Spirax Sarco Spirax-Monnier MP User manual

Other Spirax Sarco Controllers manuals

Spirax Sarco

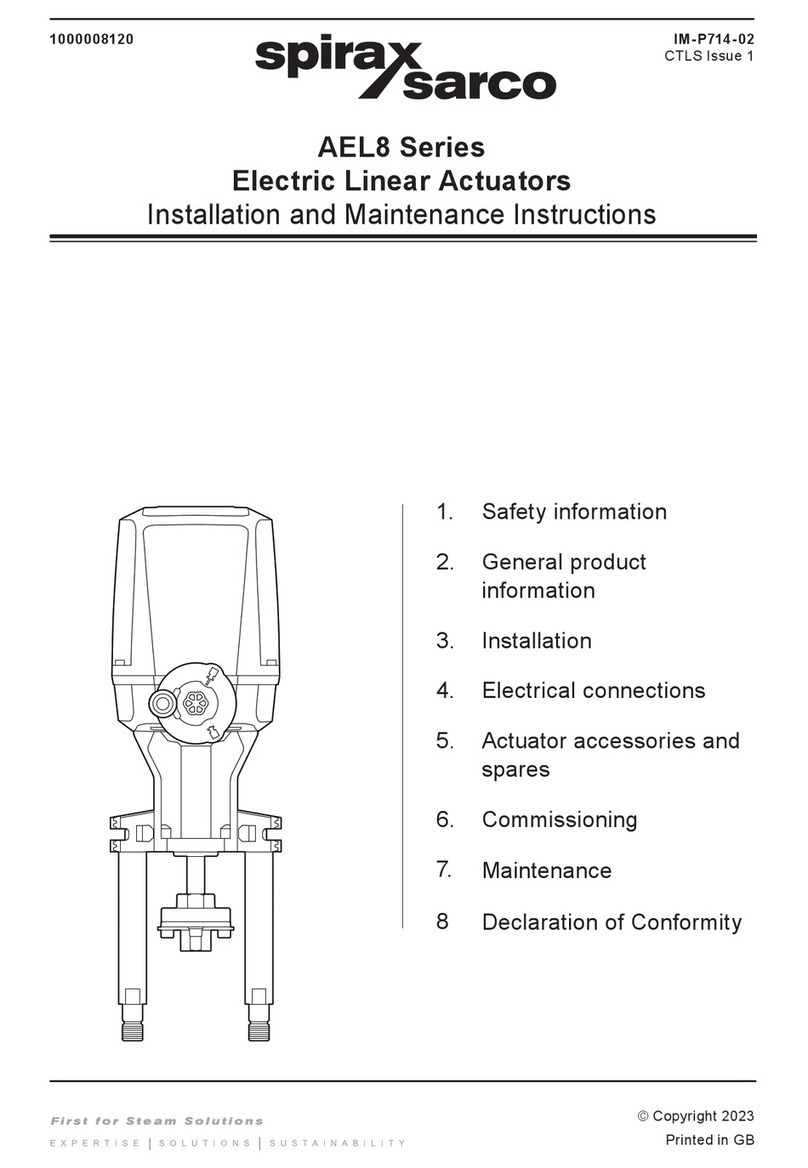

Spirax Sarco AEL8 Series User manual

Spirax Sarco

Spirax Sarco PN 3000 Series User manual

Spirax Sarco

Spirax Sarco BC1100 User manual

Spirax Sarco

Spirax Sarco 25T User manual

Spirax Sarco

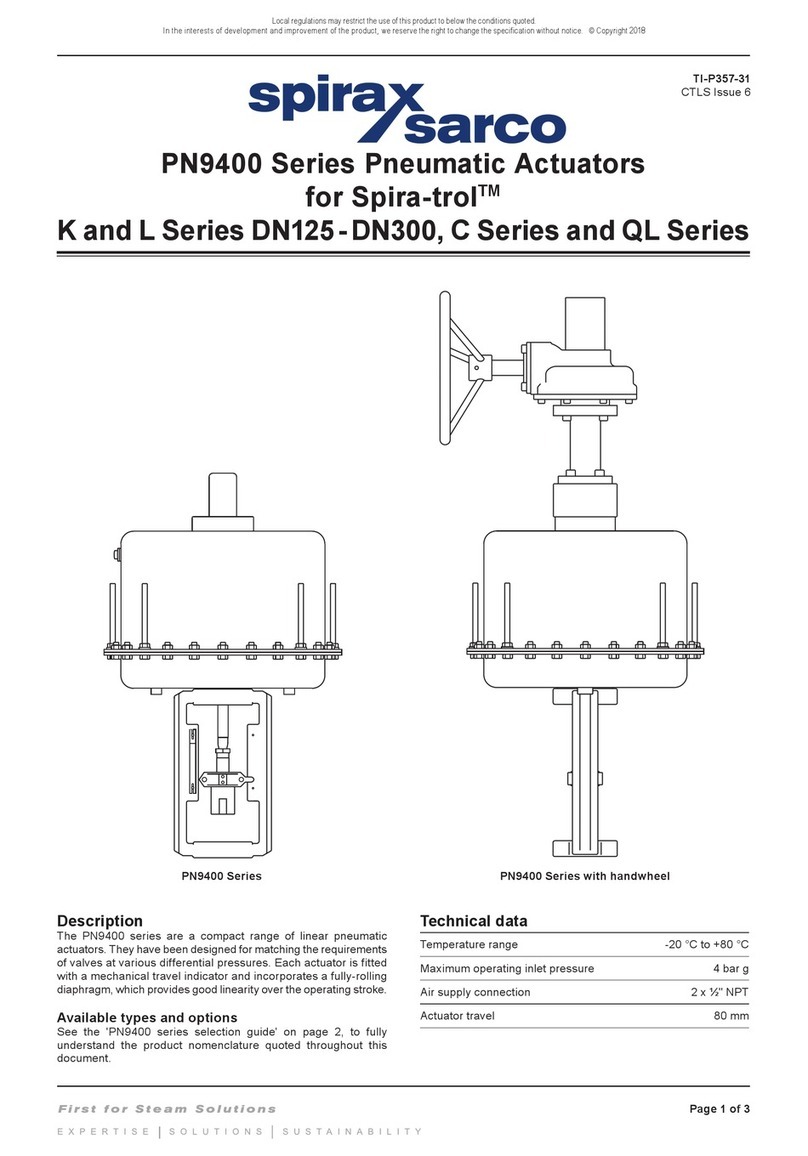

Spirax Sarco PN9400E Series Instruction manual

Spirax Sarco

Spirax Sarco SX Series User manual

Spirax Sarco

Spirax Sarco LC2610 User manual

Spirax Sarco

Spirax Sarco LCR2251 User manual

Spirax Sarco

Spirax Sarco SX80 User manual

Spirax Sarco

Spirax Sarco LC2400 User manual

Spirax Sarco

Spirax Sarco 600 Series User manual

Spirax Sarco

Spirax Sarco 25T User manual

Spirax Sarco

Spirax Sarco LC3050 User manual

Spirax Sarco

Spirax Sarco AEL3 Series User manual

Spirax Sarco

Spirax Sarco AEL7T User manual

Spirax Sarco

Spirax Sarco SP500 User manual

Spirax Sarco

Spirax Sarco 3000 Series User manual

Spirax Sarco

Spirax Sarco SX75 Series User manual

Spirax Sarco

Spirax Sarco IP2AM User manual

Spirax Sarco

Spirax Sarco AEL7 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions