4

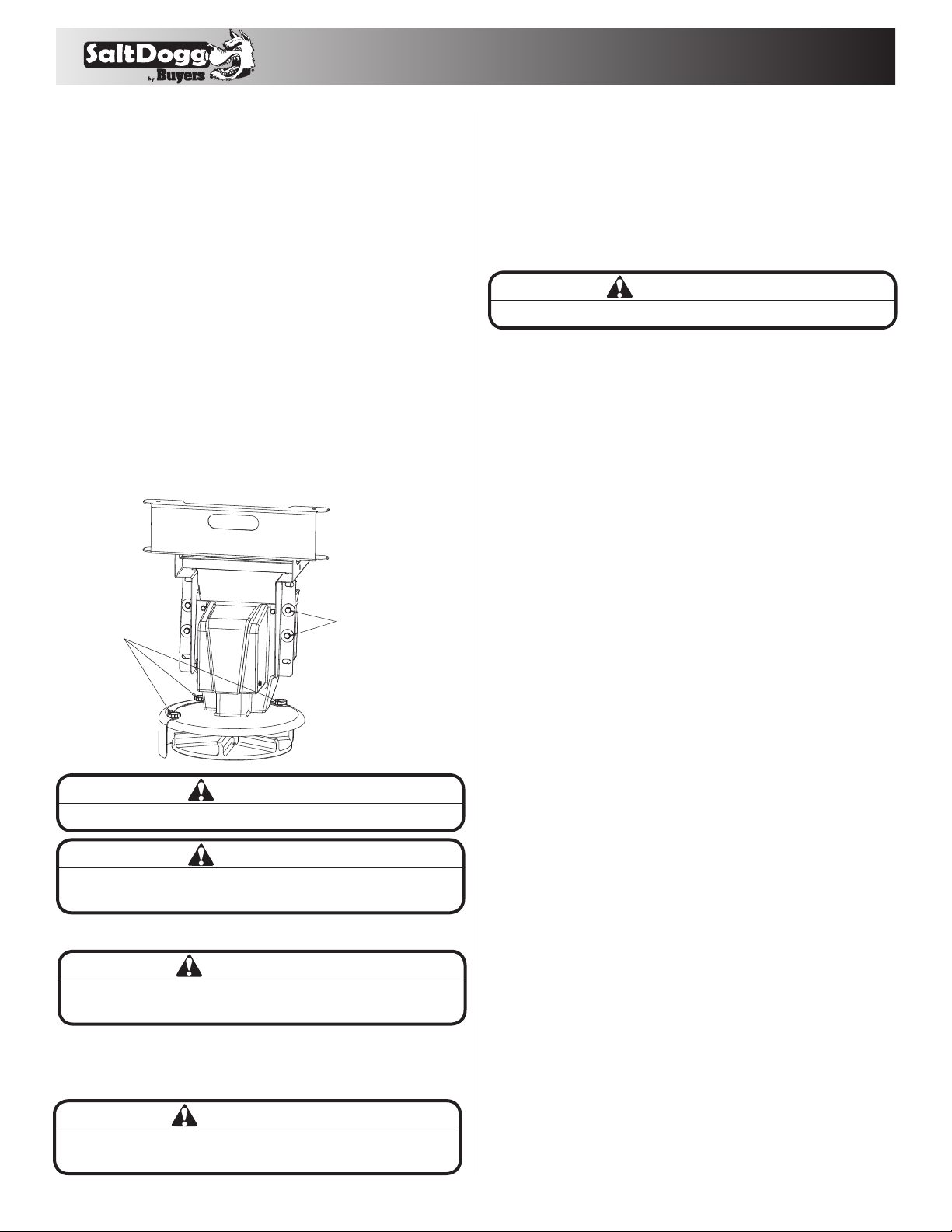

Loosen Screws, Rotate

Shields to Adjust

Spray Pattern

Unscrew Bolts, Slide

Lower Chute Up or Down

Into Desired Position,

Reinstall & Tighten Bolts

Spreader Operation

1. This spreader is equipped with a dual independent speed

controller. To start spreader, press “POWER” switch. Switch

will be illuminated. Auger/ chain and spinner will start rotating.

Auger and spinner can be adjusted independently.

2. To activate vibrator press “VIBRATOR” switch, vibrator switch

will illuminate. Vibrator can operate continuously for 30 min max

with 15 min brakes to avoid overheating.

3. To stop spreader press “ON-OFF” switch again.

4. The controller is equipped with electronic overload and

current spike protection. Controller is not serviceable.

Controller has two LED lights: “ERROR” and “FLASH NUMBER”.

If there is a problem the ERROR LED will illuminate and FLASH

NUMBER LED will give a series of flashes. Count the number of

flashes and refer to the troubleshooting guide provided with the

controller. Additionally you can go online for the troubleshooting

codes at https://snowdogg.com/media/3802/3026671_A.pdf

5. Spreading pattern can be controlled by repositioning of the

baffles on the chute as shown in Fig. 6. Chute heights can be

adjusted to accommodate different vehicle heights (Fig.6).

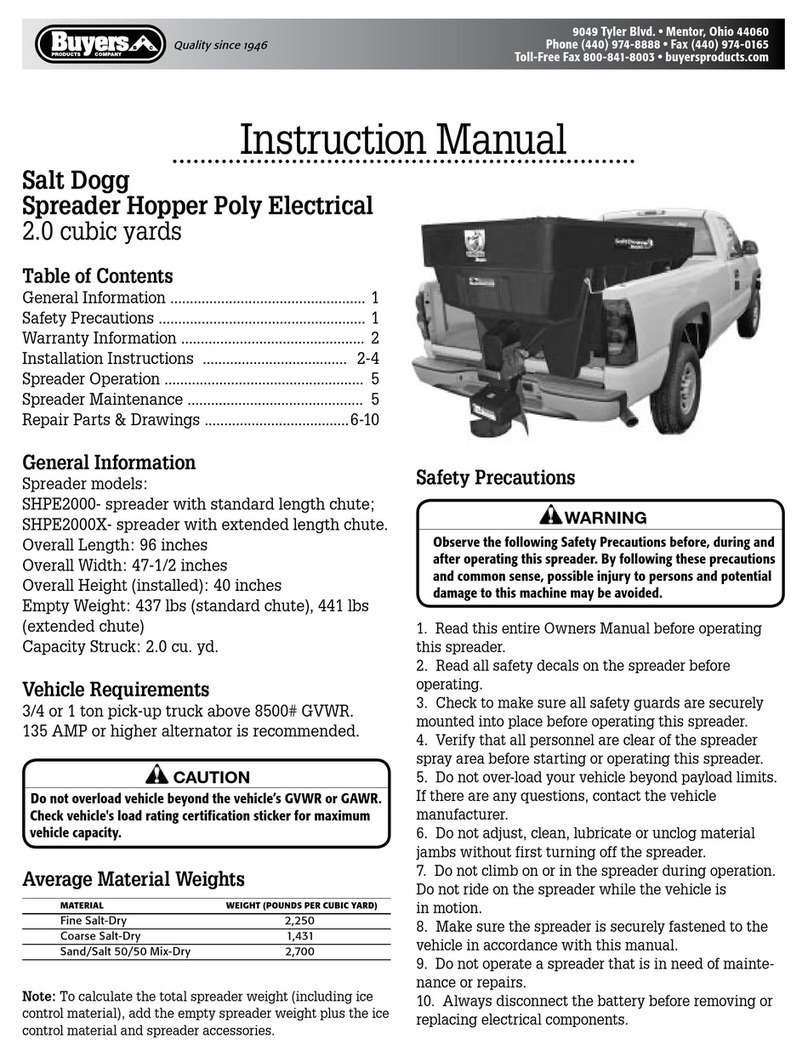

1. Ensure that the spreader is securely mounted to the vehicle

and that the top screen is installed and secured in the hopper.

2. Remove the tarp, if used.

3. Determine the amount of material that you can safely

transport using your vehicles GVWR/GAWR and the following

table on page 1.

4. Fill the spreader evenly with your material, making sure not to

fill past the top of the hopper.

Fig. 6

WARNING

Never attempt to lift spreader with material in hopper!

WARNING

Never leave material in hopper for extended period of time.

Material can freeze, solidify and seriously damage the spreader

IMPORTANT

Only use dry salt, sand, sand/salt, or cinder/salt mixes in the

spreader. Other materials could cause damage to the machine.

IMPORTANT

When filling the spreader, do not exceed the gross-vehicle-weight

rating (GVWR) or gross-axle-weight rating (GAWR).

IMPORTANT

Overfilling the hopper could damage the spreader & your vehicle.

Spreader Maintenance

1. Wash spreader after every use. Make sure no material is left

under auger/ chain and/or inside trough.

2. Inspect and retighten fasteners after every 5-7 hours of operation.

3. Lubricate bearings every 7-10 hours of operation using

general automotive grease.

4. Inspect terminals/connectors every time you disconnect

spreader from wire harness. Apply thin layer of dielectric grease

on terminals. If any tarnish/corrosion is found, clean terminals

and apply dielectric grease.

5. Use dielectric grease on all electrical connectors before an

electrical connection is made or after connector is disconnected

6. Empty the spreader of all ice control materials when not in

use. Wash out the spreader to prevent material builds up.

7. It is recommended to cover spreader with the tarp during

storage periods.

End of Season Maintenance

1.

Wash spreader. Make sure no material or residue is left in and

outside the hopper.

2.

Lubricate bearing using general automotive grease.

3.

Inspect wire harness, connectors for broken insulation, missing

components. Replace if necessary.

4.

Apply dielectric grease on all electrical connectors.

5.

Store hopper indoors, in a dry, cool place.

6.

Remove controller from truck. Store controller indoors, in a dry

cool place.

7.

Inspect wire near connectors. Check for broken or missing

insulation. Check for tarnished or corroded wires. Trim corroded

wires and replace connectors if necessary

8.

Make sure no material is left on the spinner disc.

9.

Inspect and retighten vibrator fasteners after every 2 hours.

Summer Storage

1.

Apply dielectric grease or similar protective compound on all

electrical connectors & protect them with caps before storage.

2. Disconnect and remove speed controller from vehicle and

store it in dry and cool place. Protect controller from excessive

heat and moisture.

3. Clean hopper and trough from all kinds of debris.

4. Remove, thoroughly lubricate and reinstall trough bearing.

5. Protect hopper from excessive temperatures during

summer storage.

Spreader Materials

The density of materials that can be loaded into the spreader varies

and therefore so will the amount of a given material that can be

carried by the spreader before the maximum load rating is reached.