Spinlock XX Series User manual

The perfect way to hold very high loads on new high-tech low

stretch ropes; safely, permanently and without rope wear.

3R308A/4

www.spinlock.co.uk

XX Clutch

XX0812 - XX powerclutch for 8-12 mm lines

XX0812/L - lock open version XX powerclutch

XX0812/S - silver anodised XX powerclutch

XX0812/LS - lock open version XX powerclutch silver anodised

XX0812/HS - XX powerclutch for side mounting starboard

XX0812/HP - XX powerclutch for side mounting port

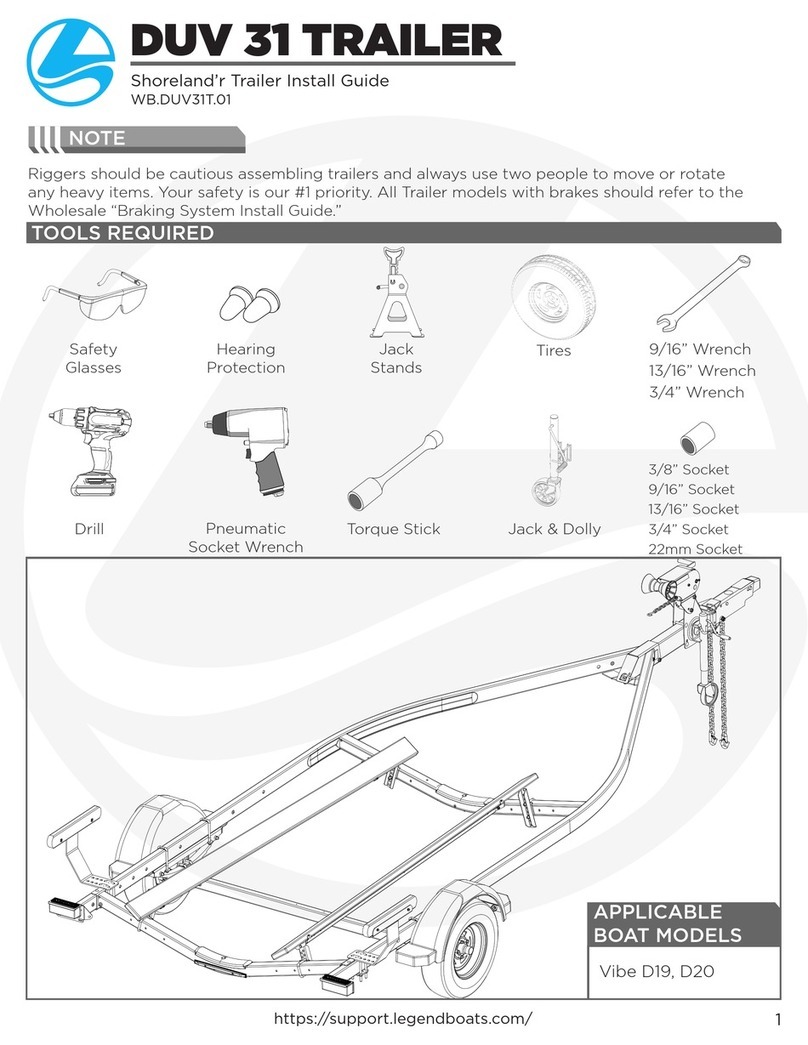

ZS Jammer

ZS Open Jammer

ZS Rope Sense

Alloy

ZS0810

ZS1214

ZS1618

Carbon

ZS1014C

ZS1014B

- supplied ready for bonding

ZS1618C

ZS1618B

- supplied ready for bonding

ZS1824C

ZS2632C

ZS0810/OPEN

- 8-10 mm lines

ZS1014/OPEN

- 10-14 mm lines

ZS1418/OPEN

- 14-18 mm lines

ZS1824/OPEN

- 18-24 mm lines

ZS2632/OPEN

- 26-32 mm lines

ZS-LC/5 - 5 Tonne load cell with inbuilt read out

ZS-LC/10 - 10 Tonne load cell with inbuilt read out

ZS-LCW/5 - 5 Tonne Wireless load cell

ZS-LCW/10 - 10 Tonne Wireless load cell

www.spinlock.co.uk

Contents

English

Français

2 3

Introduction 4

Performance 5-7

How to use

ZS Alloy Jammers and ZS Carbon Jammers 8-9

ZS Open Jammers 10-11

ZS Remote Lock Back Switch 12-13

XX0812, XX0812/L Clutch 14-15

Installation

ZS Alloy Jammers 16

ZS Carbon Jammers 17

ZS Remote Lock Back Switch 18-19

XX0812, XX0812/L Clutch 20-21

Maintenance

ZS Alloy, Carbon Jammers and Open Jammers 22-23

XX0812, XX0812/L Clutch 24-27

Options for the XX0812 range

Handle Assembly Replacement XX0812-HDLB 28-29

Converting XX0812 to XX0812/L lock open version 30-31

XX0812 side mounting 32

ZS and XX Custom Options 33

ZS and XX Spares 34-35

ZS Rope Sense 36-46

RP25 rope treatment 47

Special Projects Team and customer support 48-49

Introduction 52

Performance 53-55

Mode d’emploi

Coinceurs ZS Alloy et ZS Carbon 56-57

Coinceurs ZS Open 58-59

Commutateur de verrouillage arrière ZS–RLB à distance 60-61

Bloquers XX0812, XX0812/L 62-63

Installation

Coinceurs ZS Alloy 64

Coinceurs ZS Carbon 65

Commutateur de verrouillage arrière ZS–RLB à distance 66-67

Bloquers XX0812, XX0812/L 68-69

Entretien

Coinceurs ZS Alloy, Carbon et Open 70-71

Bloquers XX0812, XX0812/L 72-75

Options pour le serie XX0812

Remplacement du mécanisme de la poignée XX0812-HDLB 76-77

Transformer le bloqueur XX0812 en Open XX0812/L 78-79

Fixation latérale XX0812 80

Options sur-mesure ZS et XX 81

Pièces détachées ZS et XX 82-83

Système de mesure de charges ZS Ropesense 84

Traitement des cordages RP25 85

Special Projects Team et service client 86-87

page no. page no.

www.spinlock.co.uk

4 5

Introduction Performance

Introduction

Performance

Spinlock are the experts in high load rope holding. These

high load models are designed to match the advances in

high strength ropes. With their unique wedge action they

will hold expensive sheets and halyards safely and securely,

with low risk of damage.

Products in the high load range include the ZS Alloy, ZS

Carbon, ZS Open Jammers and XX Powerclutch, holding

ropes from 8mm to 32mm and loads up to 12000kg.

High Load products included in this instruction booklet

include:

The ZS and XX range of clutches and jammers are designed to generate

high compressive loads on the rope to ensure the core bears the greater

part of the load without over stressing the polyester or other fibres of

the outer braid. The structure of the jammers and clutches can withstand

loads beyond the stated max holding load. The data shown, represents

the maximum SWL we recommend for each product for a given diameter

with polyester covered ropes.

The actual load achievable can vary considerably according to the quality

and construction of the rope used. Before selecting the rope to use in

the product, check:

• The actual measured diameter under load.

• That the rope cover includes polyester - Vectran, HMPE (Dyneema,

Spectra) or PBO cannot be gripped on standard jaws, unless

blended with polyester.

• The cover is a close t on the core with an interface layer or bre

coating. Nominal section should be round.

• Sleeved areas are fully pre-tensioned with smooth entry and exit

tapering.

• The load rating for the rope and safety factor recommended by the

rope manufacturer.

Recent development in rope manufacture has centred on the use

of blended covers, where high tech fibres such as Aramid, Technora,

Dyneema or Vectran are co-braided with polyester or polypropylene.

Whilst hardwearing, with a high degree of heat resistance, these covers

can be harder to hold in clutches or jammers compared to polyester

covered lines. Contact the Special Projects Team for advice on new

digital custom jaw surfaces to suit specific blended covers or see

page 34 for spares and upgrades.

ZS Alloy

ZS0810

ZS1214

ZS1618

ZS1014B and ZS1618B are supplied designed for bonding directly

onto spars, booms and decks (see page 17).

ZS1214, ZS1014C, ZS1014B, ZS1618C and ZS1618B are supplied

with jaws and rear blocks prepared for use with ‘ZS-RLB’ Remote

Lock Back Switch allowing pre tensioning of the jaws for release

and remote operation of the jammer (see page 18).

ZS Carbon

ZS1014C

ZS1014B

ZS1618C

ZS1618B

ZS1824C

ZS2632C

XX Clutch

XX0812

XX0812/L

XX0812/S

XX0812/LS

XX0812/HS

XX0812/HP

ZS Open

ZS0810/OPEN

ZS1014/OPEN

ZS1418/OPEN

ZS1824/OPEN

ZS2632/OPEN

www.spinlock.co.uk

6 7

Performance

Performance

Performance

Model Line Dia Maximum

SWL

Weight

without

fastners

Weight

with

fastners

Stud

Fastners

(supplied)

Fastners

(side

mounting)

XX0812

XX0812

/HS & /HP

ZS0810

ZS1214

ZS1618

ZS1014C

8-12mm

(5/16-1/2”)

8-12mm

(5/16-1/2”)

8-10mm

(5/16-3/8”)

12-14mm

(7/16-9/16”)

16-18mm

(5/8-11/16”)

10-14mm

(3/8-9/16”)

1800kg

(3970lbs)

1800kg

(3970lbs)

1500kg

(3310lbs)

2200kg

(4850lbs)

4000kg

(8820lbs)

4000kg

(8820lbs)

1.05kg

(2.3lbs)

1.05kg

(2.3lbs)

0.7kg

(1.55lbs)

1.05kg

(2.3lbs)

2.0kg

(4.4lbs)

0.65kg

(1.45lbs)

1.126kg

1.126kg

0.77kg

1.195kg

2.36kg

0.89kg

2 x M8

5 x M6

3 x M8

4 x M8

4 x M10

4 x M10

Not supplied

see page 30

Not supplied

see page 30

6 x M6

6 x M6

use A4-70

6 x M8

use A4-70

Use

ZS1014B

ZS1618C 16-18mm

(5/8-11/16”)

6000kg

(13230lbs)

1.15kg

(2.5lbs)

1.517kg 6 x M10 Use

ZS1618B

ZS1824C

ZS2632C

18-24mm

(11/16-15/16”)

26-32mm

(1-1 1/4”)

8000kg

(17640lbs)

12000kg

(26460lbs)

1.75kg

(3.85lbs)

5.1kg

(11.24lbs)

2.361kg

5.956kg

10 x M10

14 x M10

Bond

-

ZS1014B

Bonded

10-14mm

(3/8-9/16”)

4000kg

(8820lbs)

0.63kg - - -

ZS0810/

OPEN

ZS1014/

OPEN

ZS1418/

OPEN

ZS1824/

OPEN

ZS2632/

OPEN

8-10mm

(5/16-3/8”)

10-14mm

(3/8-9/16”)

14-18mm

(9/16-11/16”)

18-24mm

(11/16-15/16”)

26-32mm

(1-1 1/4”)

1200kg

(2650lbs)

1800kg

(3970lbs)

3200kg

(7040lbs)

5200kg

(11440lbs)

7800kg

(17160lbs)

0.9kg

(1.98lbs)

1.2kg

(2.65lbs)

1.9kg

(4.19lbs)

4kg

(8.8lbs)

6.1kg

(13.45lbs)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

ZS1618B

Bonded

16-18mm

(5/8-11/16”)

6000kg

(13230lbs)

0.91kg - - -

AlloyCarbonOpen/Mobile

www.spinlock.co.uk

8 9

ZS Alloy Jammers and ZS Carbon Jammers

How to use

How to use

ZS Alloy / Carbon installation

pages 16-17 maintenance

pages 22-23 spares

pages 34-35

The jammers are relatively simple to operate, but because of the high loads

it is important to fully understand their function before use.

To Open : Pull handle out until latch clicks. The latch must be fully engaged

to hold the jaws open.

The rope can now be inserted and run freely in either direction. On large

diameter ropes it may be easier to lead the rope through the jammer with

the jaws removed. (see maintenance).

To lock line : Hoist sail and tension with winch. Before easing load off

winch, release the latch in the handle and push the jaws forward onto the

rope. Continue to apply firm pressure on the handle as the load is eased

off the winch onto the jammer. Once the jaws are fully engaged onto the

rope, they will slide forward a few millimeters as the full load is secured.

To Re-Open : The full load in the rope must be returned to the winch

before the jammer can be opened. Never attempt to the open jammer

without transferring the load back onto the winch. Only when the load

is secured on the winch is it safe to pull the handle back and engage the

latch. The jaws are now fully locked open and the rope can be controlled

from the winch to run freely through the jammer.

Note : For safety reasons ZS Jammers can only be released after the rope

load has been transferred to the winch drum.

www.spinlock.co.uk

10 11

ZS Open Jammer

How to use

How to use

ZS Open maintenance

pages 22-23 spares

pages 34-35

The ZS OPEN can be locked onto any loaded line, the perfect solution for

peeling spinnakers, headsails, reefing and dealing with an emergency.

1. Secure strop to padeye or winchbase of sufficient strength and aligned

as close to the line of load as possible.

2. Open the sideplate and engage the ZS OPEN onto the line. Then close

ensuring full engagement of the sideplate latch.

3. Slide jammer along the line so the strop is tight (this reduces runout)

and engage jaws, by releasing the jaw latch.

4. Carefully release the original loaded line from winch so the strop and

ZS OPEN jammer take the load.

Releasing the ZS Open Jammer

The ZS Open Jammer is released by holding the handle and sliding the

body forward, not pulling the handle back. Ensure there is enough slack in

the strop to allow disengagement of the Jaws.

Important Notes

Ensure prior to transferring a load that the:

• Coverplate is fully engaged onto the main body

• Latches are locked into the location pins

This ensures that the burst loads are shared by both side plates. Failure to

do this will cause the body to permanently deform and the cover plate will

no longer t. If the unit should be overloaded the white PTFE bearing will

show signs of deforming at its contact with the upper and lower faces of

the body.

www.spinlock.co.uk

12

ZS–RLB Remote Lockback Switch

How to use

13

How to use

For use with ZS Jammers or existing halyard locks. Allows the ZS Jaws to be

pre-tensioned for release.

ZS1214, ZS1014C, ZS1014B, ZS1618, ZS1618C and ZS1618B Jammers are

all supplied with jaws and rear block drilled for trip line attachment and

lead. Older style ZS Jammers in this range can be modied to use the ZS-

RLB contact the Special Projects Team for assistance in modifying older

products.

Step 1

The start position - ZS-RLB closed,trip line slack and ZS Jammer loaded.

Step 2

Open the ZS-RLB to pre-tension the trip line - the ZS Jammer is now ready

to release.

Step 3

Take up load on winch - the ZS-RLB will automatically open the Jaws and

allow the line to be released to the winch.

ZS-RLB installation

pages 18-19 spares

pages 34-35

loaded

line

loaded

line

load taken

on winch

loaded

line

loaded

line

load taken

on winch

loaded

line

loaded

line

load taken

on winch

1

2

3

www.spinlock.co.uk

14 15

XX0812, XX0812/L Clutch

How to use

How to use

XX0812 installation

pages 20-21 maintenance

pages 24-27 spares

pages 34-35

The XX holds loads 50% higher

than any conventional clutch

and is smooth and controlled

to release. Optimised for high

performance 8-12mm diameters,

the XX fills the critical load

holding gap between clutches

and high load ZS jammers.

As well as the standard clutch, a

Lock Open version, the XX0812/L,

is also available which allows the

line to run freely in both directions

with the handle closed, important

for spinnaker and mainsheet

applications where locking off

is only occasionally needed. The

XX0812/L also features an automatic

jaw release when the load is taken

on a winch. A standard XX can be

upgraded to a Lock Open version

with XX-MLDG or XX-LCK kit.

Line feeding into the XX0812 :

Using a long screwdriver, place shaft

through front bullseye and locate

tip on front face of lower jaw. Push

backwards until the jaw stops. With

the jaws in this position raise and

fully open the handle. This locks the

jaws back at their biggest clearance

and allows easy threading of your

new rope.

This process is not necessary for the

XX Lock Open Version.

Line feeding into

the XX0812

Safety Note : In stronger winds,

rope damage can be caused

releasing a highly loaded

line. This can be prevented by

transferring the rope load to

the winch before release.

XX0812/L Lock Open Clutch Operation

1. With the lock open latch in the UP

position the line runs freely through the XX

2. When the latch is pushed DOWN with the

handle closed, the line is held secure

3. To release the line, the handle can then be

opened, OR

4. With the handle in the closed position,

move the lock open latch to the UP

position. When the load is taken securely

on a winch the jaws will automatically

release, allowing the line to run free, with

the handle still in the closed position. The

jaw will remain open until the latch is

returned to the down position, even if

the handle is cycled.

With your new rope threaded you

can now close the handle. As the

handle closes, the XX clutch will

automatically engage the rope.

Release : As a safety feature, no

release action begins until the handle

is rotated beyond 60 degrees.

To protect the user and rope fibre,

normal hand pressure will not

release the rope above this load.

Important : Always start the release

process with the handle in the closed

position for full release efficiency.

If at any time you only part open

the handle we advise completely

opening and closing (cycling) the

handle, with the line secured on the

winch, to ensure the mechanism is re-

set for full release next time. Failure

to do this will result in poor holding

power and worn jaw surfaces.

Sleeving : Secondary sleeving

(internal or external) of the

rope significantly improves the

performance levels of any clutch

or jammer. Any external sleeving

should be a very tight fit. If you are

going to sleeve your rope, ensure

that the overall diameter does not

exceed 12mm and has a taper to

run freely through the clutch. Core

inserts provide the smoothest

transition for fast line speed

applications.

Watch the XX Demonstration Video at www.spinlock.co.uk

www.spinlock.co.uk

16 17

ZS Alloy Jammer ZS Carbon Jammer

Installation

Installation

ZS Alloy / Carbon how to use

pages 8-9 maintenance

pages 22-23 spares

pages 34-35

If fitting to the deck, install the jammers forward of the winch, close enough

for easy operation of the handle and latch, ensuring enough space is left

behind the product for removal of the jaw assembly for maintenance. The

jammers are provided with studs (A4-70 stainless steel) in a pattern. This

helps spread the load into lightweight composite decks or masts.

They are a tight t to ensure good thread engagement. Drilling templates

for deck layout are provided with the product.

Warning : The studs should be screwed a maximum of 15mm into

the body. Over tightening may damage internal bearing surface

Side Mounting : Replace the six body fasteners with longer bolts. These

can be inserted from either side by removing the round insert nuts. These

must be at least A4-70 stainless steel bolts if the maximum safe working

loads are to be reached. Refer to specication chart (page 7).

Double check the hole pattern before drilling. The pattern is not

reversible.

Mast Mounting : Mast mounting plates are available, see page 34 for

details. CAD templates can be download from:

www.spinlock.co.uk/cadlibrary

The Jammers are not designed to withstand high side loads. If the lead

angle to the winch is greater than 10 degrees, fit lead blocks or organisers

aft of the jammers. Contact the Special Projects Team for details of our TS

High Load Aft Organiser.

If fitting to the deck, install the jammers forward of the winch, close

enough for easy operation of the handle and latch, ensuring enough

space is left behind the product for removal of the jaw assembly for

maintenance. The jammers are provided with studs (A4-70 stainless

steel) in a staggered pattern. This helps spread the load into lightweight

composite decks or masts.

Warning : The studs should be screwed a maximum of 15mm into

the body. Over tightening may damage internal bearing surface.

They are a tight t to ensure good thread engagement. Drilling templates

for deck layout are provided with this product.

Side mounting : ZS1014B and ZS1618B Carbon Jammers are designed

to be side bonded.

Mast Mounting : Mast mounting plates are available, see page 34 for

details. CAD templates can be download from:

www.spinlock.co.uk/cadlibrary

Bonded Mounting : ZS1014B and ZS1618B are designed for bonding

directly onto decks, spars and booms.

Note: we are unable to provide engineering data on materials and

instructions for bonding. You must refer to your own engineering design

data, load data and materials supplier for guidance.

The Jammers are not designed to withstand high side loads. If the lead

angle to the winch is greater than 10 degrees, fit lead blocks or organisers

aft of the jammers. Contact the Special Projects Team for details of our TS

High Load Aft Organiser.

www.spinlock.co.uk

18

ZS–RLB Remote Lockback Switch

Installation

19

Installation

ZS-RLB how to use

pages 12-13 spares

pages 34-35

For use with ZS1214, ZS1618, ZS1014C, ZS1618C, ZS1014B and ZS1618B

Jammers or existing halyard locks. Allows the ZS Jaws to be pre-tensioned

for release.

1. Mount the ZS-RLB in it’s preferred location using M5 fasteners.

2. Choose a suitable very low stretch control line 2-4mm which can be

spliced.

2. Attach the control line to the jaw set using a thumb knot or similar -

see diagram below. Remove rear block and jaw step ( see page 22).

3. Thread the control line through the spring and rear blockand fasten

the rear block into place.

4. With the control line cut to approximately the correct length, splice the

control line to the eye of the RLB-Spring using an adjustable splice.

5. Ensure the control line has a free, un-interrupted, low friction run

to the jammer. If necessary use bulls eyes or blocks to ensure a

smooth run.

6. With the jaw set loaded on the correct diameter line and the RLB

closed adjust the control line splice so it is just taut.

7. Check operation as described (see page 12 and 13). Some adjustment

may be necessary before making the splice permanent.

8. Changes in the rig set-up or line diameter will require the control line

splice to be adjusted.

Open

Closed

www.spinlock.co.uk

20 21

XX0812, XX0812/L Clutch

Installation

Installation

XX0812 how to use

pages 14-15 maintenance

pages 24-27 spares

pages 34-35

1. Align the clutch with the required rope lead, checking height and

minimising the angle of alignment.

2. Drill two holes to suit the M8 fasteners using template (never drill

through the clutch). For spars, etc. where no access is possible, use an

M8 tap to thread the surface material, ensuring the material has

sufficient strength to carry the full clutch load, the fasteners must be

replaced with M8 A4-80 stainless socket cap or CSK Machine screws.

3. Check each fastener (already pre-assembled into clutch) to make certain

that its hexagonal head is properly seated in its locking moulding.

4. Fasten clutch firmly after sealing upper threads with silicone sealant.

In through-deck applications any excess thread can now be ground off.

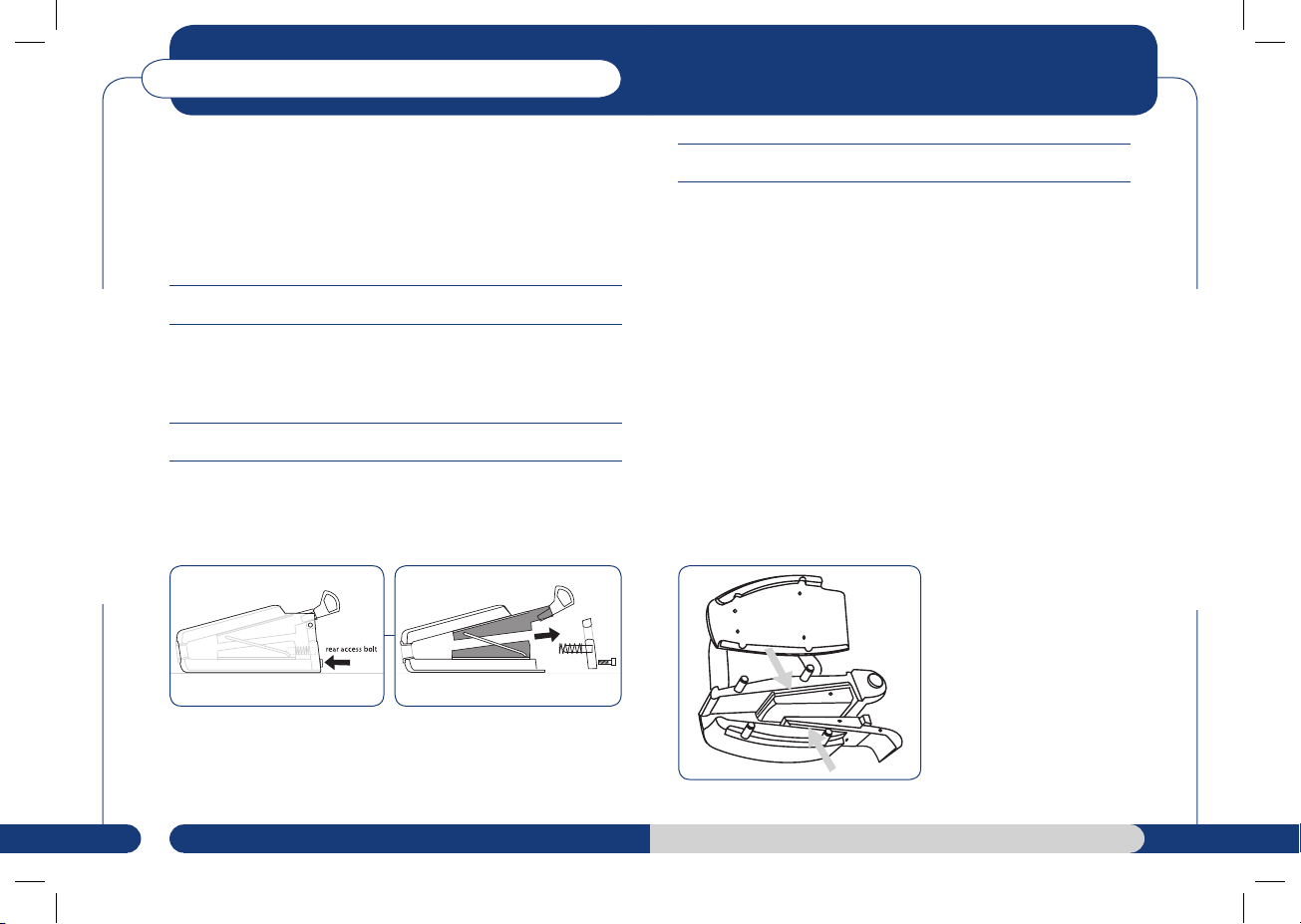

To access the fasteners : The XX0812 is supplied tted with High

Tensile A4-80 stainless steel hex head fasteners so access is unlikely to be

needed.

If you want to fit your own fasteners, you will only need to remove the rear

end moulding to gain access to the aft fixing position.

The forward fastener can be accessed from above (see Diagram 1). The

simplest way to remove this fastener is to remove the nut and washer and

turn the product upside down. The M8 fastener can now be removed.

For Lock Open Versions, ensure the lock open latch is in the down position.

Lift handle 50mm to gain access to the M5 Allen screw on the top surface

that retains the rear moulding. Remove this screw. (See Diagram 2).

Hold rear cover at top and rotate and pull out from the top (See Diagram 3).

Pull the complete rear moulding and jaw assembly free from the body (See

Diagram 3).

The fastener will now be visible. Leave the retaining moulding in place.

(See Diagram 3).

Watch the XX Jaw Set Removal Video at www.spinlock.co.uk

1 2

3

M8 fastener M5 allen screw

www.spinlock.co.uk

22 23

ZS Alloy, ZS Carbon and ZS OPEN Jammers

Maintenance

Maintenance

ZS Alloy / Carbon how to use

pages 8-11 installation

pages 16-17 spares

pages 34-35

Spinlock ZS Jammers are made from the highest quality materials for

durability and low maintenance in a harsh marine environment.

ZS Jammers are carefully designed for easy and regular servicing at sea. Their

life and performance will be improved if regularly flushed with fresh water.

The jaws can be easily removed for inspection and replacement:

For ZS Alloy and ZS Carbon

• Remove the screw securing the rear block.

• Remove rear block.

• Pull out the handle and jaw assembly.

For ZS OPEN

• Open the sideplate to allow removal of the jaw assembly -

compress jaws together to extract sideways.

ZS Alloy, ZS Carbon and ZS Bonded

All

• Check for excessive wear on the grip surface - the black anodised

surface, if worn, will have silver aluminium showing through.

• Check condition of the white bearings surfaces are clean and smooth.

Replace if necessary.

• Ensure all internal faces are clean and smooth.

The white jaw bearings should be lubricated only with silicone grease.

Do not use mineral oil or solvent based lubricants like WD40.

Replacement jaw sets must be installed with grease provided.

For further information and instructions on maintenance of ZS jammers,

please refer to the Spinlock website or contact Pro Support.

ZS OPEN

www.spinlock.co.uk

24 25

XX0812, XX0812/L Clutch XX0812, XX0812/L Clutch

General maintenance

Full Servicing

XX0812 how to use

pages 14-15 installation

pages 20-21 spares

pages 34-35

General maintenance:

Three Simple Steps – flush, drain and lubricate

1. The internal mechanism should be regularly flushed out with fresh

water through the end bullseyes, and the handle pivot area.

2. Check that the lower ‘drainage’ holes in both end mouldings are clear

of any debris. This will help reduce the accumulation of any rope debris

building up inside the product.

3. Lubricate handle pivot areas with a silicone grease. Unless this simple

procedure is carried out regularly, the specified performance will not be

achieved. Take care not to contaminate rollers or jaw surfaces with any

lubricant.

Note : Any decrease in performance is usually caused by lack of

maintenance and servicing. The XX0812 relies on the smooth running of

2 sets of roller bearings for maximum performance. The rollers and their

‘running’ surfaces must remain as clean as possible.

Removal from deck

If removing the XX0812 from the deck, care must be taken to ensure

the fasteners do not damage the internal mechanism and plastic rear

moulding. Do not hammer from below.

Watch the XX Servicing Video at www.spinlock.co.uk

Full servicing and Jaw Replacement:

The clutch should be given a thorough service periodically to ensure

maximum performance is maintained. The clutch mechanism is fully

accessible whilst attached to the deck - even with other clutches banked

alongside - by the following steps.

If upgrading jaws from a Pre 2010 XX0812, then part XX-Kit is required.

See www.spinlock.co.uk for full upgrade instructions, including video

from the Pre 2010 Model.

1. Remove the rope from the clutch.

2. For Lock Open Versions, ensure the lock open latch is in the

down position.

3. Lift handle 50mm to gain access to the M5 Allen screw on the top

surface that retains the rear moulding. Remove this screw.

4. Hold rear cover at top and rotate and pull out from the top.

5. Pull the complete rear moulding and jaw assembly free from the body.

www.spinlock.co.uk

26 27

XX0812, XX0812/L Clutch

Full servicing

Full servicing

XX0812 how to use

pages 14-15 installation

pages 20-21 spares

pages 34-35

6. After removal, thoroughly clean all components and body with fresh

water and inspect the following critical items :

Roller Cages (both are identical) - unclip from jaw and look for signs

of wear or flats on the roller surfaces. If flats are found replace &

consider upgrade to XX-Roll+. Ensure rollers cages are re-attached in

correct orientation.

Jaw Bearing Surfaces - ensure that both are clean and smooth.

Jaw Grip Surfaces - clean off any rope debris. Check for excessive

wear on the grip surface. If the black anodised surface has aluminium

showing through, replace with a new XX-Jaw Assembly.

Jaw Spring - should be able to hold jaws apart, be a smooth shape

and located on either side of the top jaw.

Jaw Linkplates - check these are attached to both sides of both jaws

with pins and secured by both pins. Ensure free movement of link

plates/pins in jaws.

Release Pin - located centrally in top jaw. Check for any signs of

surface wear.

Clutch Body - flush clean inside, paying particular attention to the

upper and lower roller surfaces, the two drainage runs in the base and

their exits at the end mouldings.

Handle - do not remove this from the body. Check that the operation

holds the handle in the closed and fully open position (via the leaf

spring mounted at the front of the wedge). Lubricate pivots with

silicone grease.

Re-assembly

1. For Lock Open Versions ensure the lock open latch is in the

down position.

2. Lift handle 50mm.

3. Insert jaw assembly in body of XX.

4. Angle rear moulding backward, to locate lower fixing hooks in body.

5. Rotate top of cover into place flush with XX body.

6. Insert M5 Allen screw on the top surface that retains the rear

moulding. Hand tighten only.

7. If Lock Open version, ensure latch is fully operational in both up and

down positions as well as opening and closing the handle fully.

8. For standard versions, open and close the handle fully to ensure fully

operational.

9. Open handle fully and Insert rope through XX body.

See page 15 for rope feeding advice.

www.spinlock.co.uk

28 29

Handle Assembly Replacement XX-HDLB

Handle assembly replacement

Handle assembly replacement

XX0812 how to use

pages 12-13 installation

pages 16-17 spares

pages 32-33

1. Remove the rope from the clutch.

2. For Lock Open Versions, ensure the lock open latch is in the

down position.

3. Lift handle 50mm to gain access to the M5 Allen screw on the top

surface that retains the rear moulding. Remove this screw.

4. Hold rear cover at top and rotate and pull out from the top.

5. Open handle fully to remove the two M6 CSK screws on top of the

product.

6. Pull the complete rear moulding and jaw assembly free from the body

7. Slide out the handle assembly through the rear of the body.

8. Thoroughly clean with fresh water and inspect the following

critical items:

Roller Cages (both are identical) - unclip from jaw and look for

signs of wear or flats on the roller surfaces. If flats are found replace

& consider upgrade to XX-Roll+. Ensure rollers cages are re-attached

in correct orientation.

Jaw Bearing Surfaces - ensure that both are clean and smooth.

Jaw Grip Surfaces - clean off any rope debris. Check for excessive

wear on the grip surface. If the black anodised surface has

aluminium showing through, replace with a new XX-Jaw Assembly.

Jaw Linkplates - check these are attached to both sides of both jaws

with pins and secured by both pins. Ensure free movement of link

plates/pins in jaws.

Release Pin - located centrally in top jaw. Check for any signs of

surface wear.

Clutch Body - flush clean inside, paying particular attention to the

upper and lower roller surfaces, the two drainage runs in the base and

their exits at the end mouldings.

Re-assembly

1. For Lock Open Versions ensure the lock open latch is in the

down position.

2. Fully close the handle and then lift handle 50mm.

3. Insert jaw assembly in body of XX.

4. Angle rear moulding backward, to locate lower fixing hooks in body.

5. Rotate top of cover into place flush with XX body.

6. Insert M5 Allen screw on the top surface that retains the rear

moulding. Hand tighten only.

7. If Lock Open version, ensure latch is fully operational in both up

and down positions as well as opening and closing the handle fully.

8. For standard versions, open and close the handle fully to ensure fully

operational.

9. Open handle fully and Insert rope through XX body.

www.spinlock.co.uk

30 31

Converting XX0812 to XX0812/L lock open version

XX0812 to XX0812/L

XX0812 to XX0812/L

XX0812 how to use

pages 14-15 installation

pages 20-21 spares

pages 34-35

The XX0812 can be converted to the XX0812/L with the purchase

of the XX-LCK.

Fitting procedure:

1. Check kit components before commencing (Diagram 1).

2. Lift handle 50mm to gain access to the M5 Allen screw on the top

surface that retains the rear moulding. Remove this screw.

3. Hold rear cover at top and rotate and pull out from the top.

4. Pull the complete rear moulding and jaw assembly free from the body.

5. Remove Latch Pivot Pin (diagram 2).

6. Insert Latch Spring and Latch Lever Support into Latch Lever (diagram 2).

7. Insert Latch assembly into rear moulding from rear (diagram 3).

8. Insert jaw spring ends into latch lever support, such that the spring

coils align with holes in latch support.

9. Push Latch Lever and Lever Support together and locate with Rear

Cover to allow all holes to align.

10. Push pin through holes in Rear Cover, Latch Lever, Latch Support and

Spring Coils. An audible ‘Click’ will be heard (Diagram 4).

11. Insert jaw assembly in body of XX.

12. Angle rear moulding backward, to locate lower fixing hooks in body.

13. Rotate top of cover into place flush with XX body.

14. Insert M5 Allen screw on the top surface that retains the rear

moulding. Hand tighten only.

15. Ensure lock open latch is fully operational in both up and down

positions as well as opening and closing the handle fully.

16. Put latch into ‘Up’ position and Insert rope through XX body.

3

1

4

2

www.spinlock.co.uk

32 33

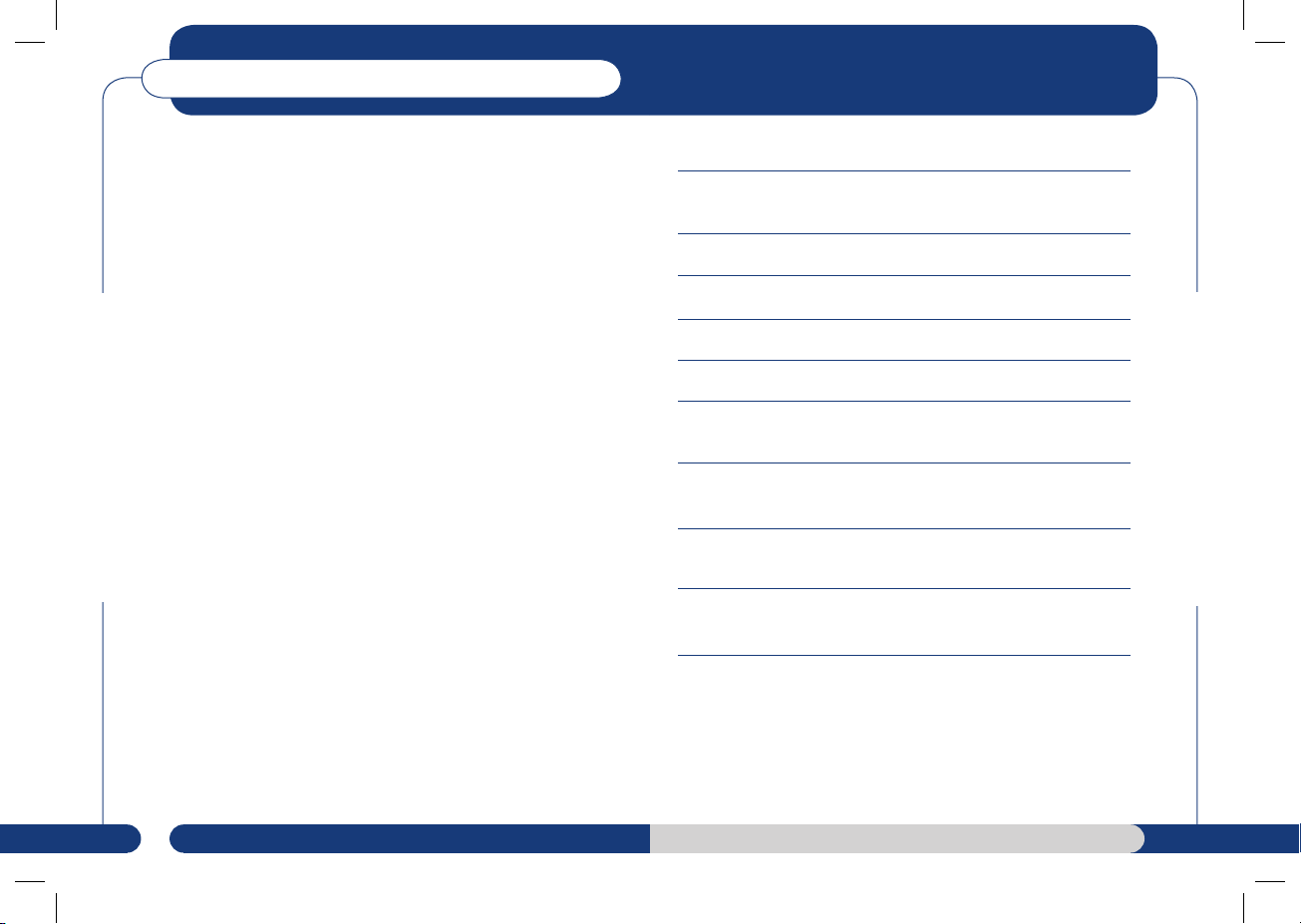

XX0812 Side Mounting

Custom options

XX0812 Side Mounting

XX0812/HP and XX0812/HS are supplied ‘handed’ ready for side

mounting.

Remove the jaw set (page 25) and fasten to the deck using 5 x M6 A4-

70 stainless steel fasteners (supplied). Insert jaw set and close rear block.

(Page 25.)

Align rope with entry and exit mouldings for smooth running and

minimum friction.

ZS Alloy

• Custom Colours to match hull, deck or spar.

• Handles Engraved with line application.

• Remote release system.

ZS Carbon

• Custom Colours to match hull, deck or spar.

• Handles Engraved with line application.

• Available specically for bonding.

• Remote release system.

• Jaw surfaces matched to specic rope types.

ZS Open

• Handle Engraved with line application.

• Deck and rig mounting options available.

XX0812

• Available in Black, White and Silver nishes.

• Handles Engraved with line application.

• For weight saving on XX clutches contact the Special Projects team.

XX0812/HS

www.spinlock.co.uk

34 35

Spares

Spares

Spares

ZS Alloy, Carbon and Open Jammer Range XX0812 Clutch

Part No. Product Description

ZS-JAW08 ZS0810 Jaw Assembly

ZS-JAW10C ZS1014C Jaw Assembly*

ZS-JAW10H ZS1014C, ZS1014B Jaw Assembly**

ZS-JAW12 ZS1214 Jaw Assembly*

ZS-JAW12H ZS1214, ZS1014B Jaw Assembly**

ZS-JAW16 ZS1618, ZS1618C Jaw Assembly

ZS-Jaw16H ZS1618C, ZS1618B Jaw Assembly**

ZS-JAW18C ZS1824C Jaw Assembly

ZS-SPG08 ZS0810 Spring Set

ZS-SPG12 ZS1214, ZS1014C & B Spring Set

ZS-SPG16 ZS1618, ZS1618C & B Spring Set

ZS-SPG18C ZS1824C Spring Set

ZS-MNT0810 ZS0810 Alloy Mounting Plate

ZS-MNT1214 ZS1214 Alloy Mounting Plate

ZS-MNT1618 ZS1618 Alloy Mounting Plate

ZS-MNT1014C ZS1014C Alloy Mounting Plate

ZS-MNT1618C ZS1618C Alloy Mounting Plate

ZS-MNT1824C ZS1824C Alloy Mounting Plate

ZS-RLB ZS1214, ZS1618 ZS Remote Lock

ZS1014C, ZS1618C Back Switch

ZS1014B, ZS1618B

ZS-RLB/L ZS1824C, ZS2632C

For ZS Open spares contact : [email protected]

* For polyester only

covered lines

** For blended only

covered lines

Part No. Description

XX-KIT Jaw Set and Moulding Kit

to upgrade post 2005 XX0812

to 2010 model

XX-JAW Jaw Assembly for XX0812

post 2010

XX-LCK Upgrade for XX0812 to

Lock Open version XX0812/L

XX-HDLB Handle Assembly (Black)

XX-MLDG Replacement moulding

kit for XX0812

post 2010

XX-ROLL PEEK™ Standard Roller Set (not illustrated)

XX-ROLL+ Torlon Roller Set (not illustrated)

www.spinlock.co.uk

36 37

ZS Rope Sense Load Displays ZS-LC/5 & ZS-LC/10 Load Display

ZS Rope Sense Load Displays

ZS-LC/5 & ZS-LC/10

Simple, soft loop attachment offers fast connection to any

applications, for quick mobile load measurement

• Design loads often vary widely from actual loads. ZS Rope Sense offers

teams the ability to quickly and easily confirm actual working loads

and refine deck hardware and rope selection.

• Used either stand alone or with ZS Open Jammers.

• Continuous load read out or ‘Peak Load’ mode.

• Wireless versions also available (no LCD Read Out) which transmits

directly to your PC via a USB aerial. Data can be viewed

instantaneously on screen as a read out and graph format.

• Easily exported to Excel.

• Overall accuracies 0.02% over full scale deection.

• Rated to IP65 for water and dirt resistance.

ZS-LC/5 5 Tonne load cell with inbuilt read out

ZS-LC/10 10 Tonne load cell with inbuilt read out

ZS-LCW/5 5 Tonne Wireless load cell, no read out. Including USB

aerial and PC software

ZS-LCW/10 10 Tonne Wireless load cell, no read out. Including USB

aerial and PC software

ZS-WD Wireless read out display for ZS-LCW/5 and ZS-LCW/10

ZS-LOOP/5 5 Tonne soft loop attachment

ZS-LOOP/10 10 Tonne soft loop attachment

Introduction

Compact, light weight mobile load

cells for use with soft connections with

inbuilt readout.

Use

• Can safely work between a deck

eye, strong point or traveller

car and block to measure loads.

• Use with ZS/OPEN mobile jammer linked by a ZS/LOOP to measure

loads in any line.

• The unit can give a continuous TRACKING load read out or

measure PEAK load.

Operating Instructions

• Mount the load cell in the desired position.

• Designed to use either ZS-LOOP attachment in a ‘basket’ formation

or tied directly to sheets or halyards with one complete turn around

the cell before termination as illustrated below:

Line Attachment ZS-LOOP ‘Basket’

Attachment

X

www.spinlock.co.uk

38 39

ZS-LC/5 & ZS-LC/10 Load Display ZS-LC/5 & ZS-LC/10 Load Display

ZS-LC/5 & ZS-LC/10

ZS-LC/5 & ZS-LC/10

Power Button

• Turn the cell ON by holding down the power button until the screen

comes on. The cell will read load instantly and does not need to be

‘unloaded’ when turned on.

• The load reading will update continuously until 6 minutes has passed

when the unit will automatically power down.

• To turn OFF manually press and hold until the screen goes past ‘Zer’ to

OFF then release the button.

Page Button

• Use this button to switch between TRACKING, PEAK and PEAK

READING modes.

• To enter PEAK press and hold down the page button until the screen

ashed between P and a reading.

• In PEAK mode the unit will remain ON until the battery runs out unless

turned OFF.

• To read the PEAK load hold down the page button until PPP ashes

intermittently with the reading.

• Return to TRACKING mode by holding down the page button. This

resets the PEAK READING to zero.

• BASIC INSTRUCTIONS ARE SHOWN ON THE BATTERY COVER

Zeroing

• From time to time it may be necessary to ZERO the reading due to

climatic conditions. To ZERO press and hold the POWER button and

release when ‘Zer’ appears on screen.

Overload

• If the screen ashes OL in any mode the unit has experienced a

signicant overload and will require re-calibration.

• OVERLOADING 200% OF SWL WILL RESULT IN PERMANENT

DAMAGE TO LOAD CELL

• A calibration certicate is available and valid for 12 months. The unit

must be returned to Spinlock for re-calibration.

Battery Life

• The PP3 9v battery supplied with the unit will last between 2 and 6

hours depending on the range of load measured.

• When the battery power is low the decimal place will start to ash.

• VERY LOW VOLTAGE BATTERIES MAY GIVE INACCURATE

READINGS.

• STORAGE WITH BATTERY CAN RESULT IN LEAKAGE AND

DAMAGE.

Battery Replacement

• To change the battery carefully unscrew the 3 at blade stainless steel

screws with an appropriate sized screw driver.

• Lift of the plastic battery cover and place down without disturbing the seal

• Lift out and detach the battery without straining the wires.

• Clip on a new PP3 9v battery and place inside the compartment with the

battery terminal at the same end as the wire exits the load cell body.

• Replace the plastic battery cover and carefully locate the 3 bolts before

screwing evenly until the seal is compressed an even amount all round.

• DO NOT OVER TIGHTEN THE SCREWS

This manual suits for next models

25

Table of contents

Languages:

Other Spinlock Boating Equipment manuals