SPY 780 User manual

Spy®

model

780

portable

dc

holiday

detector

o p e r at i n g

instructions

PIPELINE INSPECTION COMPANY

picltd.com

2picltd.com

welcome

Thank you for purchasing the SPY®Model 780 DC Holiday Detector.

Pipeline Inspection Company and our SPY®brand of coating inspection,

jeep meter and pig tracking equipment has been serving companies

all over the world since 1953. With the purchase of this high precision

instrument you can now enjoy access to worldwide service and support

only SPY®and our vast Distributor network can offer.

For more information about SPY®brand equipment please visit our

website at www.picltd.com.

The SPY®Model 780 DC Holiday Detector meets the Electromagnetic

Compatibility Directive and the Low Voltage Directive. This product is a

Class A, Group 1 ISM equipment according to CISPR 11. Group 1 ISM

product: A product in which there is intentionally generated and/or used

conductively coupled radio-frequency energy which is necessary for the

internal functioning of the equipment itself. Class A products are suitable

for use in all establishments other than domestic and those directly

connected to a low voltage power supply network which supplies

buildings used for domestic purpose.

is a registered trademark of Pipeline Inspection Company,

Houston, Texas 77055, United States.

A copy of this Operating Instructions Manual can be downloaded on our

website at www.picltd.com.

picltd.com 3

Table

of

contents

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

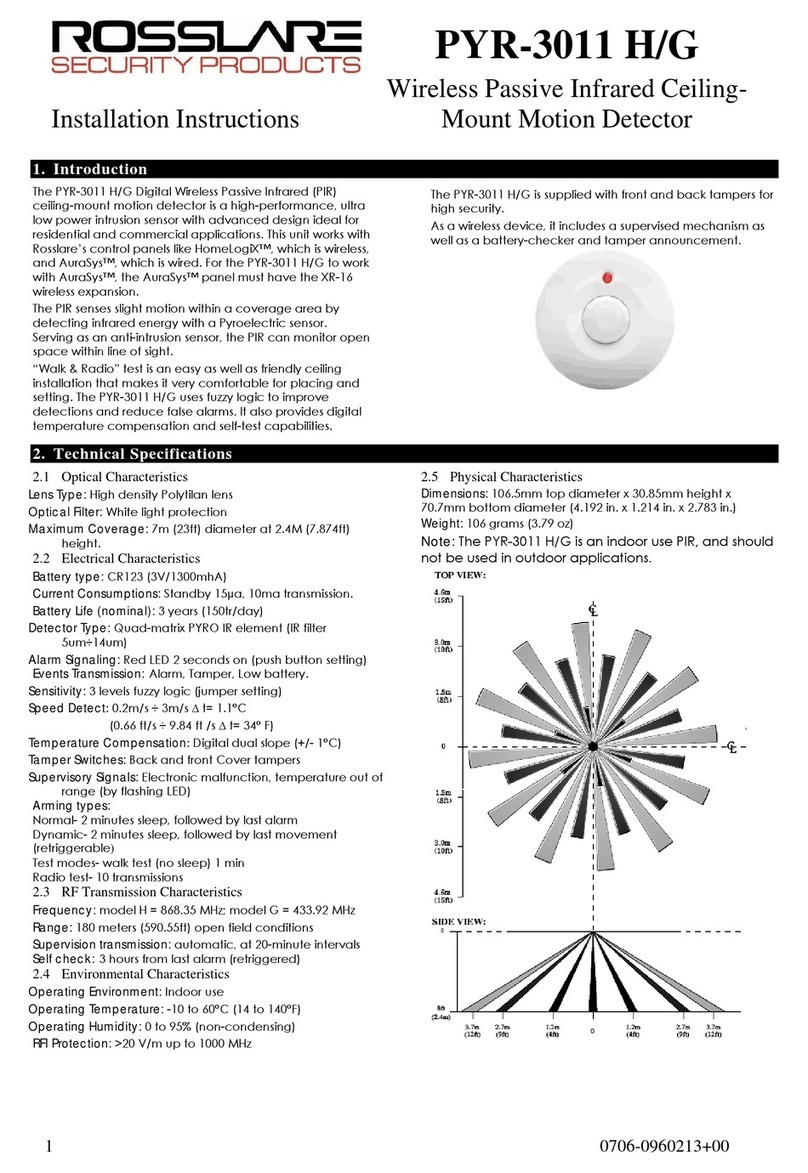

Principles of Holiday Detector Operation . . . . . . . . . . . . . . 7

SPY®Model 780 DC Holiday Detector Overview . . . . . . . . . . 8

Connecting Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls and Voltage Adjustments . . . . . . . . . . . . . . . . . . . 12

DC Paddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Field Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Charging and Storage Instructions . . . . . . . . . . . . . . 16

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . 20

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electrode Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Related Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4picltd.com

operator safety

PLEASE READ THESE INSTRUCTIONS CAREFULLY PRIOR TO

USING THE EQUIPMENT!

WARNING! This is a HIGH VOLTAGE device capable of producing

an electrical shock if not properly grounded and/or operated in accordance with

instructions and procedures prescribed in this manual! If you have a pacemaker

or other life critical electronic medical device DO NOT use this device.

Only trained and responsible personnel should operate high voltage equipment.

Display warning labels prominently prior to and during testing. Portable holiday

detectors are designed to operate and maintain an electric current output well

below levels which could cause injury. However, you may experience a mild shock

if the test electrode or ground is touched while the equipment is activated. Wear

rubber or plastic gloves and non-conductive footwear to minimize potential shock.

Keep in mind that the shock prevention effectiveness of the rubber or plastic glove

and footwear is limited to the condition of their protective surface. Make sure your

gloves and footwear are void of tears and holes and are in good condition.

Use of Portable Holiday Detectors is limited to finding defects in insulating

materials. Testing should be conducted clear of personnel not involved in the

testing procedure. Personnel operating Portable Holiday Detectors should

be aware of the safety limitations imposed by their environment at all times.

Operator should have an assistant to ensure that unauthorized personnel are kept

clear of the testing area.

DANGER! Portable Holiday Detectors create an arc or spark.

Use of a Portable Holiday Detector in or around combustible or flammable

environments can result in an explosion. When operating in any potentially

hazardous area, consult with the plant or site safety officer before proceeding

with a holiday detection test in any potentially hazardous or suspect area.

DANGER! If you have a pacemaker DO NOT use this device.

picltd.com 5

DO NOT CUT the ground cable to a shorter length.

CAUTION! DO NOT TOUCH the bare ground wire when the detector

is turned on.

WARNING! DO NOT USE WHEN RAINING. If it is raining then

there is a safety concern for the operator. Pure water is non-conductive, but

almost any contaminant will cause water to become conductive (dust in the air,

salt from an operator’s hands). If this conductive water covers the wand (black

plastic part of the detector where the electrode is attached) and the orange case

then the operator will become the return path for the high voltage. While this is

NOT LETHAL, it does hurt. Also the unit may become damaged.

If it isn’t raining, but the coating surface is wet, the problem becomes one

of accurately locating the coating defect (holiday). Again, the water will conduct

the electricity and you may get false holiday indications many feet from the actual

holiday(s). In this case it is recommended that you dry the testing area prior to

inspection.

CAUTION! DON’T USE AROUND SENSITIVE ELECTRONICS

OR RADIO EQUIPMENT. When in standby the SPY®Model 780 DC Holiday

Detector will generate radio frequency emissions which are within the limit

defined by the Electromagnetic Compatibility Directive. Due to its method of

operation however, the SPY®Model 780 DC Holiday Detector will generate

broadband RF emissions when the unit is generating high voltage or when a

spark is produced at the electrode. It is therefore recommended that the user

does not activate the high voltage within the vicinity of sensitive electronics or

radio equipment.

ELECTRODES/ACCESSORIES: It is imperative for the accurate operation of

unit that electrodes (Spring & Brush) and accessory attachments (Spring & Brush

Wands & Ground Cable) be kept clean and free of dirt and debris. Please clean

with a damp cloth before storing them for future use.

6picltd.com

unit

calibration

As the operator of this unit you require accurate, safe, and reliable

equipment to perform coating inspections at the proper output voltage.

Prior to leaving our manufacturing facility Pipeline Inspection Co. certifies

that SPY®Model 780 Holiday Detector has been calibrated and demonstrates

the output voltage, which appears on the display of the detector within +/-

5% of indicated setting over the range of 1000 - 5000 volts. Since output

voltage is regulated, this tolerance is maintained regardless of load.

Your unit comes with a Factory Calibration Certificate and a

Factory Authorized Calibration Decal applied to the side of the unit

both with the date your unit was calibrated.

Our units do not tend to drift but it is recommended that this unit be

calibrated at least once per year or more frequently based on heavy

usage. Recalibration of our equipment should be performed ONLY

at a SPY®Authorized Service Center due to the unique calibration

process; test equipment utilized and properly trained SPY®

technicians.

We DO NOT recommend using any other calibration service other

than a SPY®Authorized Service Center; using an outside service with

technicians not trained to work on SPY®brand equipment could damage

the unit and if the enclosure is opened will void the warranty.

When calibration is needed please return your unit to a SPY®Authorized

Service Center or SPY®manufacturing facility located at:

Pipeline Inspection Company

Attn: Calibration

1919 Antoine Dr.

Houston, TX 77055

Please include: Company Name and Contact info. For a complete

list of Authorized Service Centers please visit our website at

www.picltd.com. If a copy of the Calibration Certificate on file is

needed it may be obtained by emailing a request to sales@picltd.com.

picltd.com 7

principles of holiday

detector operation

Holiday detectors are devices that are used to detect the presence of

defects in the non-conductive coatings applied to surfaces in order to

minimize ion flow from a conductive substrate. This is accomplished

by attempting to create an electrical circuit by passing an electrode

over the non-conductive coating. A sufficient voltage is generated in

the electrode to cause a spark that will jump from the electrode to the

substrate if a defect is found. When a defect is found a horn will sound

and a LED light will turn off.

Metal objects such as pipelines, reinforcing bar (rebar), storage tanks

or structural steel are normally covered with a protective coating to

prevent corrosion. Holiday detectors are used to inspect these coatings

for pin holes, scratches or other coating faults. They work by generating

a voltage high enough to jump a gap that is longer than the thickness of

the coating.

The laws of physics determine the required voltage level to jump a given

distance, or gap. Coating type also affects voltage level requirements.

Environmental Conditions such as humidity, temperature, and other

environmental factors will also affect voltage required to jump a given

distance.

A holiday detector simply applies a voltage to the outside of the coating.

With the pipe connected to ground and with the holiday detector

connected to ground, a hole in the coating will allow a spark to jump

or “arc” from the electrode to the pipe to complete the circuit. When a

complete circuit is formed, an audible and visual signal is activated on

the holiday detector.

8picltd.com

spy®model 780 dc holiday

detector overview

The Model 780 DC Holiday Detector is a low voltage (1-5kv) detector

designed specifically for thin film epoxy coatings. The output voltage of

this detector is normally D.C. (direct current). However, if light moisture

is encountered on the pipe, the detector output starts to fast pulse. Fast

pulse enables continued operation whereas with older type thin film

detectors the operator either had to wait until the moisture evaporated

or the pipe had to be dried.

The Model 780 DC Holiday Detector incorporates circuitry allowing the

detectors to maintain a selected voltage, regardless of different pipe

diameters, coating thickness variations and battery wear (unless the

battery is totally discharged). Keep in mind that the voltage can decrease

slightly depending on ground losses and/or conditions.

picltd.com 9

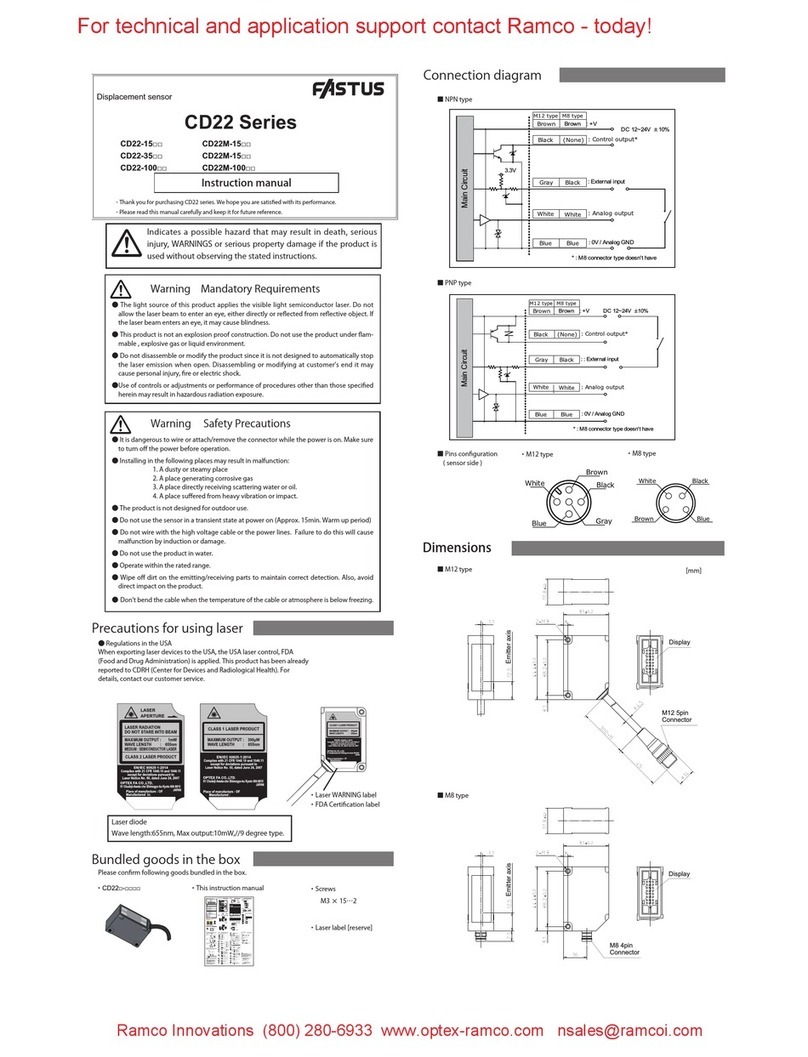

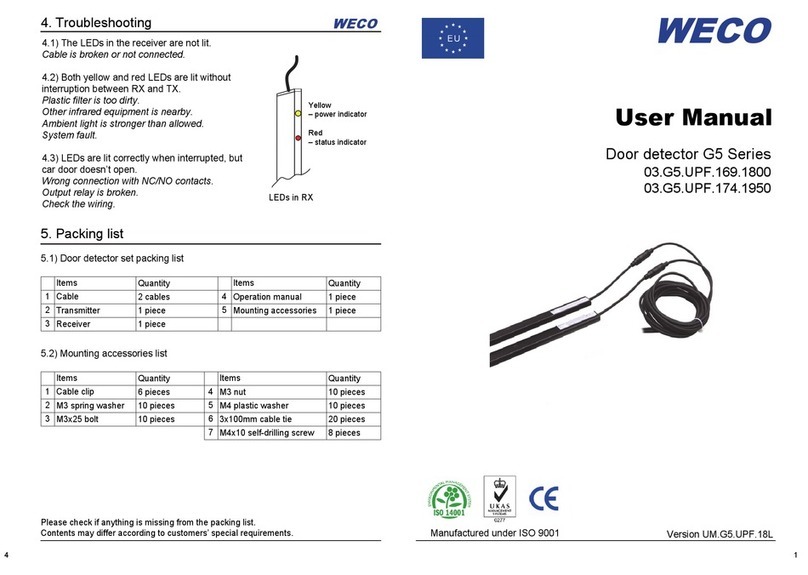

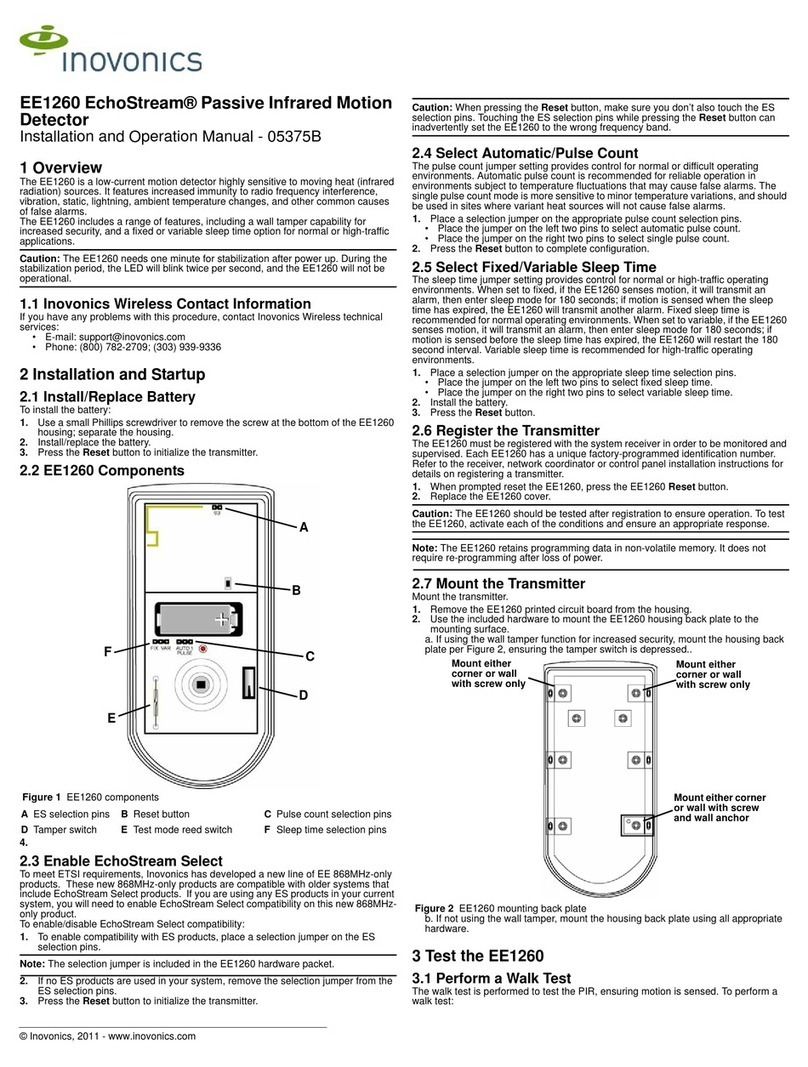

1 Spring or Brush Electrode

2 Electrode Accessory

Connection Point

3 Electrode Wand

4 Wand Release

5 Easy Carry Top Handle

6 Shoulder Strap Connection

7 Built In Digital LCD Jeepmeter

(Voltage meter)

8 Control Knob (3 positions:

Off / Voltage Set / On)

9 Voltage Set Access Hole

10 Comfort Grip

11 Ground Cable Connection Point

12 8 Hour Battery

13 Quick Release Battery Button

14 Horn

15 Model & Serial Number

10

11

12

4

3

13

14

78

9

5

15

6

6

2

1

10 picltd.com

connecting accessories

CAUTION! DO NOT TOUCH Make sure the switch is in the OFF position

prior to connecting any accessory.

STEP 1. CONNECTING THE ELECTRODE WAND. Plug into “front” of

the detector. Push the wand in until it locks in place. It can be released by

pressing the release (located near the front / bottom of the unit) upwards until

the wand pops out.

STEP 2. CONNECTING THE ELECTRODES. Connect the electrode to the

wand. The wand comes with the spring adapter attached to the wand. If spring

or full circle brush electrode attach to pipe.

CAUTION! DO NOT TOUCH THE ELECTRODE WHILE THE DETECTOR

IS OPERATING.

Battery

Control Knob

Shoulder Strap

Electrode Wand

Caution! - High Voltage

Cuidado! - Voltaje Alto

1 2 3

Clip Installation

1

4

5

3

picltd.com 11

OPTIONAL: BRUSH ADAPTER KIT. The Model 780 Kit comes with a

brush adapter kit for use in connecting flat brush/neoprene electrodes, half

circle electrodes and full circle electrodes.

STEP 3. CONNECTING THE GROUND CABLE. The ground cable plugs

into the bottom side of the rear handle. It uses a quarter turn fastener, so insert

the cable as far as possible, and then rotate it at least a quarter clockwise turn

until it locks in place.

DIAGRAM 1

TO JEEP PIPE ON SKIDS OR WHEN HANGING FROM PIPE SLINGS –

GROUND DIRECTLY TO THE PIPE CUTBACK

EXTEND GROUND CABLE TO PIPE

PROPER GROUNDING. Make sure the ground cable is uncoiled and

extended.

DIAGRAM 1: Shows the method when the pipe is on wood skids or hanging

from pipe slings; attach the holiday detector ground cable directly to the

uncoated substrate (pipe cutback) with a clamp to complete the circuit.

CAUTION! DO NOT TOUCH THE GROUND CABLE WHILE DETECTOR

IS OPERATING.

12 picltd.com

STEP 4. CONNECTING THE CLIP \ SHOULDER STRAP. First attach strap

clip on the black handle by placing the tab portion of the strap clip into the top

groove on the back side of the handle that faces the unit display. Then push up

on the bottom of the strap clip in the direction of the opposite side of the black

handle until the strap clip snaps into place around the black handle. Next attach

the shoulder strap to the front handle clip and the pin on top of the rear handle.

The front clip can slide to the left or right on the handle to allow hand placement

while using the detector.

STEP 5. BATTERY. The battery will only install one way (from the front side).

It is keyed to prevent insertion in an incorrect fashion. One end of the battery

is flat and the other has a step. The flat end goes towards the rear of the unit.

Push the battery on until it snaps in place (the spring will be almost completely

compressed when properly installed). To remove the battery, press the orange

release on the bottom left side of the unit. Newer batteries can be a bit resistant

when trying to remove the battery because of the newness of the battery and

the tight fit on the slide path; if so give a gentle tap with your palm on the battery

in the direction of removal.

DIAGRAM 2: Shows the method of attaching a grounding cable from a

grounding rod (earth ground) to the pipe cutback (substrate). Next attach the

holiday detector ground cable to the second grounding rod (earth ground) to

complete the circuit.

CUSTOM LENGTH GROUND CABLES AVAILABLE FROM SPY®

DIAGRAM 2

USE A GROUND ROD WITH A GROUNDING CABLE CLAMPED TO THE PIPE

CUTBACK WHILE HOLIDAY DETECTOR GROUND CABLE IS ALSO CONNECTED TO

A SEPARATE GROUNDING ROD

DETECTOR

GROUND CABLE

GROUND ROD

picltd.com 13

controls and

voltage adjustments

The control knob has three positions: OFF, VOLTAGE SET, and ON. In the

OFF position all power is off, including the high voltage output.

POWER ON

RIGHT

POWER OFF

LEFT

STEP 6. SETTING THE VOLTAGE OUTPUT. Turn the knob clockwise

to the middle position (voltage set) this turns on the high voltage output and

activates the internal Jeepmeter (voltage meter), the LCD display turns on,

the red LED light will blink and the horn tone will pulse on and off.

Using the SPY®provided flathead screwdriver place the flat screwdriver

head through the hole on the bottom side of the knob to change the voltage

setting, the voltage (shown on display) is in kilovolts (thousands of volts.).

Turning the screwdriver clockwise will increase the voltage and counter

clockwise will decrease the voltage.

NOTE: Voltage setting can only be viewed in the middle set position.

This is to prevent confusion during detection of holidays as the voltage will

drop when the unit discharges to substrate. Static electricity on protective

coatings can be picked up and can cause fluctuations in Voltage reading.

VOLTAGE SE T

MIDDLE

14 picltd.com

STEP 7. TURNING ON UNIT FOR HOLIDAY DETECTION. Turn the

unit clockwise to the ON position. In this position the unit is in the normal

running mode with the red LED on steady, the horn tone will be steady, and

the display will turn off.

DISPLAY IN "VOLTAGE SET" ONLY

KILOVOLTS

VOLTAGE

SET

ONOFF

PIPELINE INSPECTION CO., LTD.

CHARGE BATTERY AFTER EACH USE

KEEP ELECTRODES FREE OF TAR

DO NOT CUT OR KINK GROUND CABLE

PIPE SHOULD BE GROUNDED TO EARCH

DON'T TOUCH ELECTRODE WITH UNIT ON

Voltage Adjustment Hole

Power ON LED

picltd.com 15

dc

paddle

The Model 780 DC Holiday Detector comes with a DC Paddle to assist in

the location of Holidays (defects in the coating). Due to the low voltage

of the Model 780 DC Holiday Detector the spark that jumps the gap

from the electrode to the substrate when a holiday (defect in the coating)

is found can sometimes be hard to see as opposed to using a higher

voltage detector which produces a larger brighter spark. The DC Paddle

acts as an extension of the spring electrode giving the user a wider path

to test areas the user suspects are producing the holiday but can’t see

during standard detecting travel speed.

Immediately after holiday detector indicates a fault, roll spring electrode

back approximately 2-3 inches. Place the edge of the conductive

rubber paddle against the spring and wipe the paddle around the entire

circumference of the pipe until detector signal activates indicating the

exact location of the coating flaw.

PIPE

16 picltd.com

field

calibration

instructions

Prior to each use of the Model 780 DC Holiday Detector it is important to

perform a Field Calibration to verify that the required voltage setting for the

coating thickness will accurately detect defects (Holidays) in the coating.

There are two methods to performing a Field Calibration:

METHOD 1: ADDING TEST DEFECTS TO THE COATING.

1. Prior to turning on and setting the voltage on the detector manually add one

pinhole size defect on the coating surface, make sure the defect goes down

to the substrate (bare metal).

2. Set the voltage on the detector to the minimum voltage based on the

coating thickness 525 x sqrt (mils) and using the spring or brush electrode

travel over the test defects.

3. If you see the spark jump the gap from the electrode to the substrate in the

defect and the horn on the detector changes from a running tone to a loud

signal horn and the light on the display turns off then you have successfully

detected defects (holidays) in the coating and verified the detector operation.

4. If your test does not successfully detect the test defect then increase the

voltage by 10% and test again. If test fails again continue increasing by 10%

until test is successful.

METHOD 2: USING THE BARE METAL END OF THE TEST SURFACE.

1. Roll the spring or brush electrode toward the bare metal end of the pipe. When

the electrode is sufficiently close to the bare metal, a spark will jump from the

electrode to the pipe, the running tone will change to a loud signal horn will

sound and the light on the detector display will go out to designate a holiday.

Of course it is not a real holiday but it demonstrates what happens when the

electrode encounters a holiday and verifies correct detector operation.

2. If your test does not successfully detect the test defects then first verify the

voltage setting is accurate for the surface coating.

picltd.com 17

Quick Release

Battery Button

The SPY®battery is a completely sealed, rechargeable 12 volt unit. It can

be used in any position and under most conditions. Batteries are shipped

fully charged however prior to use we recommend you place them on

the charger to verify charge level is full.

BATTERY REMOVAL. Press the release (orange part) on the base

plate (black part) and push the battery away from the rear handle. Newer

batteries can be a bit resistant when trying to remove the battery because

of the newness of the battery and the tight fit on the slide path; if so give

a gentle tap with your palm on the battery in the direction of removal.

battery

charging

and

storage

instructions

CAUTION! Make sure the switch is in the OFF position prior to

removing the battery.

Battery

Caution! - High Voltage

Cuidado! - Voltaje Alto

18 picltd.com

CHARGING THE BATTERY. Slide the charger onto

the battery as far as possible. A discharged battery

requires 8-20 hours to fully charge.

There is no danger of overcharging the battery. After

the battery is fully charged, the charger will maintain a

trickle charge to keep the battery at peak charge.

It is recommended that the battery be charged for 8

hours after each use. After heavy usage charge the battery for 20 hours.

Do not disconnect the charge power cord while the battery is attached.

BATTERY STORAGE. The battery should be fully charged BEFORE

storing. Storage at temperatures below 75˚F is recommended. After

six months of storage or storage in extremely high temperatures, the

battery should be recharged to maintain peak efficiency and maximize

its life span.

IMPORTANT! Contacts on the battery, charger and the detector must

be kept clean and bright to assure good connection!

WARNING! Do not use any other type of charger. This charger

is specifically designed for this battery.

BATTERY DISPOSAL. The battery pack is a sealed non-

replaceable lead acid battery, when the battery pack is no

longer good it must be recycled.

Battery

Charger

picltd.com 19

TROUBLESHOOTING GUIDE CONTINUED ON THE NEXT PAGE...

troubleshooting

guide

PROBLEM POSSIBLE SOLUTION CORRECTION METHOD

HOLIDAY

DETECTOR

WILL NOT

DETECT

HOLIDAYS

Field Calibration Perform a field calibration to compensate

for environmental factors (see page 16). Use

NACE equation to set min voltage. Travel over

known holiday. Turn up voltage and repeat

until holiday is detected. (Note: Max voltage

is determined by the coating manufacture,

typical values for new coating range from 400

to 1000 Volts/mil).

Detection Testing Touch electrode/wand directly to bare ground

cable to test that the unit is functioning

properly. A spark will appear and the horn

will sound if switch is in the “ON” position.

If it does not detect then ensure ground cable

and electrode wand are correctly inserted

using steps 4 and 5 above.

If unit still fails to detect a direct short repair

may be needed, Call Pipeline Inspection

Company for support.

Minimum Voltage

Setting

Follow NACE standard SP0490-2007:

Section 3.

Check Detector Ground

Connection

With the detector OFF remove the ground

cable and fully reinsert it twisting 90 degree

until locked. Ensure the opposite end is clean

and well connected to the pipe or earth

ground.

Check Electrode/Wand

Connection

With the detector OFF remove the wand and

fully reinsert until it locks into place. Ensure

wand and electrode connection points are clean.

20 picltd.com

troubleshooting

guide

PROBLEM POSSIBLE SOLUTION CORRECTION METHOD

HOLIDAY

DETECTOR

WILL NOT

DETECT

HOLIDAYS

Check Ground

Connections

If pipe is connected to an earth grounding rod

and the ground cable from the holiday detector

is dragging the ground make sure all connections

are clean (free of debris) and secure.

If ground cable from the holiday detector

is directly connected to the pipe cutback

(substrate) make sure all connections are

clean (free of debris) and secure.

If the ground cable from the holiday detector

and the earth grounding rod are both connected

to a grounding collar make sure all connections

are clean (free of debris) and secure.

Adjust Travel Speed Travel speed is important on Pulse units

and must not be too fast or holidays could

be missed. Follow NACE standard SP0274-

2011 section 6.3: Make or find a holiday and

attempt to detect at various speeds until

reliable detection is obtained.

HOLIDAY

DETECTOR

TURNS OFF

WHILE IN-USE

Charge/Replace Battery The detector will automatically power down

if the battery voltage drops below the

required level. Ensure that the battery has

been fully charged before use.

Use a second battery that is charged and see

if the detector still turns off.

Test Battery Additional testing may be needed conducted on

the battery, see Battery Troubleshooting below.

THE DETECTOR

VOLTAGE

NEEDS TO BE

VERIFIED

Use SPY JM or DCPJM Do not use a regular multimeter as they will

get damaged and are not rated for over 1,000

Volts. The SPY JM is rated for 7,000 Volts DC

and 40,000 Volts Peak (crescent) on pulse. The

SPY DCPJM can measure up to 5,000 Volts DC.

Other manuals for 780

1

Table of contents

Other SPY Security Sensor manuals

Popular Security Sensor manuals by other brands

Inovonics

Inovonics EE1260 EchoStream Installation and operation manual

elobau

elobau 153 Series Translation of the original operating instructions

EMX Industries

EMX Industries ULT-V2 instruction manual

Werner

Werner 79208 User instructions

Coral

Coral MANTA user guide

Rosslare

Rosslare PYR-3011 H/G installation instructions