EMB WALLENSTEIN MX25 Installation guide

MANURE SPREADER

MODEL MX25

ASSEMBLY INSTRUCTION MANUAL

EMB MANUFACTURING INC.

4144 BOOMER LINE

ST. CLEMENTS, ON

N0B 2M0 CANADA

PH: (519) 699-9283

FAX: (519) 699-4146

PRINTED IN CANADA

Rev 260213 PART NUMBER: Z97520

Please review and understand the

operators manual before attempting

to operate this machinery.

2

1.0 ASSEMBLY SAFETY

1. Read and understand the Assembly Manual and all safety signs before starting.

2. Follow good safety practices:

- Keep service area clean and dry.

- Be sure electrical outlets and tools are properly grounded.

- Use adequate light for the job at hand.

3. Use properly sized tools, stands, jacks and hoists at all times.

4. Dont' handle heavy and/or bulky components alone, ask for help.

5. Position in a large open area to allow access from all sides during assembly.

6. Keep the assembly area neat and clean to prevent slipping or tripping.

7. When using lifting equipment, place jack stands under the machine to securely stablize it before

working on, beside or under it during assembly.

8. Stay away from overhead power lines and obstructions when lifting the machine during as-

sembly. Contact with power lines can cause electrocution. Contact with obstructions can

damage components or cause them to fail.

9. Tightenallfastenerstotheirspeciedtorque,thenrecheckbeforeusingthemachine.

ENGLISH TORQUE SPECIFICATIONS

SAE 2

(N.m) (lb-ft)

Bolt Torque*

Bolt

Diameter

"A"

SAE 5

(N.m) (lb-ft)

SAE 8

(N.m) (lb-ft)

1/4"

5/16"

3/8"

7/16"

1/2"

9/16"

5/8"

3/4"

7/8"

1"

8

13

27

41

61

95

128

225

230

345

6

10

20

30

45

60

95

165

170

225

12

25

45

72

110

155

215

390

570

850

9

19

33

53

80

115

160

290

420

630

17

36

63

100

155

220

305

540

880

1320

12

27

45

75

115

165

220

400

650

970

Torqueguresindicatedabovearevalidfornon-greasedornon-oiledthreadsandheadsunlessoth-

erwisespecied.Therefore,donotgreaseoroilboltsorcapscrewsunlessotherwisespeciedinthis

manual. When using locking elements, increase torque values by 5%.

*Torquevalueforboltsandcapscrewsareidentiedbytheirheadmarkings.

2.0 BOLT TORQUE

3

3.0 ASSEMBLY

This assembly manual is for all trailer model manure spreaders. The MX25G is used as

anexamplebutgenerallyappliestoallmanure spreader models.Modelspecicinstruc-

tionsareidentiedinthemanual.

Themachineisshippedfromthefactoryinapartiallydisassembledcongurationand

attached to a pallet that provides easy moving and handling. Always use tools, equip-

ment and fork lifts of appropriate size and capacity for the job.

Inspect for damage from shipping, immediately contact

the shipping company if damage is found.

When the machine is shipped, follow this assembly procedure:

1. Clear the area of bystanders, especially small children.

2. Be sure you have all the required tools before you start.

3. Move the shipping package into an area where it is accessible from all sides.

4. Remove the screws holding the lid to the shipping pallet, remove the lid and set aside away from the

assembly area.

Caution: Heavy or bulky

parts: prevent potential in-

jury ask for help when lifting or

moving heavy, bulky parts.

1

Uncrating the Spreader

1. Remove all screws securing upper part of crate to lower skid. There are two (2) screws

located at each of four corners around bottom of crate, and one in center of both sides.

Photo 1

Photo 1

2. Remove the upper portion of the crate by lifting at four corners. Photo 2

Photo 2

2

3. Locate Ground Drive Axle Assembly, Engagement Handle and Tires shipped in bed of

spreader. Photo 3

Photo 3

Axle/Tires/Engagement Handle

4. Unfasten and remove Engagement Handle Assembly secured inside spreader bed.

Photo 4

Photo 4

3

5. Remove the Hex Bolt 1/4NC x 1-1/2 & Hex Lock Nut 1/4NC temporarily mounted

at the Drive Engagement Connection Rod (for your convenience). Inset A, Photo 5).

Use this hardware to mount and secure the Engagement Handle Assembly. Photo 6

Photo 5

Photo 6

A

4

6. Using a lift truck, raise the spreader from the lower skid and place on a set of four

jacks. Position jacks at a workable height for axle and tire installment.

Exercise extreme caution when raising spreader to ensure a safe working environ-

ment. All precautions should be taken to avoid any injury. Photos 7 & 8

Photo 7

Photo 8

5

7. Locate Trailer Hitch/Tongue & Cross Bar mounted to top of shipping crate and re-

move. Photo 9

Photo 9

8. Remove two (2) Carriage Bolt 5/16NC x 3/4 & two (2) Flange Nut 5/16NC from

both left and right hand Box Sides at rear of spreader. Photo 10

Photo 10

6

9. Attach the cross bar at rear of spreader with hardware removed in Step 8. Photo 11

Photo 11

10. Remove two (2) Hex Bolt, 1/2NC x 2-3/4 & two (2) Hex Lock Nut 1/2NC from left

and right Main Frame at front of spreader. Photo 12

Photo 12

7

11. Slide the Hitch Frame into Main Frame at front of spreader and secure with the hard-

ware removed in step 10. Photo 13

Photo 13

12. Install Ground Drive Axle Assembly over top of apron chain while holding # 50 Drive

Chain above axle. Install the axle from left side, passing underneath to a second set of

hands on right side of spreader. Photo 14

Photo 14

8

13. Loosely attach axle bearing pillow blocks at right side of spreader using two (2) Hex

Bolt 5/8NC x 1-3/4 & two (2) Hex Lock Nut 5/8NC. Photo 15

Photo 15

14. Loosely attach Drive Sprocket side of axle bearing pillow blocks to spreader (left hand

side). Secure with two (2) more Hex Bolt 5/8NC x 1-3/4 & two (2) Hex Lock Nut

5/8NC. Photo 16 TORQUE ALL FOUR (4) FASTENERS TO SPECIFICATIONS.

Photo 16

9

15. Ensure Main Ground Drive Sprocket is aligned with #50 Roller Chain above.

Photo 17. This alignment is generally set at factory but should be checked in case of

misalignment during shipping.

Photo 17

If alignment is out, loosen both Set Screw, 3/8NC and slide Ground Drive Sprocket as

necessary.

Photo 18

10

16. Remove ten (10) Lug Nut 1/2NF from each axle hub and install two (2) Tires.

Photo 19 & 20

Photo 19

"V" Tread faces towards rear of spreader. Tire shown below is LEFT hand side.

Photo 20

11

17. Installed Jack at upright position. Photo 21

Photo 21

18. Installed Jack at travelling position. Photo 22

Photo 22

Table of contents

Popular Spreader manuals by other brands

Trynex International

Trynex International SnowEx SL-80 Owner's/operator's manual

New Leader

New Leader Hi-Way SUPER P Operator's manual

Dcm

Dcm 2500 PRO manual

H&S

H&S 5134 Operator's manual

Equalizer International

Equalizer International SG13TE Operator's instruction manual

WilTec

WilTec 50144 Operation manual

LEHNER

LEHNER SuperVario X Operating instructions with spare parts list

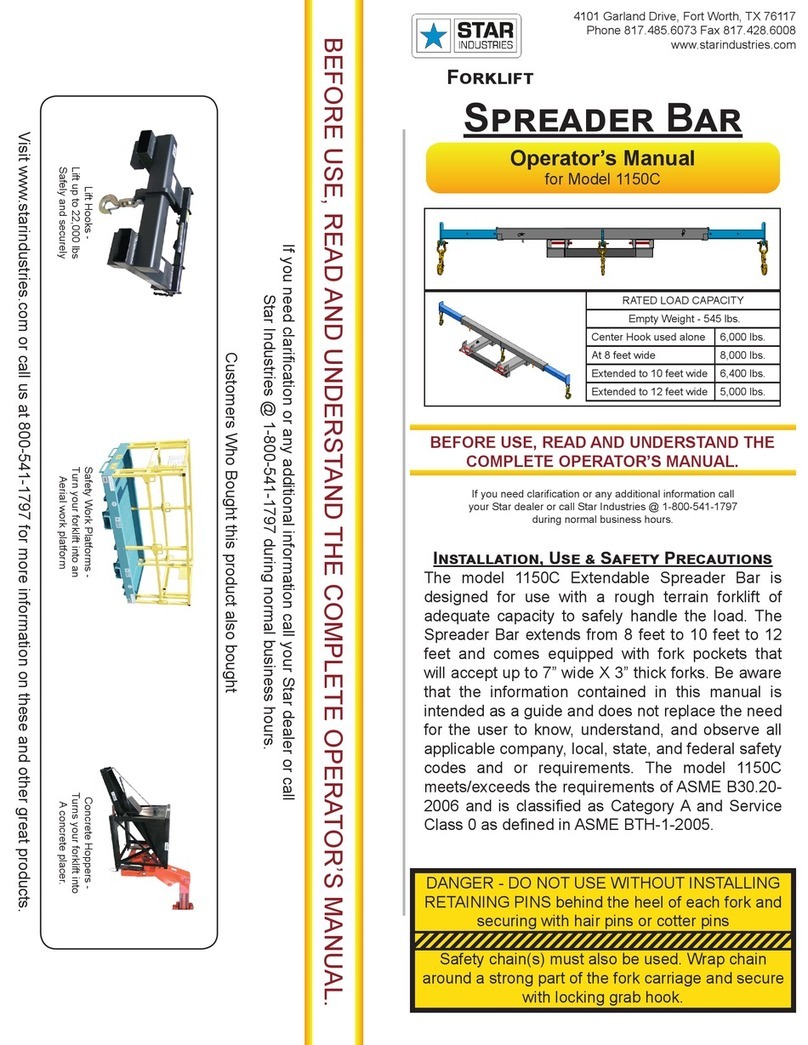

STAR INDUSTRIES

STAR INDUSTRIES 1150C Operator's manual

Hiniker

Hiniker 825 Operator's manual

Highway Equipment Company

Highway Equipment Company NEW LEADER L4000G4 user manual

Brinly

Brinly BTS-150 BH owner's manual

Farmhand

Farmhand 70LB Assembly and operating instruction