Stübbe B895 User manual

Aeration Valve B895

Aeration and Vent Valve BE891

Operating manual

Version BA-2022.08.25 EN

Print-No. 302 464

TR MA DE Rev001

STÜBBE GmbH & Co. KG

Hollwieser Straße 5

32602 Vlotho

Germany

Phone: +49 (0) 5733-799-0

Fax: +49 (0) 5733-799-5000

E-mail: co[email protected]

Internet: www.stuebbe.com

Subject to technical modifications.

Read carefully before use.

Save for future use.

Table of contents

Table of contents

1 About this document ............................... 3

1.1 Target groups ................................. 3

1.2 Other applicable documents ................ 3

1.3 Warnings and symbols ....................... 4

2 Safety ................................................. 4

2.1 Intended use .................................. 4

2.2 General safety instructions .................. 4

2.2.1 Obligations of the operating company ..... . 4

2.2.2 Obligations of personnel ..................... 4

2.3 Hazardous media ............................ 4

3 Layout and Function ............................... 5

3.1 Marking ....................................... 5

3.2 Description .................................... 5

3.3 Assembly ..................................... 5

3.3.1 B895 .......................................... 5

3.3.2 BE891 ......................................... 5

3.4 Direction of flow .............................. 6

4 Transport, Storage and Disposal ................. 6

4.1 Unpacking and inspection on delivery ... ... 6

4.2 Transportation ................................ 6

4.3 Storage ....................................... 6

4.4 Disposal ....................................... 6

5 Installation and connection ....................... 6

5.1 Preparations for installation ................. 6

5.2 Planning pipelines ............................ 6

5.3 Installing fitting in pipe ....................... 7

5.3.1 Connection with solvent welding/butt-weld

spigot ends ................................... 7

5.3.2 Connection with union nut and insert .. . .... 7

5.4 Performing the hydrostatic test .............. 7

6 Commissioning ..................................... 7

7 Maintenance ......................................... 7

7.1 Servicing ...................................... 7

7.2 Maintenance .................................. 7

7.2.1 Removing fitting .............................. 7

7.2.2 Cleaning/replacing the ball/float and

O-rings ........................................ 8

7.2.3 Replacement parts and return .............. 8

8 Troubleshooting .................................... 9

9 Technical data, operating limits, dimensions and

weights ............................................... 9

List of figures

Fig. 1 Name plate (example) ....................... 5

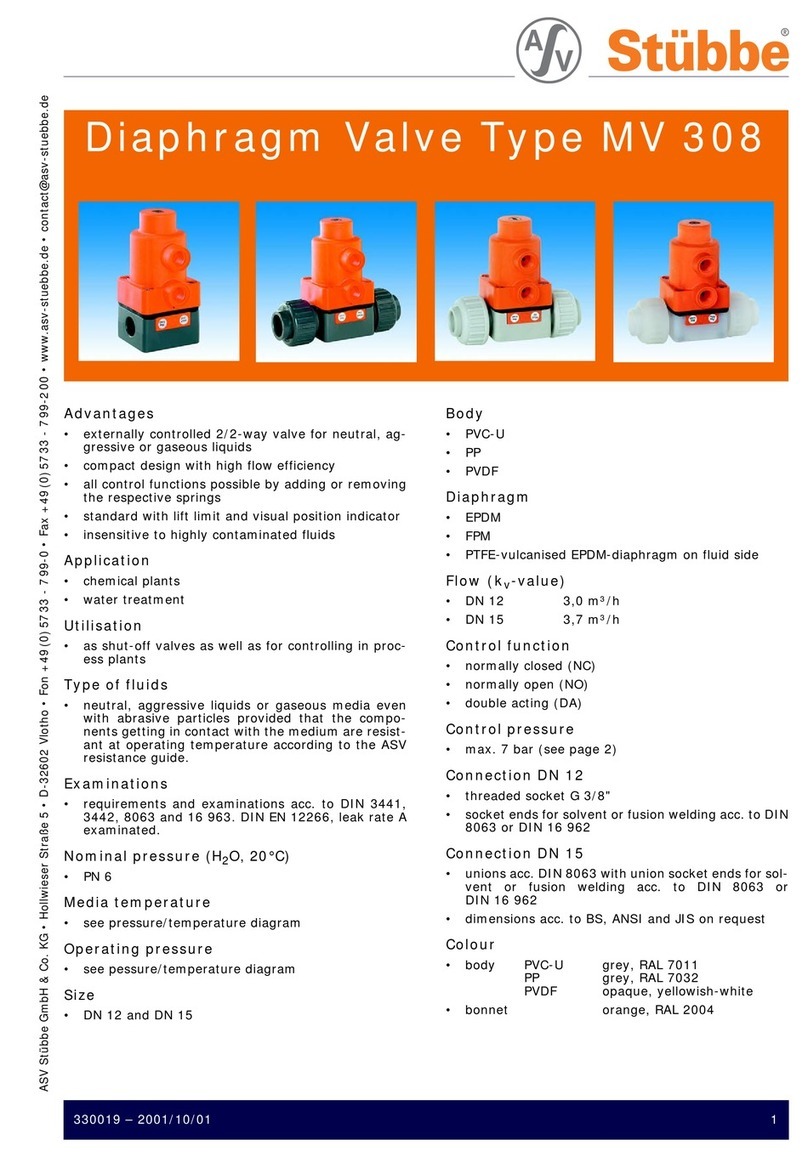

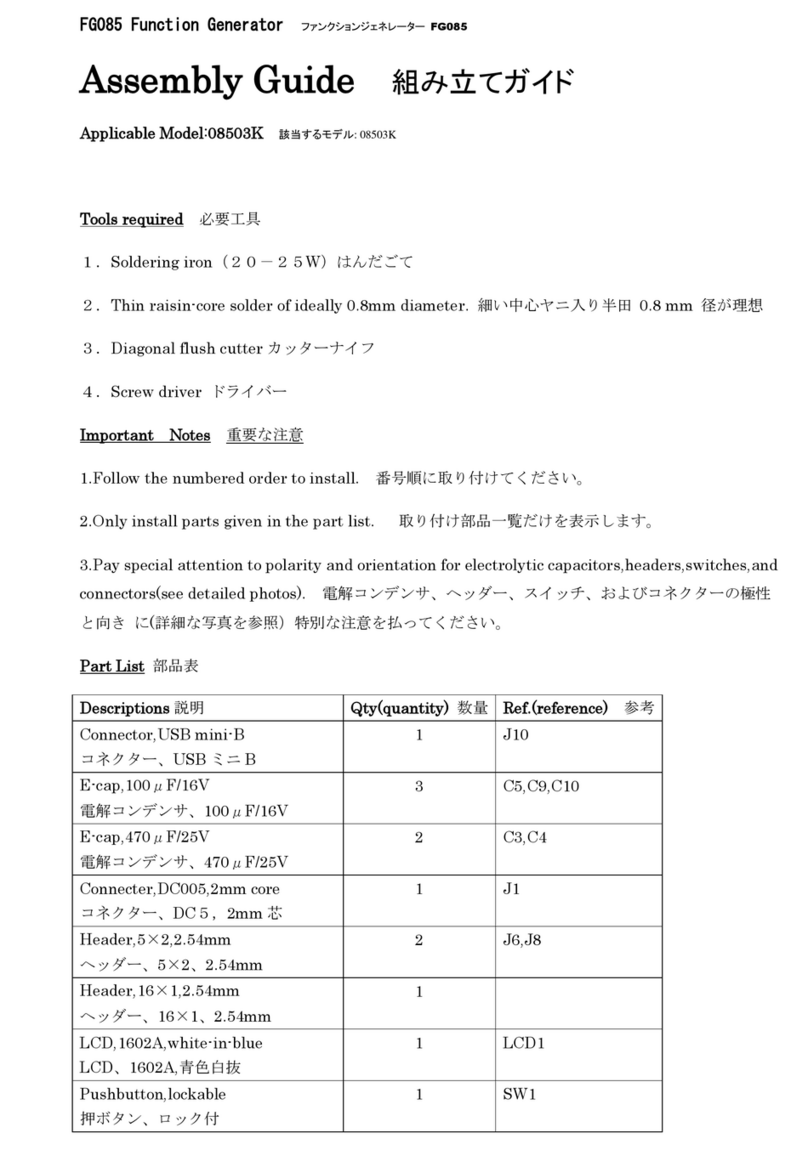

Fig. 2 Design B895 .................................. 5

Fig. 3 Design BE891 ................................ 5

Fig. 4 Fitting with directional arrow ................. 6

List of tables

Tab. 1 Other application documents, purpose and

where found .................................. 3

Tab. 2 Warnings and symbols ....................... 4

Tab. 3 Troubleshooting .............................. 9

2 B895, BE891 BA-2022.08.25 EN 302 464

About this document

1 About this document

This manual

• is part of the fitting

• applies to all series referred to

• describes safe and proper operation during all operating

phases

1.1 Target groups

Operating company

• Responsibilities:

– Keep this manual available at the place of operation,

also for future use.

– Ensure that employees read and observe this manual

and other applicable documents, especially the safety

instructions and warnings.

– Observe any additional country-specific rules and reg-

ulations that relate to the system.

Qualified personnel, fitter

• Mechanics qualification:

– Qualified employees with additional training for fitting

the respective pipework

• Electrical qualification:

– Qualified electrician

• Responsibility:

– Read, observe and follow this manual and the other

applicable documents, especially all safety instructions

and warnings.

1.2 Other applicable documents

To download:

Resistance lists

Resistance of materials used to

chemicals

www.stuebbe.com/pdf/300051.pdf

To download:

Data sheet B895

Technical data and conditions of operation

www.stuebbe.com/pdf/302470.pdf

To download:

Data sheet BE891

Technical data and conditions of

operation

www.stuebbe.com/pdf/302476.pdf

CE declaration of conformity

Conformity with standards

www.stuebbe.com/pdf/300168.pdf

Tab. 1 Other application documents, purpose

and where found

302 464 BA-2022.08.25 EN B895, BE891 3

Safety

1.3 Warnings and symbols

Symbol Meaning

• Immediate acute risk

• Death, serious bodily harm

• Potentially acute risk

• Death, serious bodily harm

• Potentially hazardous situation

• Minor injury

• Potentially hazardous situation

• Material damage

Safety warning sign

Take note of all information

highlighted by the safety warning

sign and follow the instructions to

avoid injury or death.

Instruction

1., 2., ... Multiple-step instructions

Precondition

→Cross reference

Information, notes

Tab. 2 Warnings and symbols

2 Safety

The manufacturer accepts no liability for damages caused

by disregarding any of the documentation.

2.1 Intended use

The fitting is used for aerating and venting vessels.

• Only use the fitting with suitable media (→ Resistance

lists).

• Adhere to the operating limits (→ Data sheet).

• Use the fitting exclusively when a leakage drain is con-

nected to the outlet side.

Prevention of obvious misuse (examples)

• Do not use the fitting for media containing solids.

• Donotusethefittingformediathatclogorgumuptheball

or the float, impairing their opening and closing action.

• Do not use the fitting where the media flow is in the opposite

sense to the marked direction of flow.

2.2 General safety instructions

Read and observe the following regulations before carrying

out any work.

2.2.1 Obligations of the operating company

Safety-conscious working

• Only operate the fitting if it is in perfect technical condition

and only use it as intended, remaining aware of safety and

risks, and adhering to the instructions in this manual.

• Ensure that the following safety aspects are observed and

monitored:

– Intended use

– Statutory or other safety and accident-prevention reg-

ulations

– Safety regulations governing the handling of haz-

ardous substances

– Applicable standards and guidelines in the country

where the pump is operated

• Make personal protective equipment available.

Qualified personnel

• Ensure all personnel tasked with work on the fitting have

read and understood this manual and all other applicable

documents, especially the safety, maintenance and repair

information, before they start any work.

• Organize responsibilities, areas of competence and the

supervision of personnel.

• The following work should be carried out by specialist tech-

nicians only:

– Installation, repair and maintenance work

– Work on the electrical system

• Make sure that personnel to be trained only

work on the fitting under the supervision of specialist tech-

nicians.

2.2.2 Obligations of personnel

• Observe the instructions on the fitting and keep them leg-

ible, e.g. name plate and identification marking for fluid

connections.

• Only carry out work on the fitting if the following require-

ments are met:

– System is empty

– System has been flushed

– System is depressurized

– System has cooled down

– System is secured against being switched back on

again

• Do not modify the fitting in any way.

2.3 Hazardous media

• When handling hazardous media (e.g. hot, flammable,

explosive, toxic, hazardous to health or the environment),

observe the safety regulations for the handling of haz-

ardous substances.

• Use personal protective equipment when carrying out any

work on the fitting.

• Collect leakingpumpedliquidandresiduesinasafeman-

ner and dispose of them in accordance with environmental

regulations.

4 B895, BE891 BA-2022.08.25 EN 302 464

Layout and Function

3 Layout and Function

3.1 Marking

PVC-U • FPM

1

2

3

4

B895

DN10

147700

Hollwieser Str. 5, DE-32602 Vlotho

Fig. 1 Name plate (example)

1Type

2 Nominal diameter [mm]

3 ID number

4 Materials (body, seals)

3.2 Description

Medium-activated valve for aerating and venting vessels

• Vertical installation

• Variants of connections:

– Spigot ends for solvent or fusion welding

sizes DN10–50

– Spigot ends for solvent or fusion welding

sizes DN65/80

• Observe the „TOP“ marking, arrow is pointing upwards

Type B895:

• for venting

• Valve „Open“ at depressurization (venting), valve

„Closed“ by spring-loaded closure element

• Opening pressure approx. 0.05 bar, this value should be

checked by the system operating company

Type BE891:

• for aerating and venting

• Valve „Open“ at depressurization (venting) and during

filling due to the weight of the closure element, valve

„Closed“ due to flotation of the closure element

• When the valve is closed, venting is only possible when the

container pressure falls below the atmospheric pressure

even with air build-up (outgassing media).

3.3 Assembly

3.3.1 B895

12

3

4

5

6

7

9

4

5

10

6

8

11

8

7

Fig. 2 Design B895

1Size DN10–50 7Pressure spring

2Size DN65/80 8 Housing

3 Union threaded neck 9 Insert (here: outlet)

4O-ring 10 Union nut

5O-ring 11 Pressure disc

6Ball/float

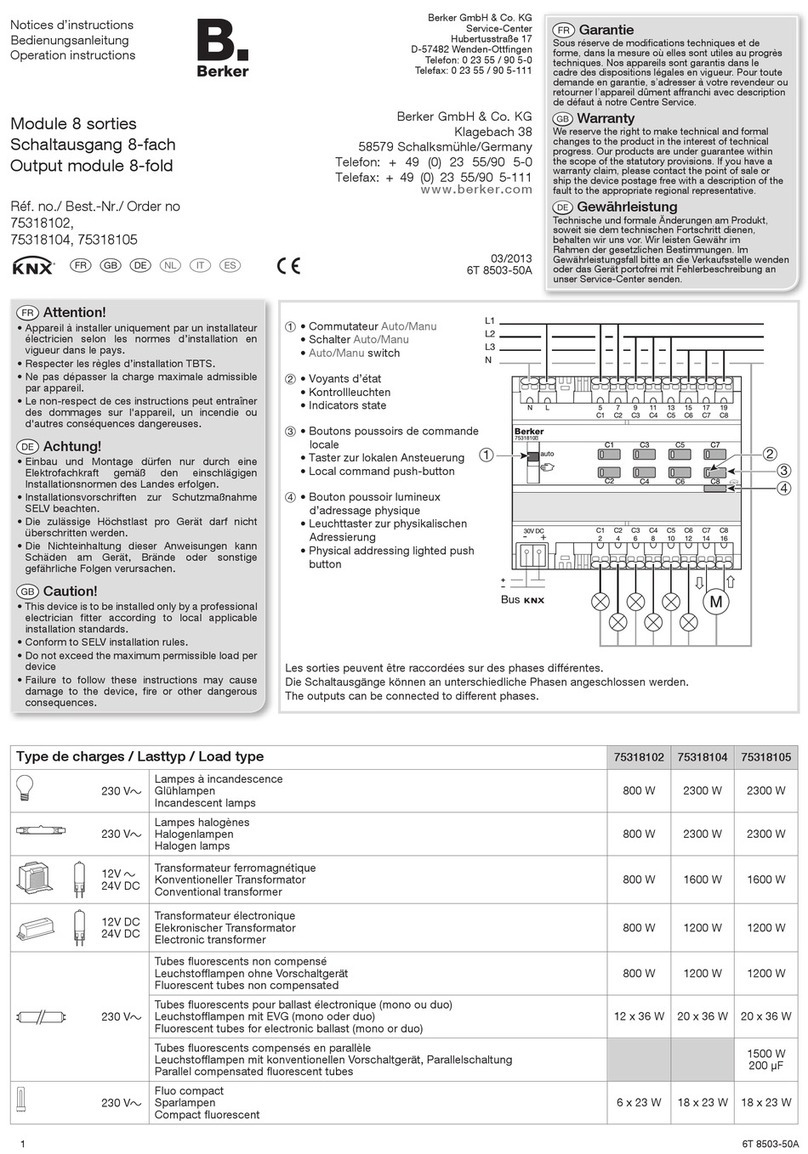

3.3.2 BE891

12

3

4

5

6

7

8

4

9

5

7

6

10

Fig. 3 Design BE891

1Size DN10–50 6Ball/float

2Size DN65/80 7Housing

3 Union threaded neck 8 Insert (here: outlet)

4O-ring 9 Union nut

5O-ring 10 Pressure disc

302 464 BA-2022.08.25 EN B895, BE891 5

Installation and connection

3.4 Direction of flow

1

Fig. 4 Fitting with directional arrow

1 Directional arrow

4 Transport, Storage and

Disposal

4.1 Unpacking and inspection on delivery

1. Unpack the fitting when received and inspect it for trans-

portation damage.

2. Report any transportation damage to the manufacturer

immediately.

3. Ensure that the information on the name plate agrees with

the order/design data.

4. For immediate installation, damage packaging material

according to local regulations.

– For later installation, leave the fitting in the original

packaging.

4.2 Transportation

1. If possible, transport fitting in original packaging.

2. To transport, lift the fitting by hand, weight specifications

(→ Data sheet).

4.3 Storage

NOTE

Material damage due to inappropriate storage!

Store the fitting properly.

Make sure the storage room meets the following condi-

tions:

–Dry

– Frost-free

– Vibration-free

– Not in direct sunlight

– Storage temperature +10 °C to +60 °C

4.4 Disposal

Plastic parts can be contaminated by poisonous or radioac-

tive media to such an extent that cleaning will not be suffi-

cient.

WARNING

Risk of poisoning and environmental damage from

medium!

Use personal protective equipment when carrying out any

work on the fitting.

Before disposing of the fitting:

– Collect escaping medium and dispose separately

according to local regulations.

– Neutralize residues of medium in the fitting.

Remove plastic parts and damage them in accordance with

local regulations.

Dispose of the fitting in accordance with local regulations.

5 Installation and connection

5.1 Preparations for installation

1. Ensure the design of the fitting is consistent with the pur-

pose intended:

– Materials used (→ Type plate).

– Medium (→ Order and design data).

2. Ensure the required operating conditions are met:

– Resistance of body and seal material to the medium

(→ resistance lists).

– Media temperature (→ Data sheet).

– Operating pressure (→ Data sheet).

3. B895 provides for additional venting of the vessel in order

to facilitate filling.

4. Consult with the manufacturer regarding any other use of

the device.

5.2 Planning pipelines

WARNING

Risk of poisoning and environmental damage from

medium!

Leaks due to impermissible pipework forces.

Ensure that the fitting is not subject to any pulling or thrust-

ing forces or bending moments.

1. Plan pipes safely:

– No pulling or thrusting forces

– No bending moments

– Adjust for changes in length due to temperature

changes (compensators, expansion shanks)

– Installation position vertical

2. Dimensions (→ Data sheet).

6 B895, BE891 BA-2022.08.25 EN 302 464

Maintenance

5.3 Installing fitting in pipe

WARNING

Risk of poisoning and environmental damage from

medium!

Leak due to faulty installation.

Installation work on the pipes should only be performed

by technicians who have been specially trained for the

pipework in question.

Connect the outlet side of the fitting to a leakage drain.

NOTE

Material damage due to contamination of the fitting!

Make sure no contamination reaches the fitting.

Flush the pipe with a neutral medium.

The fitting is installed according to the connection type of

the pipes.

For connection with solvent welding/fusion spigot ends:

Use suitable solvent welding/fusion socket ends.

Observe direction of flow (→ 3.4 Direction of flow, Page 6).

5.3.1 Connection with solvent welding/butt-weld

spigot ends

1. Prepare pipe ends according to connection type.

2. Adhesively apply or weld fitting with solvent welding/butt-

weld socket ends (→ manufacturer specifications).

5.3.2 Connection with union nut and insert

1. Prepare pipe ends according to connection type.

2. Unscrew union nuts and slide over free pipe ends.

– Check mounting direction.

– Take care to prevent the ball/float falling out of the

housing.

3. Connect inserts with pipe ends.

4. Position fitting between the pipe ends.

5. Hand-tighten the union nut.

5.4 Performing the hydrostatic test

Pressure test using neutral medium, e.g. water.

1. Pressurize the fitting. ensuring:

– Test pressure < permissible system pressure

– Test pressure < 1.5 PN

– Test pressure < PN + 5 bar

2. Check the fitting for leaks.

6 Commissioning

Fitting correctly installed and connected

WARNING

Risk of injury and poisoning due to medium spraying out!

Use personal protective equipment when carrying out any

work on the fitting.

After the initial stresses due to pressure and operating tem-

perature, check if the fitting is sealed.

7 Maintenance

WARNING

Risk of injury and poisoning due to hazardous or hot

media!

Use personal protective equipment when carrying out any

work on the fitting.

Safely collect the media and dispose of it in accordance

with environmental regulations.

7.1 Servicing

1. Visual and function check (every three months):

– Normal operating conditions unchanged

–Noleaks

– No unusual operating noises or vibrations

2. Ensure that the fitting is functioning properly (opening, clos-

ing).

3. Clean the fitting with a moist cloth if necessary.

7.2 Maintenance

7.2.1 Removing fitting

1. Ensure that:

– System is empty

– System has been flushed

– System is depressurized

– System has cooled down

– System is secured against being switched back on

again

2. Remove fitting from the pipe.

3. Decontaminate fitting if required.

– Dead space in the fitting may still contain medium.

302 464 BA-2022.08.25 EN B895, BE891 7

Maintenance

7.2.2 Cleaning/replacing the ball/float and O-rings

Refer to the drawings (→ 3.3 Assembly, Page 5).

B895, size DN10–50

Fitting disassembled

1. Carefully unscrew the screw-in part (3). The compression

spring (7) exerts a compressive force.

2. Change the O-rings (4, 5).

3. Clean the ball (6), or if damaged, replace it.

4. Assemble the parts.

B895, size DN65/80

Fitting disassembled

1. Carefully unscrew the union nuts (10). The compression

spring (7) exerts a compressive force.

2. Remove the inserts (9).

3. Change the O-rings (4).

4. Removing the thrust washer (11)

5. Remove the compression spring (7).

6. Remove the float (6).

7. Clean the float (6), or if damaged, replace it.

8. Replace the O-ring (5) on the cleaned float.

9. Assemble the parts.

BE891, size DN10–50

Fitting disassembled

1. Unscrew the screw-in part (3).

2. Replace the O-rings (4, 5).

3. Clean the ball (6), or if damaged, replace it.

4. Assemble the parts.

BE891, size DN65/80

Fitting disassembled

1. Unscrew the union nuts (9).

2. Remove the inserts (8).

3. Change the O-rings (4).

4. Remove the thrust washer (10).

5. Remove the float (6).

6. Clean the float (6), or if damaged, replace it.

7. Replace the O-ring (5) on the cleaned float.

8. Assemble the parts.

7.2.3 Replacement parts and return

1. Have the following information ready to hand when order-

ing spare parts (→ Type plate).

– Fitting type

– ID number

– Nominal pressure and diameter

– Body and seal material

2. Please complete and enclose the document of compliance

for returns

(→ www.stuebbe.com/en/service/download).

3. Use only spare parts from STÜBBE.

8 B895, BE891 BA-2022.08.25 EN 302 464

Technical data, operating limits, dimensions and weights

8 Troubleshooting

WARNING

Risk of injury and poisoning due to hazardous or hot

media!

Use personal protective equipment when carrying out any

work on the fitting.

Safely collect the media and dispose of it in accordance

with environmental regulations.

Consult with the manufacturer regarding faults which are not

identified in the following table, or which cannot be traced to

the indicated causes.

Error Possible cause Corrective action

Fitting installed the wrong way round. Check the direction of flow in the fitting

(→ 3.4 Direction of flow, Page 6). if

necessary install the fitting correctly

(→ 5.3 Installing fitting in pipe, Page 7).

Fitting is not sealing.

Ball/float or the associated O-rings

dirty or worn.

Clean and if necessary replace the ball/float

and associated O-rings (→ 7.2.2 Cleaning/

replacing the ball/float and O-rings, Page 8).

Medium is leaking from the

housing.

O-ring on the housing worn. Replace the O-ring on the housing

(→ 7.2.2 Cleaning/replacing the ball/float

and O-rings, Page 8).

Fitting installed the wrong way round. Check the direction of flow in the fitting

(→ 3.4 Direction of flow, Page 6). if

necessary install the fitting correctly

(→ 5.3 Installing fitting in pipe, Page 7).

Vessel is not being aerated

(B895).

The ball/float is stuck in position by

the seal.

Clean and if necessary replace the ball/float

and associated O-rings (→ 7.2.2 Cleaning/

replacing the ball/float and O-rings, Page 8).

Ensure that the fitting is suitable for the medium in

question (→ resistance list).

The fitting is stuck in the

„Closed“ position: The vessel is

pressurized.

Drain the medium out of the vessel until the ball/float

is released from the valve seat and the air can

escape.

Vessel is not being vented

(BE891).

The fitting is stuck in the

„Closed“ position: The vessel is

depressurized.

Clean and if necessary replace the ball/float,

valve seat and O-rings (→ 7.2.2 Cleaning/

replacing the ball/float and O-rings, Page 8).

Ensure that the fitting is suitable for the medium in

question (→ resistance list).

Tab. 3 Troubleshooting

9 Technical data, operating

limits, dimensions and weights

The particulars are described on the data sheet (→ Data

sheet).

302 464 BA-2022.08.25 EN B895, BE891 9

This manual suits for next models

1

Table of contents

Other Stübbe Control Unit manuals