SPX Power Team J24T User manual

HYDRAULIC TOE JACK

Part Number J24T Maximum Capacity: 2 Ton

Part Number J55T Maximum Capacity: 5 Ton

Part Number J106T Maximum Capacity: 10 Ton

Read and carefully follow the warnings and operating instructions before using this jack. Most problems with new

equipment are caused by improper operation or setup.

NOTE: Inspect the jack upon arrival. The carrier, not the manufacturer, is responsible for any damage

resulting from shipment.

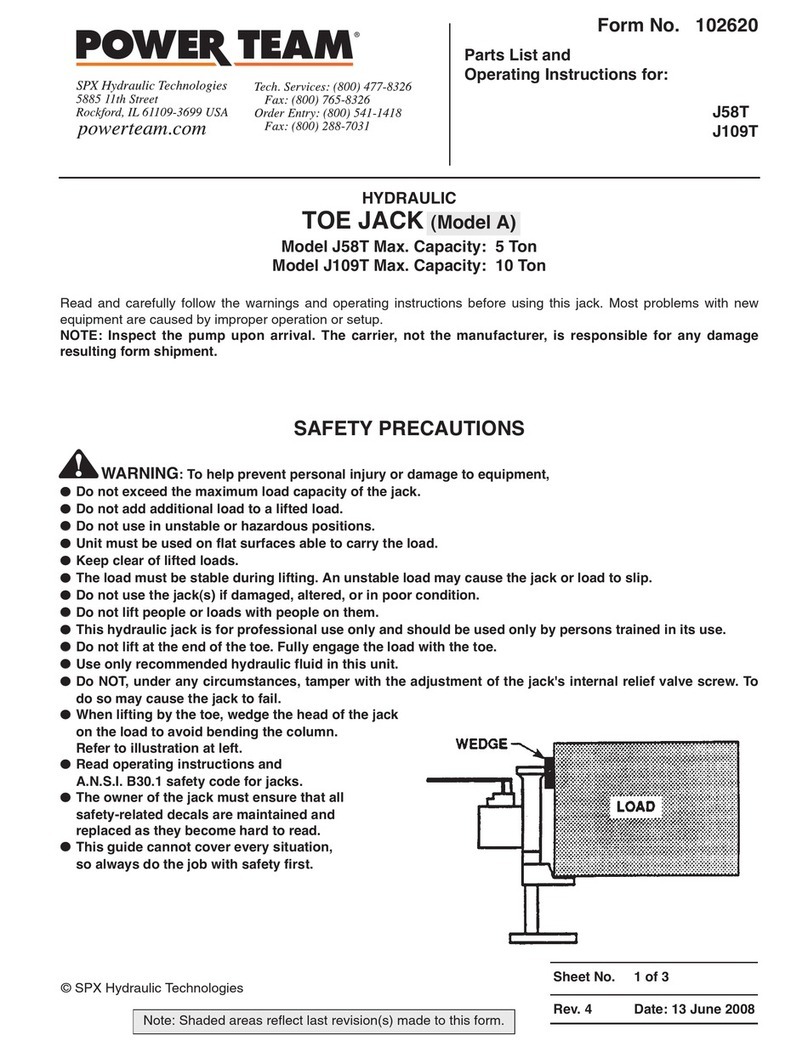

SAFETY PRECAUTIONS

WWAARRNNIINNGG::To help prevent personal injury or damage to equipment,

•Do not exceed the maximum load capacity of the jack.

•Do not add additional load to a lifted load.

•Do not use in unstable or hazardous positions.

•Unit must be used on flat surfaces able to carry the load.

•Keep clear of lifted loads.

•The load must be stable during lifing. An unstable load may cause the jack or load to slip.

•Do not use the jack(s) if damaged, altered, or in poor condition.

•Do not lift people or loads with people on them.

•This hydraulic jack is for professional use only and should be used only by persons trained in its use.

•Do not lift at the end of the toe. Fully engage the load with the toe.

•Use only Power Team hydraulic fluid in this unit.

•Do NOT, under any circumstances, tamper with the adjustment of the jack's internal relief valve screw. To

do so may cause the jack to fail.

•Read operating instructions and A.N.S.I. B30.1 safety code for jacks.

•The owner of the jack must ensure that all safety-related decals are maintained and replaced as they

become hard to read.

•This guide cannot cover every situation, so always do the job with safety first.

Form No. 102947

Parts List and

Operating Instructions

for:

J24T

J55T

J106T

Sheet No. 1 of 5

Rev. 2 Date: 28 Dec. 1998

© SPX Corporation

Tech. Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

SPX Corporation

5885 11th Street

Rockford, IL 61109-3699 USA

Internet Address:

http://www.powerteam.com

®

Parts List and Operating Instructions, Form No. 102947, Back sheet 1 of 5

OPERATING INSTRUCTIONS

IMPORTANT: Do not carry the jack by the jacking lever.

Lifting a Load

1. Position the load on the toe of the jack.

WWAARRNNIINNGG::Do not lift a load on the end of the toe. Fully engage the load with the toe.

IMPORTANT: When lifting by the toe, wedge the head of the jack on the load to avoid bending the column.

2. Turn the release valve knob in a clockwise direction until it is snug.

3. Pump the jacking lever in an up and down motion.

Lowering a Load

1. Slowly loosen the release valve knob by turning it in a counterclockwise direction. The more the knob is loosened,

the faster the load will be lowered. To stop the jack from lowering a load, tighten the release valve knob by turning

it in a clockwise direction.

PREVENTIVE MAINTENANCE

IMPORTANT: The greatest single cause of failure in hydraulic units is dirt. Keep the jack clean and well

lubricated to prevent foreign matter from entering the system. If the jack has been exposed to rain, snow,

sand, or grit, it must be cleaned before it is used.

1. When the jack is not in use, keep the piston and pump rods fully retracted. Store the jack on its base and in a well

protected area where it will not be exposed to corrosive vapors, abrasive dust, or any other harmful elements.

2. Visually inspect the jack before each use. Take corrective action if any of the following problems are found:

a. Cracked or damaged housing e. Incorrectly functioning swivel heads or adjusting screws

b. Excessive wear, bending, or other damage f. Loose hardware

c. Leaking hydraulic fluid g. Modified or altered equipment

d. Scored or damaged piston rod

Parts List and Operating Instructions Form No. 102947

TROUBLE-SHOOTING GUIDE

Repair procedures must be performed in a dirt-free environment by qualified personnel who are familiar with this

equipment.

Sheet No. 2 of 5

Rev. 2 Date: 28 Dec. 1998

TROUBLE CAUSE SOLUTION

Erratic Action

Jack does not advance

Jack only extends partially

Jack advances slowly

Jack advances but doesn’t hold

pressure

Jack leaks oil

Jack will not retract or retracts

slowly

1. Air in system

2. Viscosity of oil too high

3. Internal leakage in cylinder

4. Cylinder sticking or binding

1. Release valve is open

2. Low/no oil in reservoir

3. Air-locked system

4. Load is above capacity of system

1. Reservoir is low on oil

2. Piston rod is binding

1. Pump not working correctly

2. Leaking seals

1. Cylinder seals are leaking

2. Pump check valve not working

correctly

3. Overload valve leaking or not

adjusted correctly

1. Worn or damaged seals

1. Release valve is closed

2. Cylinder damaged internally

3. Reservoir too full

1. With jack sitting on its base and

ram retracted, bleed air by

opening release valve. Pump for

10 seconds.

2. Change to lower viscosity oil.

3. Replace worn seals. Check for

excessive contamination or wear.

4. Check for dirt, gummy deposits,

or leaks. Check for misalign-

ment, worn parts, or defective

seals.

1. Close release valve

2. Fill with oil and bleed system

3. Bleed the system

4. Use correct equipment

1. Fill reservoir

2. Check for dirt, gummy deposits,

or leaks. Check for misalign-

ment, worn parts, or defective

seals.

1. Rework pump

2. Replace seals

1. Replace seals

2. Clean/replace check valve

3. Replace/adjust overload valve

1. Replace seals

1. Open release valve

2. Send jack to authorized service

center for repair

3. Drain oil to correct level

Parts List and Operating Instructions, Form No. 102947, Back sheet 2 of 5

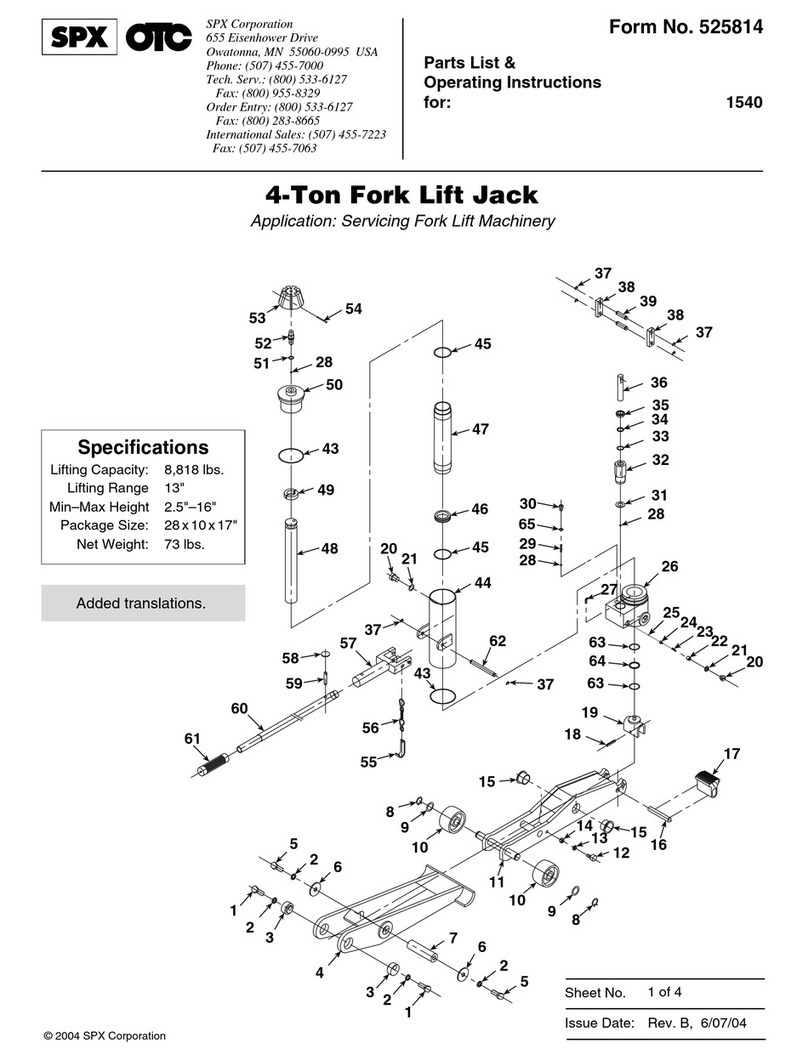

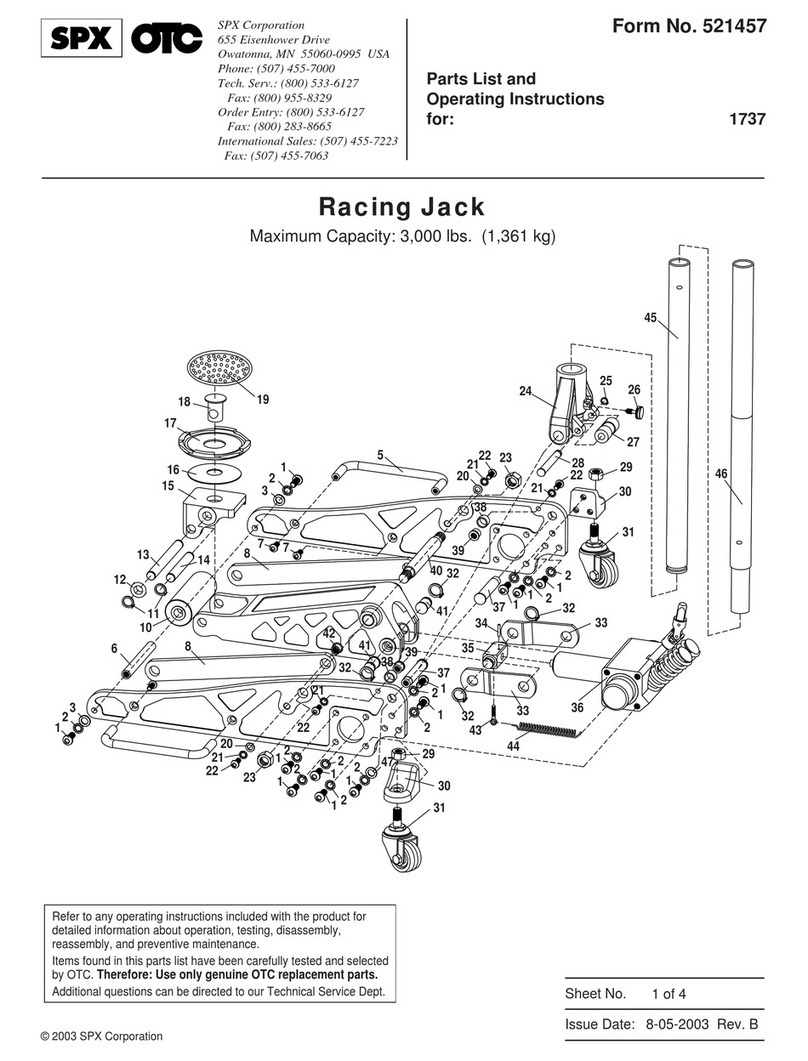

PARTS LIST FOR 2 TON JACK (J24T)

18

17

32*

31*

16

15

14

13

22

23

33*

24

21

4

3

2

12

11

10

9

8

7

25*

5

28*

29*

30*

6

1

19

20

* = Parts marked with an asterisk (*)

are in Repair Kit No. J24T-26.

Parts List and Operating Instructions Form No. 102947

Sheet No. 3 of 5

Rev. 2 Date: 28 Dec. 1998

1J24T-1 1 Handle

2J24T-2 1 Snap Ring

3J24T-3 1 Handle Socket Assembly

4J24T-4 1 Pump Plunger Pin

5J24T-5 1 Pump Plunger

6J24T-6 1 Release Assembly

7J24T-7 1 Safety Valve Push Nut

8J24T-8 1 Safety Valve Plug

9J24T-9 1 Safety Valve Adjusting Screw

10 J24T-10 1 Safety Valve Spring

11 J24T-11 1 Safety Valve Ball Guide

12 J24T-12 1 Safety Valve Ball

13 J24T-13 1 Pump Stay Pin

14 J24T-14 1 Snap Ring

15 J24T-15 1 Ram Guide Ring Stopper

16 J24T-16 1 Ram Guide Ring

17 J24T-17 1 Ram Packing Guide

18 J24T-18 1 Ram

19 J24T-19 1 Bolt

20 J24T-20 1 Washer

21 J24T-21 1 Hanger

22 J24T-22 1 Snap Ring

23 J24T-23 1 Stuffing Ring

24 J24T-24 1 Stopper Ring

25 *J24T-25 1 Filler Plug

28 *J24T-28 1 Pump Backup Ring

29 *J24T-29 1 Pump Packing

30 *J24T-30 1 Release Packing

31 *J24T-31 1 Ram Packing

32 *J24T-32 1 Ram Backup Ring

33 *J24T-33 1 Cylinder Packing

PARTS INCLUDED BUT NOT SHOWN

421686 1 Decal

Part numbers marked with an asterisk (*) are contained in Repair Kit No. J24T-26.

Item Part No.

No. No. Req’d Description

Parts List and Operating Instructions, Form No. 102947, Back sheet 3 of 5

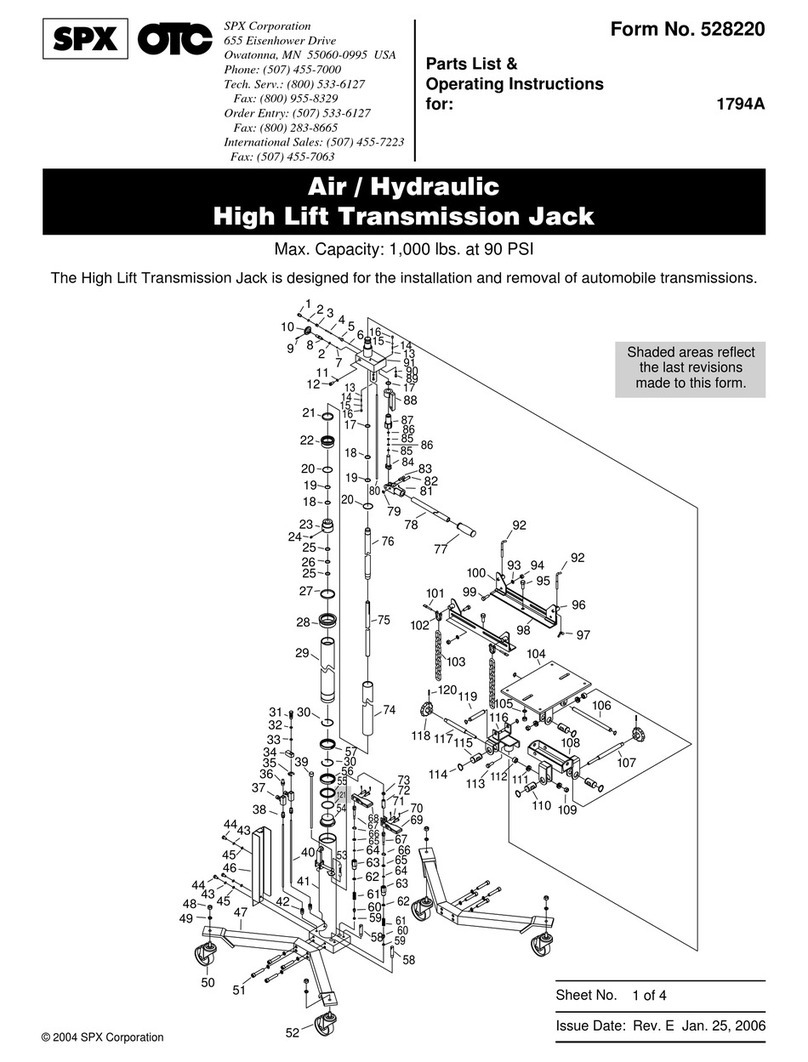

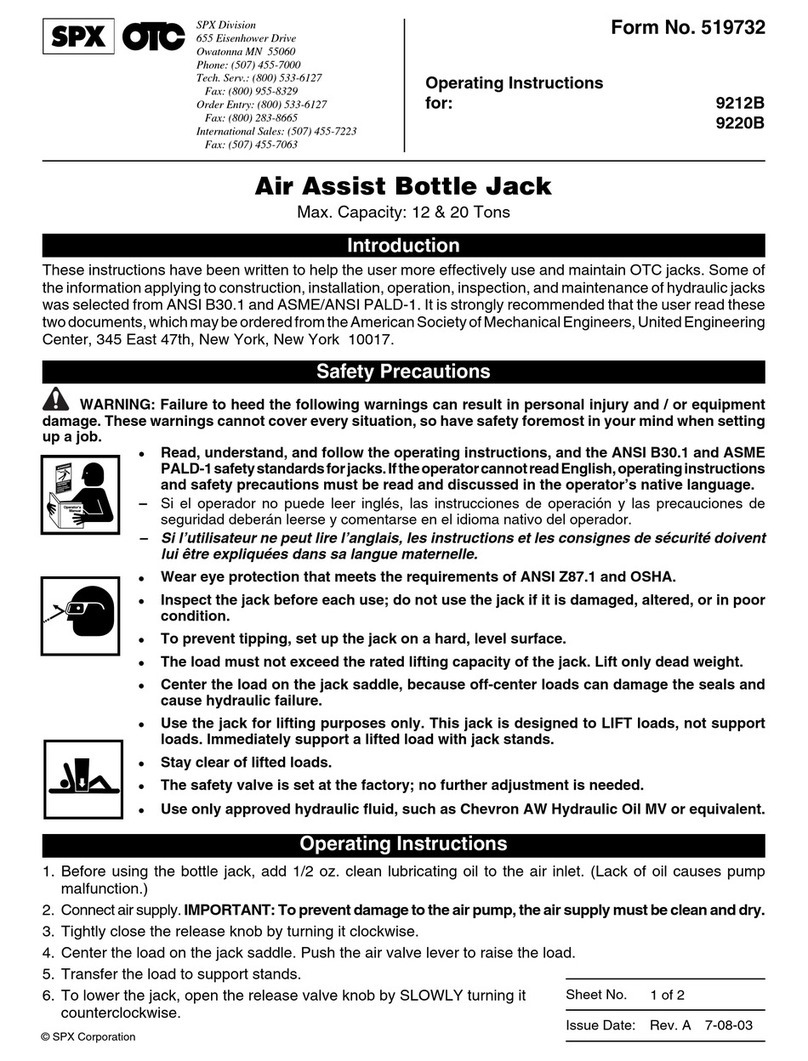

PARTS LIST FOR 5 TON JACK (J55T)

1

2

3

4

5

22

21

36*

35*

20

34

31*

32*

7

6

2

8

927*

15

15

16

16

17

17

33*

18

10

11 12 1314 30

19

26

37*

25

24

23

* = Parts marked with an asterisk (*)

are in Repair Kit No. J55T-28.

Parts List and Operating Instructions Form No. 102947

Sheet No. 4 of 5

Rev. 2 Date: 28 Dec. 1998

Item Part No.

No. No. Req’d Description

1J55T-1 1 Handle

2J55T-2 1 Snap Ring

3J55T-3 1 Handle Socket Assembly

4J55T-4 1 Pump Plunger Pin

5J55T-5 1 Pump Plunger

6J55T-6 1 Pump Stop A

7J55T-7 1 Pump Stay Pin

8J55T-8 1 Pump Base

9J55T-9 1 Pump Stop B

10 J55T-10 1 Safety Valve Ball

11 J55T-11 1 Safety Valve Ball Guide

12 J55T-12 1 Safety Valve Spring

13 J55T-13 1 Safety Valve Adjusting Screw

14 J55T-14 1 Safety Valve Plug

15 J55T-15 2 Valve Plug

16 J55T-16 2 Valve Spring

17 J55T-17 2 Valve Ball

18 J55T-18 1 Release Assembly

19 J55T-19 1 Return Spring

20 J55T-20 1 Ram Guide Ring

21 J55T-21 1 Ram Packing Retainer

22 J55T-22 1 Ram

23 J55T-23 1 Hanger

24 J55T-24 1 Snap Ring

25 J55T-25 1 Stuffing Ring

26 J55T-26 1 Stopper Ring

27 *J55T-27 1 Filler Plug

30 J55T-30 1 Push Nut

31 *J55T-31 1 Pump Backup Ring

32 *J55T-32 1 Pump Packing

33 *J55T-33 1 Release Packing

34 J55T-34 1 Ram Guide Ring Stopper

35 *J55T-35 1 Ram Packing

36 *J55T-36 1 Ram Backup Ring

37 *J55T-37 1 Cylinder Packing

PARTS INCLUDED BUT NOT SHOWN

421687 1 Decal

Part numbers marked with an asterisk (*) are contained in Repair Kit No. J55T-28.

Parts List and Operating Instructions, Form No. 102947, Back sheet 4 of 5

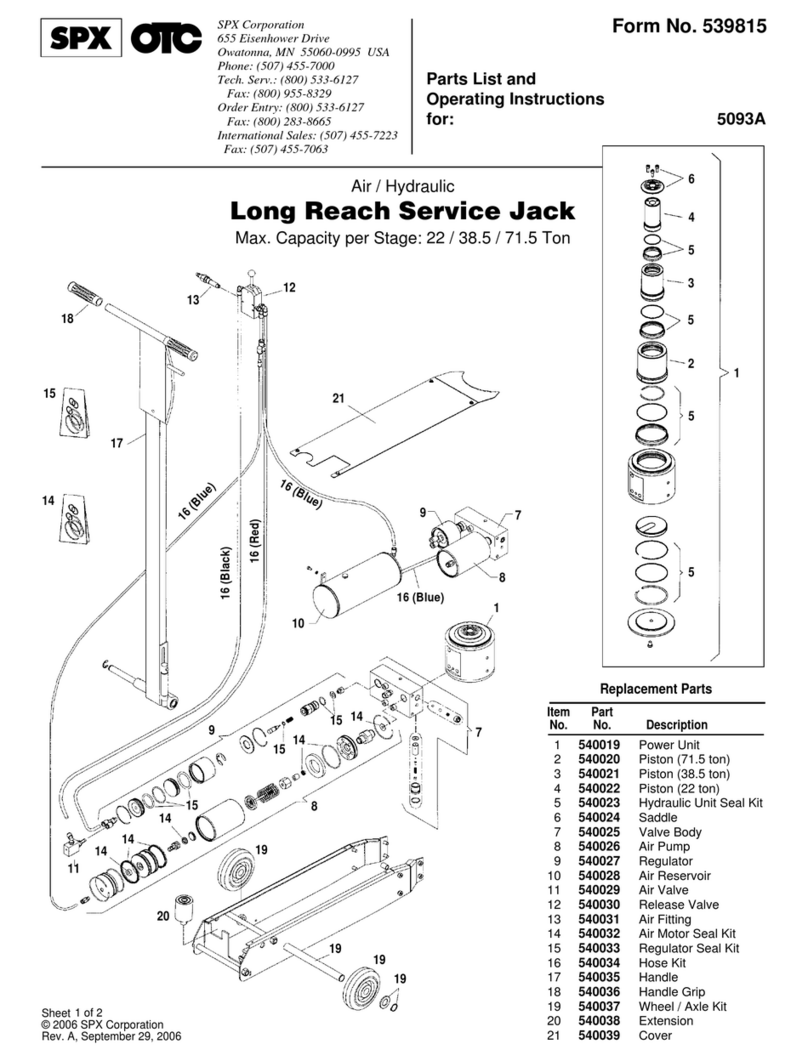

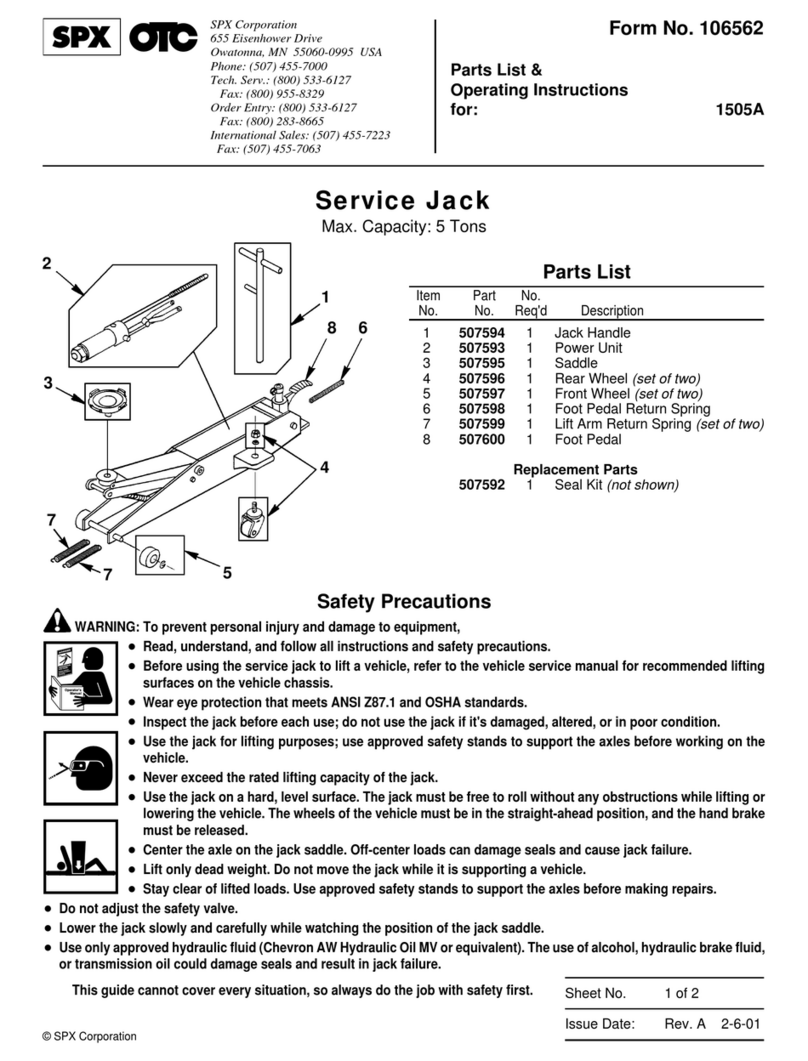

PARTS LIST FOR 10 TON JACK (J106T)

26 25

1

24

39*

38*

23

41

24

3

5

34*

35* 6

7

8

9

2

31*

15

15

16

16

17

17

18

36* 10

11121314 37

19

20

21

17

22

27

28

29

40*

30

* = Parts marked with an asterisk (*)

are in Repair Kit No. J106T-32.

Note: Shaded areas reflect last revision made to this form.

Parts List and Operating Instructions Form No. 102947

Sheet No. 5 of 5

Rev. 2 Date: 28 Dec. 1998

Item Part No.

No. No. Req’d Description

1J106T-1 1 Handle

2J106T-2 1 Snap Ring

3J106T-3 1 Handle Socket Assembly

4J106T-4 1 Pump Plunger Pin

5J106T-5 1 Pump Plunger

6J106T-6 1 Pump Stop A

7J106T-7 1 Pump Stay Pin

8J106T-8 1 Pump Base

9J106T-9 1 Pump Stop B

10 J106T-10 1 Safety Valve Ball

11 J106T-11 1 Safety Valve Ball Guide

12 J106T-12 1 Safety Valve Spring

13 J106T-13 1 Safety Valve Adjusting Screw

14 J106T-14 1 Safety Valve Plug

15 J106T-15 1 Valve Plug

16 J106T-16 1 Valve Spring

17 J106T-17 1 Valve Ball

18 J106T-18 1 Release Assembly

19 J106T-19 1 Return Spring

20 J106T-20 1 Ram Spring Stopper Ring

21 J106T-21 1 Ram Spring

22 J106T-22 1 Vertical Pin

23 J106T-23 1 Ram Guide Ring

24 J106T-24 1 Ram Packing Retainer

25 J106T-25 1 Horizontal Pin

26 J106T-26 1 Ram

27 J106T-27 1 Hanger

28 J106T-28 1 Snap Ring

29 J106T-29 1 Stuffing Ring

30 J106T-30 1 Stopper Ring

31 *J106T-31 1 Filler Plug

34 *J106T-34 1 Pump Backup Ring

35 *J106T-35 1 Pump Packing

36 *J106T-36 1 Release Packing

37 J106T-37 1 Push Nut

38 *J106T-38 1 Ram Packing

39 *J106T-39 1 Ram Backup Ring

40 *J106T-40 1 Cylinder Packing

41 *J106T-41 1 Ram Guide Ring Stopper

PARTS INCLUDED BUT NOT SHOWN

421688 1 Decal

Part numbers marked with an asterisk (*) are contained in Repair Kit No. J106T-32.

This manual suits for next models

2

Table of contents

Other SPX Jack manuals

Popular Jack manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 322261 1901 Operation and safety notes

Clarke

Clarke STRONG-ARM CHDDWD Operation and maintenance instruction

Clarke

Clarke CTJ1800A Operation & maintenance instructions

Sealey

Sealey AS2500 instructions

U-Line

U-Line H-1545 quick start guide

Cattini Oleopneumatica

Cattini Oleopneumatica YAK 312 Operating and maintenance manual

Performance Tool

Performance Tool W1622 owner's manual

Omega Lift Equipment

Omega Lift Equipment 32105B Operating instructions & parts manual

Chicago Pneumatic

Chicago Pneumatic CP80020 Operator's manual

Napa

Napa 791-2230 A Operating manual & parts list

Pro-Lift

Pro-Lift F1650A owner's manual

Clarke

Clarke CTJ2000G manual