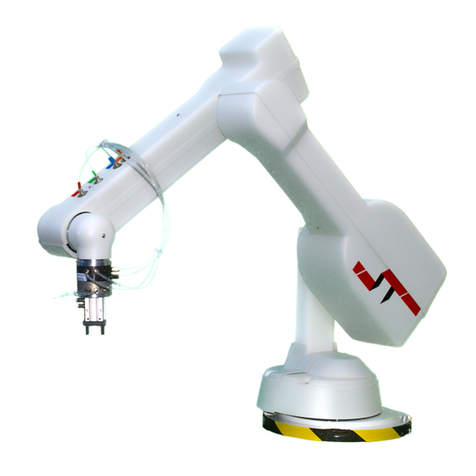

ST Robotics R12 User manual

R12 ToolChanger instructionspage 1STrobotics

R12 Tool Changerinstructions.

WARNING:PROGRAMMING AND SETTING UPTHER12 TOOL

CHANGERSYSTEMISNOTTRIVIAL.

Bepreparedtocrashtherobotandrestartafew times.

Pleaseread the R12 manualand the getting started manualtogainexperiencebefore

using the toolchangers.

Overview

SomeROBOFORTH‘code’issupplied withthe system, see later.

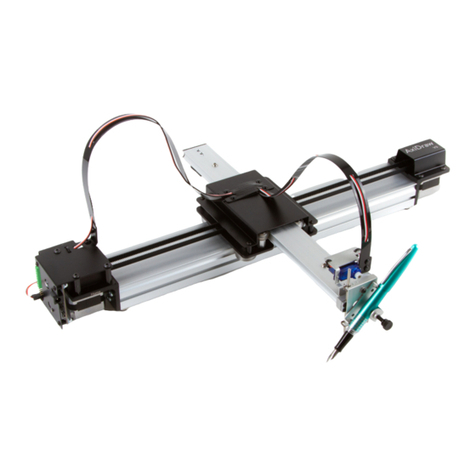

The pneumaticdevicescompriseapneumaticgripper, avacuumpickup with4cupsand a

toolchangersystem. The robot can pick up eitherthe vacuumpickup orthe pneumatic

gripperoran electricgripper(oranyotherdevice)withthe toolchanger. The toolnot in

useisparked on arack.

Pneumaticgripperand vacuumpickup

THISITEMMAYBE MOUNTEDONWOODENBASE WITHTEMPORARY

CONNECTIONSFORTESTING ONLY

The pneumatics circuit comprises3valvesand aVenturitoproducevacuum. See

diagrambelow. Connect tothe robot baseasindicated on the robot.

Diagram1

Port 4of valveV2isblocked off. When all valvesareoff thereisno airflow.

If thereisno vacuumpickup then the Venturiand valveV2will be missing and valveV1

will be blocked off at port 3.

R12 ToolChanger instructionspage 2STrobotics

Pneumaticconnectionstothetool changer.

Diagram2

connectionsforpneumaticgripperareshownasG. The pairG2on the robot-side adaptor

will line up withthe similarpairG2on the toolside adaptor. Connectionsforthe vacuum

areshownasV. If thereisan electricgripperthiswouldnormallybe connected through

the contactsshownasE1. E2arespare. Oryou can useall 5connectionsforother

electronicdevice.

The controllerhasan output port PA with8bits, 2of whichcontrolthe pneumaticvalves.

Referring tothe Forthdefinitionsbelow(and on yourcd), R12TOOLCHANGE

PA 2selectseitherthe vacuumorthe gripper.

PA 0turnsthen bothon. PA 0iscontrolled byGRIPand GRIPPER.

If PA 2isONthen airgoestothe grippervalve. GRIPclosesthe gripperand UNGRIP

opens. Thiscan onlybe used if the gripperiscurrentlylocked tothe robot. Otherwiseair

will just comeout of the robot-side adaptor.

If PA 2isOFF then airgoestothe vacuumvalve. GRIPthen sendsairtothe Venturi

whichcreatesavacuum. The vacuumtube isa3rd tube through the robot tothe tool

changer.

R12 ToolChanger instructionspage 3STrobotics

Withno toollocked on the robot at all you need toturnoff all the air. SobothPA 0and PA

2shouldbe off. PA 2OFF divertsairtothe vacuumvalveand PA 0OFF switchesthe air

tothe blocked port. The definition AIRSTOPdoesthis.

: VAC PA 2 ; ( OFF = VAC, ON = GRIPPER

: VACON

VAC OFF

;

: AIRSTOP

VAC OFF GRIPPER OFF

;

Onceyou havethe vacuumtoolattached then just useGRIPand UNGRIPwhichoperate

PA 0and simultaneouslyturnon valvesV2and V3.

.

If you havethe gripperattached first do VACONthen useGRIPand UNGRIP.

Don't forget toAIRSTOPbeforeyou disengage the tool.

If you havethe vacuumpickup attached select it withVACOFF. Thismayseemcounter-

intuitivebut ensuresasafesituation when the controllerisswitched off.

Pneumaticgripperand electricgripper.

The pneumatics circuit isasdiagram1but without V2orVenturi. Notethat the electric

gripperusesPA 0and PA 1. PA 1must not be used byanyvalveorotherdevice.

AvariableGTYPE hasthe value 0forapneumaticgripperor1forelectric.

When you areabout tousethe pneumaticgripperenter

0GTYPE !

Forthe electricgripperenter

1GTYPE !

R12 ToolChanger instructionspage 4STrobotics

WARNING

Beforetryinganyofthefollowingcommandsbesureto

KEEP OUTOFTHEROBOTENVELOPE

Take greatcareinteachingthechangerpositions. Use alow speed.

Ifyoucrashtherobotturnoff power, take back tohomeandre-calibrate.

Notice:

Anydamagetotherobot6th axisduetocollisionisnotcoveredbywarranty.

How toprogramthetool changer.

Beforeyoustartyoumustsetthetool intheunlockedpositionbyhand.

Find the hardstop whichisasmall pillarthat can moveagainst astop. Rotatethe changer

byhand clockwiseasfarasit will go, withthe pillaragainst the stop. Thisisessential. If at

anytimethisgetsmoved whilenot holding atoolthen you must set it againbyhand.

See programbelow. Thiswill be on yourCD asaproject, R12TOOLCHANGE.run

Gotothe safeposition

READYfora5-axisR12 orREADY2fora6-axisR12.

The robot will end up at aposition withthe hand centerlevelwiththe toolchanger,

pointing down.

Onceyou havefamiliarized yourself withthe useof projectsyou can load the project. The

positionswherethe toolsareparked arepredefined aspositionsin2routes, APATH(for

the gripper) and BPATH(forthe vacuumpickup). Yourpositionswill be completely

different. You will need tostart overwiththeseroutes. You can deletethe linesone by

one oryou can enterAPATHERASE BPATHERASE then click the red up-arrow.

Do not useALIGN

(enterNONALIGN)

Starting withthe gripper, inRobWinselect and open APATH. (deleteall linesinit if not

alreadydone).

Next click the J(jog)button and movethe robot overthe rack and downtowardsthe first

tool(suggest vacuumpickup)using the teachpad inJog mode.

Watchthe guide spikesgoing intothe holesinthe tool-side adaptor. You will need to

change roll forcertain–J6on a6-axisand J5on a5-axis. You will alsoneed tomoveinX

and Yaxestoget the best fit. You will need tochange the increment downto1mm or

even 0.1mm toget the position exact.

R12 ToolChanger instructionspage 5STrobotics

Onceclosed withthe tool(asmall gap istolerated)exit the jog mode and click 'append

position'

Nowmoveup around 10mm sothat the spikesarestill aimed at the holes. Exit Jog,

highlight the line you just learned and click 'insert position'. The target position isnowline

2. Nowmoveup alot furtherand insert position again. The target position isnowline 3.

Click line 2and goto

Click line 3and goto

the toolisnowtogether.

Using Jog and J6for6-axisorJ5for5-axisrotatein5degree incrementsinpositive

(clockwise)direction. You will see the T-barinthe changermovealong the ramp. You

shouldintheoryneed 90 degreestoget tothe end of the rampbut avalue of 87 degrees

istypical.

Click append position.

Nowmoveup 5mm at atimeuntil the adaptorplateclearsthe spikeson the rack. At this

point the adaptorplatemayspring furtherclockwise. InthiscaseuseJog and J6orJ5to

rotateback the otherwayin1degree incrementsuntil it isobviousthe platecan go back

downstraight. Nowgo downon Zuntil the plateisflat on the rack.

Click append position.

Goup approx10mm

Append position

Goup alot more(e.g. 50mm)

Append position.

Goup even furthersothe tooliswell clearof the rack.

Append position.

Testinthereverse direction

You have7lines. Click line 6and goto. Then 5,4etc. The robot shouldunlock the tooland

moveup.

Testintheforwarddirection.

Click line 1, goto, 2gotoetc. The robot nowhasthe tool.

NowtryAPUT

whichputsthe toolback.

AGETgetsthe tool.

OnRobWinusefile, save.

Repeat all the aboveprocedurefortoolBwithrouteBPATH.

OnRobWinusefile, save.

USAVE tosavetoflash.

Thereisavideo forfurtherhelp:

https://www.youtube.com/watch?v=3ZySsIZDnbQ

R12 ToolChanger instructionspage 6STrobotics

Recovery

If the robot crashesforanyreason proceed asfollows

ENCOFF

UseJog toget awayfromthe accident.

HOME

START

CALIBRATE

Check/resetthetool totheunlockedpositionbyhand.

Find the hardstop whichisasmall pillarthat can moveagainst astop (ascrewhead).

Rotatethe changerbyhand anti-clockwisethen clockwiseagainasfarasit will go, with

the pillaragainst the stop. Thisisessential. If at anytimethisgetsmoved whilenot

holding atoolthen you must set it againbyhand.

R12 ToolChanger instructionspage 7STrobotics

( STARTER PROJECT FOR TOOL CHANGING ON R12.

( USING A PNEUMATIC GRIPPER AND A VACUUM PICKUP

DECIMAL

: VAC PA 2 ; ( OFF = VAC ON = GRIP

: SLOW 1000 SPEED ! ;

: VACON

VAC OFF

;

: GRIPON

VAC ON

;

: AIRSTOP

VAC OFF GRIPPER OFF

;

: BGET

AIRSTOP

BPATH SEGMENTED RUN

;

: BPUT

AIRSTOP

BPATH SEGMENTED RETRACE

;

: AGET

AIRSTOP

APATH SEGMENTED RUN

;

: APUT

AIRSTOP

APATH SEGMENTED RETRACE

;

Once you have the vacuum pickup use

VACON

then GRIP and UNGRIP as required.

When you have the pneumatic gripper use

GRIPON

then GRIP and UNGRIP as required.

Whyuse SEGMENTEDmode:

CONTINUOUSand SMOOTHaresmootherbut you can not round the cornersbeforeand

afterrotating inthe tooladaptorsinceit must be fullyseated beforerotating. If you want to

makeit smoothercreate2routesforeachtool, one forthe wayinand one forthe wayout.

Table of contents

Other ST Robotics Robotics manuals