Squarell Technology FLEX User manual

FLEX

Development kit

because you want to know

User Manual

because you want to knowwww.squarell.com

Version Description Date

120313 Initial creation 13- 03-2012

120727 Minor changes 27-07-2012

120803 Minor changes 03 - 08-2012

140624 Squarell Support Portal added to chapter 9 24- 06-2014

14 0 811 Fully improved version 11- 0 8 -2 014

14 0 911 New design and improved content 11-09-2014

Copyright © 2015 Squarell bv, the Netherlands

Under international copyright laws, neither the documentation nor the software may be copied, photocopied, reproduced, translated or reduced to

any electronic medium or machine-readable from , in whole or in part, without the prior written permission of Squarell bv, the Netherlands, except in

the manner described in the software agreement. iConfigure is a trademark of Squarell bv in the Netherlands.

Microsoft, MS-DOS, Windows, Windows NT, Windows 95, Windows 98, Windows ME, Windows 2000, SQL Server, FoxPro, Excel, Access and

MS Query are trademarks of Microsoft Corporation.

Although care has been taken in preparing the information contained in this document, Squarell bv does not and cannot guarantee the accuracy

thereof. Anyone using the information does so at their own risk and shall be deemed to indemnify Squarell bv from any and all injury or damage

arising from such use.

All rights reserved by Squarell bv.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Introduction......................................................................................................3

1.1 About the FLEX Development Kit ................................................................................................ 3

1.2 Kit Contents ............................................................................................................................. 4

CANbus basics..................................................................................................5

Making an on desk simulation.......................................................................8

3.1 Preparation.............................................................................................................................. 8

3.2 Hardware setup....................................................................................................................... 8

3.3 Start the second FLEX “2” as interface to the telematics unit / PC ................................................. 9

3.4 Monitor the RS232 output of the Flex with iCheck ......................................................................10

3.5 Monitor the RS232 output of the FLEX with Docklight..................................................................12

Make scan file from vehicle CANbus or test device.................................15

4.1 Hardware setup ......................................................................................................................15

4.2 In vehicle setup with wired connection ......................................................................................15

4.3 Record a CANbus scan with iUpload .......................................................................................16

J1708 signals...................................................................................................18

5.1 Hardware setup wired.............................................................................................................18

5.2 Read data from J1708 bus.......................................................................................................18

5.3 Hardware setup DatacliQ........................................................................................................19

K-Line signals wired ......................................................................................20

6.1 Hardware setup ..................................................................................................................... 20

What to do next? ............................................................................................21

CANbus Termination.....................................................................................22

Abbreviations and Terminology..................................................................23

Technical Support..........................................................................................24

because you want to knowwww.squarell.com

Content

Appendix ...............................................................................................................25

1. Introduction

Thank you for purchasing the FLEX Development Kit.

We are confident that the FLEX development kit provides the means to create powerful vehicle data solutions

based on CANbus, J1708 and K-line.

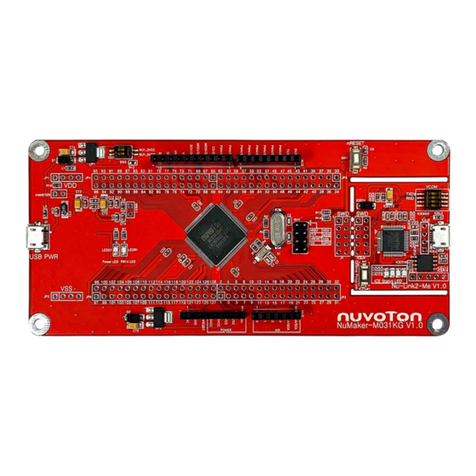

1.1 About the FLEX Development Kit

The FLEX Development Kit is a total solution to start using FLEX in trucks, vans and cars equipped with a CANbus.

With this kit you are able to:

• Make an on desk simulation for a driving truck

• Make CANbus scans from vehicles

• Replay CANbus scans in your on desk simulation

• Load new software into the Squarell FLEX device

• Install the FLEX in a truck connected to your telematics solution

This manual describes how to:

• Set up a working environment with software and hardware

• Learn how to do the basic tasks like monitoring and simulation of the vehicle data network

If you have any questions or need additional information, please do not hesitate to contact us

via our support portal or via your account manager.

After using this kit set up, both Flex devices can be reused in any supported vehicle.

because you want to knowwww.squarell.com

3

1.2 Kit Contents

because you want to knowwww.squarell.com

Quantity Product Product Name

2FLEX12 FLEX device

1 x FLEX loaded with SQU-FLX12-TDK.DCF

1 x FLEX loaded with SQU-8000-TRKS-000000.DCF

18510-280 J1708 DatacliQ cable

1 USB to RS232 USB cable with a RS232 connector

1Combined cable Consists of 8612-U1, 8612-CQ and Power supply

2CANcliQ cover

1DatacliQ cover

Software

iUpload Downloadable from support.squarell.com

iCheck Downloadable from support.squarell.com

Docklight (evaluation version) Downloadable from support.squarell.com

Expertview www.expertview.live.com

Other downloads

FLEX user manual Downloadable from support.squarell.com

iCheck user manual Downloadable from support.squarell.com

iUpload user manual Downloadable from support.squarell.com

Squarell RS232 protocol Downloadable from support.squarell.com

4

because you want to knowwww.squarell.com

5

2. CANbus basics

In the next chapters we discuss how to:

• Create a desk simulation of a vehicle

• Create a desk simulation for vehicle data reading

• Understand the RS232 output

• Check the output via iCheck tool

• Understand the CAN output check the output via iUpload tool

Please read the following instruction guidelines before starting the installation procedure:

CANbus

CANbus is a data network for the vehicle.

It reads technical data like:

Engine speed, fuel consumption, Torque, pedal position, PTO, Retarder, ABS, Cruise, Temperature.

All the Euro3-4-5-6 truck models have CANbus.

[and other vehicles, vans, cars, machines, trains, ships, airplanes]

Termination

Termination resistance avoids reflections of the CANbus signal. A proper CANbus needs to have a 120 termination on

both ends of the CANbus. Missing a terminator or a terminator in the wrong place can cause errors on the CANbus.

Without termination With termination

(in red circle effect of missing terminator)

CANbus

Electronic

diesel

controler

Ground

ABS/EBS

brake

systems

Automatic

gearshift

Retarder PTO

Terminator

120 Ohm

Terminator

120 Ohm

Firmware

The FLEX firmware handles the communication between the hardware and the software (DCF) loaded in the device.

Squarell recommends to always use the latest firmware version (announced on support.squarell.com) to benefit from the

latest developments and bug fixes. A new firmware version can be loaded using Squarell iUpload. A new device is

always loaded with the latest firmware version available.

DCF

DCF is a Device Configuration File (software). It programs the device how to handle the incoming and outgoing data.

The two software files (DCFs), pre loaded on the TDK devices, are used for the following purposes:

TRUCK SIMULATION DCF (SQU-FLX12-TDK.DCF, loaded on device number 1)

This DCF sends random data over the J1708, K-line and CANbus1.

With this data, tests can be performed to capture vehicle data, monitor and record FLEX messages.

FLEX DCF for Trucks (SQU-8000-TRKS-000000.DCF, loaded on device number 2)

These DCFs are DCFs with RS232 and CANbus output.

The input is via the CANcliQ or direct hardwire into the vehicle CANbus.

CANcliQ

The Squarell CANcliQ reads vehicle signals without making a wire-to -wire connection. This technology guarantees

that non intrusive signals are sent to the vehicle CANbus. This eliminates liability matters, warranty issues or possible

wrong connections.

Benefits

• No direct CANbus connection

• One cable fits all vehicles

• 100% non intrusive technology

• Safe and reliable reading of CANbus data

• No soldering, wire cutting or crimping

• No physical wire to wire connections

• Isolation of vehicle wires stays intact

• Quick installation

• No warranty and liability issues

The CANcliQ is standard on all our interface modules.

because you want to knowwww.squarell.com

6

DATAcliQ

With the DATAcliQ, we can retrieve data from several sources continuing to offer better and more complete vehicle

data solutions. While we ensure that retrieving vehicle data is non intrusive and safe, we offer a more complete and

richer user experience.

At this moment Squarell has DATAcliQ’s available to read CANbus, J1708 or ISO11992.

Output RS232/CAN protocol

All Squarell devices are configured to send output data via RS232 and CAN. The output of every standard Squarell DCF

is conform the respective protocol. The advantage of the RS232 output is that we have set the most important vehicle

parameters in standard data strings. Based on these parameters, you can develop reports for advanced vehicle and

driver behaviour. The integration is easy as many modems or tracking units can transmit the data immediately.

The advantage of the CANbus output is that the device is a real replacement for the vehicle’s FMS interface. The FMS in-

terface is used as a safe connection between the vehicle’s CANbus and a modem or tracking unit. Besides the standard

FMS/CANbus messages, Squarell has added additional parameters that can be used to create advanced reports.

You can identify a Squarell DCF by the “SQU” tag in the first digits of DCF name.

To get familiar with the standard Squarell output we advise you to read the Squarell RS232 protocol description and the

Squarell CANbus protocol description, which can be found in the download section on the Squarell support portal.

because you want to knowwww.squarell.com

7

3. Making an on desk simulation

The first step is to have one FLEX unit (marked with number 1 = simulates a truck) act like a vehicle CANbus. From

this simulated vehicle CANbus the other FLEX unit (marked with number 2) reads the CANbus and converts the

data into the Squarell RS323 output data.

3.1 Preparation

• Download and install Docklight*

• Download and install iCheck*

• Download and install iUpload*

• Request an Expertview account (if not already done)

• Remove the end termination from the cables yellow/green & white/blue

* from support.squarell.com

3.2 Hardware setup

The parts that are needed are:

• FLEX “1” device

• cable xxxxx

Make the following setup:

The FLEX device is pre-loaded with the truck simulation software. This software (also known as DCF) simulates a

trip of a truck and can be used for testing.

because you want to knowwww.squarell.com

BU WH

YE GR

FLEX

Multi Source Vehicle Data Interface

S/N: 27197809Type: FLX12

12p SFD ASFD B

Sending Device

Not connected

OG YE

RD GRBN BK

BU

OG

GR/YE

USB

8

1

3.3 Start the second FLEX “2” as interface to the telematics unit / PC

• FLEX “2” device

• 8612-CQ 12-Pole Cable with CANcliQ

• 1 PC with serial port or USB port (please make sure correct drivers are installed)

Connect FLEX “2” to the setup as in the picture:

Click the CANcliQ around the Blue/White CANbus of device FLEX 1, it picks up the signal (white is CAN high, blue

is CAN low). As the CANcliQ only closes once, it is recommended to remove the locks and use tie wraps to close the

CANcliQ (later you can replace the modified CANcliQ cover by the spare one provided in the kit).

The Squarell standard trucks DCF is pre-loaded in the FLEX 2 device. This software (also known as DCF) supports trucks

and can be used for testing. The DCF processes, cleanses, filters, calculates and checks the received data and converts

the data to proper output (this can be RS232 and/or CANbus). Both the RS232 output as well as the CANbus output

(blue/white) are activated.

because you want to knowwww.squarell.com

FLEX

Multi Source Vehicle Data Interface

S/N: 27197809Type: FLX12

12p SFD ASFD B

FLEX

Multi Source Vehicle Data Interface

S/N: 27197809Type: FLX12

12p SFD ASFD B

Receive Device

Sending Device

To PC

with RS232 monitor

Not connected

BU WH

YE GR

OG YE

RD GRBN BK

BN BK

OG YE

BU WH

RD GR

BU

OG

OG

BU

GR/YE

USB

USB

9

1

2

because you want to knowwww.squarell.com

10

3.4 Monitor the RS232 output of the Flex with iCheck

Squarell has created a tool to easily perform a quick check of the installation. The program “iCheck” can be installed on

a laptop or PC and shows you the RS232 output of the device. When you see the most important parameters coming

through, you are sure that you have installed the Squarell device with the correct CANbus, J1708 and/or K-line (currently

iCheck only works together with Squarell DCF’s with RS232 output).

Download iCheck from the Squarell Support portal.

Run the program after the installation is completed.

Connect the RS232 cable of device 2 (see 3.3) to your PC (or via USB - RS232 to a free USB port).

Make sure the RS232 port is not in use by any other program (like Docklight)

because you want to knowwww.squarell.com

11

Click on “Start Monitoring”

When the installation is done right, the values for the parameters will appear.

Select Port Settings and select the right COM port.

All other default settings are right for this test.

More information on iCheck can be found in the manual which is downloadable from the Support portal.

because you want to knowwww.squarell.com

12

3.5 Monitor the RS232 output of the FLEX with Docklight

Connect the RS232 cable of device 2 (see 3.3) to your PC (or via USB - RS232 to a free USB port).

On the PC start the program “Docklight” (you can download Docklight from support.squarell.com).

Select the appropriate com port for the RS232 cable.

Double click on the COM port to modify the settings.

Select the baud rate 9600, 8 bits, 1 stop bit, No parity.

FLEX 1 has preloaded software (DCF) that is simulating a vehicle.

Press the play button.

Docklight is now showing the Data that is processed in FLEX 2 and read from the CANbus with the CANcliQ

$FMS1,4061.025,4029,97.45,24.2,1585,71,0,34.4,1,1,0,0,49.6,118,2.16,1255,1705.5,6605,2005,0<CR><LF>

The Squarell RS232 protocol Document (downloadable from the support portal) shows you what the data means.

Chapter 3.2 “Detailed description of the $FMS1 message” gives information on the messages.

The following text is copied from the Protocol Document:

“This message is sent every 5 seconds at default. The format of the message is:

$FMS1,<value1>,…,<value20><CR><LF>”

because you want to knowwww.squarell.com

13

because you want to knowwww.squarell.com

14

No. Parameter Description Unit Signification

1Odometer Total vehicle distance km 1/2 0 0

2 Total fuel (*1) Total fuel used (TFU) liter 1/2

3Engine hours Total engine hours hour 1/20

4Actual speed Actual vehicle speed km/h 1/10

5Actual engine speed Actual engine speed RPM 1/8

6Actual engine torque Actual engine torque % 1

7Kick down switch State of the kick down switch 0= no 1=yes 1

8Accelerator pedal

position

Position of the accelerator pedal %4/10

9Brake switch State of the brake switch 0= no 1=yes 1

10 Clutch switch State of the clutch switch 0= no 1=yes 1

11 Cruise active State of the cruise control 0= no 1=yes 1

12 PTO active *2 State of the PTO see (*2) 1

13 Fuel level Percentage fuel level %4/10

14 Engine temperature Coolant temperature of the engine Celsius 1

15 Turbo pressure Turbo pressure of the engine bar 1/50

16 Axle weight 0 Weight of the steering axle of the

vehicle

kg 1/2

17 Axle weight 1 Weight of the first axle of the vehicle kg 1/2

18 Axle weight 2 Weight of the second axle of the

vehicle

kg 1/2

19 Axle weight 3 Weight of the third axle of the vehicle kg 1/2

20 Service distance Distance to drive until next service km 1/10

As you can see from the example Data string:

Parameter 1 is Odometer and has a value of 4061.025 km

Parameter 2 is Total Fuel and has a value of 4029 Liter

Parameter 3 is Engine Hours and has a value of 9 7. 4 5 hours

In this example $FMS4 is also sent every 5 seconds and $FMS3 is sent every 30 seconds.

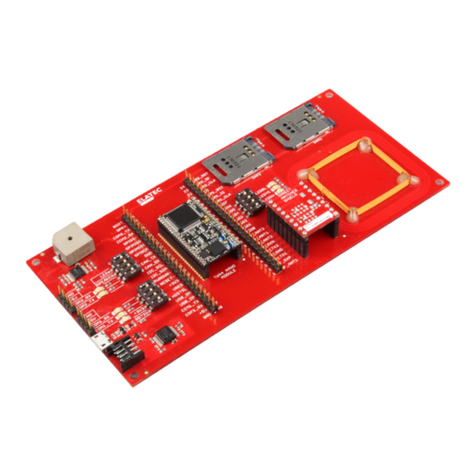

4. Make scan file from vehicle CANbus or test device

With a scan file you can make an extraction of the CANbus data from a vehicle. You can also simulate this on

your desk, using the setup below.

4.1 Hardware setup

The parts that are needed are:

• 1 * FLEX device FLEX12 loaded with a reset dcf (use iUpload to load reset dcf)

• 8612-U1 or 8612-CQ 12-pole cable (both part of the combined cable)

4.2 In vehicle setup with wired connection

In the vehicle make sure the power and ground are well connected.

Find the CANbus wires by using the Squarell installation instructions (all instructions are included in the Squarell

Installer certification training package, these trainings are run every month at squarell). For a installation instruction

you can contact the Squarell support department.

A CANbus scan can be made by using the blue/white wires, a CANcliQ or a DatacliQ for CANbus.

When using the wired connection the FLEX CANbus will be connected to an existing CANbus both Terminators in

the FLEX cable need to be removed. See chapter 8 for more information on CANbus termination.

• Cut the blue loop near the connector

• Cut the terminator at the end of the flying leads

Connect the FLEX device to the PC via the RS232 cable.

because you want to knowwww.squarell.com

15

CANcliQ

Squarell

FLEX

DatacliQ

Squarell

FLEX

DatacliQ

Squarell

FLEX

CANcliQ

Squarell

FLEX

DatacliQ

Squarell

FLEX

DatacliQ

Squarell

FLEX

4.3 Record a CANbus scan with iUpload

Start iUpload and click on “read devices” to locate the connected FLEX device. Click on the device line to select the

correct device.

because you want to knowwww.squarell.com

16

Monitor and log SFD Device port (CANbus scanning)

By selecting the requested SFD port you can monitor the activity on that port. Click on the correct SFD device and click

on ‘Start’ button. You should now see all incoming data on that port (takes 2-3 seconds).

To make a CANbus scan via a wired connection select ID 101.

To make a CANbus scan via a CANcliQ connection select ID 102.

To make a CANbus scan via a DatacliQ for CANbus select ID 180 (or 181).

You can save the message log by clicking the ‘Log’ button. The below window appears. This .txt file can be saved to

a location on your PC.

because you want to knowwww.squarell.com

17

Note:

With above monitor option you can make a live vehicle CANbus scan using a wired connection, the CANcliQ

or DataCliq. This CANbus scan can be sent for analysis to the Squarell Technical department. But you can also

monitor incoming messages from the Bluetooth device for example.

because you want to knowwww.squarell.com

5. J1708 signals

5.1 Hardware setup wired

To test multiple signals besides the CANbus this setup should be made. Connect green and red from Flex no. 1 to

green and red of Flex no.2.

18

BU

OG Cut the orange wire

BU WH

YE GR

OG YE

RD GR

RD GR

OG YE

BU WH

BN BK

BN

BK

BU

OG

GR/YE

FLEX

Multi Source Vehicle Data Interface

S/N: 27197809Type: FLX12

12p SFD ASFD B

FLEX

Multi Source Vehicle Data Interface

S/N: 27197809Type: FLX12

12p SFD ASFD B

Test Device

Truck simulator Device

To PC / Telematics Device

J1708

5.2 Read data from J1708 bus

Open iUpload and start the Function interface Mode (select the device Select SFD Devices

Choose the “internal J1708”channel (ID201) and press start. The J1708 Data as received by FLEX #2 is shown.

After clicking “Stop”, this data can be saved as .txt file by clicking the “Log” button

The same can be done with a DatacliQ for J1708 connected to FLEX#2. And connected to green and red J1708

wires of FLEX #1.

1

2

because you want to knowwww.squarell.com

19

5.3 Hardware setup DatacliQ

To test multiple signals besides the CANbus this setup should be made

The DatacliQ can be connected to SFD1 or SFD2 port. The FLEX will identify the signal automatically.

Please “read the devices” again to be able to see the new ID.280.

BU

Cut the orange wire

BU WH

YE GR

OG YERDGR

RD GR

OG YE

BU WH

BN BK

BU

OG

GR/YE

J1708 K-Line CAN2 CAN1

OG

FLEX

Multi Source Vehicle Data Interface

S/N: 27197809Type: FLX12

12p SFD ASFD B

FLEX

Multi Source Vehicle Data Interface

S/N: 27197809Type: FLX12

12p SFD ASFD B

Test Device

Truck simulator Device

To PC / Telematics Device

DATACLIQ

280

1

2

Table of contents