SPY 780 User manual

PIPELINE

INSPECTION

COMPANY

LTD.

Portable Holiday Detectors

OPERATING

INSTRUCTIONS

SPY

®

‚PORTABLE

HOLIDAY DETECTORS

Models 780, 785, & 790

2

Safety Disclaimer

Only trained and responsible personnel should operate high

voltage equipment. Display warning labels prominently prior to and

during testing. Portable holiday detectors are designed to operate

andmaintainanelectriccurrentoutputwellbelow levels whichcould

cause injury. However, you may experience a mild shock if the test

electrode or ground is touched while the equipment is activated.

Wear rubber or plastic gloves and non-conductive footwear to

minimize potential shock. Keep in mind that the shock prevention

effectiveness ofthe rubber orplastic glove and footwear islimited to

the condition of their protective surface. Make sure your gloves and

footwear are void of tears and holes and are in good condition.

Use of Portable Holiday Detectors is limited to finding defects in

insulating materials. Testing should be conducted clear of personnel

not involved in the testing procedure. Personnel operating Portable

HolidayDetectorsshouldbeawareofthesafetylimitationsimposedby

their environment at all times. Operator should have an assistant to

ensurethat unauthorizedpersonnelare kept clear of the testingarea.

Danger: Portable Holiday Detectors create an arc or spark. Use

of a Portable Holiday Detector in or around combustible or

flammable environments can result in an explosion. When operating in

any potentiallyhazardousarea, consultwiththeplant or site safetyoffi-

cer before proceeding with a holiday detection test in any

potentiallyhazardousorsuspectarea.

EMI Disclaimer

WARNING....This is a class A product. In a domestic environment

this product may cause radio interference in which case the user may

berequired totake adequate measures.

NOTE....

Holiday detectors create a spark during their normal course

of operation when a defect in the pipe coating is found.

This spark will cause radio interference. During the device’s passive

or search mode, it qualifies as a class A product.

3

Table of Contents

Safety & EMI Disclaimer .............................. 2

Principles of Operation................................. 4

Differences Between Models......................... 5

Operating Instructions .............................. 6-8

Battery Instructions ..................................... 9

EC Declaration of Conformity...................... 10

Warranty................................................. 11

Warning! This is a HIGH VOLTAGE device capable of

producing an electrical shock if not properly grounded and/or

operated in accordance with instructions and procedures

prescribedinthismanual!

4

Principles of Operation

Metal objects such as pipelines, reinforcing bar (rebar), storage

tanks or structural steel are normally covered with a protective

coating to prevent corrosion. Holiday detectors are used to inspect

these coatings for pin holes, scratches or other coating faults. They

work by generating a voltage high enough to jump a gap that is

longer than the thickness ofthe coating.

The laws of physics determine the required voltage level to

jump a given distance, or gap. Coating type also affects voltage

level requirements.

A holiday detector simply applies a voltage to the outside of the

coating. With the pipe connected to ground and with the holiday

detector connected to ground, a hole in the coating will cause a

spark to jump or “arc” from the electrode to the pipe to complete the

circuit. When a complete circuit is formed, a signal is activated on the

Holiday Detector.

AbriefdescriptionofthestepsnecessarytooperateaSPY®‚Model

780, 785 or 790 holiday detector is presented here with detailed

steps following later in the manual.

To operate the detector,make sure the control switch is in the OFF

position (fully ccw), then install the battery. The battery is keyed so it

can only be installed in one way. Then install the electrode wand on

the front of detector and insert the ground cable into the rear

of detector (inside handle). Ground the pipeline and connect the

electrode, spring or brush. Turn the control knob to the middle posi-

tion (set voltage). This activates the internal Jeepmeter. A pulsing tone

and light warn that this is the “set voltage” mode. Set the voltage to

the required value. Turn the unit on (fully cw). A running tone and

light indicates the detector is operating. Roll the spring toward the

bare metal end of the pipe. When the electrode is sufficiently close,

a spark will jump from the electrode tothe pipe, the running tone and

light will go out, and a loud signal horn will sound to designate a

holiday. Of course it is not a real holiday but it demonstrates what

happens when the electrode encounters a holiday and verifies correct

detector operation.

Differences between 780, 785, & 790

Model 780, 785, and 790 holidaydetectors incorporate new

circuitryallowing the detectors to maintain a selected voltage,

regardless of different pipe diameters, coating thickness variations

and battery wear (unless the battery is totally discharged). Keep in

mind that the voltage the coating actually “sees” will decrease

slightly depending on ground losses and/or conditions.

The model 780 holiday detector is a low voltage (1-5kv) detector

designed specifically for thin film epoxy coating.sThe output voltage of

this detector is normally D.C. (direct current). However, if moisture is

encountered on the pipe, the detector output automatically switches

to a fast pulse. Fast pulse enables continued operation whereas

with older type thin film detectors the operator either had to wait until

the moisture evaporated or the pipe had to be dried.

The model 785 holiday detector is a high voltage (1-15kv)

detector designed to cover a wide range of coatings from thin films to

tapes to extruded or coal tar types of coatings. Since the operating

characteris- ticsof thisdetectorareverybroadit is recommended

thatthinfilm epoxycoatings be inspected with the model 780

detector.

The model 790 holiday detector is a high voltage (5-35kv)

detector designed specifically for tapes, extruded or coal tar types of

coatings, and thicker somatic type coatings.

780•785•790

5

6

Operating Instructions

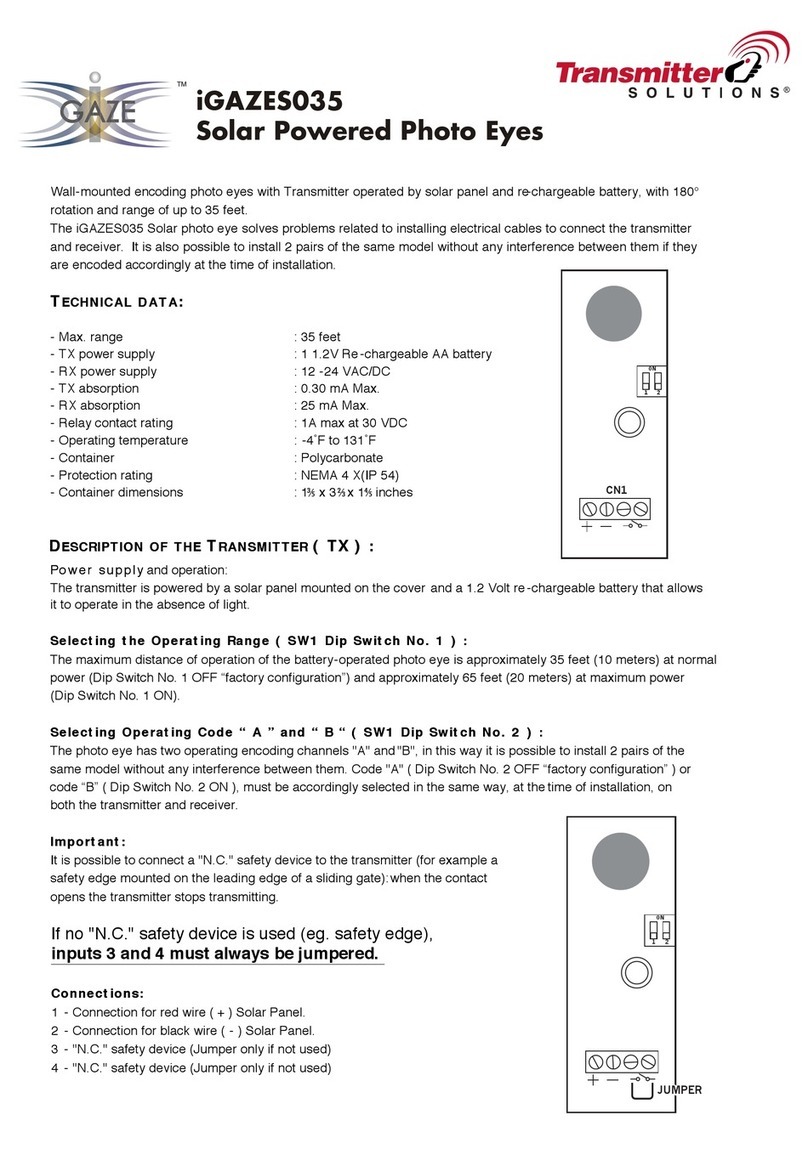

Connecting Accessories

The electrode wand plugs into the “front” of the detector. Push the

wand in until it locks in place. It can be released by pressing the release

(located near the “front” of the unit on the bottom) upwards until the

wandpops out.

The ground cable in plugged into the rear handle. It uses a quarter

turn fastener, so insert the cable as far as possible, then rotate

it at least a quarter turn until it locks in place.

Thebatteryinstallsfromthefront.Notethebatterywillonlyinstallone

way - it is keyed to prevent insertion in an incorrect fashion. One end of

thebatteryis flatandthe otherhasa step.The flatendgoestowardsthe

rear of the unit. Push the battery on until it snaps in place (the spring will

be almost completely compressed when properly installed). To remove

the battery, press the release on the bottom left side of the unit (the release

is orangeto stand out against the black base of thedetector).

Electrode wand

connects here

Ground cable

connects here

Battery Slidesthis

direction to remove

Front

Rear

7

Screwdriverhole

Controls

The control knob has three positions: OFF,VOLTAGESET,and

ON.

In the OFF position all power is off, including the high voltage

output. Turningthe knob clockwise 30 degrees to the VOLTAGE

SET position turns on the high voltage output, blinks the red LED,

pulsesthe run tone, and turns on the display. The voltage displayed

is in kilovolts (thousands of volts.) A screwdriver can be placed

through the hole in the rear of the knob nearest the operator to

change the voltage setting. Turning the screwdriver clockwise will

increase the voltage. In the ON position the voltage adjustment is

not accessible. In this position the unit is in the normal running

mode with the red LED on steady, the run tone steady, and the

display off.

CAUTION!

DO NOT TOUCH bare ground wire when the detector is on.

DO NOT CUT the ground cable to a shorter length.

Carrying Strap

CAUTION! DONOTTOUCHtheelectrode or

groundwirewhiledetectorisoperating.

Shoulder strap connection

Spring or brush

electrode connection

Built in Jeepmeter with digital

readout to verifysetting

Easy carry top handle

Positive groundlight

8 hour battery

Toattachthecarrying strap, first snake

the clip under the handle from the front,

insertthetabinto thetopcenter groove on

the front handle, and then snap the clip

around the front handle. The strap is

clipped between the front handle clip and

the pin in the rear handle at thetop.

Comfortable grip

Ground cable enters here

8

Battery Instructions

General : The SPY® battery is a completely sealed, rechargeable

12 volt unit. It can be used in any position and under

most conditions.

To Charge The Battery :

Slide the charger onto the battery as far as possible. The

charger will have an amber LED on while charging. This

LED will be green when charged. A discharged battery

requires 4-8 hours to fully charge.

There is no danger of overcharging the battery. After

the battery is fully charged, the charger will maintain a

trickle charge to keep the battery at peak charge.

It is recommended that the battery be recharged as soon

aspossible after use.

Donotdisconnectthechargepowercordwhilethebattery

is attached.

Battery Storage:

The battery should be fully charged BEFORE storing.

Storage at temperatures below 75˚F is recommended.

After six months of storage or storage in extremely high

temperatures, the battery should be recharged to maintain

peak efficiency and maximize its lifespan.

This Portable Holiday Detector is an accurate, reliable

instrument which is only warranted if it is properly handled,

maintained and operated as prescribed by Pipeline

Inspection Co., Ltd.

BATTERY REMOVAL:

Press the release (orange part) on

the base plate (black part) and push

the battery away from the rear handle.

9

WARNING! Do not use any other type of charger.

This charger is specially designed for this battery .

Battery Release

10

EC Declaration of Conformity

Manufacturer of Equipment:

PipelineInspectionCo.Ltd.

Authorized Representative in the EC Community:

PipelineInductionHeatLTD

ThePipelineCentreFarringtonRoad

Rossendale Road Industrial Estate

Burnley, Lancashire BB11 5SW

England,UnitedKingdom

Attn: Michael Burnley

Description of Equipment:

Holiday Detectors

Models 780, 785, 790 and accessories

Holiday detectors are devices that are used to detect thepresence of

defects in the non-conductive coatings applied to surfaces in orderto

minimize ion flow from a conductive substrate. This is accomplished by

attemptingto createan electricalcircuitby passingan electrodeoverthe

non-conductive coating. A sufficient voltage is generated in the

electrode to cause a spark that will jump from the electrode to the

substrate if a defect is found. When a defect is found a horn will sound

and a light will turn off.

Specifications: The products mentioned above were submitted as

acommonfamilyastheyutilizecommondesigns,componentsandmeth-

odsofconstruction.Representativetestswereperformedoneachdevice

thatwouldexhibitthe“worstcase”scenarioforapproval.

11

Warranty

Pipeline Inspection Co., Ltd., hereafter referred to as (SPY

®

) warrants

that SPY®‚ Model 780/785/790 Series Holiday Detectors and

Jeepmetersshall,undernormaluseand service,be free fromdefectsin

material and workmanship. SPY®‘s entire warranty obligation shall be

limited to, at SPY®'s option, the repair or replacement free of charge to

thebuyerofanydefectiveequipmentorpartsthereofwhichprovetobe

defectivein materialand workmanshipundernormaluseandservice.

Claims for defective parts must be made in writing within twelve

(12) months after shipment of the equipment from the works of SPY

®

.

Fast wearing and consumable parts including, but not limited to,

electrodes and ground cables, are expressly excluded from the

warranty. SPY® shall have the option to require return of a claimed

defective part to SPY®'s plant in the U.S.A., freight prepaid by buyer

for examination to establish buyer's claim.

ExceptwithSPY®'sprior written approval, SPY® shall notbeliable

(a)forthecostofrepairs,alterationsorreplacementsoranyexpense

connected therewith made or incurred bythe buyer or its designers,

or(b)fordefectsresultingfrom alterationsorrepairsmade byothers

than SPY

®

‚or its approved representatives.

SPY® shall not be liable for damages, including but not limited to

direct, special, indirect or consequential, resulting from the handling,

or use, whether alone or in combination with other products, or any

SPY

®

equipment or third party designed or manufactured equipment,

includingwithoutlimitation,anyloss ordamage sustained orcaused

by the operation and use of the equipment which is improperly

operated or its successful operation is impaired by natural elements

afteritsdeliverytothebuyer.

Theforegoingwarrantyisexclusiveandinlieuofallotherwarranties

whether written, oral or implied (including without limitation, any

warranty of merchantability or fitness for purpose).

printed 10.06

Liberty Sales and Distribution, LLC

2880 Bergey Road, Suite F

Hatfield, PA 19440

Phone: (877) 373-0118

Fax: (888) 850-3787

Email: sales@libertysales.net

Other manuals for 780

1

This manual suits for next models

2

Table of contents

Other SPY Security Sensor manuals