Page 9

The Sportwerks™ .26 engine features a slide-valve

carburetor and includes three inserts of various

diameters. These carburetor inserts are used to alter

the power curve of the engine. The three diameters

included have the following effect:

6.5mm – Gives smooth controllable acceleration;

offers best fuel mileage; best-used for

slick tracks/surfaces or beginning

gas drivers.

7.5mm – Develops good mid-range power; easier

to control than the 9mm insert; best for

medium traction, average-sized tracks/

areas.

9mm – Offers explosive, sometimes difficult to

control acceleration; uses the most fuel;

used only for high traction, large track/

open areas; for expert drivers only.

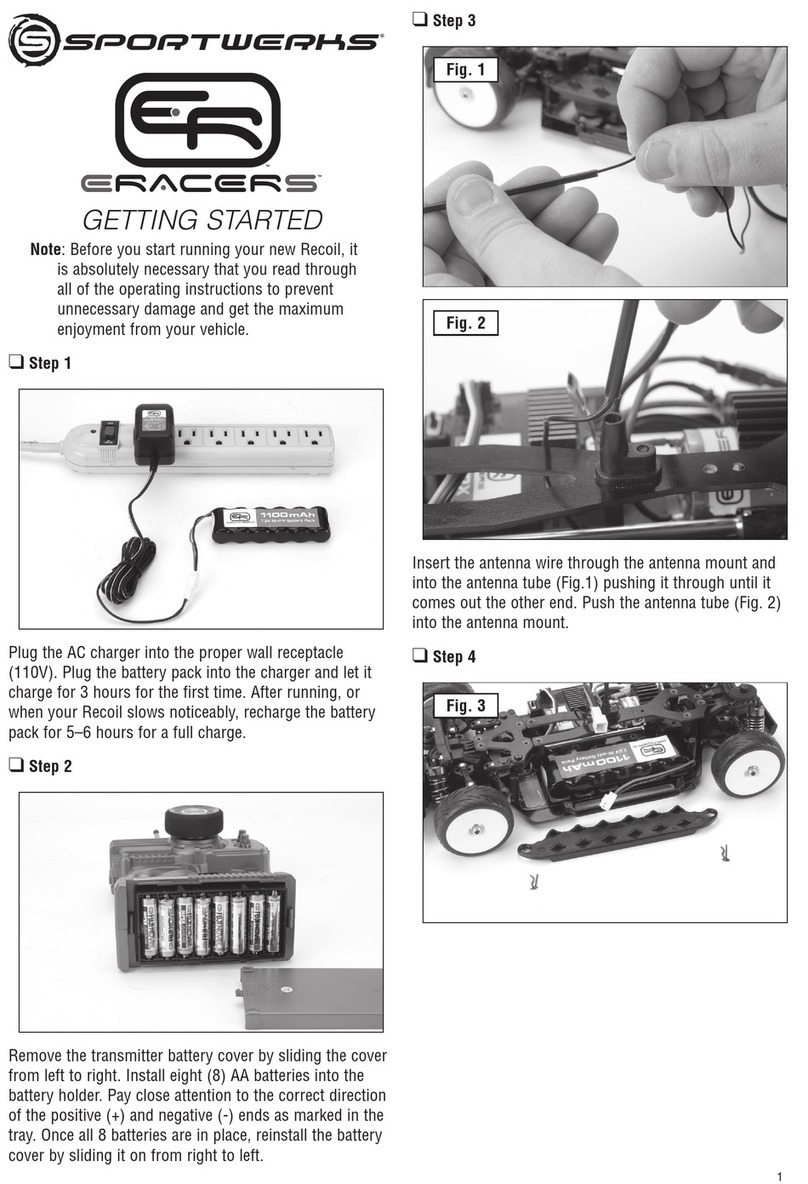

Setting the needles

While the needles are preset at the factory, it’s a good

idea to verify that the needles are properly set slightly

rich for break-in. Following are the recommended

starting settings:

High- Speed Needle: 3 1/2 turns out

(counterclockwise) from closed

Low- Speed Needle: 2 turns out

(counterclockwise) from closed.

Note: When checking the adjustment of the low-

speed needle, it is crucial that the throttle slide is

closed completely and that you do not over-tighten

the needles. When you feel resistance, immediately

stop turning. This is the closed position.

Starting Your Engine For The First Time

Break-in

The first startups and the first several minutes that

your engine is running is the most critical time of

its life and, in many ways, dictates how well it will

perform and how long it will last.

During the first runs, when the engine starts, the

exhaust should emit blue/white smoke, indicating

that the engine is rich (a good thing during break-in).

During the first tank of fuel, you may wish to set a

higher than normal idle speed in order to keep the

engine from stalling. Drive your truck while “blipping”

the throttle and avoid operating the engine at full

throttle for more than 2–3 seconds at a time. Run

the entire first two tanks of fuel in this manner. After

the first two tanks of fuel, begin leaning out the high-

speed needle valve 1/8 turn at a time. It generally takes

about 5 or 6 tanks of fuel before you’d want to start

tuning for “maximum” power. Patience during break-in

will be rewarded with an engine that performs reliably

and to its maximum power potential. Remember, glow

plug failure is a common occurrence when breaking

in a new engine. To test your plug, let the engine idle

at a properly adjusted low-speed needle setting with

the glow igniter attached. Then, remove the igniter.

If you hear no appreciable change in engine rpm, the

plug is still good. If the engine loads up and the rpm's

decrease, it’s time to replace the glow plug.

The Sportwerks Carburetor

High-Speed

Needle Valve

Low-Speed

Needle Valve

Idle Screw

Lean

Lean

Carb Insert