Chapter 1

SEITAL S.r.l. Rev. 2 of 11/02/98

Page 1-2 Use and maintenance handbook: Centrifugal separator SE 40CX

1.3. Handbook index

1. HANDBOOK USE 1-1

1.1. HOW TO READ THE HANDBOOK........................................................................................1-1

1.2. HOW TO BRING UP-TO-DATE THE HANDBOOK.................................................................1-1

1.3. HANDBOOK INDEX .............................................................................................................1-2

2. GENERAL INFORMATION 2-1

2.1. MANUFACTURER AND MACHINE DATA.............................................................................2-1

2.2. TECHNICAL SERVICE.........................................................................................................2-1

2.3. GLOBAL ASPECTS OF SAFETY ...........................................................................................2-1

2.3.1. INSTALLATION.................................................................................................................2-1

2.3.2. WARNINGS FOR THE OPERATORS....................................................................................2-1

2.3.3. MAINTENANCE PROGRAMS.............................................................................................2-2

2.3.4. INVOLVED OPERATORS AND TECHNICIANS.....................................................................2-2

2.3.5. MAIN WORKING MODES ..................................................................................................2-2

2.3.6. FORESEEABLE ERRORS AND INCORRECT BEHAVIOURS...................................................2-3

2.3.7. LIST OF USED SYMBOLS AND WARNINGS ........................................................................2-3

2.3.8. SAFETY PRESCRIPTIONS..................................................................................................2-3

2.4. USED TERMS AND ABBREVIATIONS...................................................................................2-6

2.5. RESPONSIBILITY ................................................................................................................2-6

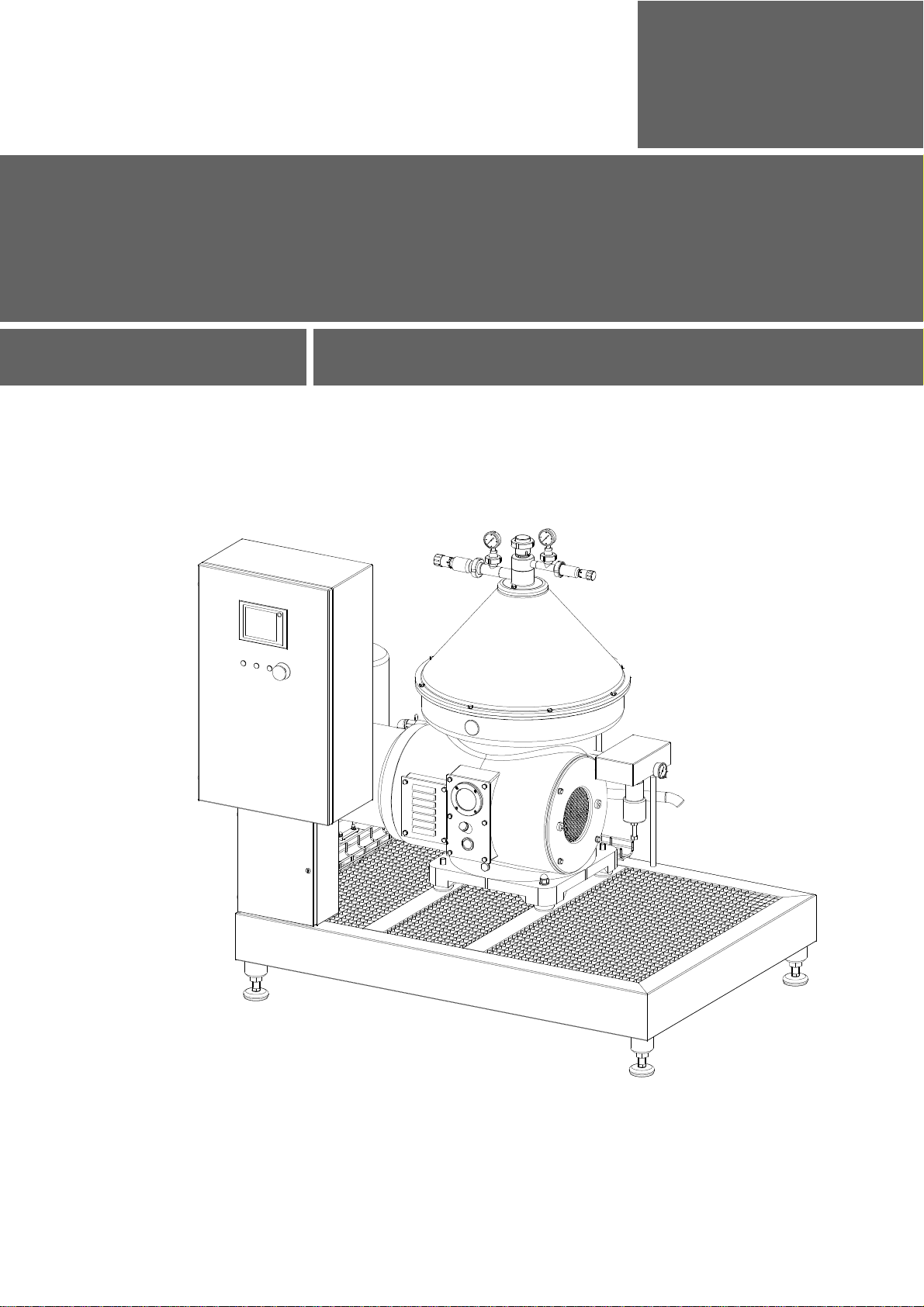

3. MACHINE DESCRIPTION 3-1

3.1. GENERAL DESCRIPTION ....................................................................................................3-1

3.2. OPERATING PRINCIPLES....................................................................................................3-1

3.3. TECHNICAL CARD ..............................................................................................................3-3

3.4. NOISE LEVEL......................................................................................................................3-4

3.5. DESTINATION AND FORESEEN PLACE OF USE...................................................................3-4

3.6. IMPROPER USES AND CONTRA-INDICATIONS ...................................................................3-4

4. LIFTING, TRANSPORT, STORAGE 4-1

4.1. MACHINE DELIVERY..........................................................................................................4-1

4.2. PACKING AND UNPACKING................................................................................................4-1

4.3. LIFTING AND TRANSPORT OF THE PACKED MACHINE.....................................................4-1

4.4. LIFTING AND TRANSPORT OF THE MACHINE WITHOUT PACKING ..................................4-2

4.5. WAREHOUSE STORAGE......................................................................................................4-4

5. INSTALLATION/PREPARATION TO START 5-1

5.1. ENVIRONMENT...................................................................................................................5-1

5.2. WORKING NECESSARY SPACE...........................................................................................5-2

5.3. EQUIPMENT........................................................................................................................5-2

5.4. LOCATION AND ASSEMBLY ON PLACE..............................................................................5-2

5.5. LUBRICATION.....................................................................................................................5-3

5.5.1. BEARINGS AND GEARS LUBRICATION .............................................................................5-3

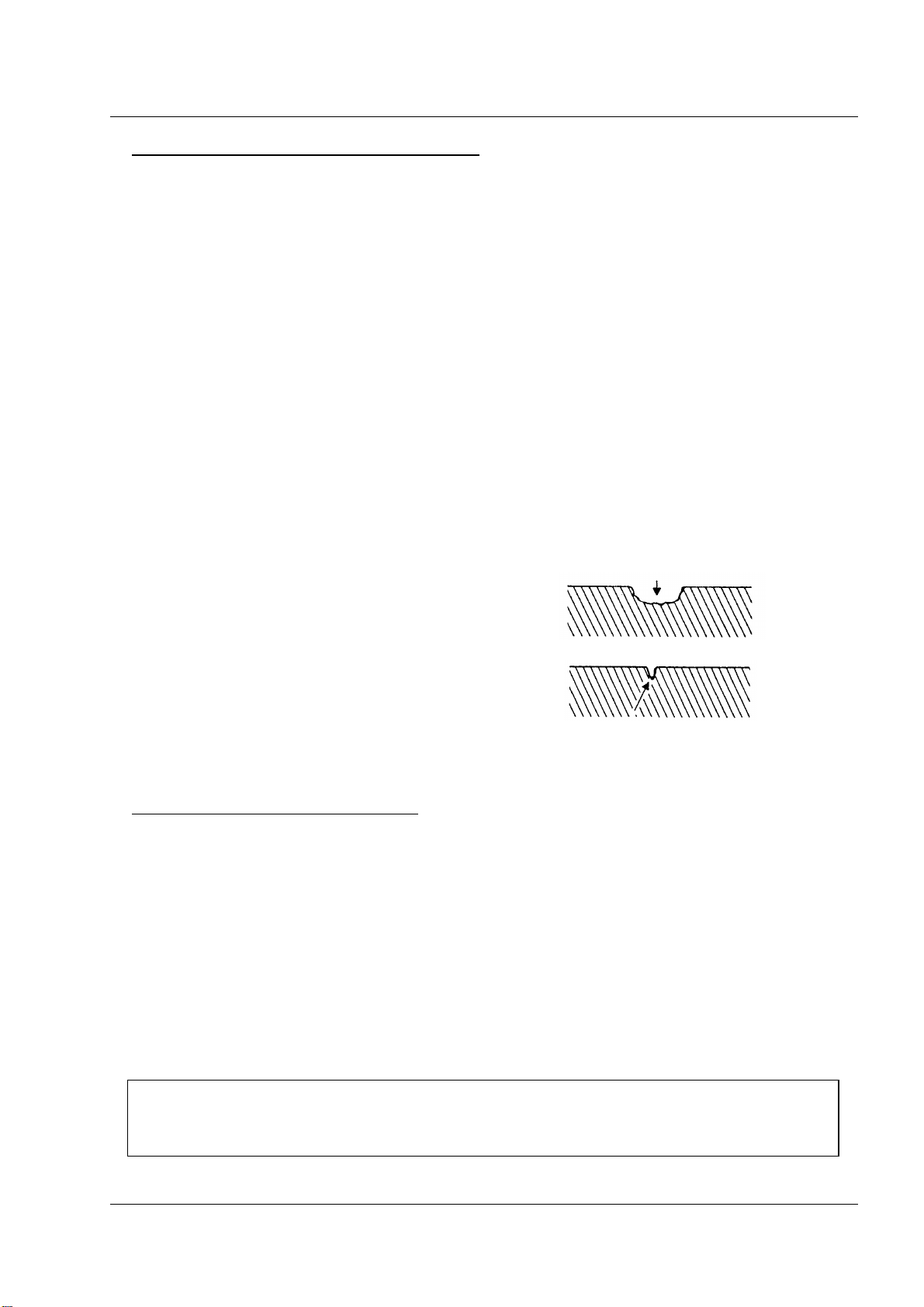

5.5.2. LUBRICATION OF THREADS AND CONTACT SURFACES OF THE BOWL PARTS ..................5-5

5.6. SYSTEMS CONNECTION......................................................................................................5-5

5.6.1. ELECTRICAL SYSTEM CONNECTION ................................................................................5-5

5.6.2. HYDRAULIC CONNECTION FOR OPERATING WATER........................................................5-6

5.6.3. SEPARATOR HYDRAULIC CONNECTION...........................................................................5-7

5.6.4. PNEUMATIC SYSTEM CONNECTION .................................................................................5-8

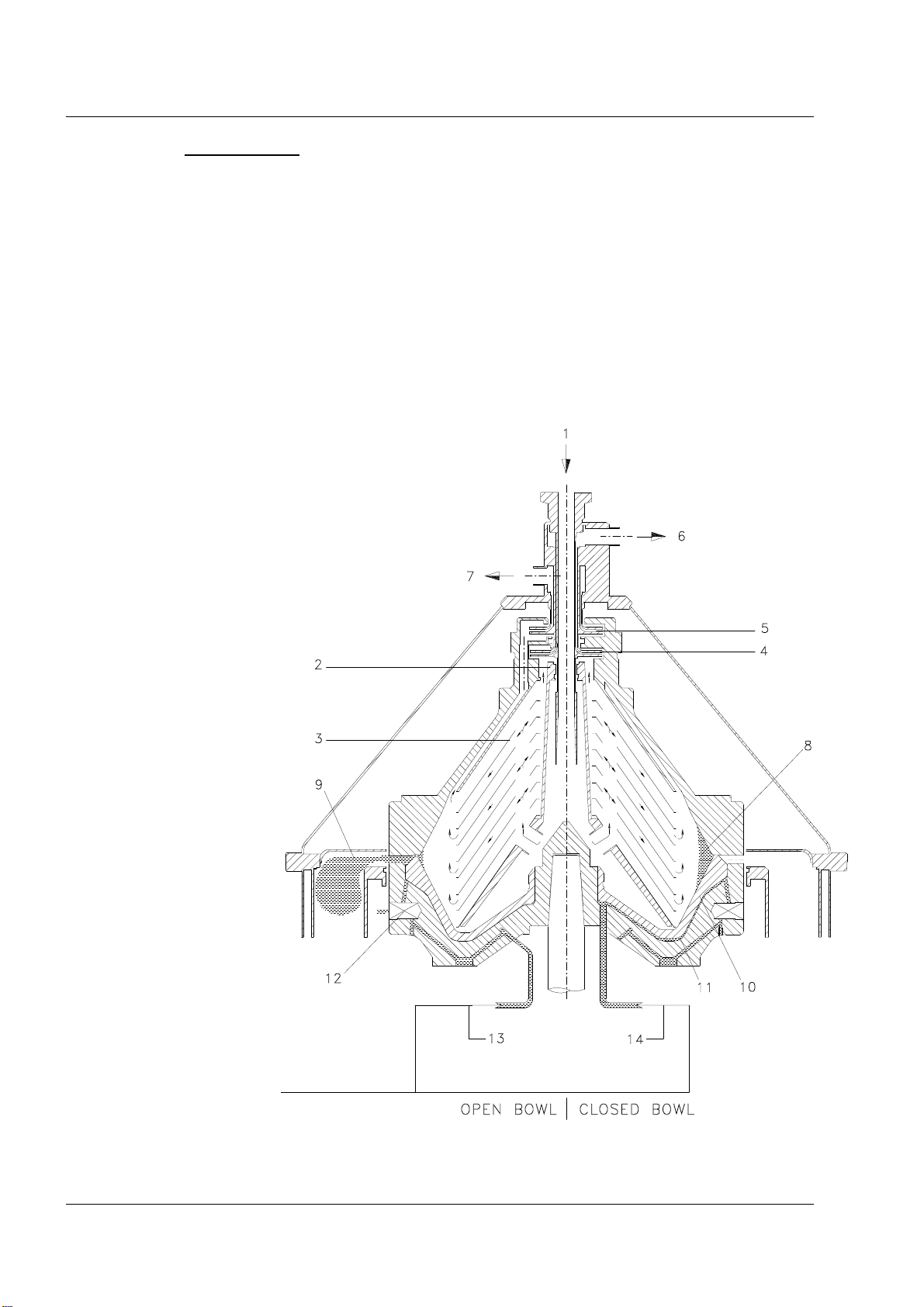

6. BOWL AND INLET-OUTLET FLOW UNIT 6-1

6.1. BOWL ASSEMBLY ...............................................................................................................6-1