Spire SPI-PULSE 25 User manual

iR-8-3

DTI

C

)

Approved

iflr

rliblic

rilecxse;

-

80

9

15

005

-urff7

:I

-PUz

7

TRANSMISSION

LINE

PULSER

OPERATING

MANUAL

.,

SP~/

IE

COPRTO

.......

l'1..

Bedford,

Massachusetts

01730

'I I

7* SPIE ORPRAIO

TABLE

OF

CONTENTS

UNPACKING

PROCEDURE

. .. .. .. . ... .. .. .. . .. 2

INTRODUCTION

. . . .. .. .. ... ............. 3

* USPECIFICATIONS .. .. ..... ................ . 4

IOPERATINGINSTRU

CTION

ONS...

.. .. .. . . . . .. . . 6

CHARGE

LINE

.. .. ...... .. .. .... ........

12

INSTRUCTIONS

FOR

INPUT

VOLTAGE

SELECTION

ION

EXPORT

MODEL

(115/230

VAC,

50/60

HZ)

.......... .

13

IREPLACEMENT

OF

HIGH-VOLTAGE

SWITCH

ASSEMBLY

.......

15

jSPI-PUISE

25

TROUBLESHOOTING

CHART.

.. . .. .......21

ELECTRONIC

WIRING

DIAGRAM.

.. .. .. .. . .. ... . . .

22

lh2aounoe

Ii~

I

DX

u1tri

but

on__

Availad/i

Dist.,

special

-AlL

If

your

"P"P

S

25

insruen

is--foun

il-ito

b

dIefeciewti-n erfo

aeo

1I

I

I

I

II

I

WARRANTY

I

Spire

products

are

warranted

to

be

free

from

defects

in

material

and

workmanship.

I

If

your

SPI-PULSE

25

instrument

is

found

to be

defective

within

one

year from date

of

delivery,

repair

or

replacement

will

be

made

at

no

charge.

This

warranty

is

in

lieu

of

all

other

warranties

expressed

or

implied.

Any

defective

instrument

will

be

repaired

or

,i

replaced

at

Spire's

discretion

during

the warranty

period.

This

warranty

does

not apply

if

the

instrument

has

been

subject

to

accident,

abuse.

alteration,

improper

application,

or

any

other

form

of

misuse.

The

warranty

also

does

not

cover

consequential

loss

or

damage,

including,

but

not

limited

to,

loss

of

peripheral

equipment

and

loss

of

time

due

to

the

malfunction

of

the instrument.

ISpecification

and

price

change

privileges reserved.

S

1

Copyright

1978

by

Spire

Corporation.

All

rights

reserved.

[SPI-PULSE

is

a

registered

trademark

of

Spire

Corporation.

[1

UNPACKING

PROCEDURE

Carefully

unpack

your

SPI-PULSE

25

when

it

arrives.

Check for

concealed damage.

L

If

any

found,

report

it

to

the

carrier

immediately.

i2

Aa-......

fMMS

I

INTRODUCTION

The 50-ohm

SPI-PULSE

25

transmission

line

pulser

is

designed

to

generate

high-voltage,

fast-risetime

pulses

over

a

range

from

0

to

1,000

volts

without

Internal

adjustment.

Pulse width,

amplitude,

and

repetition

rate

are

individually

controlled

by

the

operator.

The

instrument

can

be

triggered internally

or

externally,

either

by

single

shot

or

repetitively

up

to

275

hertz.

The

SPI-PULSE

25

uses

a

low-reactance,

high-voltage

switch

packaged

in

a

50-ohm

geometry

to

discharge

a

transmission

line

charge

store.

Discharging

the

line

into

a

j

matched,

50-ohm

load

results

in

a

step-function

wave

of

one-half the

stored

voltage

traveling

down

the

transmission

line

in-

transit-ttfi-M

reflecting

off

the

open

end

of

the

transmission

line,

and

returning

at

the

same

amplitude

in

a

second

period

of transit

time,9Thus

a

square

pulse with

an

amplitude

one-half

that

of

the

storage

voltage

and

a

width

of

2',is

produced.

Typical

applications

for this high-performance

pulser include

laser

diode

pulsing

in

fiber

optic

communications

research,

timing

signal

generation,

current

injection

testing

to

establish

EMI

burnout

levels,

and

high-voltage

instrument

calibration.

t3

I

I

I

I|

3

-

SPECIFICATIONS

Performance

Specifications

1.

Peak

output

voltage

.... ...........

1,000

volts

(into

50-ohm

load)

(Amplitude

adjustable

by

knob)

2.

Peak

output

power..... .. ..

.20

kilowatts

3.

Risetime

........ ..................

0.5

nanosecond

4.

Failtime.

. ...............

0.5

nanosecond

I

5.

Pulsewidth

.. .. .............. ....

1-500

nanoseconds

(Length

of

50-ohm

charge

cable

used

determines

pulsewidtb:

approximately

3

ns/ft)

6.

Polarity

....... .................. .

Selectable

by

switch

(+ or-)

7.

Droop

..... .................. ..

<3%

of output

voltage

8.

Overshoot

..... .. ................

<5%

of

output

voltage

9.

Output

impedance

.... .............

50

ohms

10.

Pulse

repetition

rate

a)

Manual

(pushbutton)

mode

..... ...

Single

shot

b)

Continuous

-node

............ ...

30-275

hertz

(Adjustable

internal oscillator)

11.

External

trigger

mode:

a) Input

voltage

... ........... ...

2.5-50

volts

b)

Input

impedance

.... ..........

1

megohm

(nominal)

c

e)

Minimum

pulsewidth

o.........

100

nanoseconds

(Minimum

pulsewidth

at

3

volts'

amplitude)

d)

Pulse

repetition

rate

......... ...

0

to

275

hertz

e)

Jitter

..............

50

microseconds

12.

Switching

system

.. .............

Special

gas-pressurized

reed

IL

switch

13.

Switch

operating

life

.. . .......

108

pulses

(approximate

-

dependent

on

output voltage)

14.

External

power

requirements

a)

Standard

model

..........

115

VAC,

60

Hz

b)

Export

model

..... .....

115/230

VAC,

50/60

Hz

'4

L

Specifications

-

SPI-PULSE

25

Dimensions

and Weights

46U.S. Metric

I

.

Width.

.. .. ... . ... .... . .....

19

1/2"1

49.59 cm

2.

Height

......

...

.. .. .. .. .. .

47/8"

12.38

cm

3.

Depth.

.. .. .. . .... .... . .....

183/4"1

47.83

cm

4.

Weight

(net)

.. .. .. ... ..... . ....

26

lb.

11.79

kg

.5.

Weight

(shipping)

.. .. ........ . ...

36

lb.

16.33

kg

I5

L

OPERATING INSTRUCTIONS

This

section

provides

simplified

operating instructions

for

the

SPI-PULSE

25,

as

well

as

typical

test

configurations

in

which

it

can

be

used.

WARNING:

Potentially

lethal

voltages are present

both

at

the

front

panel

jacks

and

internally.

The

OUTPUT

and

CHARGE

LINE

jacks (see

Figure

1)

must

be

properly

terminated

when

the

instrument

is in

use.

1.

Connect

the

instrument

to

the

power

source.

Domestic

version:

115

volts

and

60

Hz

Export

version:

Select

either

115

volts

or

230

volts

(see

section,

"Instructions for

Input Voltage

Selection

on

Export

Model

(115/230

VAC,

50/60

Hz)")

2.

Make

the

following

front

panel

connections (see

Figure

1).

a.

OUTPUT

connector

(GR-874)

-

connect

to

the

device

to

be pulsed.

b.

CHARGE

LINE

connector

(GR-874)

-

connect

to

the

desired

length

of

charge

line

cable.

Use RG-9

or

similar

cable;

the

RG-9

cable

provides

approximately

3

nanoseconds

of

pulsewidth

per

foot

of

-

cable.

NOTE:

The

OUTPUT

and CHARGE

LINE

connections

must

be

NOT

made

for

the

instrument

to

operate.

I

, 6

REP

RATE

*.U Y

_

ISP"-PLSE

25

ExT

r"+ .

_

CAUTION

i

0

HGH

VO6.GE

T

______

R;

I.

Operating

Instructions

-

SPI-PULSE

25

C.

MONITOR

OUT

connector

(BNC)

-if

desired,

connect

a

monitoring

device,

such

as

an

oscilloscope.

NOTE

1:

Typical

monitoring

devices

are

a

high-speed

oscilloscope

for

pulse-shape

or

amplitude

monitoring,

and

a

low-speed

oscilloscope

or

frequency

counter

for

repetition

rate

monitoring.

NOTE

2:

The

monitor

output

voltage

equals

OUTPUT

voltage/100

if

the

MONITOR

OUT

is

terminated

in

50

ohms.

The

monitor

output

voltage

equals

OUTPUT

voltage/50

if

the

MONITOR

OUT

is

unterminated

or

terminated

in

high

impedance.

d.

TRIGGER

IN

connector

(BNC)-

if

desired,

connect

an

external

signal

to

trigger

the

SPI-PULSE

25.

NOTE

1:

The

TRIGGER

IN

connection

will

function

only

when

the

TRIGGER

MODE

switch

(see

below)

is

in

the

EXT.

(external)

position.

NOTE

2:

The

trigger

input

pulse

must

meet

the

following

specifications:

V

Minimum

trigger

voltage

.. ......... ..

2.5

volts

Maximum

trigger

voltage

.. ...........

50

volts

Input

impedance

..... ............. 1

megohm

(nominal)

Minimum

pulsewidth

... ...........

.100

nanoseconds

Maximum

pulse

repetition

rate

........ ..

275

hertz

This

input

is

CMOS

and

TTL

compatible.

• [

f8

.ID

* *>

Operating

Instructions

-SPI-PULSE

25

3.

Select

the

TRIGGER

MODE

(see

Figure

1)

by

setting

the

selector

switch

to

one

of

the

following

three

positions:

a.

REP.

RATE

-

an

internal

oscillator

controls

the

output

repetition

rate

(30

to

275

Hz).

NOTE:

The

exact

output

frequency

must

be

monitored

externally

via

an

oscilloscope

plugged

into

the

MONITOR

OUT

connector.

b.

SINGLE

-

the

SPI-PULSE

25

provides

one

output

pulse

per

each press

of

the

SINGLE

pushbutton

(see

Figure

1).

C.

EXT.

-

the

TRIGGER

IN

connector

is

activated

to

provide

one

output

pulse

per

input

pulse

at

the connector.

4.

Select

the output

POLARITY

(see

Figure

1).

a.

-

=

a

negative-going

pulse

b. +

=

a

positive-going

pulse

*5.

Set

the

AMPLITUDE

control

knob

to

minimum,

fully

counterclockwise

(see

Figure

1).

6.

Press

the

ON

pushbutton

to

turn

the instrument

on;

the

pushbutton

illuminates.

*

NOTE:

If

the instrument

is

in

the

REP.

RATE

mode,

you

will

now

hear

the

buzzing

of

the

internal

high-voltage

switch.

If

you

don't

hear

the

buzzing,

go

to

the

"1SPI-PULSE

25

Troubleshooting

Chart".

j7.

Press

the

14.V.

(high-voltage)

pushbutton to

activate

the

OUTPUT

connector; the

pushbutton

illuminates.

8.

Turn

the

AMPLITUDE

control

knob

clockwise

to

the

desired

level.

UI9

Operating

Instructions

-

SPI-PULSE

25

*.

9.

If

the

TRIGGER

MODE

selector

switch

is

in

the

REP.

RATE

position,

turn

the

REP.

RATE

control

knob

to

the

desired

frequency.

Clockwise

rotation

increases

the

frequency.

NOTE:

Because

of

the

mechanical

nature of

the

reed switch

employed

in

this

unit, resonant frequencies

may

be

encountered

that

will

produce

irregular

pulses.

This

condition

is

generally

audible.

A

slight

shift

in

the

repetition

rate

will

alleviate the

condition

if

it

occurs.

For

your

convenience,

the

schematics

of

several

typical

test

setups

are

presented

in

Figure

2.

t.0

L

i

10

CHARGE

LINE

OUTPUT

SOIL

0

47j.

(TYP)

DIODE

FREE-RUNNING

LASER

DIODE

PUMPING

CHARGE

LINE

OUTPUT

13

raC@

13

~MONITOR

@

DEVICE

UNDER

0

TEST

IN

TRIGGER

SCOPE

ON

OPERATING

INPUT I

VOLTAGES

SING!

E

-SHOT

DESTRUCTIVE

TESTING

CHARGE

LINE

OUTPUT

O©O,,TRIR

MONITOR

13

N?

OUT?

0EVICE

CELL

1

TRI1GER

PULSE

SCOPE

+TO

OTHER

TIMED

DEVICES

[EXTERNALLY

TRIGGERED POCKELS

CELL

g

FIGURE

2.

TYPICAL

TEST

CONFIGURATIONS

1

1

CHARGE

LINE

The

SPI-PULSE

25

instrument

operates

by

charging

a

known

length

of

coaxial

cable,

then

discharging

the

cable

into

a load.

Thus

the

cable

characteristics

determine

the

output

characteristics.

Approximately

3

nanoseconds

of

output

pulsewidth

are

provided

per

foot

of

cable;

for

critical

applications,

however,

the

cable

length

should

be

adjusted

by

output

pulsewidth

measurement

or

TDR

techniques.

For

optimum

pulse

shape

a

double-shielded,

silverplated

coaxial

cable

is

recommended,

with

RG-9B/U

or

RG-214/U

being

suitable.

One

end

must

have

a

GR-874-type

of

connector

affixed,

while

the

other

end

is

left

open-circuited.

Since

twice

the

output

voltage

appears

on

the

center

conductor

of

this

cable,

the

open

end

must

be

well

insulated,

not

only

to

protect

the

user,

but

also

to

prevent

shorting

the

cable

and

possibly

damaging

the

instrument.

Particular

attention

should

be

paid

to

trimming

the

braid,

so

that

all

the

strands

are

cut

off

cleanly

and

evenly.

Complete

charge

line

assemblies

of

any

length

(see

Figure

3)

are

available

from

Spire

Corporation.

Please

write

or

call

for

details:

Pulser

Sales, Spire

Corporation,

Patriots

Park,

Bedford,

Massachusetts

01730

(617)/275-6000.

[

FIGURE

3.

TYPICAL

CHARGE

LINE

ASSEMBLY

12

41[

-----

INSTRUCTIONS

FOR

INPUT

VOLTAGE

SELECTION

ON

EXPORT

MODEL

(115/230

VAC,

50/60

Hz)

1.

Remove

the

four

Phillips

screws

holding

the

rear

panel

to

the

instrument's

chassis.

2.

Set

the

rear

panel

to

one

side, being

careful

not

to

pull

the

power

cord

attached

to

the

rear

panel.

3.

Adjust

with

a

small

screwdriver

the

slide switch

located

on

the

lower

left-hand

side

of

the

internal

aluminum

chassis

(see

Figure

4).

Slide

the

switch

so

that

the

desired

input

voltage

-

"115"

or

"230"

-

appears

in

the

window

associated

with

the

slide

switch

(see

Figure

5).

NOTE:

The

UP

setting

of

the

slide switch equals

115

volts,

and

the

DOWN

setting

equals

230

volts,

as

shown

by

the

number

in

the

window.

4.

Replace

the

rear

panel.

NOTE:

The

export

versions

of

the

SPI-PULSE

25

are

shipped

without

a

power

plug.

When

attaching

a

plug,

observe

that

L

the

power

cord

wires

are

coded

as

follows:

Green

=

ground

(earth)

Black

=

hot

(live)

White

=

neutral.

I13

IK

1

13

OUTPUT

LOOP

FS

-

INPUT

VOLTAGE

SLIDE

SWITCH

FS

-

$

(ON

EXPORT

MODEL

ONLY)

FIGURE

4.

SPI-PULSE

25

WITH

REAR

PANEL

REMOVED

FIGURE

5.

THE

TWO

SLIDE

SWITCH

SETTINGS

1

14

REPLACEMENT

OF

HIGH-VOLTAGE

SWITCH ASSEMBLY

WARNING:

Potentially lethal

voltages are

present

both

at

the

front

panel

jacks

and

internally.

Only

personnel

familiar

with

the

techniques

of

working

safety

with

high

voltages

should

attempt

replacing

the

high-voltage

switch

assembly.

Removal

of

Old

Switch

Assembly

1.

Connect

the charge

line

cable

and

a

50-ohm load

to

the

SPI-PULSE

25.

2. Set

the

TRIGGER

MODE

selector

switch

to

REP.

RATE

(see

Figure

1).

3.

Set

the

REP.

RATE

control

knob

at

12

o'clock.

4.

Press

the

ON

pushbutton.

NOTE:

Do

not press

the

H.V.

pushbutton.

5.

Allow

the

instrument

to

run

about

30

seconds,

to

discharge

most

of

the

charge

on

the high-voltage

power supply.

i.

Unplug

the

instrument,

and

remove

the

load

and

the

charge

line

cable.

7.

Remove

the

four

Phillips

screws

holding

the front

panel

to

the

instrument's

case.

8.

Slide

the

panel

and

attached

chassis

outward

from

the

case.

[

NOTE

1:

The

power

cord

is attached

to both

the rear

panel

and

the

chassis;

however,

you

should

find

the

cord

to

r

be

long

enough

to

allow

the

complete

removal of

the

L

chassis

from

the

case.

Replace

ment

of

High-Voltage

Switch

Assembly

-

SPI-PULSE

25

NOTE

2:

Be

careful

not

to put

presure

on

the

output

loop

extending

through

the

rear

of

the

chassis

(see

Figure

4).

9.

Connect

one

end

of

an

insulated

jumper

cable

to

a

firm

chassis

ground.

10.

Carefully

connect

the

other

end

of

the

jumper

cable

to

the

high-voltage

terminal.

(Refer to

Figure

6

for

steps

10

through

19.)

WARNING:

Use

extreme

caution

since

the

high-voltage

terminal

may

still

have

high

voltage

present.

11.

Cut

the

two coil

wire

splices

in

the

middle

of

the

heat

shrink

tubing.

12.

Remove

the

tubing

from

the

ends

of

the

two

coil

drive

wires,

cutting

off

any

exposed

conductor

and

stripping

the

insulation

back

1/4

inch.

13.

Cut

the

high-voltagq

wire

adjacent

to

the

high-voltage

resistor.

14.

Remove

any

heat

shrink

tubing

from

the

wire,

cut

off

any

exposed

conductor,

strip

the

insulation

back

1/4

inch,

and

fold

the

wire

back

out of the

way.

1.15.

Cut

the

monitor-out

cable

adjacent

to

the monitor-out

resistor.

j

[16.

Repeat

step

14

for

the

monitor-out

cable.

NOTE

The

ground

nut

must

be

removed

to

release

the

L

NOTE:monitor-out

ground.

r

16

Table of contents

Popular Transmitter manuals by other brands

Becker

Becker Centronic MemoControl MC511 Assembly and operating instructions

Honeywell

Honeywell oneWireless XYR 6000 user manual

Spektrum

Spektrum NX10SE instruction manual

GDD Instrumentation

GDD Instrumentation TxIII instruction manual

Harris Broadcast

Harris Broadcast Flexiva FAX 5KW Technical manual

Hawk

Hawk Intelligent 2000-SAN Series instruction manual

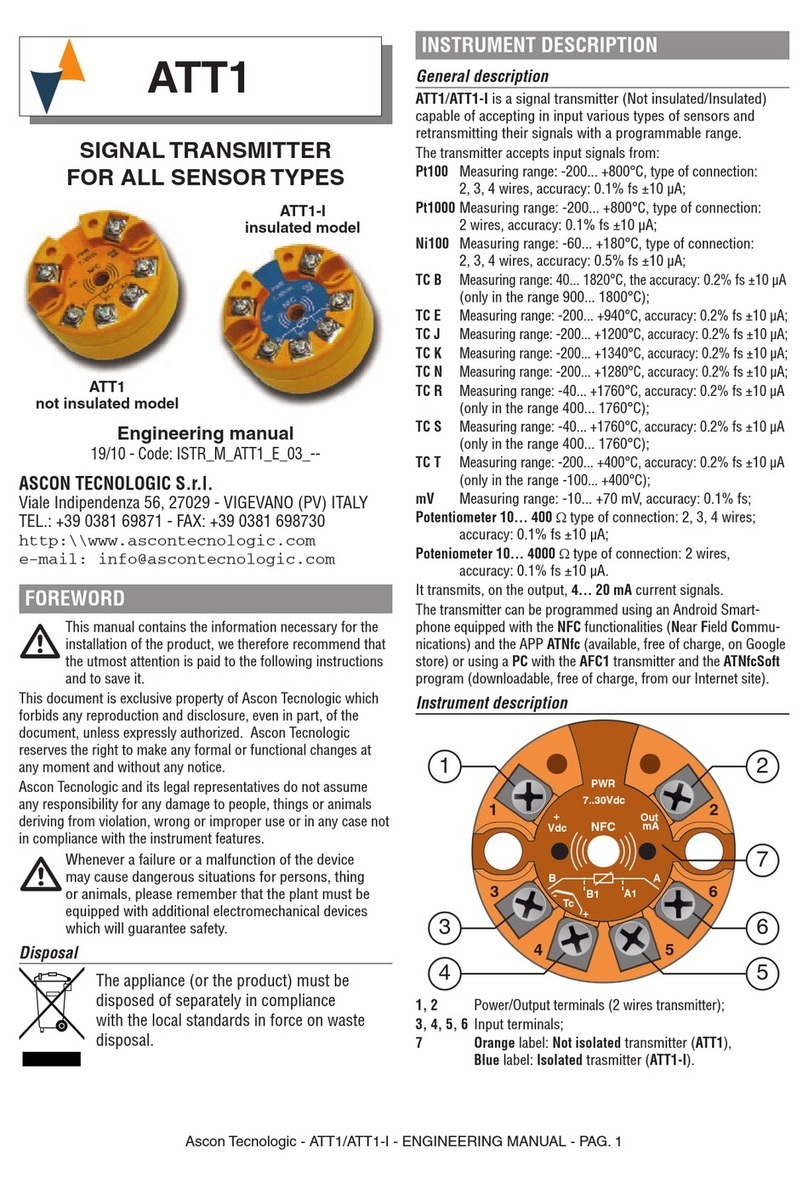

ascon

ascon ATT1 quick start guide

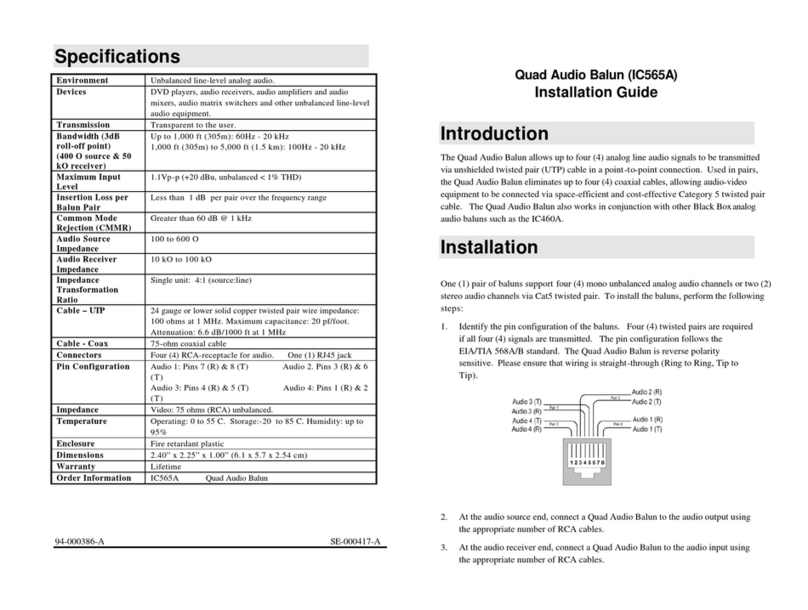

Black Box

Black Box IC565A installation guide

Oehlbach

Oehlbach BTT 5000 user manual

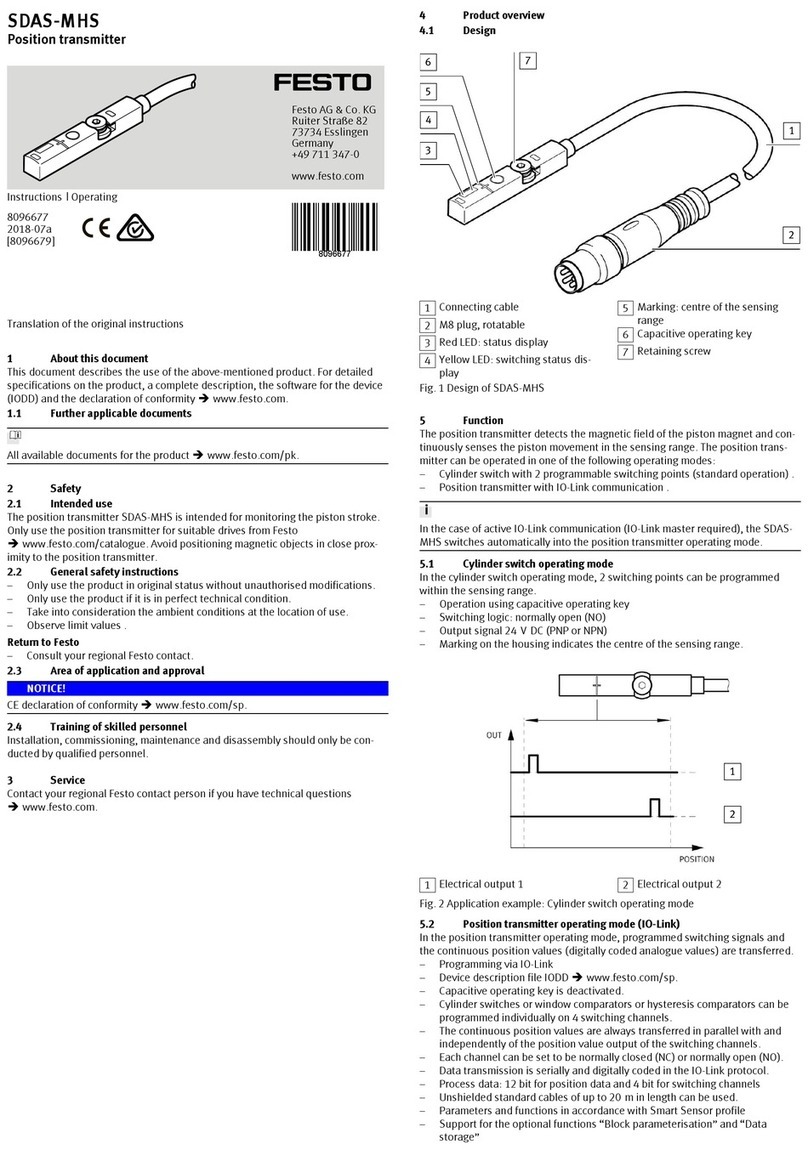

Festo

Festo SDAS-MHS Translation of the original instructions

Produal

Produal Proxima WBU Commissioning and Maintenance Instructions

RKI Instruments

RKI Instruments 65-2397RK Operator's manual