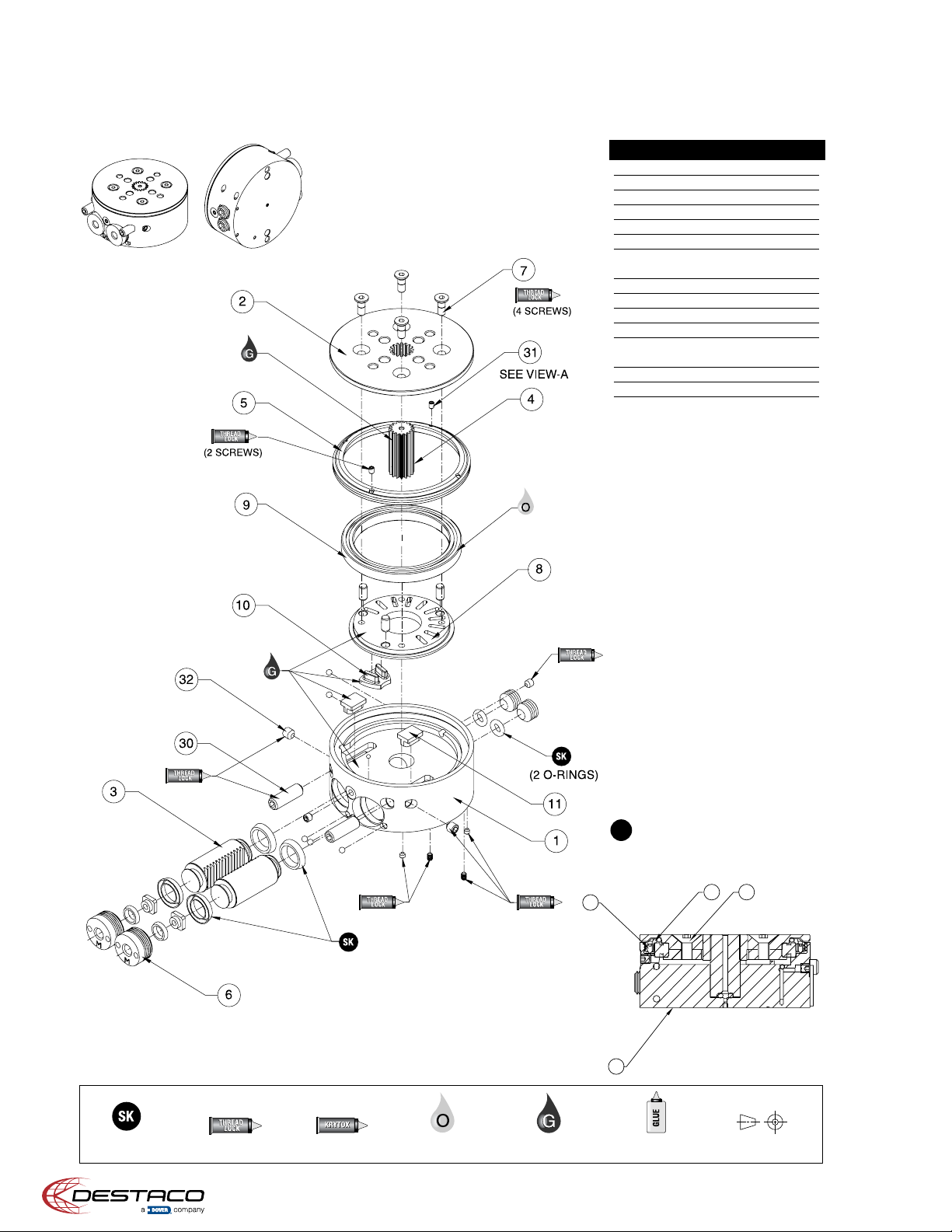

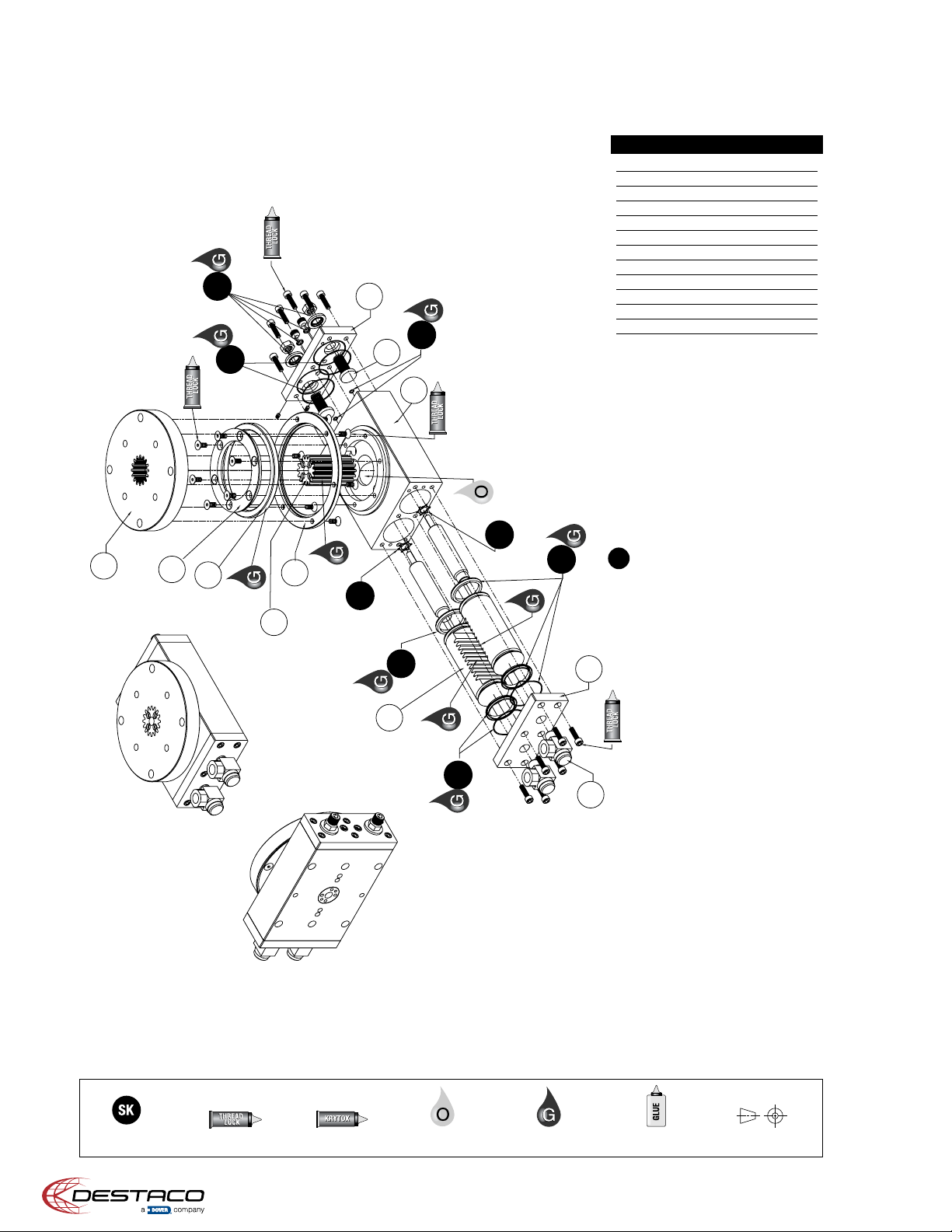

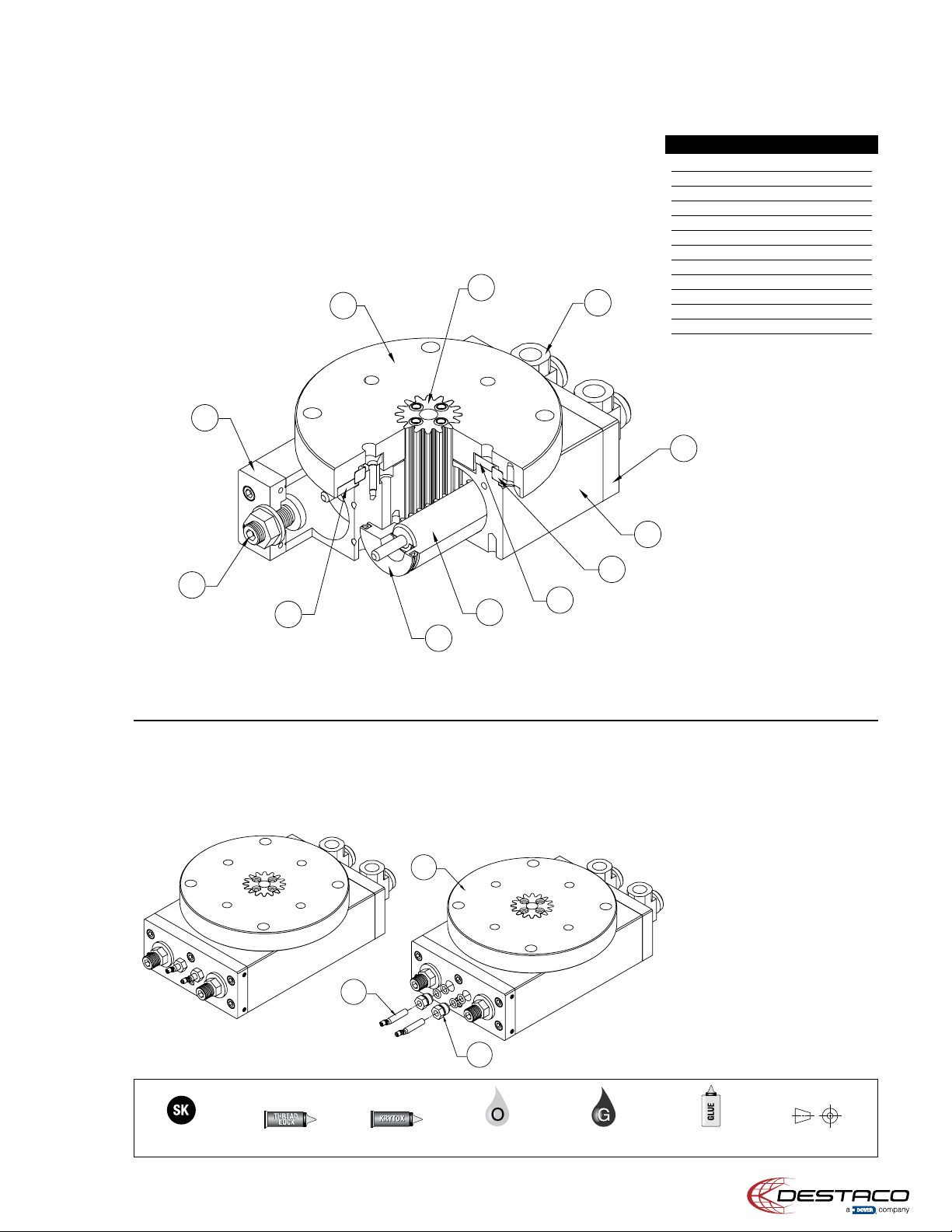

Rotary Actuators | Maintenance and Assembly Procedure

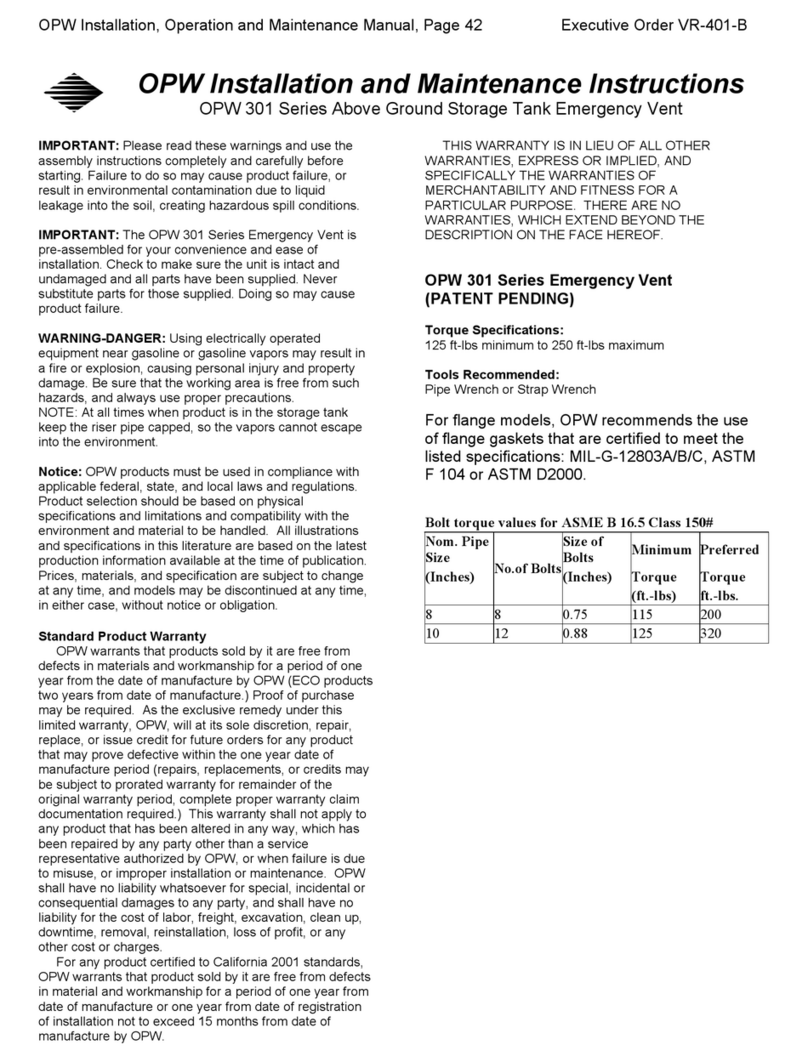

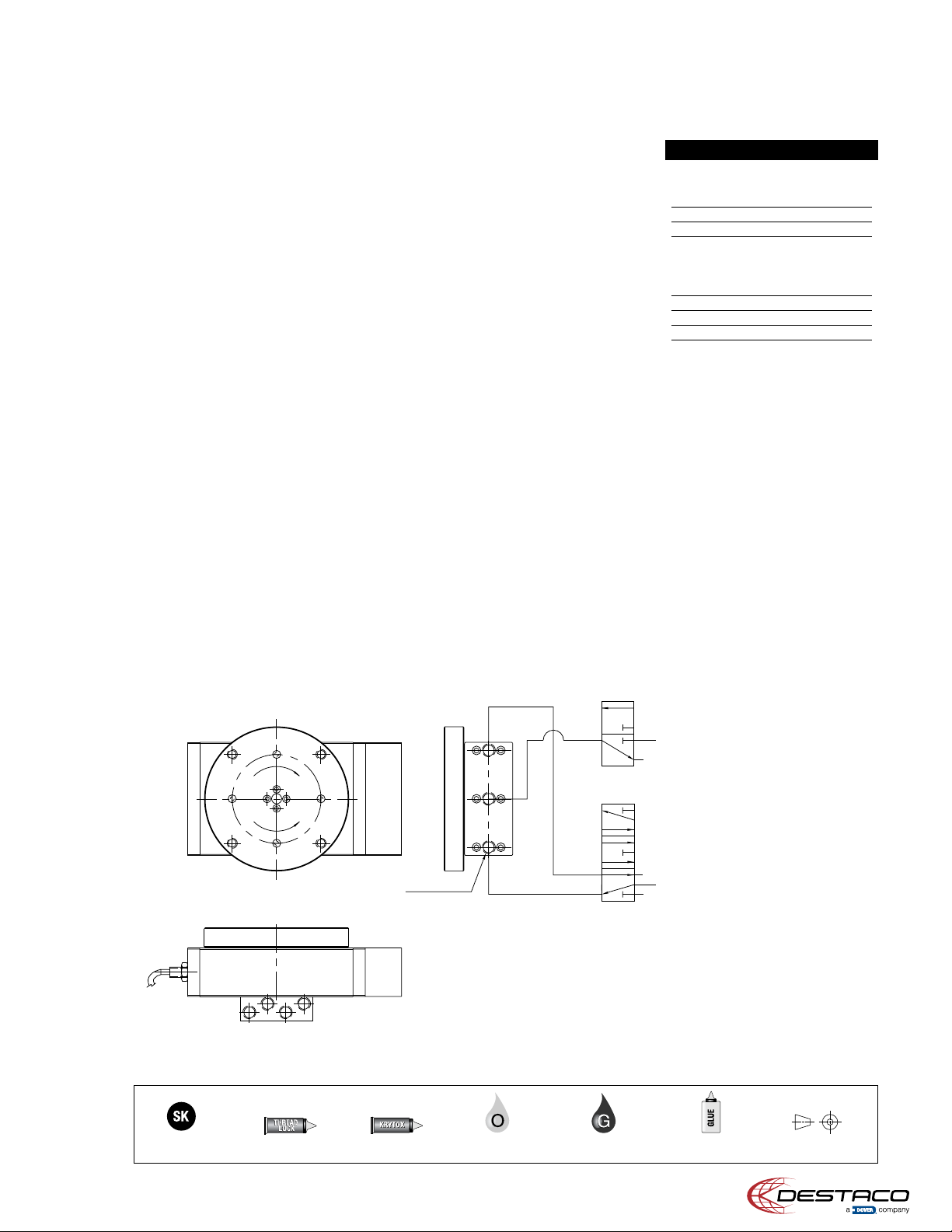

RR-36, 46 options Series

16

13

30

1

31

9

32

15

(4 O-RINGS)

(4 O-RINGS)

(6 SCREWS)

(2 SCREWS)

SK

SK

SK

SK

SK

SK

For more information call us at: 1-800-ROBOHAND or 203-261-5558 Fax: 203-452-7418 Visit us on the Internet at: www.destaco.com

3.16

RR-36 & 46

OPTIONS

MAINTENANCE

Third Angle

Projection

Seal Kit

Items

Thread

Locker

Krytox™

Lubricant

Teflon®Based

Grease

Lightweight

Machine Oil

Super

Bonder

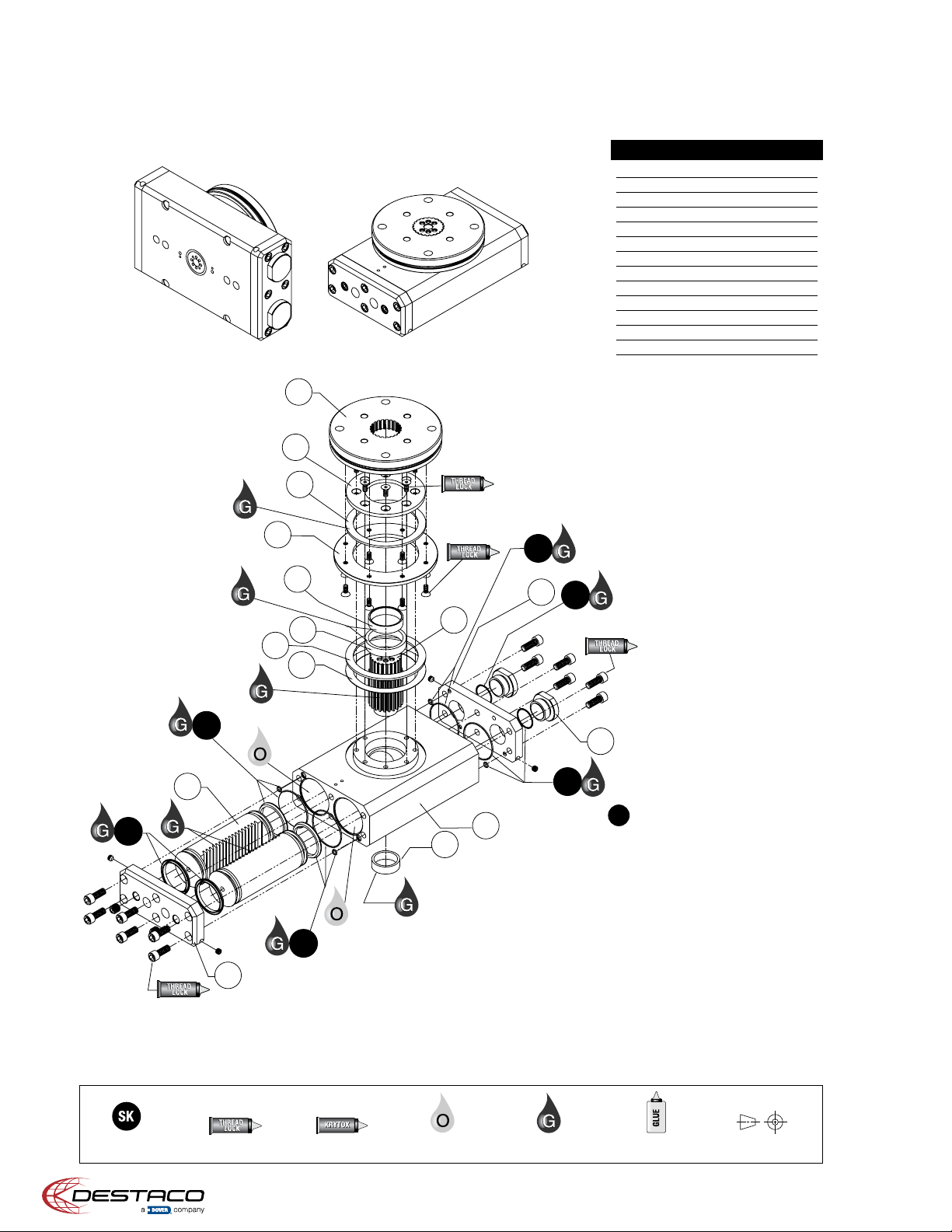

RR-36 & 46 Options Exploded View

Item Qty Name

RR-36&46-S

(Mid Position Stop Option)

13 2 Piston, Midstop

16 1 Body, Midstop

30 2 Mid-Stop Adjustment Screws

RR-36&46-M

(Rotary Manifold Option)

09 1 Manifold,Rotary

15 1 Manifold

31 2 Dowel Pin

32 2 Dowel Pin

NOTE: Contact the Robohand Sales

Department for a complete spare parts

list with order numbers and prices.

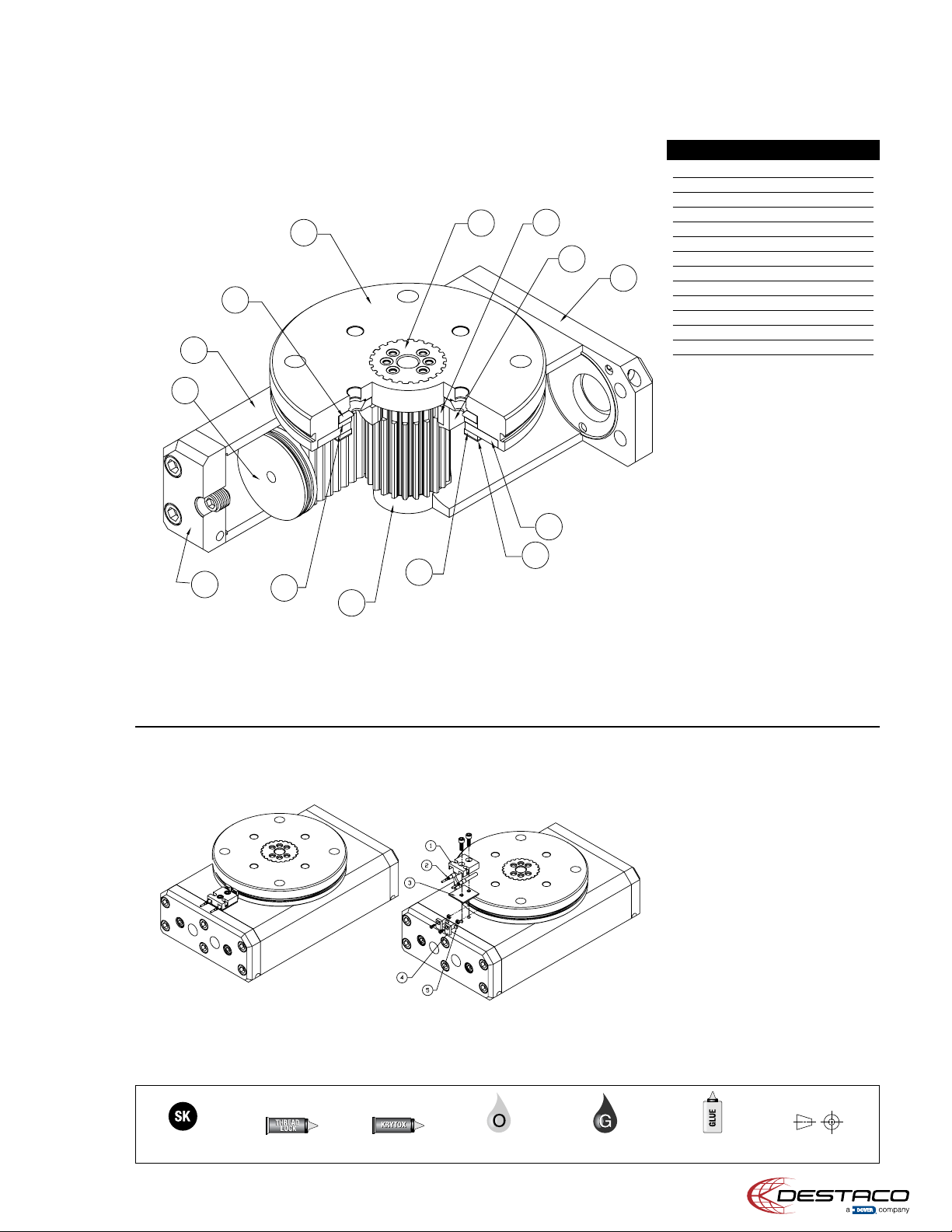

Manifold Option

Assembly Procedure

1) Lubricate and install 8 small o-rings.

(4 in the pinion, 4 in the rotary mani-

fold body).

2) Install 5 large O-rings on the rotary

manifold.

3) Press dowel pin into rotary manifold

4) Install rotary manifold in manifold

body.

5) Attach manifold assembly to rotary

actuator body.

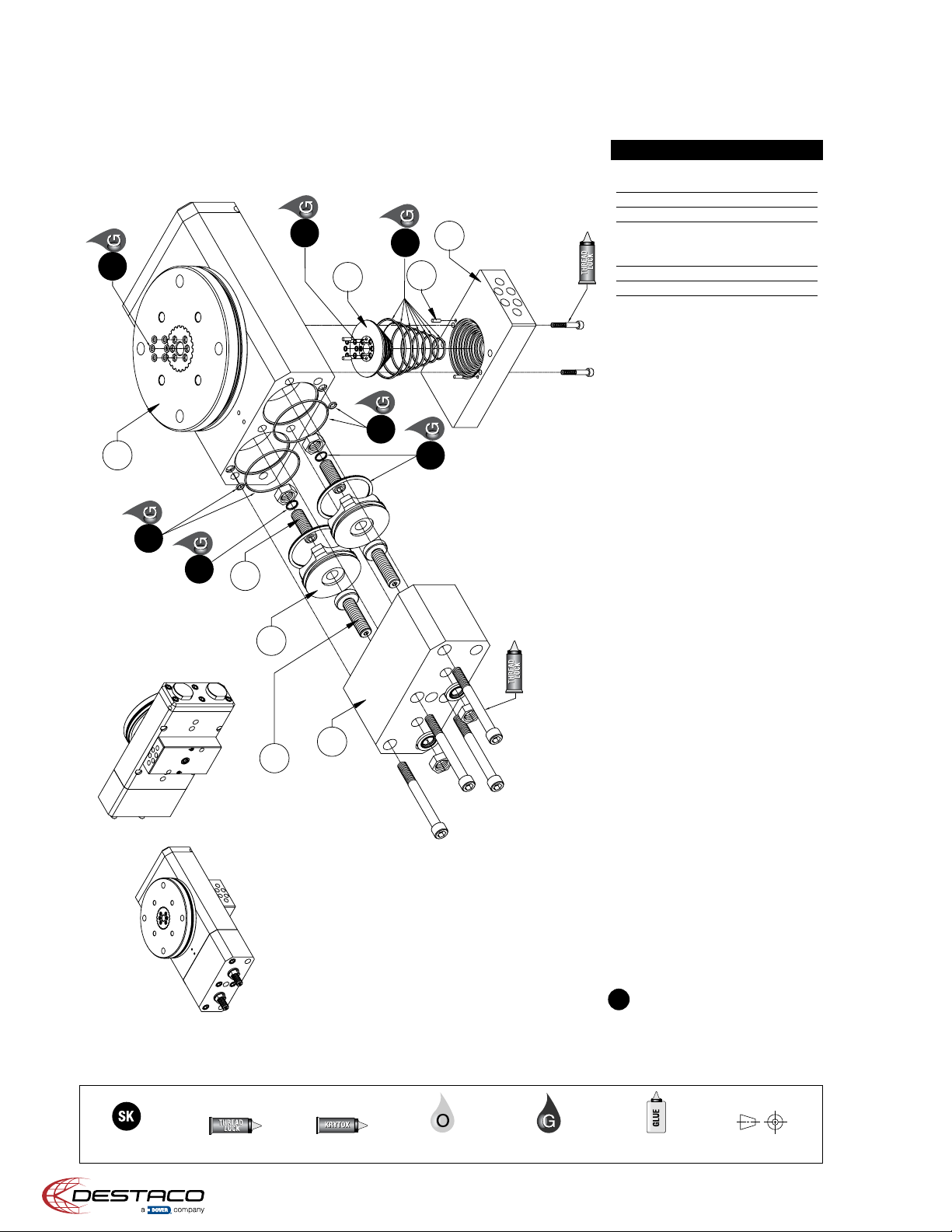

Mid-Stop Option

Assembly Procedure

1) Lubricate and install o-rings.

2) Install mid-stop pistons, adjustment

screws, seal washers, and hex nuts

in rotary actuator body.

3) Attach mid-stop body to rotary actua-

tor body.

4) Install flow controls.

Mid-Stop Adjustment Procedure

1) Remove mid-stop body from actuator

base.

2) Remove the two mid-stop pistons

from the mid-stop body and insert

them into their respective cylinder

bores in the actuator base.

3) Back off both mid-stop adjustment

screws (#30) while pushing the mid-

stop pistons firmly into the cylinder

bores. The face of the pistons should

seat against the actuator base. If not,

then continue to back out the stop

screws.

4) Turn the turntable to the desired posi-

tion and advance the mid-stop

adjustment screws until both screws

touch the main piston faces

5) Re-attach the two mid-stop pistons to

the mid-stop body and fasten mid-

stop body back onto actuator base.

Seal Repair Kit Order #’s

See Product Data Sheets

SK

3.1-3.45 (RR_DRM) RED.qxd 2/7/06 1:12 PM Page 16