Copyright 2018, InnovaPrep LLC Patented https://www.innovaprep.com/patents

Table of Contents

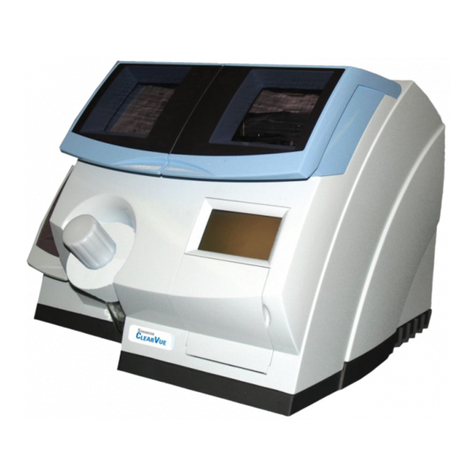

1 PRODUCT OVERVIEW .............................................................................................................................................................. 4

1.1 PRODUCT DESCRIPTION ................................................................................................................................................................. 4

1.2 APPLICATIONS .............................................................................................................................................................................. 4

1.3 DEVICE SPECIFICATIONS ................................................................................................................................................................. 4

1.4 ACCESSORIES INCLUDED WITH THE CP SELECT .................................................................................................................................... 5

2 CONCENTRATING PIPETTE METHOD OF OPERATION ............................................................................................................... 7

2.1 CONCENTRATION PROCESS ............................................................................................................................................................ 7

2.2 WET FOAM ELUTION ..................................................................................................................................................................... 8

2.3 FOAM GENERATION ...................................................................................................................................................................... 8

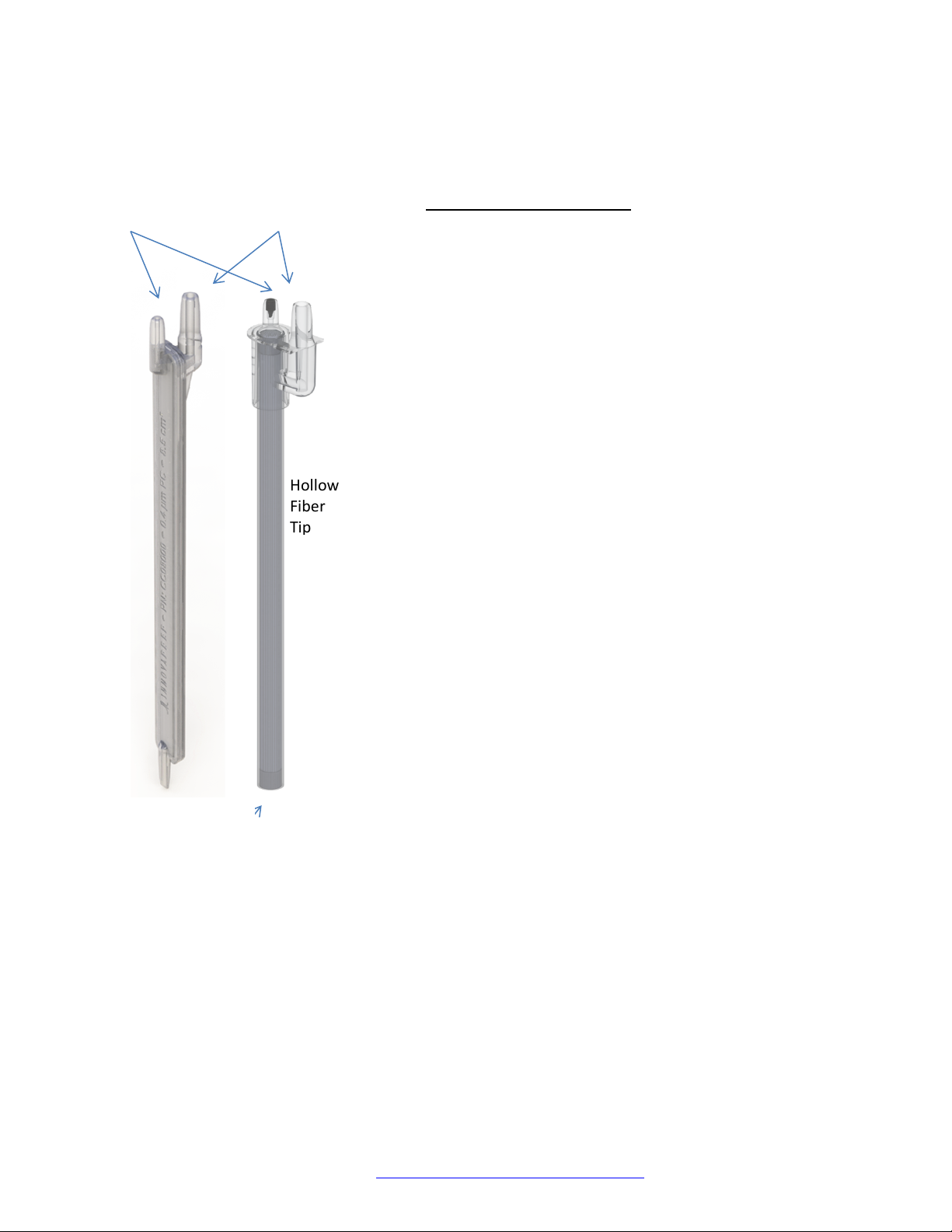

2.4 CP FILTER TIPS ............................................................................................................................................................................. 8

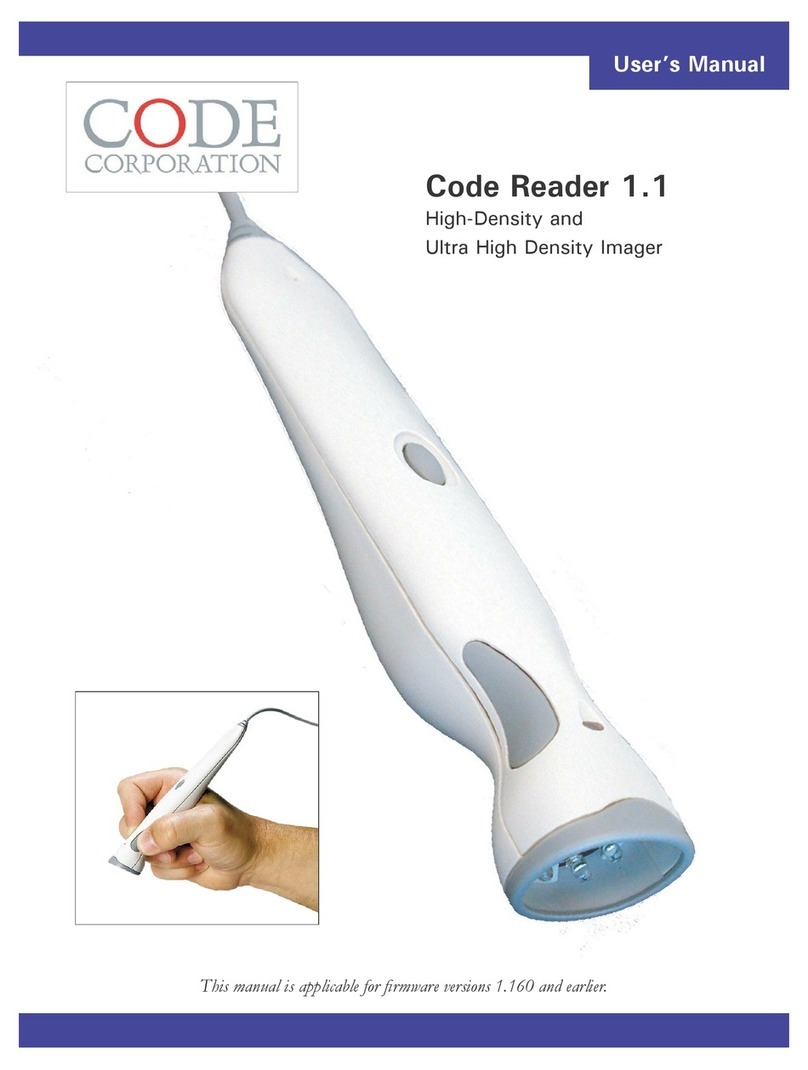

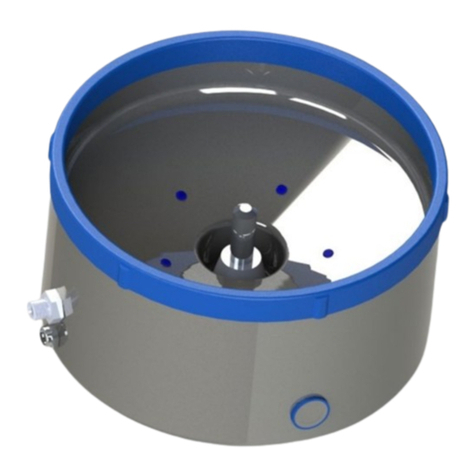

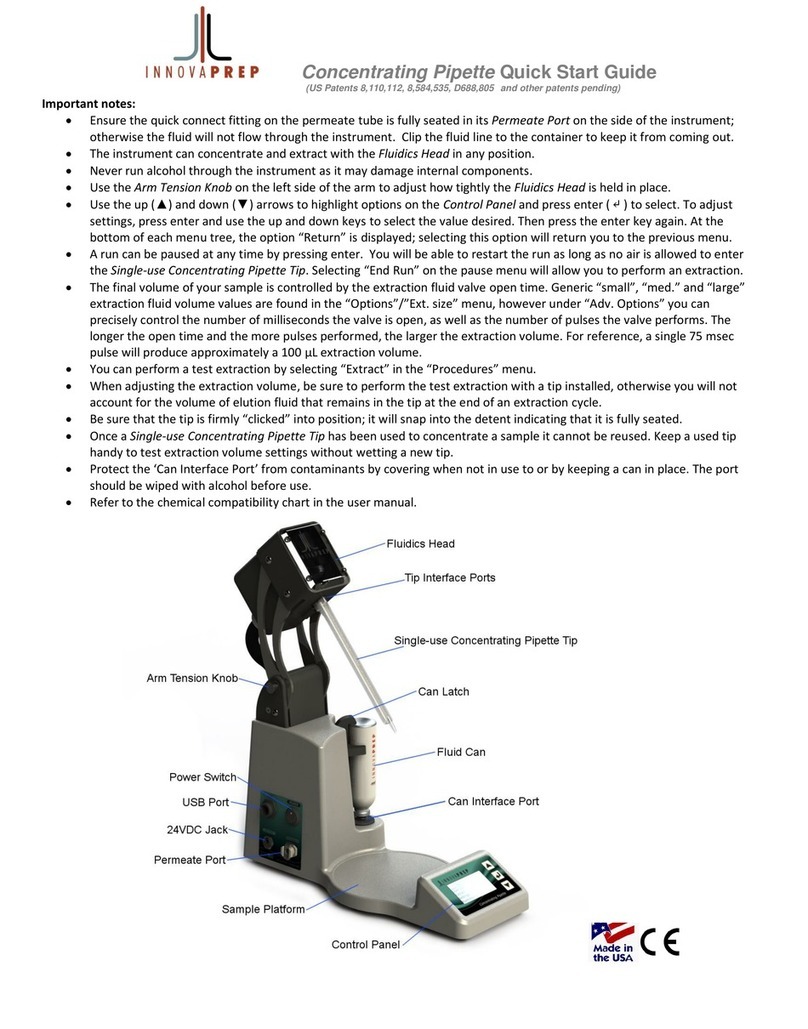

3 COMPONENTS OF THE CONCENTRATING PIPETTE ................................................................................................................. 10

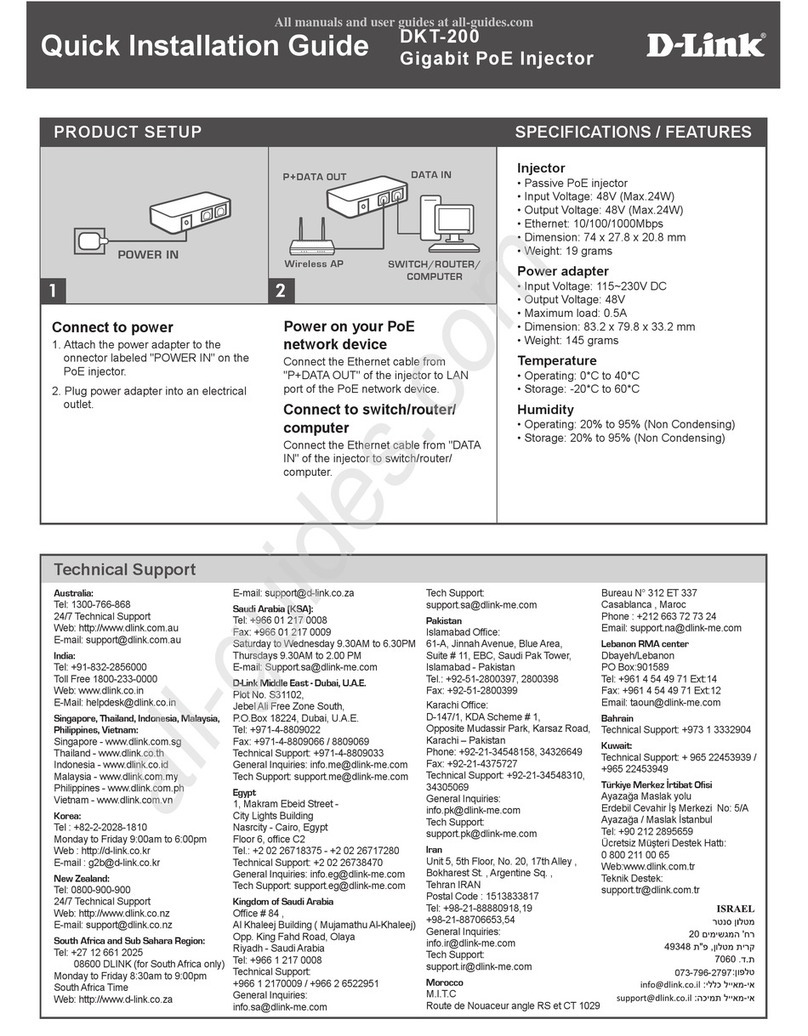

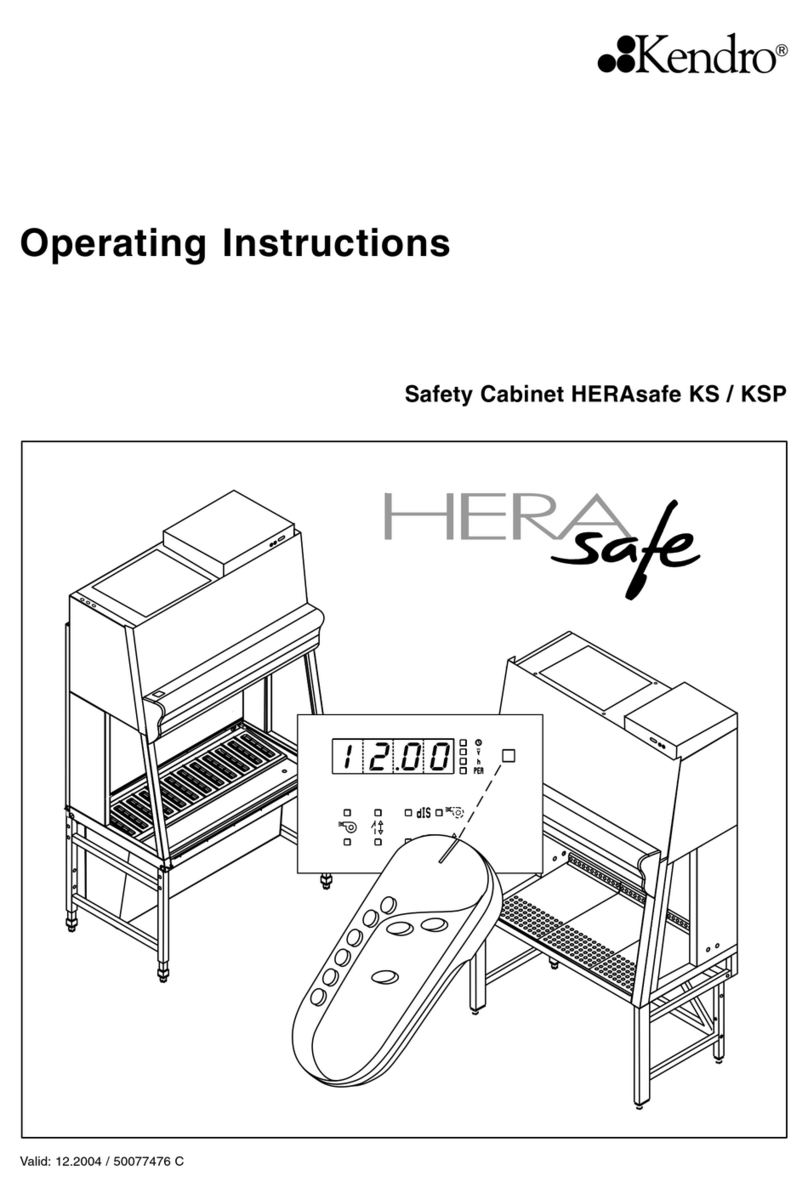

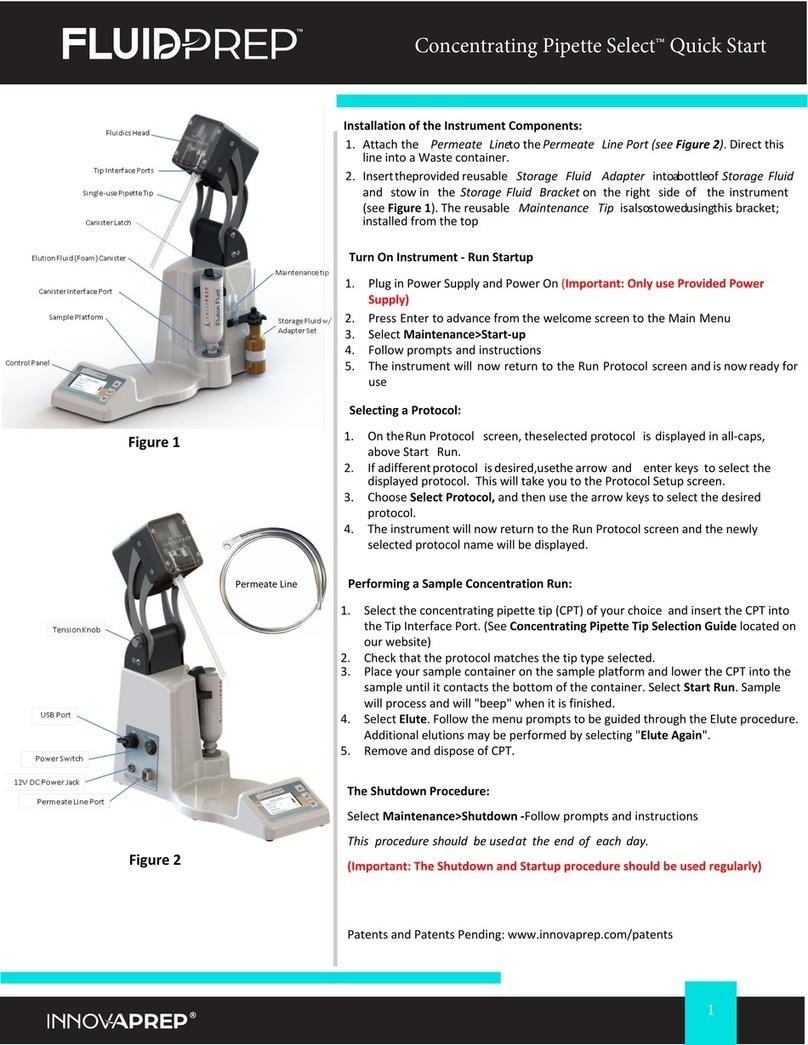

4 INSTALLATION OF THE INSTRUMENT COMPONENTS ............................................................................................................. 13

4.1 INSTALLING THE POWER SUPPLY .................................................................................................................................................... 13

4.2 INSTALLING AND REMOVING THE PERMEATE LINE TUBING .................................................................................................................. 13

4.3 INSTALLING THE STORAGE FLUID AND FLUID ADAPTER ....................................................................................................................... 13

4.4 INSTALLING AND REMOVING AN ELUTION FLUID CANISTER ................................................................................................................. 14

4.5 INSTALLING AND REMOVING CONCENTRATING PIPETTE TIPS ............................................................................................................... 15

5 NAVIGATING THE MENU ....................................................................................................................................................... 16

5.1 THE MAIN MENU ....................................................................................................................................................................... 16

5.2 THE RUN PROTOCOL MENU ......................................................................................................................................................... 16

5.3 THE MAINTENANCE MENU ........................................................................................................................................................... 17

5.4 THE INSTRUMENT SETTINGS MENU ................................................................................................................................................ 17

6 MAINTENANCE PROCEDURES ............................................................................................................................................... 18

6.1 STARTING UP THE INSTRUMENT FOR THE FIRST TIME ........................................................................................................................... 18

6.2 THE START UP PROCEDURE .......................................................................................................................................................... 19

6.3 THE SHUT DOWN PROCEDURE ...................................................................................................................................................... 19

6.4 PRIMING THE ELUTION FLUID ........................................................................................................................................................ 20

6.5 PREPARING THE INSTRUMENT FOR TRANSPORT OR SHIPMENT ............................................................................................................. 20

6.6 RECOMMENDED GENERAL MAINTENANCE FOR CP SELECT .................................................................................................................. 22

7 PERFORMING A SAMPLE CONCENTRATION RUN ................................................................................................................... 23

7.1 CONTROLLED COLLECTION OF PERMEATE ........................................................................................................................................ 23

8 CONCENTRATION RUN PROTOCOLS ...................................................................................................................................... 25

8.1 STD. OPTIONS ............................................................................................................................................................................ 25

8.2 ADV. OPTIONS ........................................................................................................................................................................... 25

8.3 DEFAULT CONCENTRATION RUN PROTOCOLS ................................................................................................................................... 26

8.4 SELECTING A PROTOCOL ............................................................................................................................................................... 27

8.5 CREATING A CUSTOM PROTOCOL ................................................................................................................................................... 27

8.6 EDITING A CUSTOM PROTOCOL ..................................................................................................................................................... 28

8.7 DELETING A PROTOCOL ................................................................................................................................................................ 28

8.8 PASSWORD PROTECTION .............................................................................................................................................................. 28

8.9 CONCENTRATING PIPETTE OPERATION CHECK LIST ............................................................................................................................ 29