ST Robotics R17 User manual

R17 RobotManual page 2

SystemComponents:

AbasicR17 robot systemcomprisesthe following:-

1R17 Robot arm

Fitted withanyoptions:

Pneumaticor electricgripper

Vacuumpickup

PneumaticToolChanger

6th axismodule

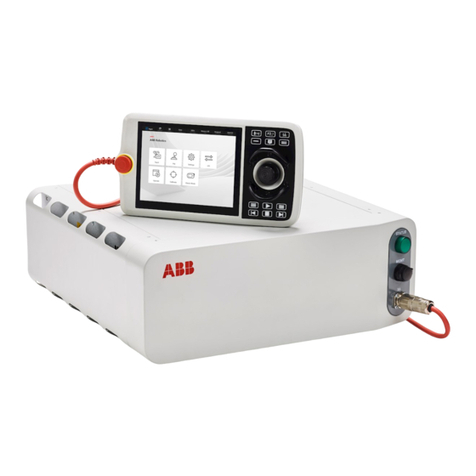

1 Controller K11R

Fitted withanyoptions:

I/O expansion

Gripper drivemodule

1Teachbox

1Cable9-wayD-type eachend (M-M)-K11Rtoteachbox

1Motor cable-K11RMSconnector torobot 25-wayD-type

1Sensor and encoder cable-25-wayeachend (M-F)

1Cable, D-type 25-waymaleto9-wayfemale-K11RtoPCRS232

1Power cabletoK11R

1Packof CONNECTORS:

1output connector

1input connector

1Diskwithsoftware and manuals.

1optionalUSB/serialadaptor

1 optionalAndroidteachconsole.

1Gripper pneumatics kit

1Quickstop pneumatics kit

Manual Contents:

1Introduction

2Important Dosand Don'ts

3Setting up

4Computer

5Controller

6Preparing for Use

7Getting Started

8Accessories

9Controller Settings

10 Robot Parameters

11 Full Calibration fromscratch

12 Connections

13 Collisions

14 TechnicalSupport

R17 RobotManual page 3

1. INTRODUCTION

The R17, DEUCALIONisarobot armof the verticallyarticulated format. Thisisthe format

whichmost closelyresemblesthe human armand soitspartsarenamed afterthe human

arm. It ismoreversatilethan otherformatsbut the drawback isthat backlashand

complianceineachjoint areadded togetherjoint byjoint. R17 hasanominalreachof

750mm i.e. it is750 mm fromthe shoulderjoint tothe wrist, plusanother100 mm orsofor

the hand, depending on the "end effector"fitted. R17 and R17HPLaredriven bystepping

motorsmicrostepsof 0.18 degreesperstep resulting aftergearing inanominalresolution

of 0.1mm orbetterat the end effector. R17HS hasaxes4and 5driven bystepping

motors; axes1,2and 3aredriven byhigh powerservomotors.

If fitted the pneumaticgripperisoperated bycompressed airfrom3to7bar. Thismaybe

supplied byacompressorsupplied withthe set, orfromanotherairsupply.

The R17 robot systemcomprises3mainunits:-the robot, the controller, acomputeror

dumbterminal. The computerisused toprogramthe controller. Onceprogrammed the

controllerwill run the robot independentlywithout the need foracomputerbut it isagood

idea toleavealowcost terminalconnected whilethe robot isinuse.

OVERVIEW

The controllercontrolsall movement of the robot. Asthe controllermaybe bothreading

sensorsand signalsfromand controlling associated equipment it followsthat all decisions

about robot activityareusuallymade bythe controllerwhichiscapableof running without

anyhost computer. The function of the computeristo(a)programthe controller, (b)to

copy(back up)the contentsof controllerRAMtodisk and optionally(c)toperforma

supervisoryrolesending commandstothe controllerthrough the serialinterface.

Toprogramthe controllerwithacomputeryou need torun the utilityROBWIN7.EXE.

When ROBWINisexecuted it immediatelyopensacommunicationswindow. Once

communication isestablished all yourcommandsgo tothe controllernot tothe computer

you aretyping on. Programming the controllerinvolvesprogramming the robot and the

interaction withotherequipment. The robot and interfacing areprogrammed using

ROBOFORTHII © and FORTH. Therearetwomanuals, ROBOFORTHcovering robot

programming and the systemmanual, whichdescribesthe controllerand interfacing. The

softwaremanualsareon disk and written inHTMLsoyou can usedynamiclinks tosee

connected concepts. Thereisalsoaglossaryon disk, whichgivesabrief description of

everycommand. Somecommandsareused onlybyROBWINorarenot veryusefuland

theseareinthe glossarybut not inthe ROBOFORTHmanual.

All FORTHand ROBOFORTHcommandsareinUPPERCASE (press capslock). You

can add commandswritten inlowercasebut thesewouldbe different commandsfrom

thosespelled inuppercase.

©RoboForthiscopyright DavidNSands1983-present

R17 RobotManual page 4

2. IMPORTANTDOSAND DON'TS

(1)DON'T everdisconnectorconnect the robot whilethe controllerisswitched on. This

will result indamage tothe electronics and the connectorsthemselves. Warrantyclaims

will not be accepted fordamage resulting fromthis.

Onthe R17HSorR17HSWdo not leavethe motorcabledisconnected but the power

cableconnected orviceversa.

(2)DO be verycarefulnot to"crash" i.e. driveanyjoint against asolidobject sothat it

stalls. Depending on the speed damage mayresult. At lowerspeedsthe motorsgenerate

highertorquessocan do moredamage. DON'T drivethe waist against the stop.

(3)Forthe abovereason DON’TuseCALIBRATEunless you aresurethe robot will not

crashintosomething inthe workspace.

(4)DON'T useCALIBRATEunless you aresurethe robot isinthe validposition for

calibration including taking intoaccount anycomplexend effectorfitted.

(5)DON'T back-drivethe 6th axis; damage can result.

(6)DO haveyourhand poised overthe emergency stop button whenevertesting a

program. Rememberthat becauseof itsgeometryarevolutearmwill describe wide arcs

fromfarapart points, and maycollide withobjectswithinitsreach.

(7)DO takeappropriatemeasurestoassess the risks and protect personnelfrominjury

(see next section)

(8)DON’Tcontinuouslyrotatean electricgripper–it will breakthe internalwiring.

(9)DON’Tleavethe robot switched on but not moving forverylong periodsof time(say

morethan aweek)asmotorheat can damage the belts.

(10)DON’Ttrytosaveaproject if the controllerisswitched off.

(11)DO makeaback-up of the computerdisk supplied assoon aspossible.

(12)DO warmup the robot forbest repeatability. Afterswitching on fromcoldrun the

robot somesimpleall axesroutine for10-20 minutes.

R17 RobotManual page 5

SAFETYISYOUR RESPONSIBILITY

Risks

Becausestepping motorsraisemoretorque at lowspeedsasubstantiallowspeed force

can be brought tobearespeciallyon fingerswhichmaybecometrapped underor

between axes. Robot end effectorstypicallyhavesharpedgesorfingersmade of thin

metalwhichcan causeinjuryat the lowspeed high forcesorat the higherspeeds.

The biggest risk comesfromthe element of surprise. If the systemisactiveand receives

acommand fromasupervising schedulerorasignalfroman associated machine the

robot will appeartomoveunpredictably. Ahuman being caught inthe waycan receive

injury, especiallyif the end effectorhassharpedges.

However, becausethe robot issteppermotordriven, oncestalled the systemraisesan

errorand doesnot attempt furthermotion.

Safetymeasures

•Wherepossiblearobot systemshouldbe guarded. Anygateinthe guarding can

be fitted withaswitch, whichisconnected tothe controllerstop circuit.

•If physicalguardscannot be provided then light curtainsareeasilyconnected tothe

robot controllerorthe STSentrysensorsystem.

•Whereguarding isnot appropriateand bench-top robotsworkcloselywithhuman

workersinterlocks shouldbe provided. Forexampleif the userhasaccess tothe

workspacethen he/she shouldbe required topress aswitchorkeyboardkeyafter

clearing the area. The STSentrysystemcan be used sothat if ahuman entersthe

workspacethe robot will stop. It can be programmed todisplayamessage and wait

forakeyboardinput beforecontinuing.

•Agood ruleisthat the robot shouldnot be allowed tomoveoutside an area

designated bythe edge of the benchon whichit ismounted.

•Asan additionalprecaution the working area couldbe marked out withpainted

linesorblack/yellowstriped tape.

•Statisticallythe highest incidenceof contention between human and robot iswhen

bothareaccessing the sameobject. End effectorsoften havesharpedgeswhich

can causeinjury. Fitting acollision sensorcan minimizethishazard.

•At the end of thismanualyou will find aformwithwhichtodo yourownrisk

assessment of the robot inyourapplication. Therearetwoconceptstoconsider:

hazard, whichisthe robot orrobot fingersorthe product etc. and risk, whichisthe

probabilityof someone being harmed bythe hazard. The formenablesyou to

identifythe hazards, the risks and ways of minimizing the risks. Aftercompleting

the formand carrying out anysafetymeasuresthat the formhashelped you

identify, do the assessment all overagain.

R17 RobotManual page 6

3. SETTING UP

Set the robot up inthe desired location. Connect up all cables-theirpositionsshouldbe

self-evident. Cablestothe robot connect tothe rearof the controller.

Thereare5basiccables:

Motorpower –the metalized cablefromrearof controllertorobot base, 26wMSto25wD

Sensorcable –fromrearof controllertorobot base(25wDmaleto25wDfemale)

Grippercable (if supplied)-fromrearof controllertogrippervalve(9wDtoDIN)

Serial cable –fromfront of controllertocomputer(usually25wDmaleto9wDfem)

Teachpadcable –fromfront of controllertoteachpad (9wDto9wDmaletomale).

Thereisalsoa Stop Jack forconnecting an externalstop circuit. Even if thereisno

externalstop circuit the jackplug must be plugged inat the rearof the controller. The plug

hasashorting link, whichisremoved when connecting an externalcircuit.

The serial(RS232 null modem)cablefromacomputertothe controllershouldplug into

the 25-wayDconnectoron the front of the controller. The otherend (usually9wD)

connectstothe rearCOM1serialconnectorof the computer. If COM1isalreadyinuse

you can useanyCOMport orthe USB serialadapter(see laterforconfiguration). The

serialspeed is19200 Baud, 8bits, 1stop bit.

DOSutilitiesonlyworkwithCOM1. You can still usethe DOSutilitiesif you havealegacy

computerorarerunning aDOSsimulatorsuchasDOSBOX.

R17HS alsohas

Powercable

Note: the motorpowercablecontainspowerdrivestoaxes4and 5but digitalsignalsto

axes1,2,3

R17 RobotManual page 7

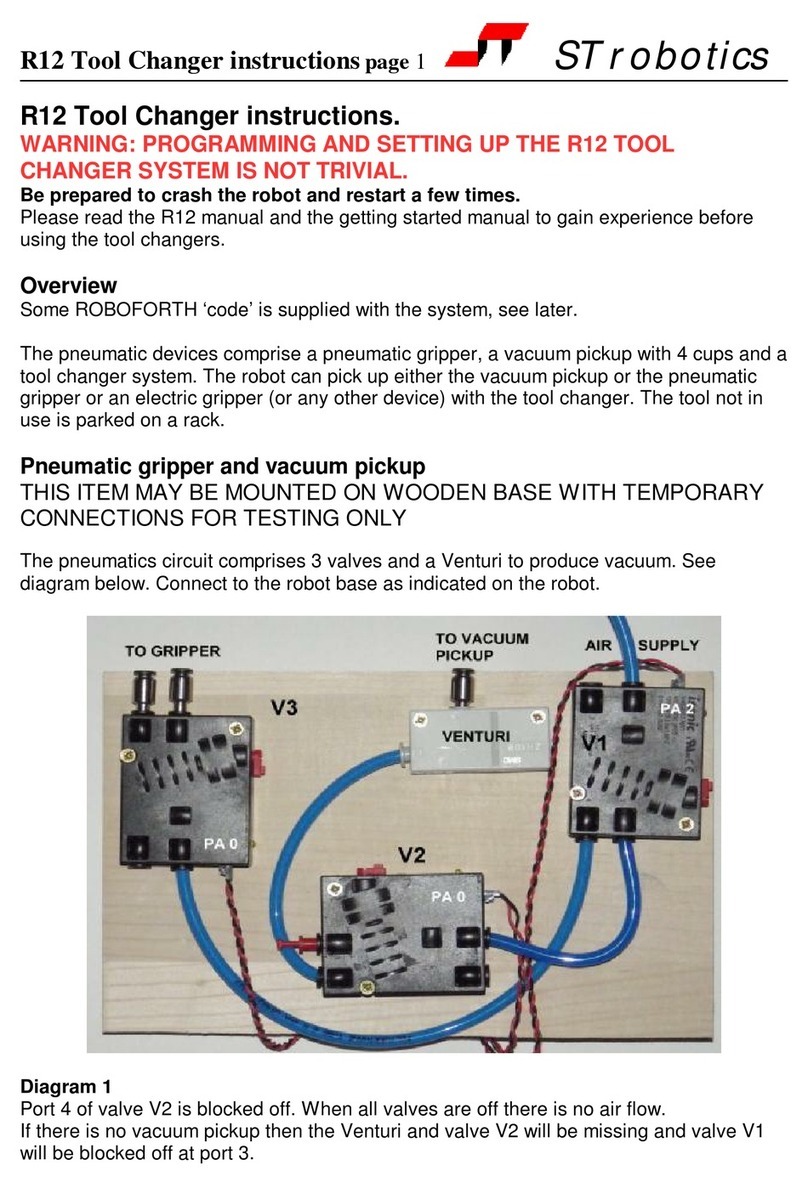

Pneumaticconnections

Connect the airline bypushing it intothe push-fit connectorson the airvalveand twofrom

the valvetothe rearof the robot. If thereisno compressorsupplied then connect the shop

airsupplytothe airvalve. The airsupplymust haveabowlfilterand apressureregulator.

Pneumaticgripper

If apneumaticgripperisfitted the robot will havetwoairlinesfitted through it, emerging on

the forearmon twopush-fit connectors. Twoexternallinesloop tothe gripper. The control

valveisusuallyexternal. The valveisoperated fromoutput port PA bit 0.

Electricgripper

If the electricgripperisfitted thisiswired through the robot and requiresno installation by

the customer. It isoperated byadrivemoduleinthe controller. It iscontrolled fromoutput

port PA bits0and 1. Onlyusethe commandsGRIPand UNGRIP. The softwareswitches

the motoron/off veryfast tocontrolthe speed of closing and opening (PWM). When

closed PA 0isset toa1and left on tocontinuouslyenergizethe motorand maintain

gripping force. AfterUNGRIPthe motorisleft non-energized.

Ared LEDshowswhen the gripperispowered (see diagrambelow).

Note: the electricgripperishardwired through the wrist mechanism. Makesureyou limit

rotation to360 degrees. If you go past the wrist rotatesensorand do anotherCALIBRATE

thismayresult inanother360 degrees. Eventuallythe wireswill twist and break. It should

be enough tosend UNTWISTbeforeeachCALIBRATE.

If indoubt removethe wrist cover(1screwand 2plasticrivets)and usethe teachpad to

untwist the gripper.

R17 RobotManual page 8

4. COMPUTER

Note: Commandstocomputerorcontrollerareinthe formof astring of characters

followed bythe enterkey. Inall myexamplesof dialog between man and machine I will

underline text typed inbythe user. I won't keep mentioning the need forthe enterkey. A

machine responsewill be inuppercasebut not underlined. Mycommentswill be inlower

case.

Beforeswitching on the controllerswitchon the computerand proceed asfollows:-

1Createadirectory(folder) ROBOTon C: drive

2Copyall the filestoyourROBOTdirectory

3If you havea USB-serial converter first install itssoftware. It shouldinstall itself

asmost versionsof Windowshavethe FTDI driveralreadyincluded.

4Plug inthe USB converterand useeitherthe serialcableorthe adaptortoconnect

tothe controller. Windows7will probablywant togo online forthe drivers, select

skipforbothdrivers, USB serialconverterand USB serialport. Onceinstalled it

shouldtell you what port numberit hasselected. If less than 10 then skipstep 5.

5If you arenot toldwhat the COMnumberisyou will need tofind out. Gotocontrol

panel, system, hardware, devicemanager, ports. You will see USB serialport -

notethe port COMnumber.

6RobWinwill onlyworkup tocom9soif yourconverterhasbeen mapped tohigher

than com9then double-click that port, then go tosettings, advanced. You will see

COMPort Numberclick the drop-down. You might see alot of COMportsmarked

"inuse". It'susuallyincorrect unless inusebybluetooth.Pick com3anyway(or

next availableafterbluetooth)up to9asindicated inthe devicemanager).It will

sayit'sinusedo you want tocontinue, click Yes.

Whatevercomnumberyou choose, makeanote.

7Find SetupRobwin.msi(orlater) and install RobWin7. You mayalsouseearlier

versionsrobwin6x.exeon the CD

8 Double-click robwin.exetorun.

9RobWindefaultstoCOM1. If you haveacomputerwitharegularserialport and

havebeen supplied witha25/9modemcablethen COM1iscorrect. But fora

USB COMport change tothe activecomport (see 6above). Click comm at the

top, then configureand makethat the samenumber. Baud rateshouldbe 19200.

10Click Settings, Open filethen enterR12R17.cfg

Forthe 6-axisversionsenterR12R17-6.cfg

R17 RobotManual page 9

5. POWERING UPTHECONTROLLER

Topowerup the controller, connect the powercordat the rearand operatethe power

switch, whichisintegralwiththe powerconnector. You mayhaveall othercables

disconnected if you wish. Howeverbe suretoturnoff the powerbeforeyou connect any

rear cable, especiallythe motorcable. When powerisswitched on the front TXlight

shouldflashwhichmeansit hassent the opening message tothe computer, whichyou

shouldsee, inthe communicationswindowof ROBWIN. If the light flashesbut nothing

appearson the screen then thisindicatesaproblemwiththe computer. Tryclicking

commsand select anotherCOMport. If you haveaUSB-serialconvertermakesurethe

COMport selected matchesthe port showninthe devicemanager. Alsomakesurethe

baud rateis19200.

The Mk5controllerCPUhasFlashROMand staticRAMon the samePCB.

Cold/warm/start selection isafront panelkeyswitch. The memoryimage isinflashROM

whichisloaded toRAMwhen you powerup (orpress reset). When powering up forthe

first timeselect COLDstart beforeyou switchon. You will see aheraldon screen that

shouldinclude the wordsCOLDSTART.

Frontpanel designations:

Fail: indicatespowersupplyprobleme.g. lowmainsvoltage. When poweristurned on it

stays lit until powersupplyissecure. Alsolightswhen reset ispressed.

OK: oppositeof fail, indicatesgood powersupply.

TX: lightswhen serialdataispassing fromcontrollertocomputer

RX: lightswhen serialdataispassing fromcomputertocontroller

STOP: stopsrobot motion (provided CPUisincontrol–see softwaremanual)

RESET: resetsCPU, DSP and otherlogic.

TEACH: teachpad input

COLD/WARM/AUTO switch–selectsstart-up mode when poweristurned on orreset is

pressed. (see section 7)

RS232 –connectstocomputer.

Note: if neitherFAILnorOKarealight then the rear12vfusemaybe blown.

R17 RobotManual page 10

If thereisno message on screen press the reset button on the front paneland watchthe

lights. The red led shouldlight asyou press the button. Asyou releasethe button the red

led goesout, the green light comeson and the yellowTXlight shouldflash. If it flashes

the controllerhassent charactersup tothe computer. Check the screen. If thereis

nothing therecheck comport and baud rate.

Assuming you havethe heraldpress the enterkeyand you shouldsee

>OK

Press capslock and you shouldnowbe abletotype commandsintothe communications

window, forexampleSTART

RearFuses

Viewed fromthe rearof the controllerfromright toleft:

Powerconnectorhas2fuses. Theseshouldbe 6.5Aanti-surge for110vpowerand 3.5A

ant-surge for220-240 power.

12vunregulated DC fuse. Thisshouldbe 3ampquick blow. The 5vlogic(and lower) all

comesfromthe 12vregulated supplysoif thisfuseblowsthe wholecontrollerisdead.

Thissupplyemergesfromthe 9wayinput and 15 wayoutput connectorsforusers

sensorsetcsoif you areblowing 12vfusesthe fault wouldbe there.

24vunregulated DC fuse. 24visan alternativeforusersexternalcircuitryasmost

industrialcontactorsetcareall 24vDC. Pneumaticvalvescan be 12vor24v.

Stop Jack

Alsoon the rearpanelisajack plug. Thisisforthe externalstop circuit and hasit’s

terminalslinked inside the plug. If the jack plug isremoved the robot will not run.

R17 RobotManual page 11

6. PREPARING FORUSE

WARNING

Beforetryinganyofthefollowingcommandsbesureto

KEEP OUTOFTHEROBOTENVELOPE

Note: ALL FORTHandROBOFORTHCOMMANDSAREINUPPERCASE.

Withpoweroff first visuallyset the robot up approximatelyinthe HOMEposition. Thisis

withthe robot vertical.

Fora5axisR17 the hand orgripperwill be pointing straight up.

Fora6-axisR17 the hand orgripperpoint backwardsasinthe picturebelow:

5-axishome 6-axishome

(handpointsbackwards)

R17 RobotManual page 12

Check thatsensorsandencodersareworking(optional)

Forassurancebeforeyou calibrateyou can check the sensorsorencodersasfollows:

Check sensorsifyoususpectanytransitdamage.

1. Switchoff the controllerand wait 10 seconds. Disconnect the motor(metallized)cable

and the R17HSservopowercable(twisted red and black pair). Connect onlythe

sensor/encodercabletothe robot –thisisthe cablewitha25wDeachend. Switchon the

controller.

2. Enter

PP <enter>

Arowof 1sappearse.g.

11111111

Theserepresent the calibration sensorson the robot. Set the robot up inan approximate

homeposition, whichiswiththe armsbolt upright. Lookunderthe waist and you will see a

peg and atoggleinthe base. The peg shouldbe 180 degreesfromthe togglesothat the

waist has+/-180 degreestravel.

3. Nowmovethe jointsslowlyinthe directionsindicated infigure3and each1will change

to0withabeep. Fromright toleft the digitsare: waist, shoulder, elbow, left hand, wrist.

You might not be abletofind the hand sensors. The left-most 3digitsshouldstay1s. For

exampleif you movethe shoulderbackwardtoitssensoryou will see:

11111101

If you then movethe elbowforwardstoitssensoryou will see:

11111001

Tocheck the waist sensorit might be easiertoplaceaknifeorsteelruleunderthe waist

sensor, whichcan be seen underthe skirt. Assuming the shoulderand elbowarenot at

theirsensorsyou wouldsee:

11111110

You can not check the 6thaxisbecauseof itshigh gearratio. But if it isinthe sensing

position you will see

11011111

Press escape toexit the PP command.

Check encoders

4. Enterthe following:

ROBOFORTH<enter>

Thisinvokesthe RoboForthdictionary. Thisisonlynecessaryafteracoldstart and you

need totype it everytimeyou switchon if the keyisset to‘cold’.

START<enter>

ENCTEST<enter>

Arowof numbersappears. Asyou moveeachjoint byhand the numberswill change.

Thisshowsthe encodersareworking. Press escape keytoexit thismode. The 6thaxis

doesnot havean encoder.

5. You arenowreadytoconnect the motors. SWITCH OFF THEPOWERFIRSTand wait

10 secondsbeforeconnecting the motorcablefromcontrollertorobot. Inthe caseof R17

HSalsoconnect the R17HSpowercablebeforeyou switchon.

R17 RobotManual page 13

7. GETTING STARTED WARNING

Beforetryinganyofthefollowingcommandsbesureto

KEEP OUTOFTHEROBOTENVELOPE

Note: ALL FORTHandROBOFORTHCOMMANDSAREINUPPERCASE.

Assuming ROBWINisloaded and running:

1. Switchon the controller

2. Press capslock and you shouldnowbe abletotype ROBOFORTHcommandsintothe

communicationswindow.

3. Type

ROBOFORTH <enter>

(if the keywasset to‘cold’)

4. Inthe communicationswindowtype

START <enter>orclick the button

Aheraldwill appearannouncing ROBOFORTHand it’sversion.

Even though you havenot yet calibrated the armyou can check out the axeswiththe

teachpad.

5. Tostart moving the armclick the button ortype

TEACH then press <enter>twotimes. Ignoreany“FN=”message.

The red “TEACH”and green “ON”lightsshouldbe on.

Withthismethod pressing akeyon the teachboxmovesthe

arm. Sinceyou might let go of the keyat anytimeand expect

the robot tostop it isnot possibletoacceleratetohigh speed.

Moreoveraslowspeed ismoredesirabletoachieveprecision,

and the teachspeed isrequested afteryou enterTEACH. At

thisstage just hit the returnkeyforthe default value.

Afterentering TEACH you arenowin"TEACH mode". To

movethe armfirst select the joint tomove, J1forwaist, J2for

shoulder, J3forelbow, J4forhand, J5forwrist roll. Ona6-

axisrobot J5isyawand J6iswrist roll. Onselecting ajoint the

terminal/computerwill beep. Then press either +or -formotion

inapositiveornegativedirection.

Totest the gripperpress the keymarked 'GRIP', then toclose

the gripperpress the +keyand toopen the gripperpress the -

key. Donot tryotherkeys forthe moment. UseTEACH mode

totest all the jointsand finallydrivethe robot toan

approximatehomeposition. Exit TEACH mode bypressing the

escape (ESC)keyon the computer/terminal.

6. Next the robot shouldbe calibrated.

Enter:

>CALIBRATE

The robot beginstofoldup asit searchesforinternalsensors. See diagrams3a-cbelow.

Notethat you haveCALIBRATEdthe armfromaposition, whichisclosetothe HOME

position. You mayCALIBRATEfromotherpositionsprovided eachjoint iswithinitssearch

range. Inthe diagramsthat follow, the searchrange ismarked YES and the forbidden

R17 RobotManual page 14

range ismarked NO. If you start acalibration withan axisinthe NO range then that joint

will foldinand collide withaphysicalstop oranotheraxis.

6th Axisversion Notethereisadifferencebetween the calibrateroutinesof 5and 6axis

versions. Inthe 5-axisversion all axescalibrateat oncebut inthe 6-axisversion they

calibrateone at atimetoprevent collision of the 6th axisgripperwiththe fore-arm.

7. Enter

>HOME

whichdrivesthe wholearmtothe HOME(000000)position.

Note: you can go direct fromCALIBRATEtosomeotherposition incaseof lack of

headroom. Diagram3a:R17 robotshownincalibrateposition

R17 RobotManual page 15

R17 RobotManual page 16

8. END EFFECTORS

PneumaticGripperconnections

If the gripperopenswhen it shouldcloseand viceversasimplyswap overthe two4mm

tubesat one end.

Programmingtheoptional confirmationsensor.

The confirmation sensorisnormallyconnected toPB 5. ThereisaRoboForthword

GRIPCHECKwhichchecks tosee that the gripperhasclosed on apart. Thisisbest

used after the robot haswithdrawnfromthe activearea, forexampleinsert thisword

at asuitableplaceforthe robot tocheck it hasavalidpick e.g.

JIG GRIP WITHDRAW GRIPCHECK

If the gripperisnot closed on an object you will get the “GripFail”error.

Adjustingtheoptional gripsensor.

It hasalreadybeen set at the factorybut shouldit requirefurtheradjustment proceed as

follows. Disconnect the airsupplysoyou can movethe gripperjawsbyhand.

1. Type PP todisplaythe input port. You shouldsee 11111111

2. Asyou closethe jawsyou shouldsee the sensorgo from11111111 to11011111 and

back to11111111 again.

3. Put the object tobe handled inthe jawsand closethe jawsbyhand. The screen

shouldshow11011111

4. Adjust the sensorbyslackening the small screwon the side and sliding it up and down

the slot asnecessaryuntil you see the 11011111. The objectiveisthat you onlysee

the zeroon the object but withno object (jawsfullyclosed)orwiththe jawsfullyopen

the screen shouldshow11111111

If you wishtomovethe gripsensortoanotherport, forexampletoPB 7then you can

patchthe definition of GRIPSENSE. Check the existing value with

‘ GRIPSENSE 2+ ? (answer should be 5)

Patchwith

7 ‘ GRIPSENSE 2+ !

R17 RobotManual page 17

Vacuumpick-upconnections:

Programmingthevacuumsensor.

The vacuumswitchisconnected toPB 5*. You can quicklycheck thiswith

GRIPCHECK

Insert thiswordat asuitableplaceforthe robot tocheck it hasavalidpick e.g.

JIG GRIP WITHDRAW GRIPCHECK

If thereisno vacuum(object not picked)you will get “Gripfail”error.

*on a6-axisrobot it isPB 6, pins7and 1

Adjustingthevacuumsensor.

It hasalreadybeen set at the factorybut shouldit requirefurtheradjustment proceed as

follows:

1.type GRIP(rememberthat thisconsumesagreat dealof airand you mayneed to

UNGRIPthen allowthe compressortorecharge beforetrying again.

2.Type PP todisplaythe input port. You shouldsee 11111111

3.Adjust the sensorusing the 1.5mm Allen keysupplied until you see 11011111 then

back off againuntil you see 11111111.

4.Coverthe vacuumcupsand the displayshouldchange back to11011111

Type 2sensor:

The adjusterforthisisinside the port. You need toremovethe tube, makeatrial

adjustment then replacethe tube totest.

R17 RobotManual page 18

Ifyouhavemultipletoolsand/oratool changer.

Notethat an electricgripperusesPA 0and1 inPWMmode toopen the gripper.

Tochange between electricgripperand pneumaticgripper:

Enter

1 GTYPE ! forelectricgripper

0 GTYPE ! forpneumaticgripper

If you havebothelectricgripperand vacuumthen the vacuumvalveshouldnormallybe

on PA 2not 0. GRIPand UNGRIPthen operatethe valve. If the vacuumisconnected to

someotherbit, not PA 0enterthe bit numberintoGTYPE

Forexample4GTYPE !if the valveisconnected toPA 4.

Then you can still useGRIPand UNGRIPwhichwill operatePA 4instead of PA 0

If you haveatoolchangerthen the toolchangeritself alsoneedspneumatics.

See the separateR17 toolchangermanual.

Quick-stop sensor

Thisisthe devicefitted between the robot flange and the end-effectortoprotect it from

collision. It works withcompressed air, requiring aseparateairline and itsownpressure

regulatortocontrolthe sensitivity, Thereforethereisanotherairline emerging fromthe

forearmaswell asan electricalcableand connector. The deviceisheldrigidbyair

pressurebut inthe event of acollision the deviceopens, releasing the pressure. An

internalpressuresensorthen breaks the stop circuit and the robot stops.

Connect using apush-fit Y-junction provided. One airline goestothe grippervalveand

the othertothe quickstop viathe flowreducer. The flowreducerservestoreducewasted

airwhen the quickstop isopen.

Quick-stop pneumaticconnections:

Forinitialsetting up you mayprefertoleavethispressureoff. Replacethe stop jack from

the quick-stop withthe dummyprovided.

When you arereadytousethe sensorconnect the airline, turnon pressureand

manipulatethe end effectoruntil the sensorlocks. Then replacethe stop jack.

Totest the sensorenter

STOPCHECK<enter>

The result when the sensorislocked will be OK

EnterSTOPCHECKbut beforeyou press enterforcethe sensoropen then press <enter>.

The result will be ‘STOPBUTTONPRESSED’.

Don’tdo thistestuntil youhaveperformedtheinitial setupinsections3and6.

R17 RobotManual page 19

9. CONTROLLERSETTINGS

Changingdefaultvalues

All the robot parametersrevert totheiroriginalvalueswhen the controllerispowered up or

the reset ispressed. If you want tochange thesevaluesand makethe changes

permanent you need towritethemtoflashROMwiththe command

USAVE

Changestoanyvariableinthe RoboForthitself aresaved withPSAVE. Beverysureyou

havenot made amistakebeforeyou usethiscommand becauseif the flashROMis

corrupted it isverydifficult torecover(see below).

FLASHROM

Coldstartmode

When powerisswitched on, orthe reset button ispressed all RAMcontentsarerefreshed

fromflashROM. All the userprogramming, whetherentered inimmediatemode orusing

ROBWINwill be lost.

Afteryou see the heraldand the words‘coldstart’enter

ROBOFORTH

Warm startmode

If powergoesoff/on orthe reset button ispressed all RAMcontentsarerefreshed from

flashROMincluding the userprogramarea. Thereforeyouruserprogramwill be over-

written withanyolderprogrampreviouslysaved. Toensurethat the newprogramis

reloaded afterapower-up orreset type the command

USAVE

Orclick USAVE inROBWIN.

If you forget todo thisand accidentallylosepowerorpress reset (orareforced topress

reset becauseof abug)then inROBWINsavethe project and re-open it.

The verycoreof the systemisForthand thisisinaprotected sectorsocan not be

changed inFlash. You can howevermaketemporarychangeswhileit isinRAMbut after

the next reset orpower-up it will revert tooriginal.

R17 RobotManual page 20

10. ROBOTPARAMETERS

WARNING –thereshouldbenoreasontoalterthese constantsunless some

changehas beenmadetotherobot, forexamplearepair.

Theseparametersareparticulartoyourrobot, sometimescalled a‘signature’. Theyare

stored inflashmemory.

RAMmemoryisloaded fromflashROMon eachpower-up orreset. If you change

something you will need toupdatethe flashROMsotest thoroughlybeforeyou do this.

If you aresupplied withanewversion of ROBOFORTHyou will need totransferthe

parameterstoadisk file, load the newROBOFORTHasdescribed abovethen overlaythe

parametersfile.

Tosavetheparameters(signature)

1. Click file–savebinary.

bank0

start address A200

length200

2. SaveasR17Cnnn.SIG –wherennn isthe serialnumberof the robot. The actual

filenamewill be R17Cnnn.SIG.ram. It'sbest touseadifferent filenameand

preservethe originalfile.

If you corrupt the sigfileinflashROMand need toreload it fromthe CD:

Toreload(overlay)theparameters.

1. Click file–load binary.

bank0

start address A200

length200

Choosefilenameyou used tosaveabove.

2. When loaded enterUSAVE tosavethe the parameterstoflashROM.

ReloadROBOFORTH

If you corrupt ROBOFORTHand havedone aPSAVE (therebysaving the errortoflash

ROM)you can reload ROBOFORTHasfollows:

1.Select coldstart and press reset.

2.Select file–load binary. Change parameterstostart 4000, length6000 (bankshould

be 0)

3.Choosethe backup filesupplied withyourrobot e.g. R17C123.RAMYou will see a

blue progress bar.

4.When finished downloading enterROBOFORTH

5.EnterPSAVE toreload the flashROM.

Other manuals for R17

1

This manual suits for next models

1

Table of contents

Other ST Robotics Robotics manuals