Sheet No.

Issue Date: Rev. A 7-08-03

© SPX Corporation

Operating Instructions Form No. 519732, Sheet 2 of 2, back

Preventive Maintenance

IMPORTANT: Dirt is the greatest single cause of failure in hydraulic units. Keep the jack clean and well lubricated

to prevent foreign matter from entering the system. If the jack has been exposed to rain, snow, sand, or grit, it

must be cleaned before it is used.

1. When the jack is not in use, keep the piston and pump rods fully retracted. Store the jack on its base and in a well

protected area where it will not be exposed to corrosive vapors, abrasive dust, or any other harmful elements.

2. Maintain the oil level at the bottom of the filler plug hole. If it’s necessary to add oil, remove the filler plug, and fill the

reservoir with Chevron AW Hydraulic Oil MV or equivalent.

2. Visually inspect the jack before each use. Take corrective action if any of the following problems are found:

a. Cracked or damaged housing e. Incorrectly functioning swivel heads or adj. screw

b. Excessive wear, bending, or other damage f. Loose hardware

c. Leaking hydraulic fluid g. Modified or altered equipment

d. Scored or damaged piston rod

Troubleshooting Guide

Repair procedures must be performed in a dirt-free environment by qualified personnel who are familiar with this

equipment.

Trouble Cause Solution

Erratic Action 1. Air in system

1. With jack sitting on its base and ram

retracted, bleed air by opening release

valve. Pump for 10 seconds.

2. Viscosity of oil too high

2. Change to a lower viscosity oil.

3. Ram sticking or binding

3. Look for dirt, gummy deposits, leaks,

misalignment, worn parts, or defective

packing.

4. Internal leakage in ram

4. Replace worn packings. Look for

excessive contamination or wear.

Ram does not advance 1. Release valve is open

1. Close release valve.

2. Low/no oil in reservoir

2. Fill with oil & bleed system.

3. Air locked system

3. With jack sitting on its base and ram

retracted, bleed air by opening release

valve, running pump for 10 seconds.

4. Load is above capacity of system

4. Use correct equipment.

Ram only extends partially 1. Low oil level in reservoir

1. Fill reservoir with oil, & bleed system.

2. Piston rod is binding

2. Look for dirt, gummy deposits, leaks,

misalignment, worn parts, or defective

packing.

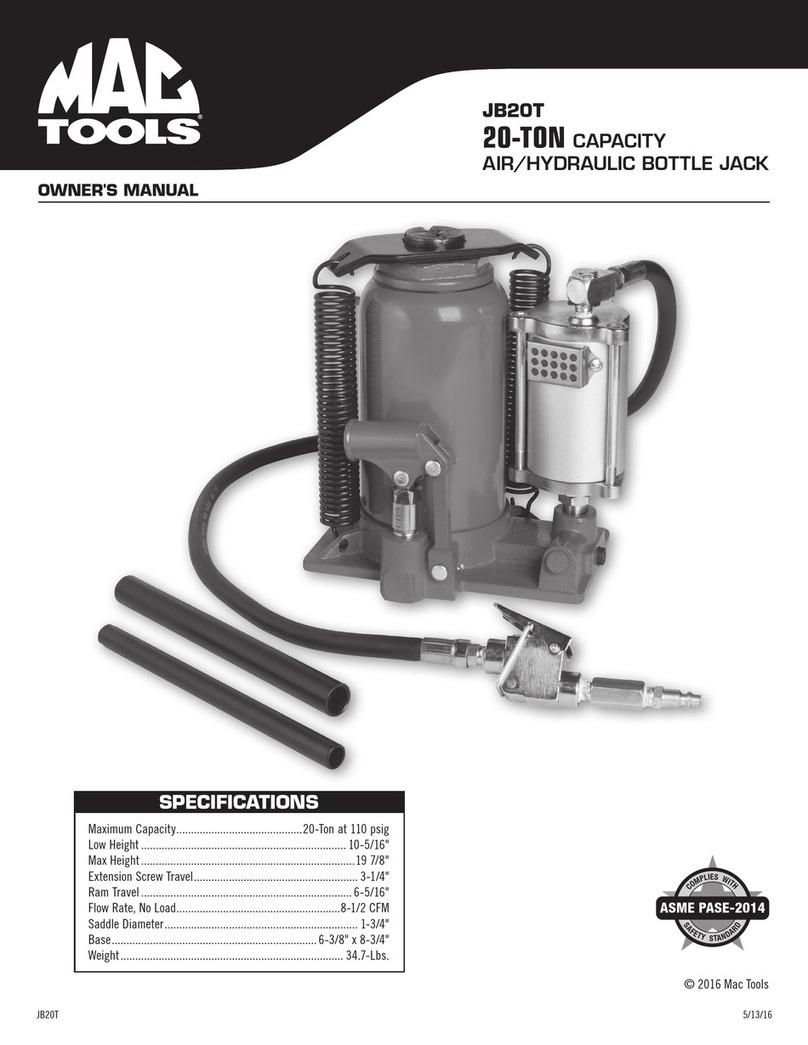

Ram advances slowly 1. Low air pressure

1. Adjust air pressure to 90–180 psi.

2. Pump not working correctly

2. Rework pump.

3. Leaking seals

3. Replace seals.

Ram advances but doesn’t1. Release valve is open

1. Close release valve.

hold pressure 2. Ram seals are leaking

2. Replace seals.

3. Pump check valve not working

3. Clean / replace check valve.

4. Overload valve leaking or

4. Replace / adjust overload valve.

not adjusted

Jack leaks oil 1. Worn or damaged seals

1. Replace seals.

Ram will not retract, or 1. Release valve is closed

1. Open release valve.

retracts slowly 2. Reservoir too full

2. Drain oil to correct level.

3. Ram damaged internally

3. Take jack to authorized service

center for repair.

2 of 2