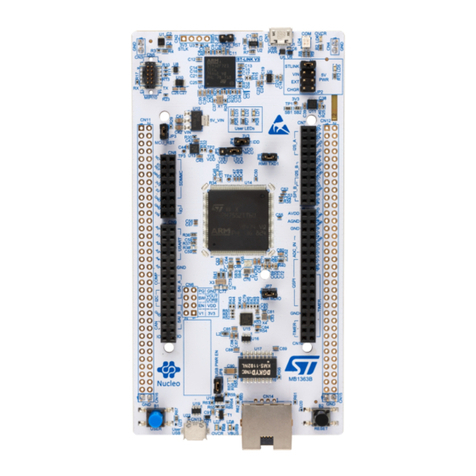

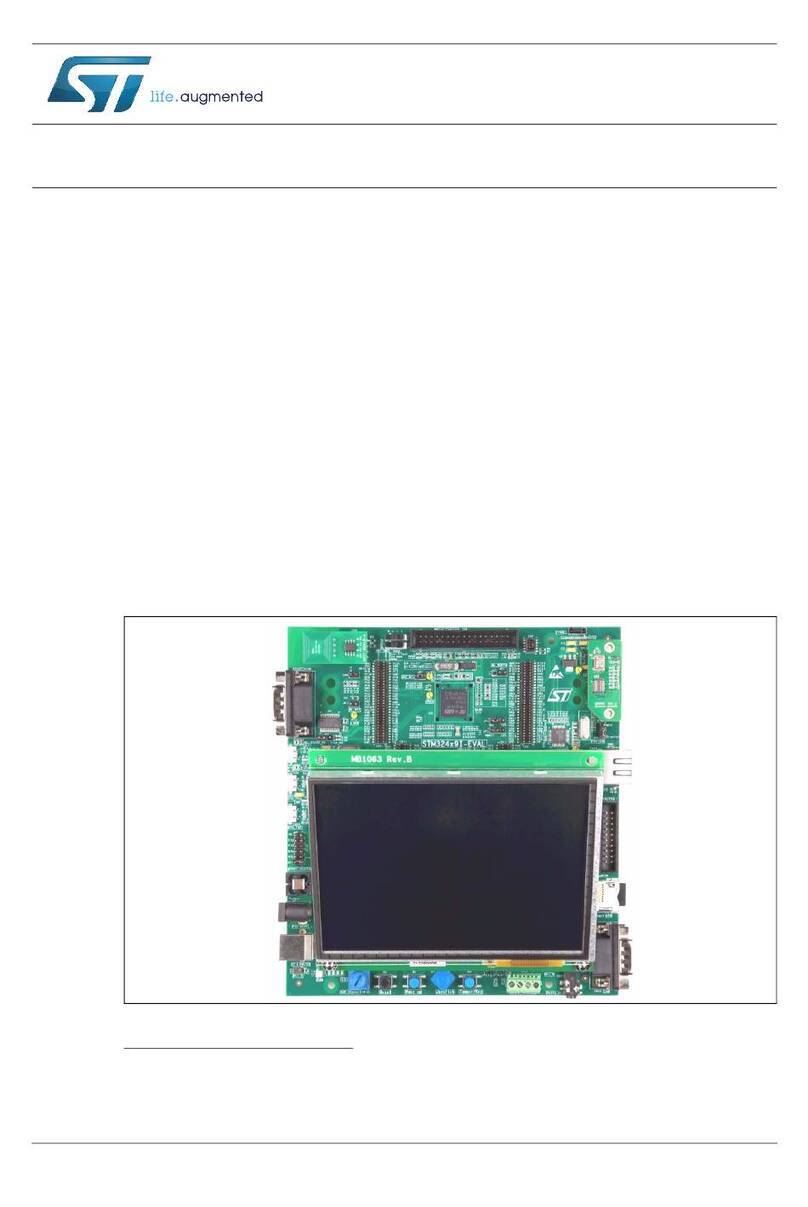

STM3220F-EVAL Board

Qing SHAO Page 3 03/06/2009

Contents

1. Hardware Layout and configuration ...................................................................................... 4

1.1 Power Supply.................................................................................................................. 6

1.2 Boot Option ..................................................................................................................... 7

1.3 Clock Source................................................................................................................... 8

1.4 Reset Source................................................................................................................... 8

1.5 Audio ............................................................................................................................... 8

1.6 EEPROM......................................................................................................................... 8

1.7 CAN................................................................................................................................. 8

1.8 RS232 & IrDA................................................................................................................ 10

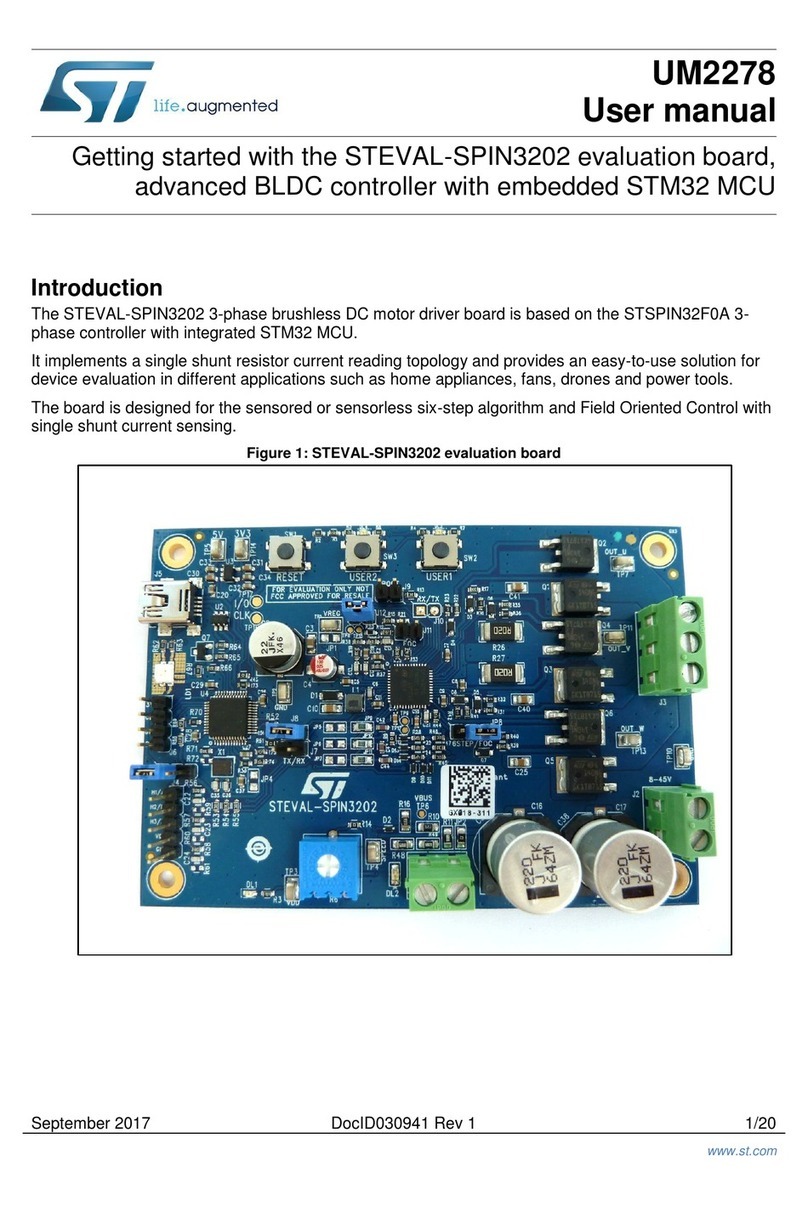

1.9 Motor Control................................................................................................................. 10

1.10 Smart Card.................................................................................................................. 11

1.11 MicroSD card............................................................................................................... 12

1.12 MEMS.......................................................................................................................... 12

1.13 Analog Input................................................................................................................ 12

1.14 USB OTG FS............................................................................................................... 13

1.15 Ethernet....................................................................................................................... 13

1.16 USB OTG HS.............................................................................................................. 14

1.17 Camera Module........................................................................................................... 14

1.18 PSRAM and OneNAND .............................................................................................. 14

1.19 Development and Debug support ............................................................................... 14

1.20 Display and Input devices ........................................................................................... 14

1.21 IDD measurement and comparator............................................................................. 15

2. Connector ............................................................................................................................ 17

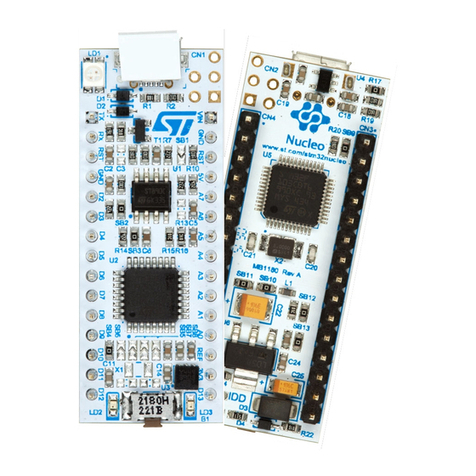

2.1 Daughter board extension connector CN1,2,3 and CN4 .............................................. 17

2.2 Motor control connector CN5 ........................................................................................ 21

2.3 MicroSD connector CN6 ............................................................................................... 22

2.4 Ethernet RJ45 connector CN7...................................................................................... 22

2.5 USB OTG FS Micro-AB connector CN8 ....................................................................... 23

2.6 USB OTG HS Micro-AB connector CN9....................................................................... 23

2.7 CAN D-type 9-pins male connector CN10(CAN2) & CN12(CAN1) .............................. 24

2.8 Audio connector CN11.................................................................................................. 24

2.9 Trace debugging connector CN13................................................................................ 24

2.10 JTAG debugging connector CN14.............................................................................. 25

2.11 Camera module connector CN15................................................................................ 25

2.12 RS232 connector CN16.............................................................................................. 26

2.13 Analog input connector CN17..................................................................................... 26

2.14 Power connector CN18............................................................................................... 26

2.15 TFT LCD connector CN19 .......................................................................................... 27

2.16 Smart card connector CN20........................................................................................ 27

3. Known limitations and bugs on PCB rev A.......................................................................... 28

4. Schematic............................................................................................................................ 29

Appendix A STM3220F-EVAL IO Assignment........................................................................ 49

Appendix B Document Revision History.................................................................................. 53