Contents UM0240

2/39

Contents

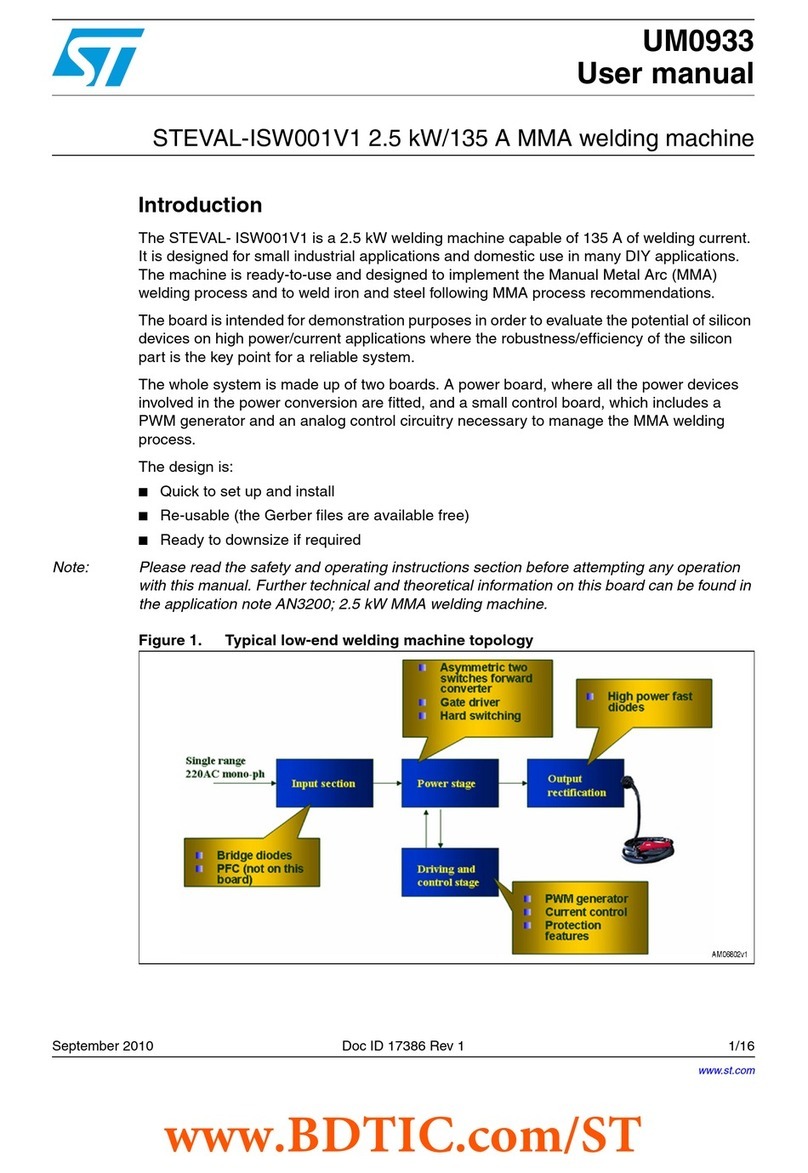

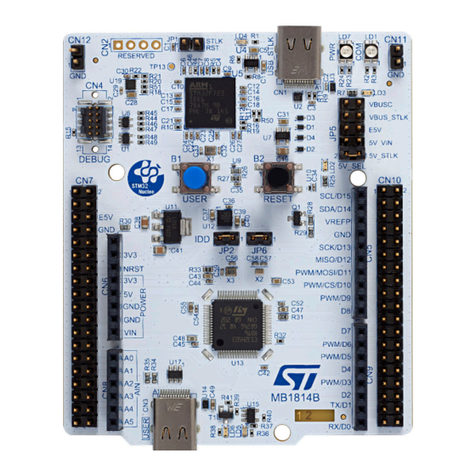

1 System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

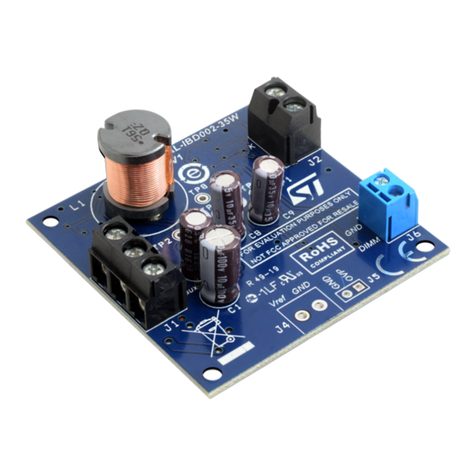

2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Main power supply (VDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 MCU Flash programming (VPP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 OpAmp negative supply (-5V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

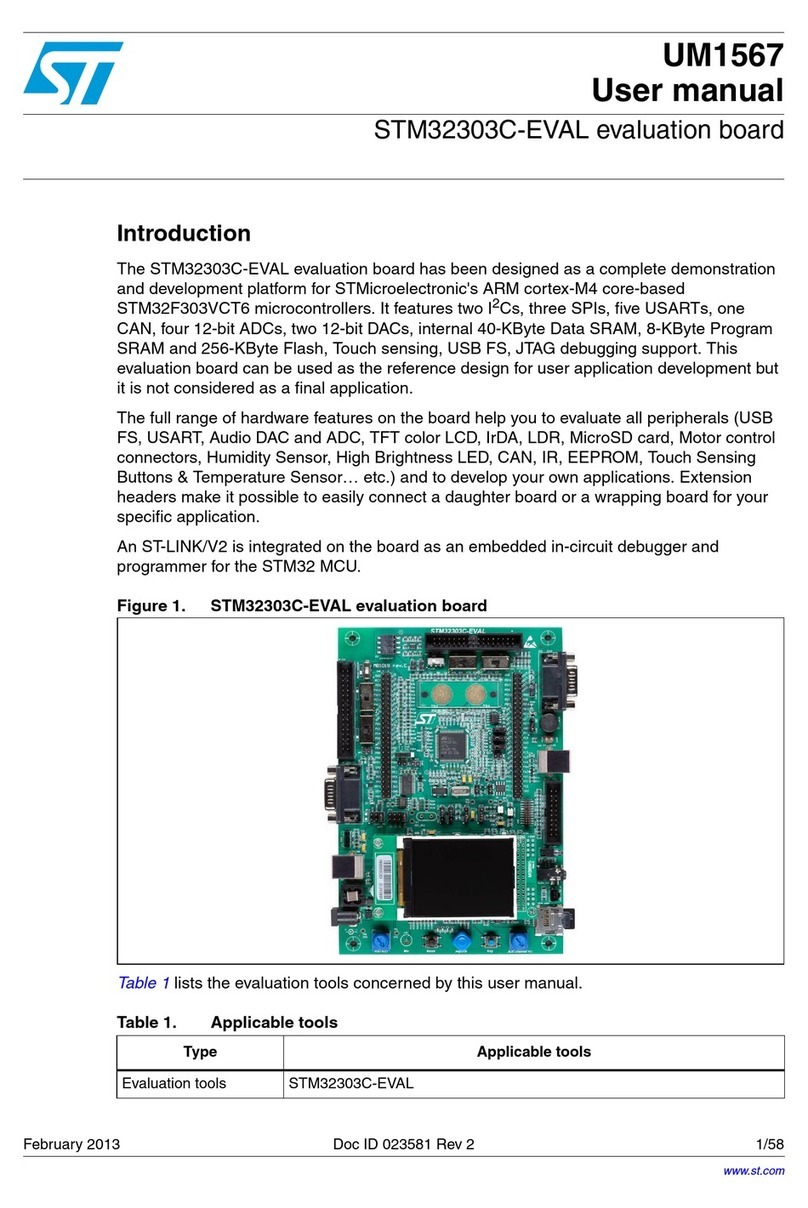

3 Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Microcontroller features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Internal time base generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

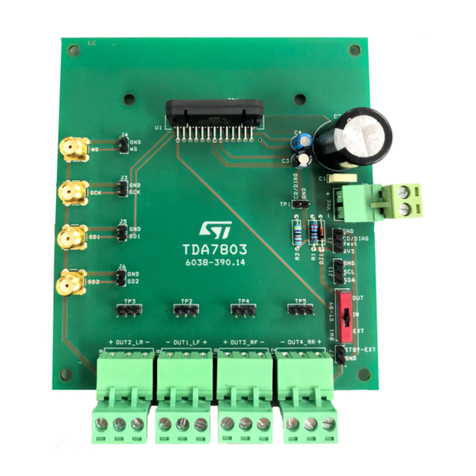

4 10-bit digital-to-analog converter (DAC) . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Operational amplifiers (OpAmp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Interfaces and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.4 Power line communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.5 In-circuit communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.6 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.7 Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.1 Power line communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.2 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26