SPX FLOW Power Team HS2000 User manual

SPX Hydraulic Technologies

5885 11th Street

Rockford, IL 61109-3699 USA

Tech Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

powerteam.com

Operating Instructions for:

HS2000

HS3000

1

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

Hydraulic Spreader

Max. Pressure: 690 bar (10,000 psi)

Unit Weight: HS2000 = 2.17 kg (4.8 lb)

HS3000 = 9.98 Kg (22 lb)

2

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

Table of Contents

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Symbols and Denitions............................................4

Safety Precautions .....................................................4

Initial Setup ...........................................................6

Operating Instructions ...................................................7

Performance Specications...............................................7

General Maintenance ...................................................8

Troubleshooting Guide ..................................................9

Power Team Facilities & Contacts .........................................11

Declaration of Conformity ...............................................12

3

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

Description

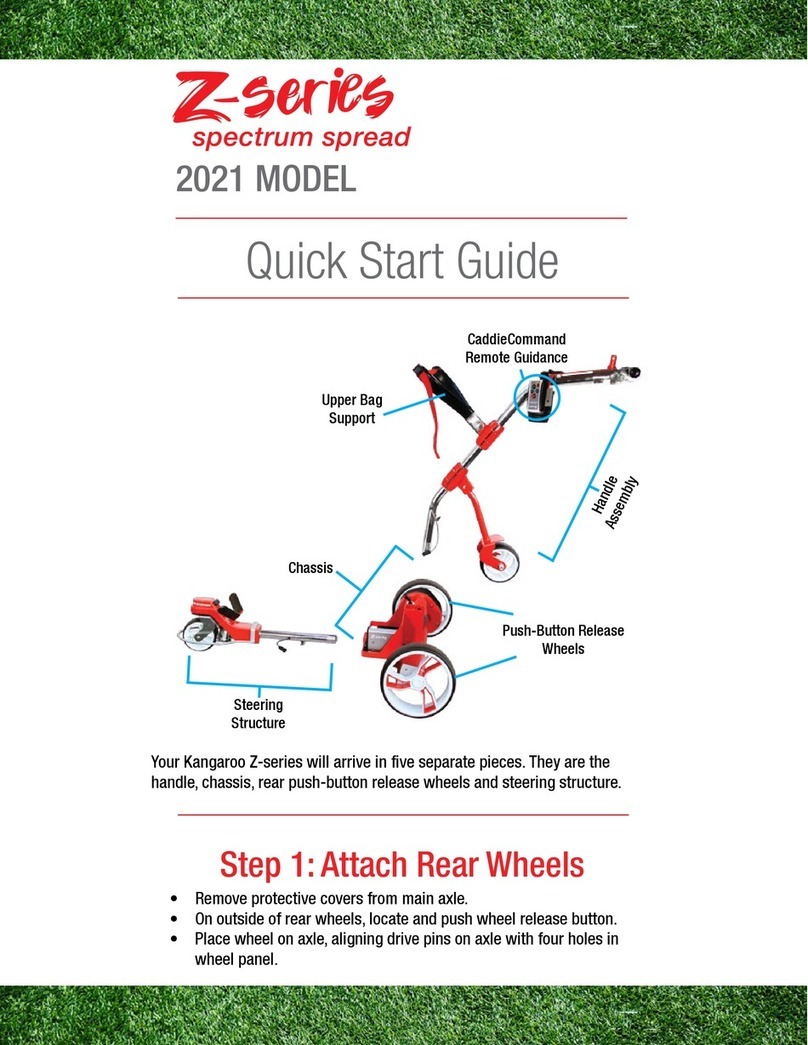

Figure 1. HS2000 Figure 2. HS3000

HS2000 Hydraulic Spreader

See Figure 1. HS2000 Hydraulic Spreader is well

suited for lifting, clamping, or spreading tasks.

HS3000 Hydraulic Spreader

See Figure 2. HS3000 Hydraulic Spreader is well

suited for lifting, clamping, or spreading tasks.

Hydraulic spreaders (HS2000 and HS3000) have been developed to separate heavy

materials or rebar and straightening tasks alike. The HS2000 has a 19 cm (4 in.) jaw

spread and rated at 690 bar (10,000 psi). The HS3000 has a 29 cm (11.5 in.) spread

and also has 690 bar (10,000 psi) rating.

NOTE:

• For a detailed parts list or to locate a Power Team Authorized Hydraulic Service Center, contact

your nearest Power Team facility. A list of all Power Team facilities is located at the end of this

document.

• Carefully inspect the tool upon arrival. The carrier, not the manufacturer, is responsibile for any

damage resulting from shipment.

4

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

The safety signal word designates the degree or level of hazard seriousness.

: Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

IMPORTANT: Important is used when action or lack of action can cause equipment failure, either

immediate or over a long period of time.

Safety Symbols and Denitions

• The following procedures must be performed by qualied, trained personnel who

are familiar with this equipment. Operators must read and understand all safety

precautions and operating instructions included with the device. If the operator

cannot read these instructions, operating instructions and safety precautions must

be read and discussed in the operator's native language.

• These products are designed for general use in normal environments. These

products are not designed for use in special work environments such as: explosive,

ammable, or corrosive. Only the user can decide the suitability of this product in

these conditions or extreme environments. Power Team will supply information

necessary to help make these decisions. Consult your nearest Power Team facility.

• Safety glasses must be worn at all time by the operator and anyone within sight of

the unit. Additional personal protection equipment may include: face shield, goggles,

gloves, apron, hard hat, safety shoes, and hearing protection.

• The owner of this tool must verify that safety-related decals are installed, maintained,

and replaced if they become hard to read.

• Shut OFF the motor before opening any connections in the system.

• The guide cannot cover every hazard or situation so always do the job with SAFETY

FIRST.

• When extending a spreader under load, always insure that the coupler(s) or

port thread(s) have not been damaged or do not come in contact with any rigid

obstruction. If this condition does occur, the coupler’s attaching threads may

become stripped or pulled from the spreader resulting in instant release of high

pressure hydraulic uid, ying objects, and loss of the load. All of these conditions

could cause serious injury or death. Never use a spreader with bent or damaged

couplers or damaged port threads.

• Always support the base against a rigid, at surface at least 75% as large as the

hydraulic spreader base for stability.

Safety Precautions

WARNING

WARNING

5

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

• Avoid o-center loads which could damage the hydraulic spreader and/or cause loss

of the load, possibly causing serious injury or death.

• Control the load at all times. Do not drop the load.

• The user must be a qualied operator familiar with the correct operation,

maintenance, and use of the spreader. Lack of knowledge in any of these areas can

lead to personal injury.

• Wear safety glasses at all times.

• Read and understand all safety and warning decals and instructions.

• Use only approved hydraulic uid. Hoses, seals and all components used in a

system must be compatible with the hydraulic uid used.

• Do not exceed the rated capacities of the spreader. Excess pressure can result in

personal injury.

• Inspect each spreader and coupler before each shift or usage to prevent unsafe

conditions from developing. Do not use cylinders if they are damaged, altered or in

poor condition. Never use extreme heat to disassemble a hydraulic spreader. Metal

fatigue and/or seal damage will result and can lead to unsafe operating conditions.

Safety Precautions continued

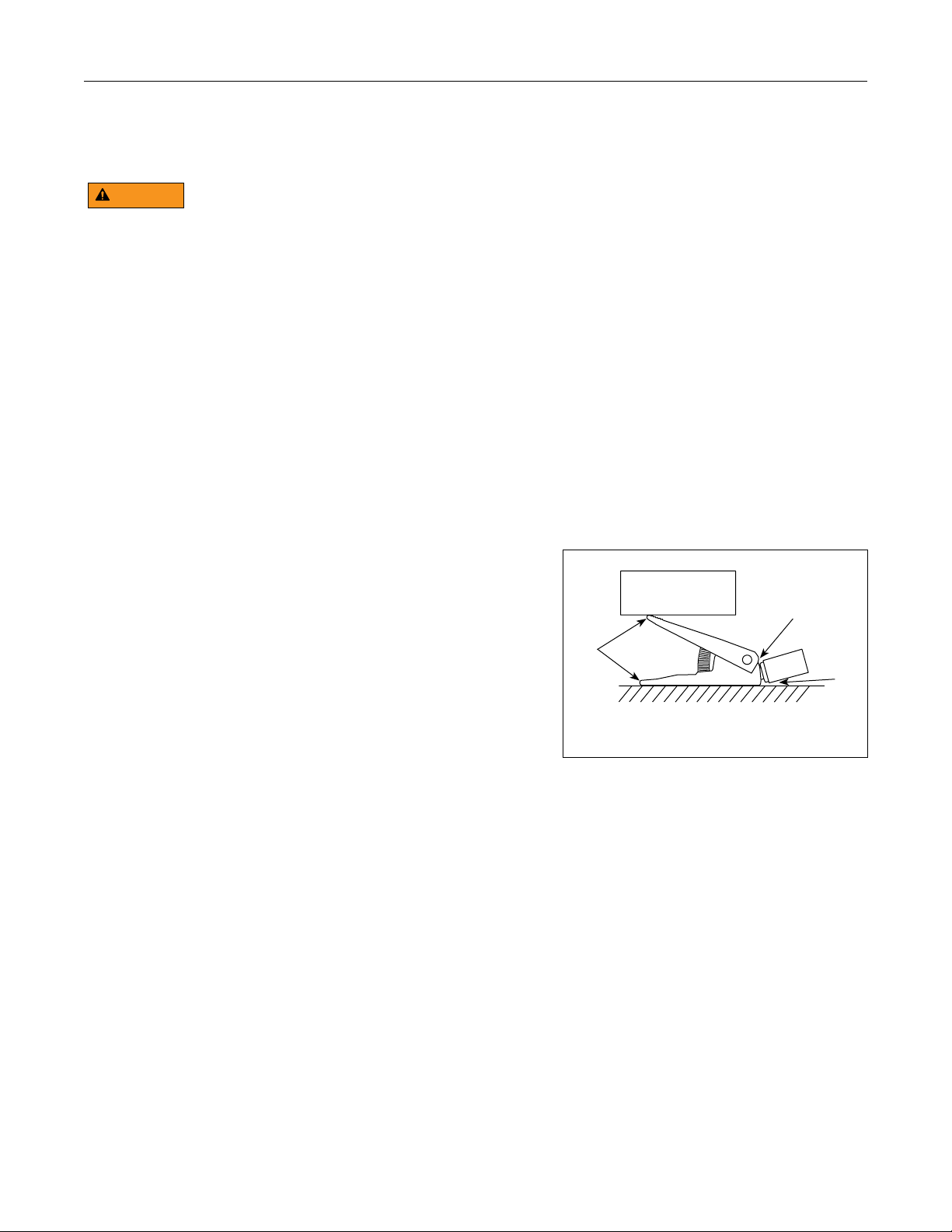

• Avoid pinch points or crush points that can be

created by the load or parts of the spreader.

• To help prevent material fatigue if the spreader

is to be used in a continuous application,

the load should not exceed 85% of the rated

capacity or stroke. Hydraulic spreaders should

not be continuously operated to the stops

without a load.

• A spreader must be on a stable base which

is able to support the load while pushing or

lifting.

• To help prevent personal injury, use shims, friction material or constraints to prevent

slippage of the base or load.

• Do not set poorly-balanced or o-center loads on a spreader. The load can tip or the

spreader can "kick- out" and cause personal injury.

• If this component is used to lift, lower, or separate loads, be certain that the load is

under operator control at all times and that others are clear of the load. Do not drop

the load.

• As the load is lifted, use blocking or cribbing to guard against a falling load or a load

that will come together after being spread apart. All personnel must be clear of the

load before lowering.

LOAD

* = PINCH POINTS

*

*

*

WARNING

6

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

Initial Setup

1. Remove all packing materials from the assembled unit.

2. Inspect the unit upon arrival. The carrier, not the manufacturer, is responsible for any

damage resulting from shipment.

IMPORTANT:

• Keep the spreader clean at all times.

• While at a job site, when the spreader is not in use, keep the piston rod fully

retracted and upside down.

• Use an approved, high-grade pipe thread sealant to seal all hydraulic connections.

Teon tape can be used if only one layer of tape is used and it is applied carefully

(two threads back) to prevent the tape from being pinched by the coupler and broken

o inside the pipe end. Any loose pieces of tape could travel through the system and

obstruct the ow of uid or cause jamming of precision-t parts.

• Use only Power Team hydraulic uid. Never use brake or transmission uids.

• Always use protective covers on disconnected quick couplers.

• Limiting the stroke will prolong spring life of this tool.

• Limiting the stroke and pressure on spreaders will also prolong their life.

Introduction

These instructions are written to help you, the user, more eectively use and maintain your hydraulic

spreader. If any questions, please call your nearest Power Team facility (see listing).

NOTE: For a detailed parts list or to locate a Power Team Authorized Hydraulic Service Center,

contact your nearest Power Team facility. A list of all Power Team facilities is located at the end of this

document.

Some of the information included in these instructions was selected from A.N.S.I. B30.1 and applies

to the construction, installation, operation, inspection and maintenance of hydraulic spreaders. It is

strongly recommended that you read A.N.S.I. B30.1 to answer any questions not covered in these

instructions. The complete A.N.S.I. B30.1 standard which contains additional information can be

obtained at a nominal cost from the American Society of Mechanical Engineers, United Engineering

Center, 345 East 47th, New York, New York 10017.

An inspection checklist (Form No. 105503) is available on request from your nearest Power Team

facility.

System Evaluation

The hydraulic spreader, hoses, couplings and pump all must be rated for the maximum operating

pressure of 690 bar (10,000 psi), correctly connected and compatible with the hydraulic uid used. An

unmatched system can cause the system to fail and serious injury. Please contact your nearest Power

Team facility with any technical questions or clarications as required.

7

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

Operating Instructions

Performance Specications

Inspection

Before each use, visually inspect for the following items:

• Cracked or damaged spreader

• Excessive wear, bending, damage, or insucient thread engagement

• Leaking hydraulic uid

• Scored or damaged piston rod

• Loose bolts, pins, or ttings

• Modied, welded, or altered equipment

• Bent or damaged couplers or port threads

Note: If any of the above conditions are present, do not use the tool.

Preventive Maintenance (yearly or sooner, if the spreader condition suggests damage)

Visual examination by the operator or other designated personnel with a dated and signed

equipment record.

Operation

Do not exceed the maximum lift and stroke of the tool.

HS2000 HS3000

Maximum Rated Capacity 907 kg (1 ton) 1360 kg (1.5 ton)

Maximum Spread Capacity 10 cm (4 in.) 29.2 cm (11.5 in.)

Minimum Clearance Required 1.5 cm (.6 in.) 3.2 cm (1.25 in.)

Cubic CM. (cu.in) of Fluid Required 10.3 (0.63) 57.4 (3.5)

Table 1. HS2000 & HS3000 Specifications

8

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

General Maintenance

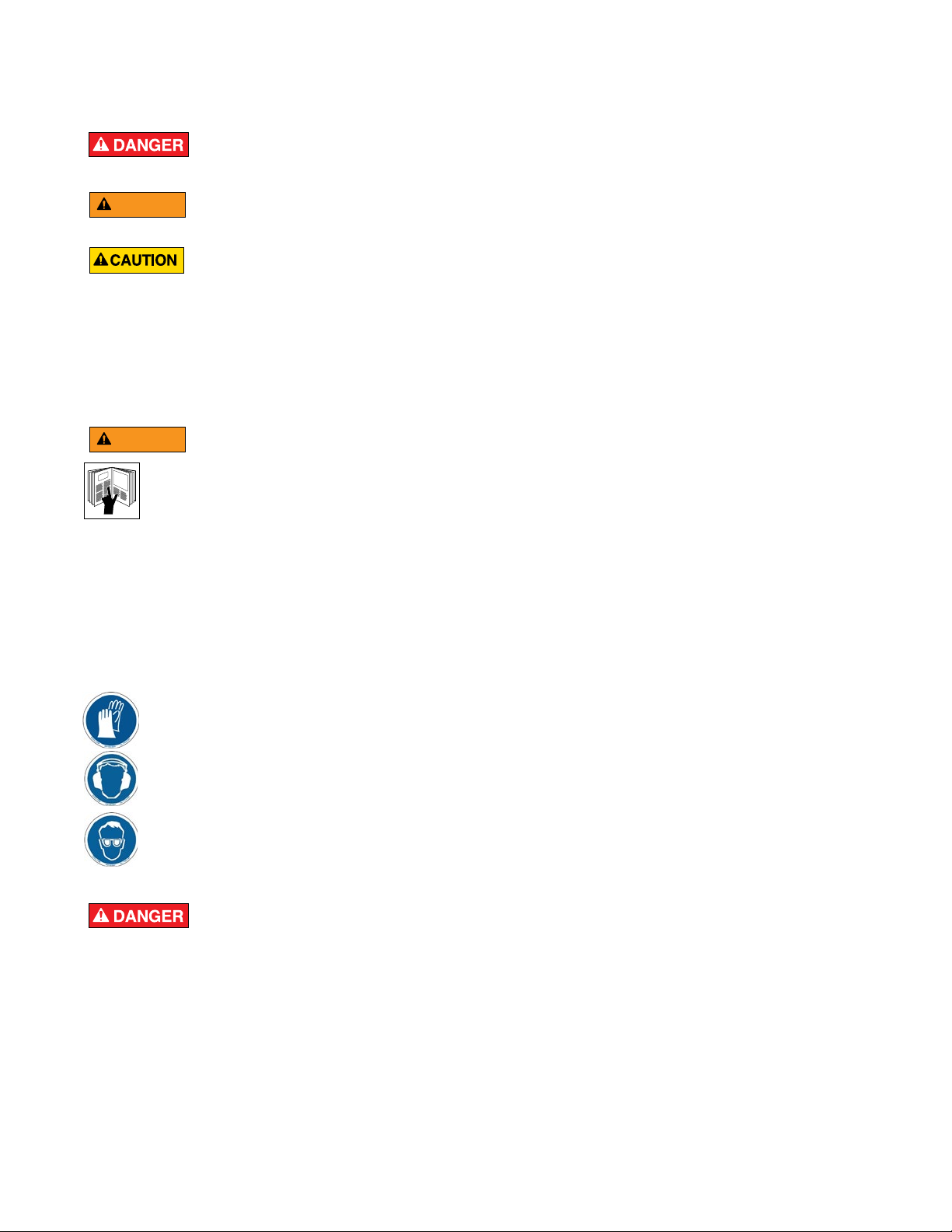

• Repairs and maintenance are to be performed in a dust-free area by a qualied

technician.

12

3

4

5

6

Figure 3. HS2000 Components

Item Description

1 Trade Name Decal

2 Upper Jaw

3 Extension Spring

4 Lower Jaw

5 Pivot Pin

6 Ram Half Coupler (w/Dust Cap)

12

3

4

5

6

7

Figure 4. HS3000 Components

Item Description

1 Trade Name Decal

2 Upper Jaw

3 Extension Spring

4 Lower Jaw

5 Pin

6 Ram Half Coupler (w/Dust Cap)

7 Handle

Inspection

See Figure 3 and Figure 4. Before each use,

visually inspect for the following items:

• Cracked or damaged spreader.

• Excessive wear, bending, damage, or

insufficient thread engagement.

• Leaking hydraulic fluid.

• Scored or damaged piston rod.

• Loose bolts, pins, or fittings.

• Modified, welded, or altered equipment.

• Handle.

Preventive Maintenance

Visual examination by the operator or other

designated personnel with a dated and signed

equipment record should be done yearly (or

sooner) if the spreader condition suggests

damage.

Storage

Store the unit in a dry, well-protected area where

it will not be exposed to corrosive vapors, debris,

or other harmful elements. If a unit has been

stored for an extended period of time, it must be

thoroughly inspected before it is used.

WARNING

9

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

• Repair work or troubleshooting must be performed by qualied personnel who are familiar

with this equipment.

• Disconnect the power supply before removing the electrical cover. Electrical work should be

performed by a qualied electrician.

• Check for system leaks by using a hand pump to apply pressure to the suspect area. Watch

for leaking uid and follow it back to its source. Never use your hand or other body parts to

check for a possible leak.

Notes:

• For a detailed parts list or to locate a Power Team Authorized Hydraulic Service Center, contact your

nearest Power Team facility.

• Plug the outlet ports of the pump when checking for leakage to determine if the leakage is in the

pump, in the cylinder, or in the tool.

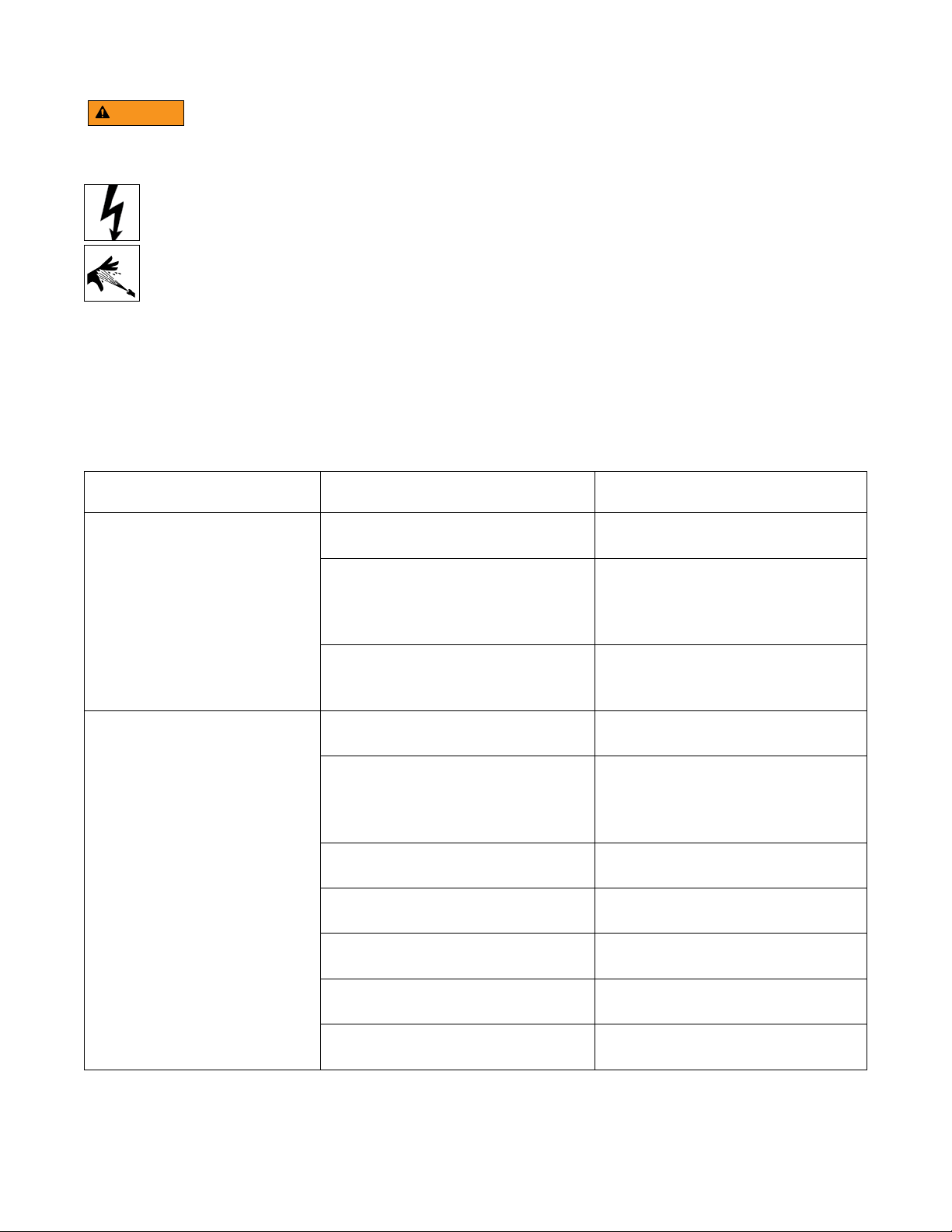

Troubleshooting Guide

Problem Cause Solution

Erratic action. 1. Air in system or pump

cavitation.

1. Add uid, bleed air and check for

leaks.

2. Internal leakage in double-

acting cylinders or external

leaking in single-acting

cylinders.

2. Replace worn packings. Check for

excessive contaminations or wear.

Replace contaminated uid as

necessary.

3. Spreader sticking or binding.

3. Check for dirt or leaks. Check for

bent, misaligned, worn parts or

defective packing.

Spreader does not move. 1. Loose couplers.

1. Tighten couplers. Make sure all

couplers are fully screwed.

2. Faulty coupler.

2. Verify that female coupler is

not locked up (ball wedged into

seat). Replace both female and

male couplers.

3. Improper valve position.

3. Close release valve or shift to

new position.

4. Low or no hydraulic uid in

pump reservoir.

4. Fill and bleed the system.

5. Air-locked pump.

5. Prime pump per pump operating

instructions.

6. Pump not operating.

6. Check pump's operating

instructions.

7. Load is above the capacity of

the system.

7. Use the correct equipment.

WARNING

10

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

Problem Cause Solution

Spreader extends only

partially.

1. Pump reservoir is low on

hydraulic uid.

1. Fill and bleed the system.

2. Load is above the capacity of

the system.

2. Use the correct equipment.

3. Piston rod binding.

3. Check for dirt or leaks. Check for

bent, misaligned, worn parts, or

defective packing.

Spreader moves slower

than normal.

1. Loose connection or coupler.

1. Tighten.

2. Restricted hydraulic line or

tting.

2. Clean and replace if damaged.

3. Pump not working correctly.

3. Check pump operating

instructions.

4. Cylinder seals leaking.

4. Replace worn seals. Check for

excessive contamination or wear.

Spreader moves but does

not maintain pressure.

1. Leaky connection.

1. Clean, reseal with thread sealant

and tighten the connection.

2. Cylinder seals leaking.

2. Replace worn seals. Check for

excessive contaminated uid as

necessary.

3. Pump or valve malfunctioning.

3. Check pump or valve operating

instructions.

2. Loose connections.

2. Clean, reseal with thread sealant

and tighten connection. Make

certain all connections are fully

secured.

Spreader will not retract

or retracts slower than

normal.

1. Pump release valve closed.

1. Open pump release valve.

2. Loose couplers.

2. Tighten couplers.

3. Blocked hydraulic lines.

3. Clean and ush.

4. Weak or broken retraction

springs.

4. Send to service center for repair.

5. Spreader damaged internally.

5. Send to service center for repair.

6. Pump reservoir too full.

6. Drain hydraulic uid to correct

level.

Troubleshooting Guide continued

11

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

POWER TEAM FACILITIES & CONTACT

www.spxow.com

SPX Flow Customer Service:

(800) 541-1418

North America Headquarters

5885 11th Street

Rockford, IL 61109

USA

Customer Service/Order Entry

Tel: +1 800 541 1418

Fax: +1 800 288 7031

Technical Services

Tel: +1 800 477 8326

Fax: +1 800 765 8326

European Headquarters

Albert Thijsstraat 12

6471 WX Eygelshoven

The Netherlands

Tel: +31 45 567 8877

SEA Headquarters

20 Pioneer Crescent #06-01

West Park BizCentral

Singapore 628555

Tel: +65 6264 4366

Fax: +65 6265 9133

India Headquarters

SPX Flow Technology (India) Pvt. Limited

Survey No. 275

Odhav, Ahmedabad - 382 415

Tel: +91-99099-85454

+91-97277-19950

China Headquarters

7F Treasury Building

1568 Huashan Road

Shanghai, 200052 China

Tel: +86 21 2208 5888

Fax: +86 21 2208 5682

Australia Headquarters

SPX Flow Technology Australia Pty Ltd

Quad 2, 6 Parkview Drive

Homebush Bay NSW 2127

Tel: +61 02 9763 4900

Fax: +61 02 9763 7888

Ft.aus.cs@spxow.com

12

© SPX FLOW, Inc. Form No. 1000665

Rev. 0 Sept. 9, 2019

Declaration of Conformity

English Original

SPX Hydraulic Technologies

5885 11

th

Street

Rockford, IL 61109-3699

United States of America

SPX Hydraulic Technologies

Andreas J. Klemm

SPX Hydraulic Technologies

Albert Thijsstraat 12

NL-6471 WX Eygelshoven

The Netherlands

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that our Hydraulic Spreader Model:

* HS2000, HS3000

to which this declaration relates are in conformity with the following:

EN, EN-ISO, ISO standards Title

Per the provisions of the Machinery Safety Directive 2006/42 EC

EN_ISO 12100 Safety of machinery, basic concepts, general principles for

design, risk assessment & risk reduction

EN 4413 Hydraulic Fluid Power –general rules and safety

requirements for systems & their components

We hereby declare that the equipment specified under * conforms to the above quoted

European Community Directive(s) and Standard(s) as per the currently valid revision.

SPX Hydraulic Technologies is certified and registered to ISO 9001: 2015.

The Netherlands September 03

rd

, 2019

------------------------------------------

Andreas J. Klemm, PhD

This manual suits for next models

1

Table of contents