6

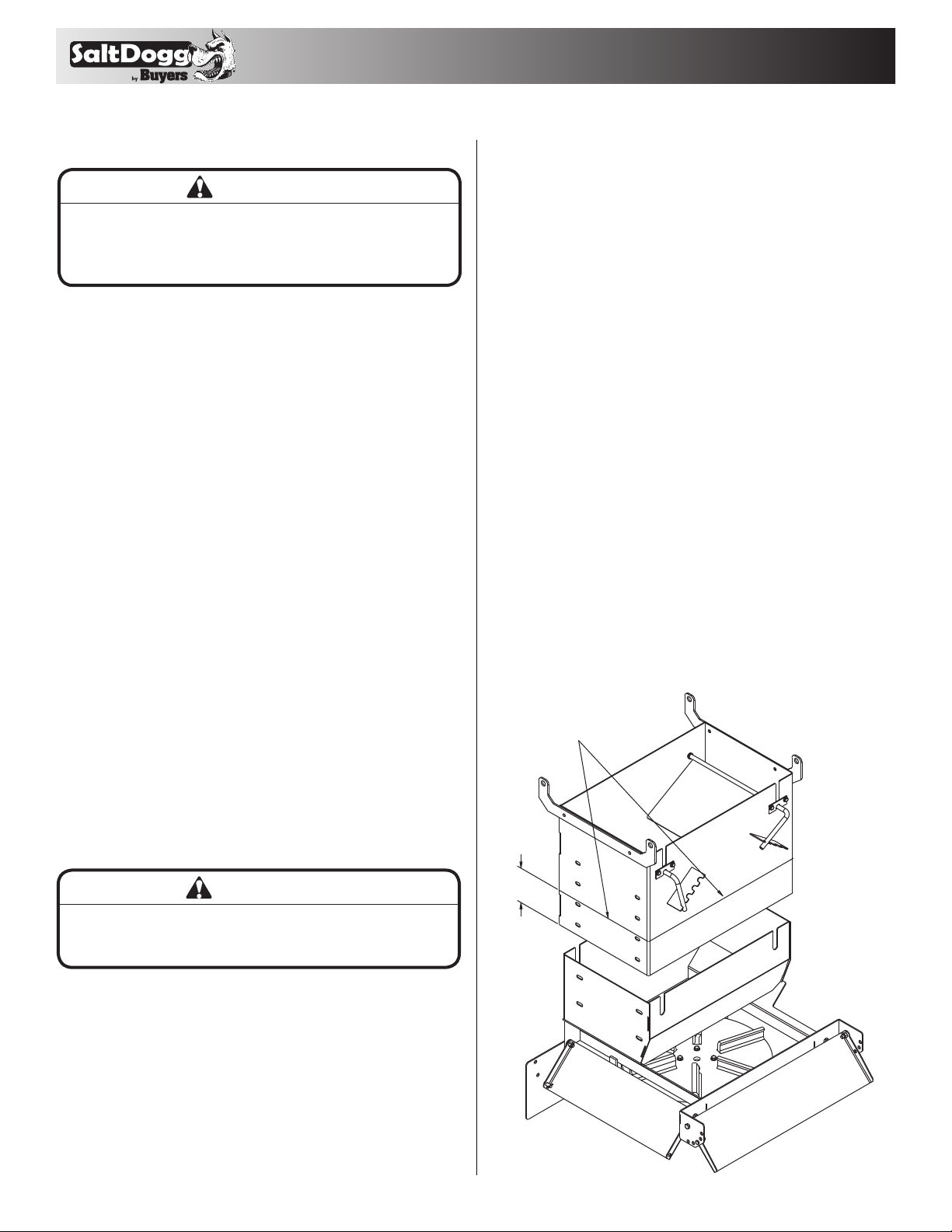

ITEM PART NO. QTY. DESCRIPTION

13032621 1 HOPPER WELDMENT 10 FT 57 IN SST ELECTRIC

3034751 1

HOPPER WELDMENT 12 FT 9CUYD SST ELECTRIC

23001522 4 BOLT, CARRIAGE 1/2-13X1 SST

33001523 4 NUT, HX FLNG-1/2-13 SST

43034718 1BRACKET CONNECTORS

53010131 2WIPER, RUBBER

6FWF038100007SS 14 WASHER, FLAT 3/8 USS SST

7FCS038016125SS 6 SCREW, HHC-3/8-16X 1.25 SST

8FNE038016044SS 15 NUT, NYLOCK 3/8-16 X 7/16 SST

93019694 1 ADAPTER GEAR BOX

10 3034230 1 GEAR MOTOR 3/4 HP 12VDC 280:1

11 3032660 1 DRIVE SHAFT

12 KS402 1 KEY, 1/4 X 1/4X2

13 4F32SCR 1 BEARING FLANGE 2.0 DIA, 4 HOLES SET SCREW

14 3010989 2 KEY, SQUARE 1/2" X 2 1/2"

15 3010845 2 SPROCKET DRIVE, ASSEMBLY

16 1457150 1 CHAIN, 10 FT. D667H CONVEYOR

3034759 1 CHAIN, 12 FT. D667X CONVEYOR 1.5x.25 BARS

17 3010358 1IDLER SHAFT, ASSEMBLY

18 3010603 2 BEARING, HD TAKE-UP 1.5 DIA.

19 3026276 4 SCREW HH, 3/4-10 X 3.0 FULL THREAD, SST

20 3010659 8 NUT, HEX NYLOCK 3/4-10 SST

21 3023046 2BOLT, WELDED TAKE UP

22 3023022 2SPRING CHAIN TENSION

23 3023044 2TAKE-UP NUT WELDMENT

24 FNH063011054SS 2 NUT, HH 5/8-11 X 17/32 HIGH SST

25 3010312 1FEED GATE, WELDMENT

26 3032849 1 BRACKET, CHAIN CHUTE

27 3010443 1 JACK ASSEMBLY, FEED GATE

ITEM PART NO. QTY. DESCRIPTION

28 FCS031018300SS 1 SCREW, HH CAP 5/16-18 X 3 SST

29 FNE031018034SS 1 NUT, NYLOCK 5/16-18 SS

30 FCS025020100SS 4 SCREW, CAP HEX HD 1/4-20 X 1 SST

31 FWF025063007SS 4 WASHER, FLAT 1/4 SAE SS

32 FNE025020031SS 4 NUT, NYLON INSERT 1/4-20 SST

33 1499020 1LABEL, WARNING 1

34 1499035 2LABEL, WARNING 3

35 1499030 1 LABEL, CAUTION 1 (PAYLOAD)

36 1499045 1LABEL, WARNING 4

37 3010916 1 LABEL, SERIAL NUMBER

38 3010918 1 DECAL, POINTER FEED GATE

39 3010917 1 DECAL, GAUGE FEED GATE

40 3017730 2 CROSS MEMBER, INVERTED VEE

41 3017731 2HANGER, INVERTED VEE

42 3000269 8 WASHER, FLAT 1/2 USS, SST

43 3006723 16 SCREW, HEX HD 1/2-13x1.5 GR5 SS

44 FNE050013053SS 16 NUT, NYLOCK 1/2-13 SS

45 3032805 1DEFLECTOR, INVERTED VEE

3034757 1DEFLECTOR, INVERTED VEE

46 3032688 1 GRATE SUPPORT 10 FT, BLACK

3028914 1GRATE SUPPORT, WELDMENT

47 3025824 1 COVER, BEARING 4F32SCR

48 3026277 1 PLUG, BEARING COVER

49 3011132 3 DECAL, SALT DOGG, BLK/WHT ON CLR 18X6.3125

50 FCS038016100SS 4 SCREW, HHC 3/8-16 X 1 304 SST

51 3017121 2 BRACKET, RECEPTACLE SZ8 DEUTSCH

52 3016740 2 SCREW, HHC-3/8-16 X 1/2 SST

53 FCS038016075SS 3 SCREW, HHC-3/8-16 X 3/4 SST

54 FCS050013100SS 4 SCREW, HHC-1/2-13 X 1 SST

Repair Parts - Hopper Assembly

Bill of Materials

1

2

3 4

5

6 7

8

9

10

11 12

13 14 15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42 43

44

45

46

47

48

49 50

51

52

53

54