Spring NeoTap Operating instructions

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

Please read these instructions completely before operating this unit

Sparkling Plumbed In

Sparkling, Boil, Chill Benchtop Unit

(Freestanding Cabinet Optional)

INSTALLATION AND OPERATION GUIDE

Preface/Parts

Piping Installation - Diagram

Piping Installation

2

3

4

5

6

CONTENTS

Push Lock Fitting and Plumbers Delight - Installation

Co2 Bottle Installation

HOT, SPARKLING, COLD - Water Operation

Trouble Shooting

Leakage Detection Diagram and Swivel Tap - Warning

Specification Sheet

1

7

8

9

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

PREFACE/PARTS

Before using this machine, we advise you to read this manual

thoroughly.

Please follow the instructions to ensure proper operation and the

lasting of the machine

Neotap - Freestanding Co2 Bottle Regulator Brass Tee-Off Valve

(Plumbers Delight)

Pressure Reducing Valve 1/4" Pipe Power Cord KDF30

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

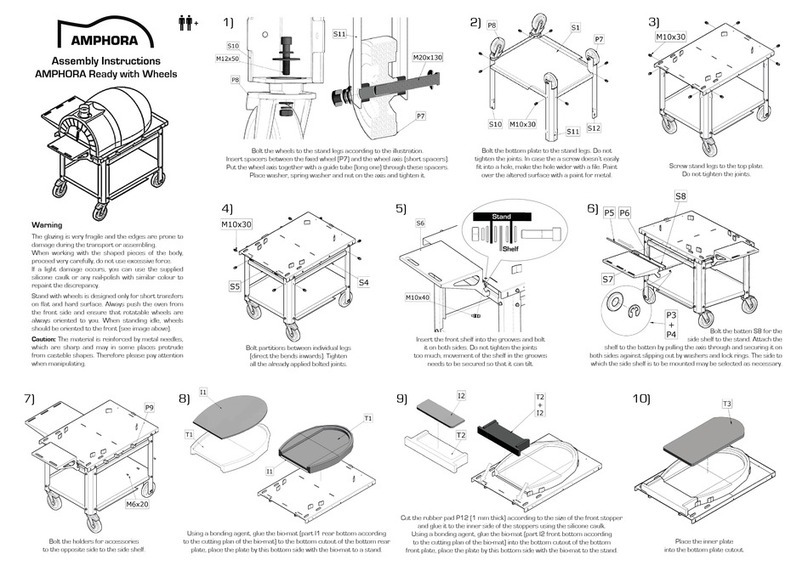

PIPING INSTALLATION - DIAGRAM

2. Using the 1/4" Pipe provided connect the 1/4" Inlet ball valve to the Pressure

Reducing Valve. The PRV is then connected to the KDF30 Filter and finally into the

Water inlet. Please ensure the filter has been flushed before cnnecting. The PRV

and Filter have a directional water flow, please connect as marked. See drawing B

Co2 bottle

Co2 Connector

KDF30 Filter

(Directional Flow. Flush all black carbon

dust before connecting to machine)

Water

Inlet

PRV

(Directional Flow)

Brass Tee Off

Valve

(Plumbers

Delight)

1/4" Pipe

PIPING INSTALLATION

1. Isolate the water supply. Disassemble the original COLD water Tap/Flexihose

connections. Reconnect the plumbers delight inline

2. Using the 1/4" Pipe provided connect the 1/4" inlet ball valve to the Pressure

Reducing Valve. The PRV is then connected to the KDF30 Filter and finally into

the water inlet. Please ensure the filter has been flushed before connecting. The

PRV and Filter have a directional water flow, connect as marked on the part

3. Connect the machine to the power supply using the cord at the rear of the unit.

Leave power and water supply OFF

4. Place the Co2 bottle upright as close to the NEOTAP unit as possible.

5. Turn the knob fully anti-clockwise to ensure the regulator is in the OFF position

6. Connect the Co2 bottle to the regulator by screwing the regulator onto the

bottle firmly (Clockwise). Be careful not to over-tighten to avoid damaging the

nut

7. Attach the regulator to the Co2 connector at the rear of the unit using the 1/4"

pipe provided. DO NOT OPEN REGULATOR - This is addressed in Co2 Operation

8. Ensure the whole unit and its components have at least 150mm ventilation

surrounding

9. Ensure all fittings, electrical connections and piping are secure to and from the

unit.

10.Turn on the Water and Power supply

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

We recommend the instructions specified in this guide be followed in sequence by a

qualified tradesperson for successful installation.

This Neotap has a 12 month warranty from purchase, but this may be voided if

unsatisfactory installation results in damage to the unit.

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

PUSH LOCK FITTING - INSTRUCTIONS

1. Cut the 1/4" Pipe square and push into the fitting.

You must remove burrs and chamfer tube end for

metal pipes to prevent the 0-ring seal being damaged.

2. The Push lock fitting will grip before it seals. Ensure

the pipe is pushed into the fitting completely

3. Pipe is secured in position

Disconnection

Push the collet against the pipe and slide out of the

push lock fitting to disconnect

PLUMBERS DELIGHT - INSTALLATION

Disassemble the original Cold Water Tap and/or Flexihose connection. Reconnect

the plumbers delight inline and use tee-off for the 1/4 inch connection to feed

machine

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

Co2 BOTTLE - INSTALLATION

1. Ensure the Co2 bottle is connected firmly to the regulator and the Co2 tube is

fitted correctly.

2. Slowly turn the dial on the regulator clockwise until the gauge reads 3BAR

(Note: If you want to reduce the pressure you must first turn the dial anticlockwise

and then vent to relieve existing pressure. The gauge will then settle and read

accurately)

3. Turn off the water at the valve and purge any air from the sparkling line by

pressing the sparkling button on the tap for 30 seconds.

4. Turn the water back on at the valve and the SODA switch at the rear of the unit.

5. Press the sparkling button on the tap for 15 seconds to allow any excess Co2 to

be dispensed

6. Operate the sparkling button on the tap 2-3 times for 15seconds each time

(1minute cooldown) until you notice the water is sparkling. Pressure will fluctuate

between 3-4 bar

All Co2 bottles should be upright during use, storage and transit. If the bottle has

been left horizontal, place upright and stand for 60+ minutes before use to allow

contents to settle

Co2 Refill Tube

Pressure Gauge

Pressure

Regulator

1/4" Pipe

Co2 Bottle

TOP VIEW - Co2 Bottle

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

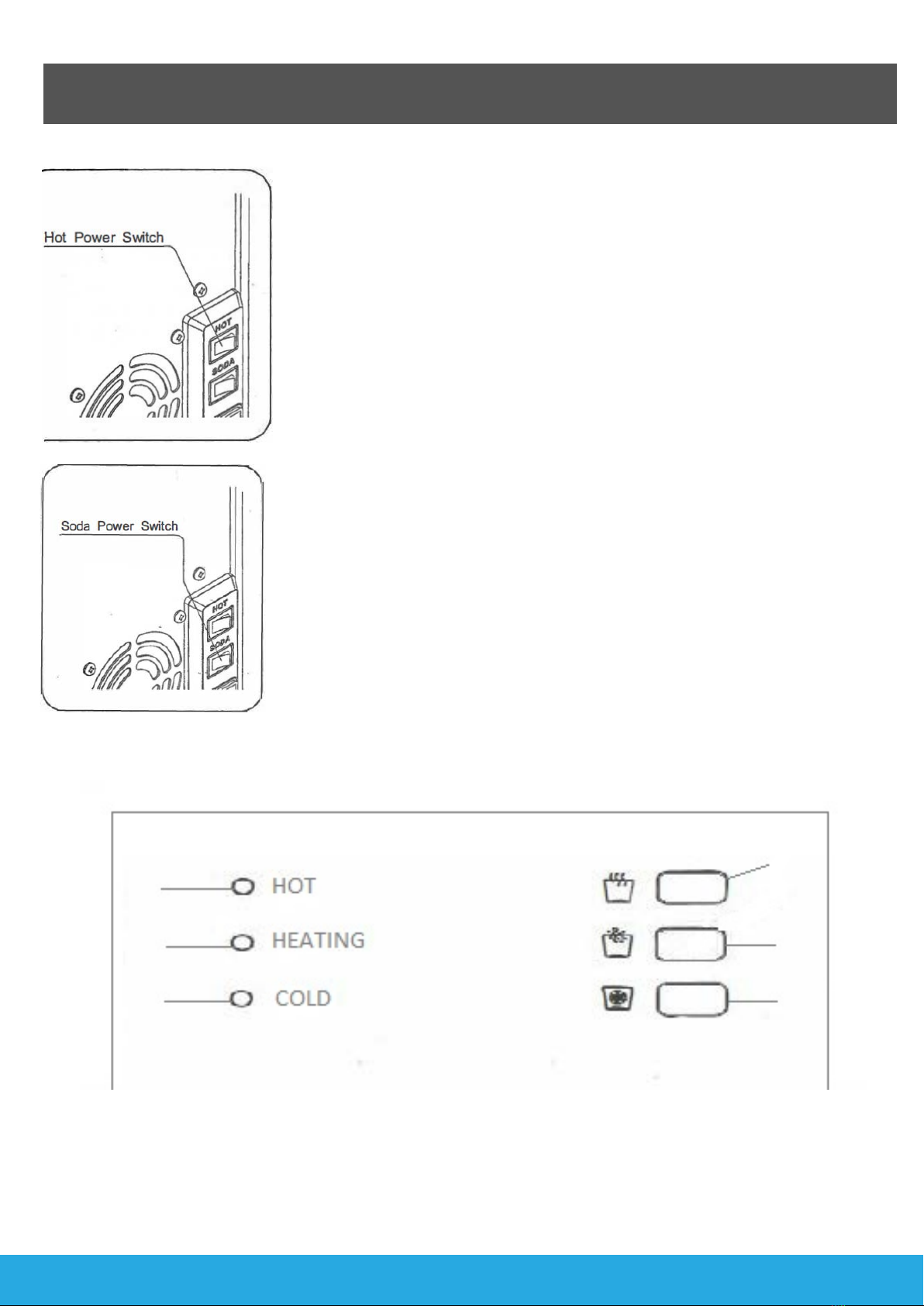

Water Operation Method

For security reasons the water will stop running after 1 minute. If you need more water

please re-push the water button

COLD OPERATION

Press the COLD button for Chilled water

Hot Water Button

Cold Water

Button

Cold Power Indicator

Heating system Indicator

Hot Power Indicator

HOT OPERATION

1. Turn on the Power supply

2. Push the HOT button on the machine and make sure

the water flows before you turn on the HOT switch at

the back of the unit (This will ensure the HOT tank is

full to prevent burning out the element

3. Once the HOT switch is on the LED light will

illuminate. It will turn off once the water is heated

4. Press the HOT button twice for HOT water (First to

unlock, second for water to flow)

SPARKLING OPERATION

1. After connecting the machine to the Co2 bottle turn

on the SODA switch at the rear of the unit

2. Press any button to fill the SODA Tank (Allow 40

minutes cooling time)

3. Press the SODA button for Sparkling Water

Sparkling Water

Button

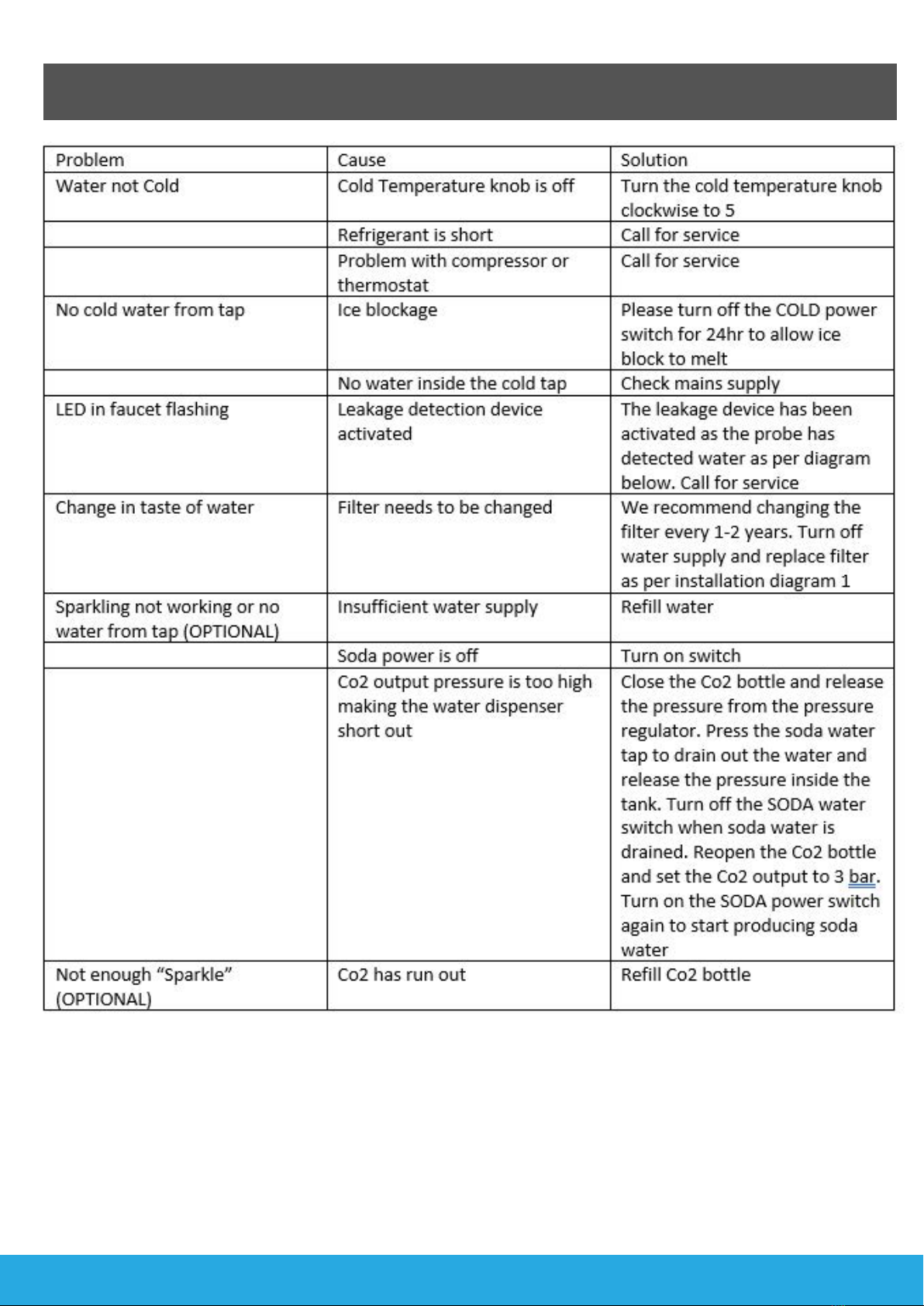

Trouble Shooting

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

This device has a leakage detection probe

fitted for safety purposes.

When the probe detects moisture you may

notice the LED on the machine flashing

accompianied by a beeping noise

We recommend turning off the electricity at

the power supply and calling a qualified

technician to carry out this work for your

safety.

Internal tubes and cables within the faucet

cannot handle completed rotation and will be

damaged if turned more than 180 degrees.

Swivel feature is intended to find correct

placement on the benchtop. Once placed,

the tap should be left alone to avoid damage

LEAKAGE DETECTION - DIAGRAM

TAP SWIVEL - WARNING

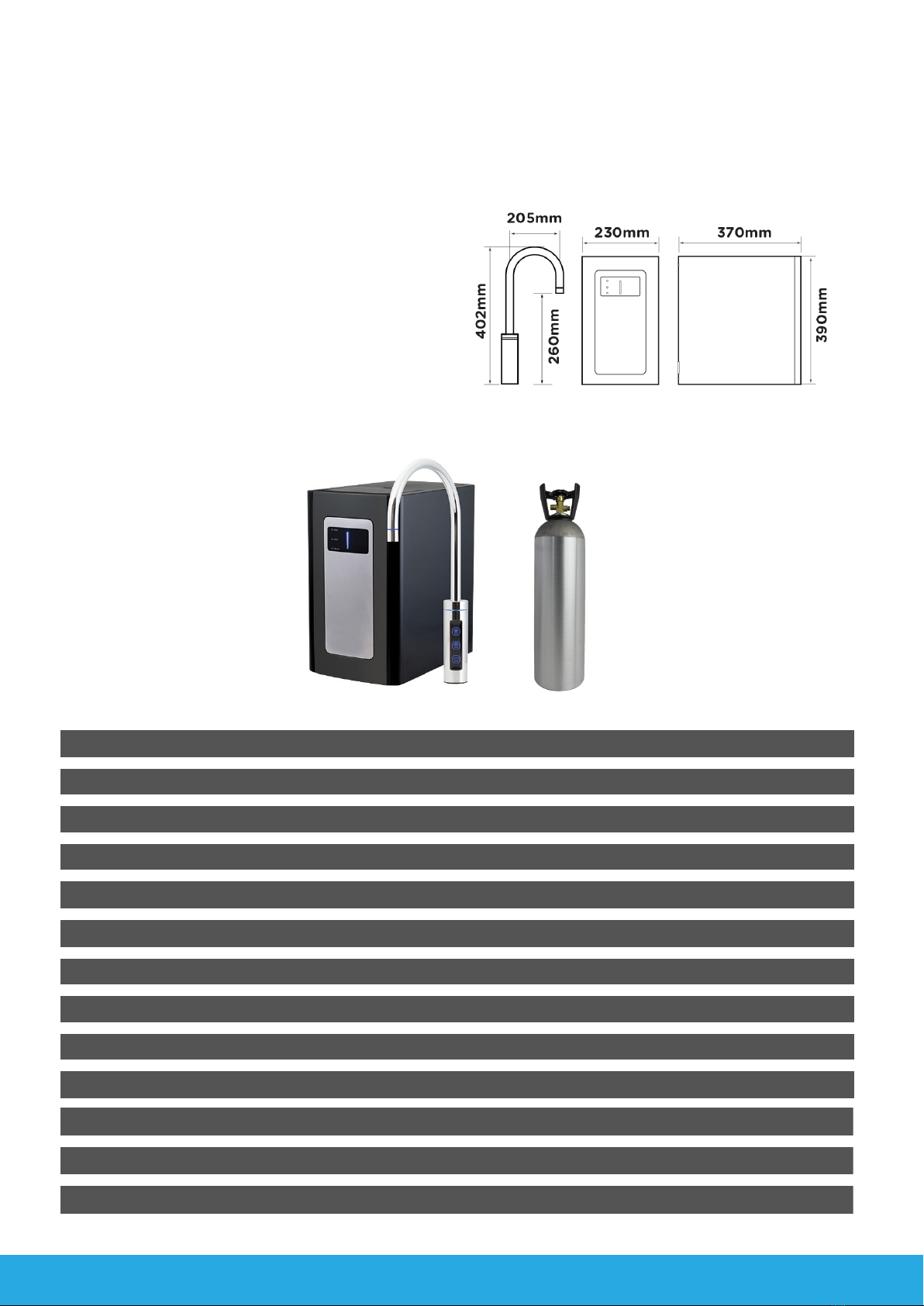

Spring NeoTap

INSTANT TAP

+ 6 4 0 9 6 3 6 - 7 0 7 0 | W W W . S P R I N G N Z . C O . N Z | S A L E S @ S P R I N G N Z . C O . N Z

Overview

Underbench filter with integrated

unit for boiling, chilled, sparkling and

ambient drinking water.

Sparkling, Boiling & Chilled, Boiling, Chilled & Ambient, Sparkling, Chilled & Ambient

Premium KDF/GAC 30, 1 Micron Filtration

4C to 10C

Model

Filtration

Cold Temperature

Chilling Capacity

Maximum Power consuption

Weight

Heating Capacity

20 Litres per hour

12 Litres per hour

Direct chill system 100W

18kg

Finish Chrome

Water connection

Power requirements

Max. recommended inlet pressure

Required hole for the tap

Ideal under sink dimension

1/2 inch

Standard 10amp power outlet (earth leakage protected

500 kPa

25mm

(w x d h) 750 x 660 x 520mm

PRODUCT DATA SHEET

Table of contents

Other Spring Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Philips

Philips HD3133 user manual

Hanseatic

Hanseatic HBCO7010PA1 user manual

Bosch

Bosch MUM 4420 UC owner's manual

Coopers of Stortford

Coopers of Stortford 10956 Instructions for use

montpellier

montpellier WS46SDX Installation and operating instructions

Lacor

Lacor 69246 Instructions for use and maintenance

John Lewis

John Lewis JLFSMC603 instruction manual

Sandra's Keukenmini's

Sandra's Keukenmini's Egg Cooker instruction manual

Rommelsbacher

Rommelsbacher DA 750 instruction manual

U-Line

U-Line Wine Captain UHWD524 User guide & service manual

WMF

WMF Pfanne ProfiResist Instructions for use and care

Bartscher

Bartscher 191004 instruction manual