SPS Polos SPIN150i infinite User manual

Polos

SPIN150i/200i

infinite

for software rev. 1.11

PolosSpin150i/200i

rev.: 1.0 Operating instruction

Welcome to the POLOS spin processing system!

The Polos is a top quality spin processor engineered for ease of use, low

maintenance, and long lifetime. Designed, Engineered, and Assembled in our state-

of-the-art facility in Germany, the Polos is constructed of high purity semiconductor

grade plastics to ensure the ultimate cleanliness. No metal components are in

contact with process chemicals, or fumes. This ensures the Polos can

accommodate a wide range of process chemicals, with no risk of metals

contamination, or system damage.

The aerodynamic design of the lid interior ensures "splash back-free" processing

and a direct drain path, while the smooth curved natural polypropylene surfaces of

the lid and process chamber directly assist the easy cleaning of the unit. The

touchscreen display are chemically resistant.

The system is built using industry-proven quality components ensuring precise

repeatable performance, a long lifetime, and zero maintenance. The Polos will

perform for you whether your needs are infrequent, with simple programs,

continuous processing, or frequent changes using complex programming steps.

Operation is intuitive; programming is simple, and up to 10000 separate programs

can be stored in the system memory. (each program can have up to 999 steps!)

This is a highly flexible system, and we offer a range of chucks, adapters, and other

options to support your future requirements.

Safety features include Secure lock of Lid Latch, Lid-Open and No-Vacuum

interlocks, Dynamic Braking and in-built programming safety interlocks.

Please take the time to read this manual to familiarize with the method of operation,

and the installation requirements of your Polos system.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 3

JH131115

Operation instruction

and safety information

Contents:

1. General information

2. Safety instruction

3. Specific safety instruction

4. Transportation and storage

5. Product description and facility requirement

6. Installation and commissioning

7. Operation instruction

8. Software instruction

9. Cleaning

10. Decommissioning, storage and disposal

11. Technical data

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 4

JH131115

1 General information

This documentation is an integral part of the Polos spin processor. The system

should not be activated or operated without this documentation.

Please read completely the manual carefully prior to installation, starting and

operation of the unit.

1.1 Safety instructions

All safety instructions will be found in section 2 of these manual and following

ones.

Prior to installation, starting-up and operation of the system relevant safety

instructions have to be read carefully and considered accordingly.

In addition to the operating instructions generally applicable legal regulations

and other provisions for the prevention of accidents and environmental

protection of the relevant country apply.

In the EU directive 89/391EWG, implemented in Germany in the Ordinance

on Industrial Safety and Health (BetrSichV), Technical Rules for

Operational Safety (TRBS 1203) and Workplaces Ordinance (ArbStättV),

the legislator demands amongst others that the working appliances are

subjected to regular and competent maintenance by trained staff and

checked for operability (effectiveness).

The piping system, especially joints, must be maintained and serviced.

Regular checks for leaks must be performed on all screwing connections

especially in case of temperature-controlled recirculation systems. A sight

inspection should be performed before the beginning of each shift.

If an exhaust module is required by chemical MSDS it has to be ensured

that the quantities of incoming and outgoing air are controlled before

commissioning, i.e. pressure differences in the working range must be

adapted.

1.2 Liability

The manufacturer will not take any liability of object, person and secondary

damage caused by improper use or ignoring of safety instructions as well as

caused by the owner’s manual due to missing updating after the system or its

software have been modified, nor will the manufacturer take any liability of

damages due to loss of data. In case of later modifications of the plant or user

software by the operator liability becomes inapplicable as well.

In addition, the terms of business that are part of the order/contract will apply.

Our products are continuously modified and improved due to innovation, legal

requirements and standards. As a consequence, the information given in this

documentation may not accurately reflect every detail of the system actually

delivered.

Please contact the manufacturer in cases of uncertainty.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 5

JH131115

The recipient may use these operating instructions as well as all additional

documents related to the system as intended only.

Products mentioned in this manual are eventually trademarks and are used for

identification purposes only.

1.3 Edition

PolosSpin150i/200i - Operating instruction

Revision: 1.0

19/08/2013

1.4 Warranty

We guarantee for the equipment as stated in the order/contract.

This warranty will expire in case of:

interference into or modification of the system without prior consent of the

manufacturer

improper use of the system

insufficient maintenance of the system

inappropriate operation of the system

negligence of correct supply requirements

application of third-part components

alteration of program or configuration without manufacturer’s consent

1.5 Service address

SPS-Europe B.V.

Midden Engweg 41

NL-3882 TS Putten

The Netherlands

Tel. (31) 341 360 590

Fax. (31) 341 360 589

e-mail: [email protected]

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 6

JH131115

2 Safety instruction

2.1 Intended use

The Polos is a process tool for typical spin process applications of wafers and other

substrates.

The range of applications depends on components and options installed, it includes

but it is not limited to:

Cleaning

Drying

Coating

Developing

Etching

Intended use includes:

adherence to entire instruction manuals

adherence to prescribed commissioning, operating and service instructions

adherence to prescribed inspection intervals

DANGER!

Chemicals

Customer has full responsibility and liability to assure that all wetted materials of the

system are resistant to the chemical(s) applied.

Please consult the technical data section for wet material list or contact SPS-

Europe B.V. in case of uncertainty.

DANGER!

Chemicals

Without proper protection the system is not suited for the application of explosive or

hazardous chemicals.

DANGER!

This Polos spin processor is not suited or designed for any other applications than

the ones stated above.

Any modification of the system requests manufacturer’s prior consent as well as his

confirmation in writing.

Note: Our products are continuously modified and improved due to innovation, legal

requirements and standards. As a consequence, the information given in this

documentation may not accurately reflect every detail of the system actually

delivered.

Please contact the SPS-Europe B.V. in cases of uncertainty.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 7

JH131115

2.2 Safety instruction: general

Prior to installation, starting and operation of the system relevant safety instruction

should be read carefully and considered accordingly.

This manual contains information and warnings to be followed by the user to ensure

safe operation and to maintain the system in secure condition. It should be located

in a suitable place close to the system.

In addition to this manual all valid, legal and other local regulations concerning

prevention of accidents as well as protection of the environment are applicable.

Please consider all instructions, in particular safety instructions, in order to achieve

safe operation of the system.

Possible hazards harming the user or resulting in damage to the system are clearly

stated within appropriate chapters of this manual.

Safety instructions plus important information are marked in the following way:

DANGER!

The word “Danger!“ combined with this or a more specific symbol indicates an

immediate hazard while using the system.

Neglecting of instructions given in this documentation or on the system itself can

result in personal injury or death of the operator or of persons being close by.

The system, other equipment or the environment can be seriously damaged as well.

WARNING!

The word “Warning!“ combined with this or a more specific symbol indicates an

impending hazard or fatal unsafe practice while using the system.

Neglecting of instructions given in this documentation or on the system itself can

result in severe personal injury of the operator or of persons being close by.

The system, other equipment or the environment can be damaged as well.

CAUTION!

The word „Caution!“ combined with this or a more specific symbol indicates a

possible hazard or unsafe practice while using the system.

Neglecting of instructions given in this documentation or on the system itself can

result in personal injury of the operator or of persons being close by.

The system, other equipment or the environment can be damaged as well.

Please consider all instructions, in particular safety instructions, in order to achieve

safe operation of the system.

Note: advice contained in this chapter is intended to supplement, not to supersede,

the safety advice given in other chapters of this manual, the instructions provided by

chemicals suppliers nor the general safety code of behavior prevailing in the user’s

country.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 8

JH131115

CAUTION!

Do not take actions on the system other than described in this manual.

CAUTION!

Do not operate the system while covers or other protective systems have been

removed.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 9

JH131115

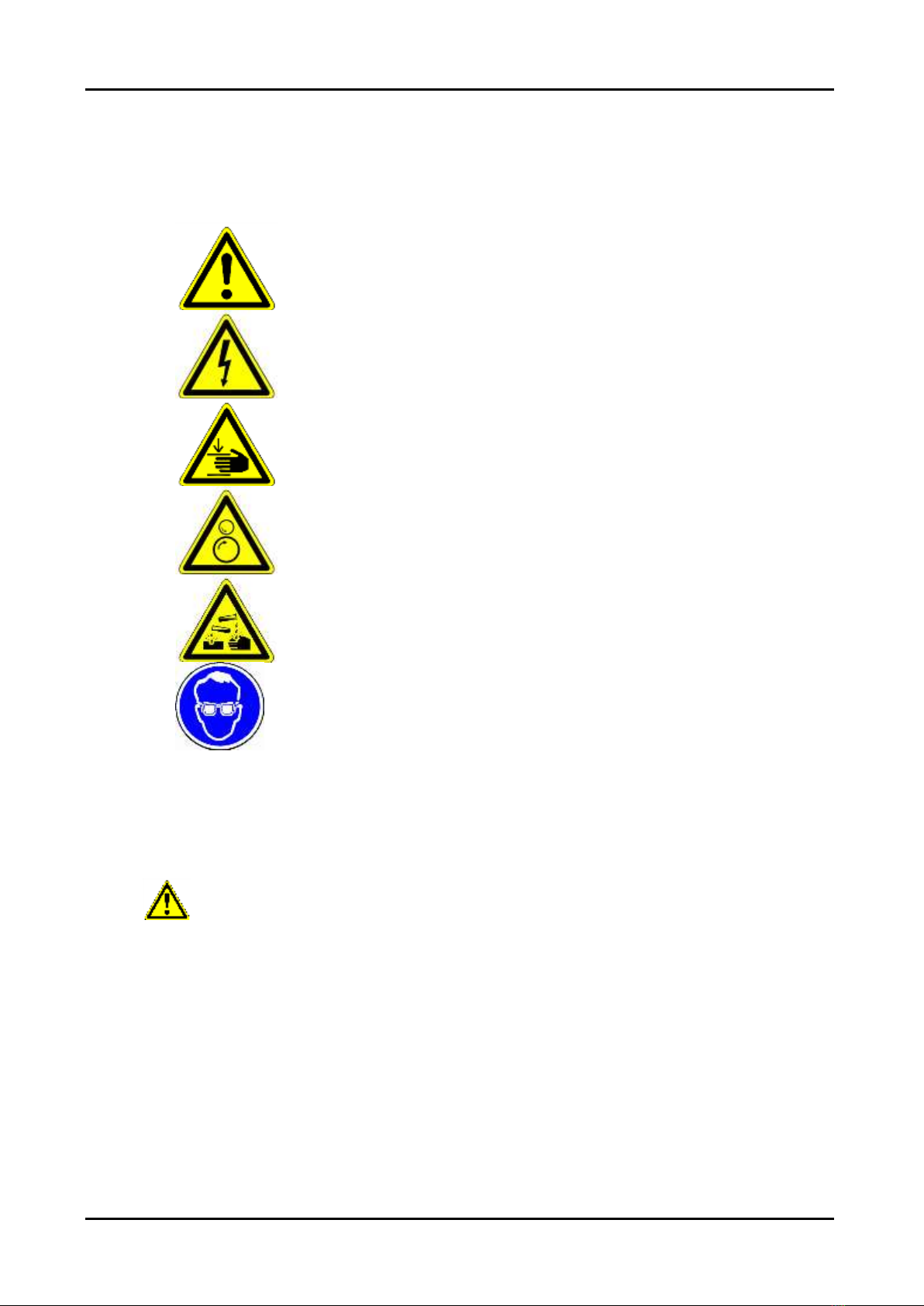

2.3 Symbols used on system

The following safety instructions (caution and command symbols) may be seen on

the system:

caution –risk of danger

caution –risk of electric shock

caution –risk of hand injury

caution –moving parts

caution –risk of corrosion

use eye protection

Note: The above symbols refer to SPS-Europe B.V. components and parts.

However, components and parts of sub suppliers may show other symbols, not

expressly mentioned or referred to in this manual.

DANGER!

The owner of the system is responsible to place adequate danger signals and labels

in suitable places.

This applies in particular to signals and labels concerning process chemicals used.

Irrespective of number of caution symbols and information placed on or around the

system all safety instructions of this manual have to be observed.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 10

JH131115

2.4 Personnel training

Persons charged with transport, storing, installation, starting, operation,

maintenance and service have to know the content of this manual.

Special training is required for personnel involved in system maintenance and

calibration.

Training can be provided by SPS-Europe B.V. on customer request.

Installation, service and repair work may only be executed by SPS-Europe B.V.

service personnel or persons qualified accordingly.

WARNING!

Customer has full responsibility and liability to provide comprehensive training

regarding unit usage and chemical safety to all employees involved on system

utilization.

2.5 Personnel obligations

WARNING!

All personnel involved in system utilization must be qualified accordingly relevant

task, knowing the perils and being able to prevent them by applying suitable safety

measures.

WARNING!

The equipment must not be operated, maintained or serviced by personnel under

effect of alcohol, drugs, medicine reducing attention.

2.6 Personal protection equipment

WARNING!

All operators involved in system must wear protective clothes adequate to

chemicals used including but not limited to:

Safety glasses/goggles and/or face shields

Chemical gloves

Protective suit with long sleeves

Chemical aprons

Closed-toe shoes

Long pants

WARNING!

Customer has full responsibility and liability to provide adequate training and

personal protection equipment to all employee involved on system utilization.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 11

JH131115

3 Specific safety instruction

3.1 System safety alarms

Depending on your system configuration one or more of following safety alarm

could be present on your system.

Interface indicators:

Unit interface provide indication, warning and alarm useful for safe utilization of the

unit.

In case of error a Warning symbol will appear on screen.

Clicking on this warning symbol, a log file will be prompted to provide detailed

information about the reason of the alarm.

CAUTION!

Above mentioned interface indicators must be observed before system start up as

well as during all process time.

WARNING!

Available indicators must be known by all personeel operating with the system.

3.2 Safety devices

Depending on your system configuration one or more of following safety device

could be present on your system:

Lid closure sensor

Lid lock sensor

Vacuum pressure sensor

Motor over-temperature sensor

External sensor(s)

Process will be interrupted in case of one or more safety device will trigger to alarm

state.

Description and location of safety devices indicated above are provided in relative

chapter of this manual.

Our products are continuously modified and improved due to innovation, legal

requirements and standards. As a consequence, the information given in this

documentation may not accurately reflect every detail of the system actually

delivered.

Note: please refer to appendixes, drawings and section technical data for

details or contact SPS-Europe B.V. in case of uncertainty.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 12

JH131115

3.3 Specific threads to the system

WARNING!

System may never work under condition different to ones indicated in relative

chapter of this manual

WARNING!

System may never be utilized, cleaned or maintained by untrained and

unauthorized personnel.

3.4 System hazards

General hazards:

This system has been designed and manufactured considering all relevant safety

regulations. Improper use or operation by persons not qualified accordingly may

result in danger:

to life and health of the operator

to the system itself

to surroundings of the user

to performance and efficiency of the system.

General hazards of the system, depending on design or type, may arise in the

following ways:

mechanical hazard caused by squeezing, shearing and cutting, catching

and winding, stitching or by freely moving parts

thrust caused by kinetic energy of moving mass

sharp corners and edges

electrical hazard caused by touching live parts (directly or indirectly)

thermal hazard causing burns

chemical hazard causing poisoning, corrosion and explosion

toxic hazard due to inhalation of vapors and gases

gases under pressure

liquids under pressure

combination of hazards caused by

ofaulty installation

oincorrect loading of substrates / wafers

oimproper usage of chuck

obreakdown of power or media supply

obreakdown and/or incorrect arrangement of preventive measures

ocombination of escaping media

hazards caused by

ohuman misconduct

onoise

oallergies, excitations of mucous membrane, unknown effects caused by

media

oejection of parts

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 13

JH131115

odisturbance / malfunction of control system

oleaking of hoses or pipes

ocombination of atmospheres or vapors

ofire hazard

onatural hazards caused by lightning, environmental catastrophes etc.

Mechanical hazards:

DANGER!

By applying components of other manufacturers additional and unknown hazards

may arise. No liability will be taken in this case.

Use only genuine parts provided by the manufacturer of the system.

Genuine parts are constructed conforming to applicable safety regulations.

DANGER!

Moving parts may cause squeezing or cutting of extremities.

Do not touch any moving parts of the system while in operation.

DANGER!

Spin speed is to be adjusted to substrate size, thickness, shape, weight and chuck

used.

Depending on substrate to be used the maximum spin speed of your system must

be limited. Please consult the system specific datasheet or contact manufacturer for

detailed spin speed recommendation.

DANGER!

Operation of the system by several persons may cause hazards based on

misconduct or missing mutual understanding.

In case that operation of the system by two or more persons would be required, is

recommended to keep a daily logbook containing usage note such as chemical

applied, error encounter, etc.

DANGER!

The system may only be operated while all doors and safety covers are closed and

locked (where applicable) and any protection systems are properly positioned.

Function of safety covers or doors has to be assured at any time.

In case of any safety deficiencies the system has to be switched off and the service

personnel has to be informed accordingly.

DANGER!

Safety covers or doors may not be removed (unless for service purposes).

The system may not be opened during processing or after power failures.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 14

JH131115

DANGER!

Contamination of the spin processor.

The spin processor has always to be operated with chuck and wafer/substrate.

In case of use of vacuum chuck (non etching application) always operate the

system with substrate loaded on chuck.

DANGER!

If required by processed chemical(s), the spin processor has always to be operated

with active exhaust system and providing all media required.

Whenever it is likely that the system is no longer mechanically safe, make it

inoperable and secure it against any unauthorized or unintentional operation.

Electrical hazards:

DANGER!

The system needs to be grounded in all cases. Do not remove or cut off any ground

wire of power supply or inside the system. Insufficient grounding can cause

additional electrostatic charging of plastic parts, hoses or pipes, and the system as

a whole.

DANGER!

This system operates under high voltages. Danger of high voltages exists even

when the system is switched off, but still connected to the power supply.

Capacitors within the system may be charged even in case the system is switched

off and disconnected from mains supply line.

DANGER!

While switched on, electrical connectors will be live. Opening of covers or removing

of parts may result in exposure to live parts.

DANGER!

Interchange of current-bearing wires may result in danger for health and life of

operator. Connection to the mains supply has to be effected by a qualified

electrician according to prevailing regulations. Neutral wire (blue) and ground wire

(green/yellow) have to be connected in due form.

DANGER!

Persons bearing a pacemaker may not operate, clean or service the unit.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 15

JH131115

DANGER!

In case of emergency the stop button must be approachable immediately.

Do not position any object between operator and emergency button.

DANGER!

Due to electrical charging plastic components or wiring, solvents and process

chemicals could be ignited. Therefore, the system and its components have to be

grounded.

Note: in case of insufficient grounding or of damaged ground conductor make sure

that the system will be inoperable and secure it against unauthorized or

unintentional operation.

DANGER!

In case fuses have to be replaced make sure that only fuses of same type and

current rating will be used.

Under no circumstances use makeshift fuses or short-circuit any fuse holders.

CAUTION!

Electrostatic discharges can cause damage to parts. When handling electronic

components several precautions are essential:

Wear a grounded wrist strap or work on a grounded static-dissipating work surface.

Leave electronic components and printed circuit boards in their original packaging

until final installation.

Handle electronic components by their body or case, avoid touching of leads.

Keep electronic components and printed circuit boards away from such static

generating materials as vinyl, plastic bags, etc.

Whenever it is likely that the system is no longer electrically safe, make it

inoperable and secure it against any unauthorized or unintentional operation.

Chemicals hazards:

Chemicals are provided and applied by the user. Proper handling of chemicals is

the user’s responsibility.

Advice contained in this section is intended to supplement, not to supersede, the

safety instructions provided by chemicals suppliers nor the general safety code of

behavior prevailing in the user’s country.

DANGER!

Chemicals

Customer has full responsibility and liability to assure that all wetted materials of the

system are resistant to the chemical(s) applied.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 16

JH131115

DANGER!

It is the user’s responsibility to mark all containers and supply lines of chemicals

(i.e. containers of media and waste) with appropriate labels and warning signs.

DANGER!

Chemicals may only be handled by personnel having the relevant knowledge and

skill.

DANGER!

When handling chemicals, please observe relevant safety regulations as well as

chemical supplier’s information (chemical safety data sheet and additional advice).

WARNING!

All operators involved in system must wear protective clothes adequate to

chemicals used including but not limited to:

Safety glasses/goggles and/or face shields

Chemical gloves

Protective suit with long sleeves

Chemical aprons

Closed-toe shoes

Long pants

DANGER!

When handling aggressive chemicals, insure proper ventilation and exhaustion of

vapors.

The Polos spin processor is designed to cooperate with facilities supplied house

exhaust which needs to be always present

Always ensure that exhaust is present working correctly before opening the system.

WARNING!

As to the outgoing air the local emission acts have to be taken into consideration

DANGER!

When handling chemicals, please observe that released chemicals may react with

each another, leading to unwanted and unknown substances. These substances

may bear major additional risks.

DANGER!

Solvents!

Inflammable, explosive, toxic

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 17

JH131115

Do not inhale its vapors (danger of suffocation and/or poisoning).

Prevent electrostatic loading.

Keep away from ignition sources.

Do not smoke.

Do not eat (danger of poisoning).

Do not touch.

DANGER!

Process chemicals !

Inflammable, explosive, toxic

Do not inhale its vapors (danger of suffocation and/or poisoning).

Prevent electrostatic loading.

Beware of ignition sources.

Do not smoke.

Do not eat (danger of poisoning).

Do not touch.

DANGER!

Corrosives

Inflammable, explosive, toxic

Do not inhale its vapors (danger of suffocation and/or poisoning).

Prevent electrostatic charging.

Beware of ignition sources.

Do not smoke.

Do not eat (danger of poisoning).

Avoid contact to eyes.

Do not touch.

DANGER!

Gases

Inflammable, explosive, toxic

Do not inhale (danger of suffocation and/or poisoning).

Prevent electrostatic charging.

Beware of ignition sources.

Do not smoke.

DANGER!

In case corrosive, gassing or noxious wet media are applied it’s at the user’s

responsibility to prevent any peril to close by staff by all means.

Whenever it is likely that the system is no longer chemically safe, make it

inoperable and secure it against any unauthorized or unintentional operation.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 18

JH131115

3.5 System restore after emergencies

DANGER!

Reactivating of the system after an emergency stop may only be done by qualified

persons. Prior to restarting, the system has to be checked for eventual hazards.

Prior to checking of risk area operate the main switch and disconnect the system

from mains power line and media supply except exhaust.

Wait until all hot parts have reached ambient temperature.

DANGER!

In case of emergency while handling chemicals, please call immediately for a safety

expert or for a physician and act according to instructions of the data sheet of the

applied process chemical.

DANGER!

Disconnect all wires of power supply prior to opening of the system. In case work

has to be done while the system remains open (for adjustments, maintenance etc.)

it should only be done by qualified personnel, knowing all potentially dangerous

points and being able to prevent hazards by taking appropriate precautions.

Whenever it is likely that the system is no longer safe, make it inoperable and

secure it against any unauthorized or unintentional operation.

The system is likely to be unsafe if:

any damage is visible

it fails to perform according to specification

it has been subject to prolonged storage under unfavorable conditions

it has been subject to severe transport stress.

In these cases the safety state of the machine has to be checked by SPS-

Europe B.V. service personnel.

Maintenance and repair work required, but not listed in this manual, should only be

done by SPS-Europe B.V. service or by persons of equivalent qualification.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 19

JH131115

3.6 First aid in emergency

In case of an emergency (accident with material or personal damage), please

observe the following instructions:

DANGER!

In case of emergency immediately stop the actual process and await complete

stand-still of the system within a safe distance.

DANGER!

Close all supply line (VAC, CDA, N2, DI Water, etc…) except exhaust system if

available.

DANGER!

In case of emergency while handling chemicals, please call immediately for a safety

expert or for a physician and act according to instructions of the data sheet of the

applied process chemical provided by chemical producer.

PolosSpin150i/200i

rev.: 1.0 Operating instruction

SPS-Europe B.V. page 20

JH131115

4 Transportation and storage

4.1 Safety indication

DANGER!

Prior to operate with the unit, the installation and operating instructions have to be

thoroughly read and observed.

CAUTION!

Heavy weights

Parts included could be heavy and have to be handled properly.

4.2 Transportation

DANGER!

An overturning unit may cause serious injuries.

During transport tipping forces of the unit including its packaging have to be

considered.

CAUTION!

Before moving the Polos attention has to be paid that the unit is adapted to ambient

temperature. Due to alteration to temperature during transport unwanted length

modification may occur.

Keep the system for at least 24 hours under approved operating condition to make

the unit adapting to ambient temperature.

4.3 Storage

The system can be stored safely under following conditions:

without any liquids (process chemicals etc.)

ambient temperature - 10°C to + 60°C

ambient relative humidity max. 80%, no condensation

dust-free and protected (eventually packed up)

When removing from storage, prior to installation, keep the system for at least 24

hours under approved operating conditions.

System start up have to be performed by SPS-Europe B.V. service personnel or

persons qualified accordingly.

This manual suits for next models

1

Table of contents

Other SPS Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

InnovaPrep

InnovaPrep CP Select user guide

InfiRay

InfiRay MH25 user manual

Fluigent

Fluigent FLPG Plus user manual

VWR

VWR INCU-Line IL 23R Cool instruction manual

ThermoFisher Scientific

ThermoFisher Scientific QuantStudio 6 Pro user guide

Oroboros Instruments

Oroboros Instruments O2k-FluoRespirometer manual

Roth

Roth BA-UAK-ASME-EN Operating instruction

Varian

Varian Micro-GC 490-GC user manual

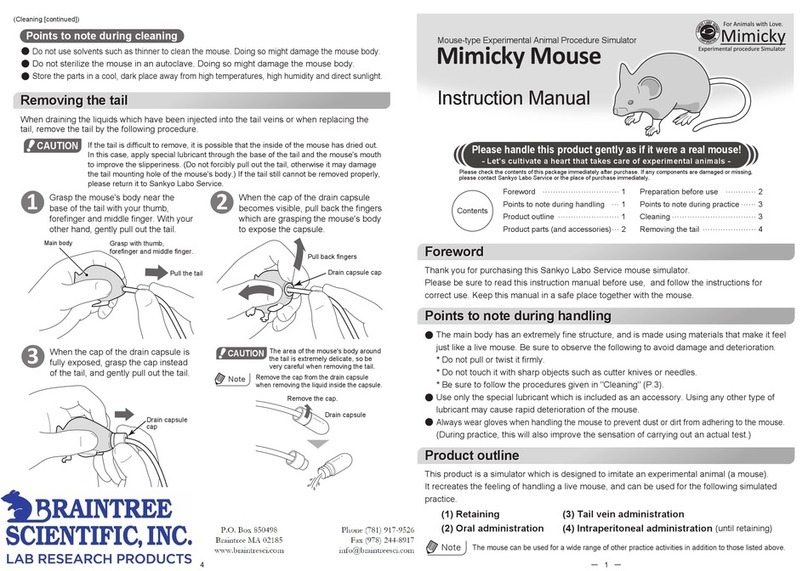

Braintree Scientific

Braintree Scientific Mimicky Mouse instruction manual

Agilent Technologies

Agilent Technologies 5975T LTM GC/MSD Troubleshooting and maintenance guide

NanoEnTek

NanoEnTek ADAM-SCC2 instruction manual

Meler

Meler MICRON+ TPD instruction manual