STABILUS Ace FRT-E2-100 Service manual

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

FRT-E2

FRT-E2-G1

FRT-E2

Rotary Dampers

Small and lightweight for finest braking

Continuous Rotation

Damping torque 0.1 Ncm to 0.4 Ncm

Table of contents Page

General instructions................................. 2

Safety information ................................... 2

Intended use........................................... 2

Description and function........................... 2

Calculation and design ............................. 2

Delivery and storage ................................ 2

Maintenance and care.............................. 2

Disassembly and disposal......................... 2

Mounting instructions................................ 3

Warranty ................................................. 4

Expected service life................................. 4

Technical data.......................................... 4

Operating and mounting instructions

General instructions and technical details

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

2

α

Calculation and design

In order to ensure an optimum fault-free and durable function of the rotary dampers, they must be correctly dimensioned and designed. The following parame-

ters must be known and used in the calculation.

- Temperature

- Damping torque

- Speed

- Cycle number

Should you have any further questions about the use of rotary dampers, please contact one of our ACE technicians.

For free calculation service, phone: +49 (0)2173 - 9226-20.

Calculation steps

1. Calculate torque for unfavourable angle

(see example on left: 0°).

2. Determine angular speed.

3. Choose a suitable rotary damper for the calculated torque.

4. With the aid of the damper performance curve, check whether

the rpm matches the desired speed.

5. If the rpm is too high – choose a higher torque.

6. If the rpm is too low – choose a lower torque.

Torque

M = L / 2 · m · g · cos α

(L / 2 = centre of gravity)

mMass in kg [1 kg = 9.81 N]

LFlap length in cm

nSpeed in rpm

Calculation example: Damping of a flap

In order to select a suitable rotary damper for the calculation

example shown, the length and the weight or centre of gravity of

the flap must be specified. Once the max. torque value with an

unfavourable angle of the flap has been determined, a suitable

brake is selected.

Intended use

ACE rotary dampers ensure the controlled opening and closing of

small covers, compartments and drawers. They can brake directly

at the pivot point or linearly via rack and pinion to attain a smooth

and quiet movement. Sensitive components are preserved. The

harmoniously gentle process increases the quality and value of the

product.

Description and function

With continuously rotating rotary dampers, fluid damping is

facilitated through shearing of thin silicone layers between the

areas of a rotor and a stator.

The damping torque is determined by the viscosity of the fluid or

the dimensioning of the damping orifice.

ACE rotary dampers are maintenance-free and ready-to-install.

The damping direction is two-sided. The outer bodies are made

of plastic. The power transmission can take place via shaft

attachment or gear (4 standard modules). For rotary dampers

with pinions, racks (modules 0.5 to 1.0) made from plastic are

available.

Delivery and storage

- After delivery please check the rotary dampers for any damage.

- The rotary damper can become damaged if it falls. Carefully

remove rotary damper from the packaging.

- Rotary dampers can generally be stored in any position.

- Storage in the original packaging is preferred.

- Always store rotary dampers dry.

- The recommended maximum storage time is two years.

- Storage of rotary dampers is permissible at -20 °C to +70 °C.

Maintenance and care

Regularly check the rotary damper for oil loss and external dam-

age. Rotary dampers are machine elements that are subject to

continuous wear. Increased service life results in reduced braking

effect. If this is no longer sufficient, the rotary dampers must be

replaced or exchanged as appropriate.

Disassembly and disposal

Take account of environmental protection (recovery of problematic

substances) during disposal of the rotary dampers. The rotary

dampers are filled with silicone oil. The corresponding data sheet

is available on request. By design, the silicone oil cannot be

refilled. The rotary dampers cannot be repaired. Faulty brakes can

be sent to our service department for determination of the cause

of failure.

WARNING

If ACE rotary dampers are used where a failure of the

product could lead to personal injuries and/or material

damage, additional safety elements must be implemented.

Free-moving masses, such as lids, flaps, covers etc., can

lead to injuries by crushing during installation of the rotary

dampers. Secure moving flap/mass against falling down!

General instructions

Safety information

This manual is for the disruption-free use of the product

types listed on page 1; its compliance is a prerequisite

for the fulfilment of any warranty claims.

Therefore, make sure to read this manual before use.

Always maintain the limits specified in the performance

table. Take into account the predominant environmental

conditions and restrictions. Note the regulations of

the trade association, TÜV or corresponding national,

international and European regulations. Installation and

commissioning only according to mounting instructions.

Rotary Damper FRT-E2 (continuous rotation)

Manual

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

3

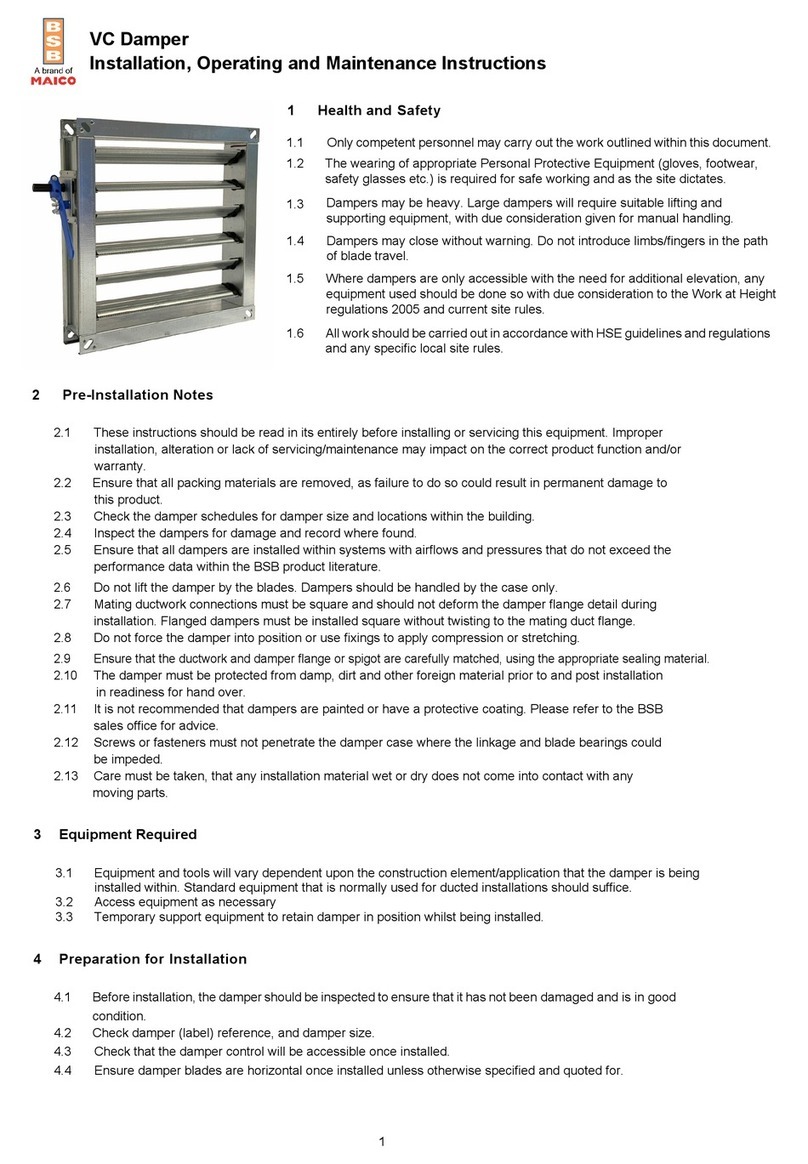

Mounting instructions and mounting accessories

Construction size: Ø 10 mm

Max. speed: 50 rpm

Lifetime: 50,000 cycles (1 cycle = 360° left-hand, 360° right-

hand), at least 80 % of the original damping torque after this. The

service life may be significantly higher or lower, depending on the

application.

Operating temperature range: 0 °C to +50 °C

Pressure angle: 20°

Material: Outer body, shaft, gear: Plastic

Mounting: in any position

Tooth: Involute gearing

P.C.D.: 6 mm

Number of teeth: 10

Module: 0.6

Damping medium: Silicone oil

Mounting information: Attach the damper to the securing tabs

in such a way that the part to be braked cannot exert any side

forces on the damper. No axial or radial forces may be introduced

via the shaft. The rotary axis was not designed for side loading

(see diagrams).

Packaging disposal: Please dispose of the transportation pack-

aging in an environmentally-friendly manner. Recycling packaging

materials saves raw materials and reduces waste. The packaging

materials do not contain any prohibited materials.

Angular offset Misalignment

Side loading End loading

Note! The rotary axes, square mounts or free-wheel

mounts are not designed for side loading.

Installation instructions

Before installation and use check whether the identification num-

ber on the product or on the packaging matches the respective

designation on the delivery note.

Rotary dampers are maintenance-free and ready-to-in-

stall.

WARNING

The specified rated damping torque

applies at a temperature of 23 °C or a

speed of 20 rpm. The damping torque can change depending

on the temperature or speed. Please observe the characteristic

curves in the mounting instructions.

The flap/mass can fall off during installation and removal

of the rotary damper. Secure moving flap/mass against falling

down!

Depending on the application, failure of the product could

lead to personal injuries and/or material damage. Use

additional safety elements.

Exceeding the permissible temperature range, the max.

speed, the cycle number and the specified damping torque

can lead to premature failure or destruction of the rotary

damper. Operating temperature range, speed of 50 rpm, cycle

number of 10/min. and the specified damping torque must be

maintained.

Dirt, swarf and aggressive liquids can cause premature

failure of the rotary damper. Protect or encapsulate rotary

damper from external materials in the surrounding area.

Do not use rotary dampers in high-pressure or vacuum

range.

0.8

0.6

0.4

0.2

0

400

300

200

100

Ncm

0 3 5 10 20 30 40 50

rpm

0.6

0.5

0.4

0.3

0.2

0.1

0

400

300

200

100

Ncm

0 10 20 30 40 50

°C

14 +/- 0.05

2 +/- 0.05

2.1

2.6

2.5 +/- 0.05

10

2.1

6

Ø

Ø

Ø

19

1.5

3

2.5

6 (5.5)

7.2

Ø

Dims. in ( ) without gear

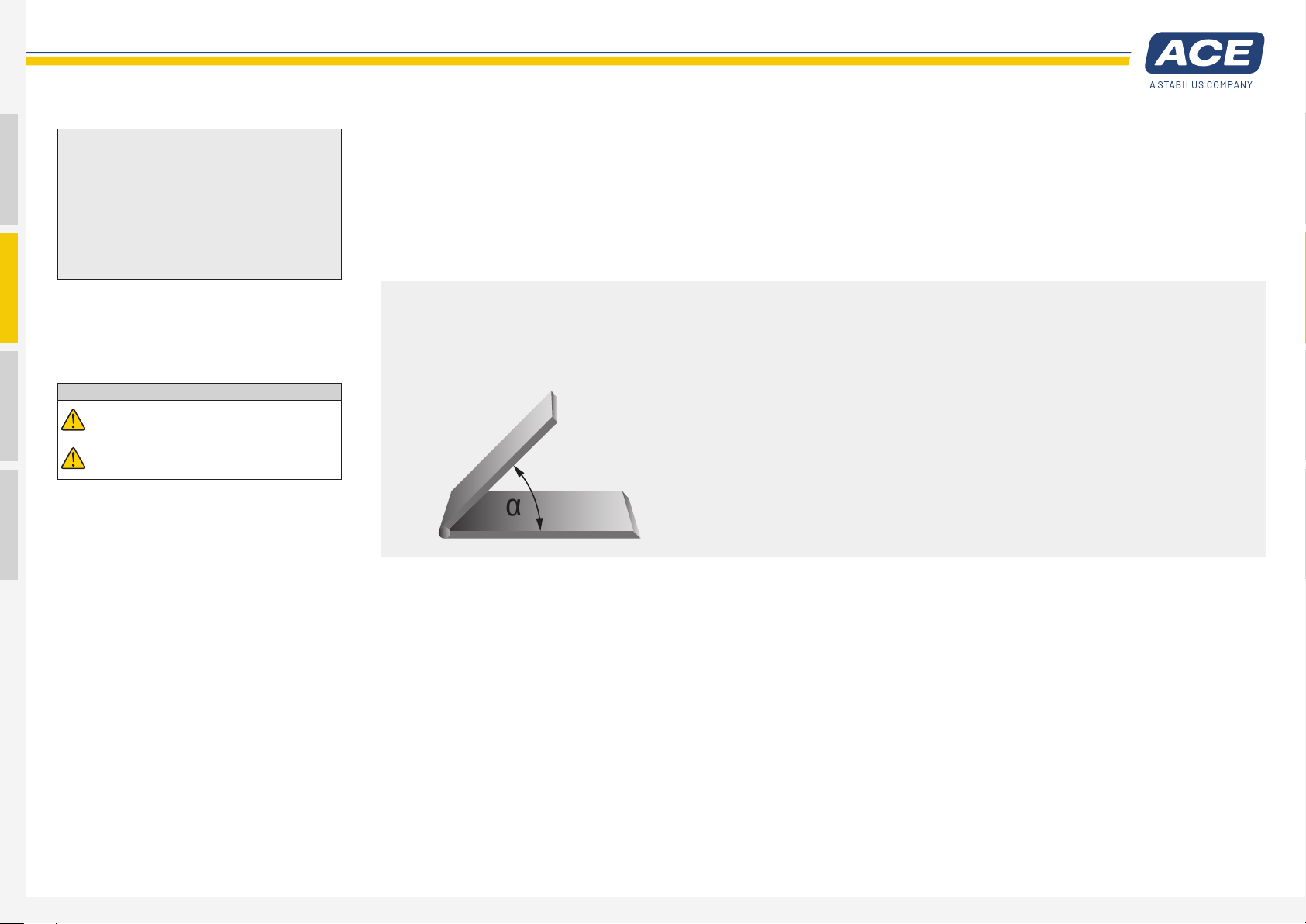

Performance data

TYPES

1Damping torque

Ncm

Damping direction Gear Module Number of

teeth Pressure angle

°

P.C.D.

mm

Weight

kg

FRT-E2-100 0.10 +/- 0.05 two-sided without - - - - 0.00032

FRT-E2-200 0.20 +/- 0.07 two-sided without - - - - 0.00032

FRT-E2-300 0.30 +/- 0.08 two-sided without - - - - 0.00032

FRT-E2-400 0.40 +/- 0.10 two-sided without - - - - 0.00032

FRT-E2-100-G1 0.10 +/- 0.05 two-sided with 0.6 10 20 6 0.00041

FRT-E2-200-G1 0.20 +/- 0.07 two-sided with 0.6 10 20 6 0.00041

FRT-E2-300-G1 0.30 +/- 0.08 two-sided with 0.6 10 20 6 0.00041

FRT-E2-400-G1 0.40 +/- 0.10 two-sided with 0.6 10 20 6 0.00041

1The indicated damping torques refer to a rotational speed of 20 rpm and an ambient temperature of 23 °C.

Characteristic curves

At 23 °C ambient temperature

FRT-E2

At 20 rpm speed

Safety instructions: Do not use rotary dampers as supports.

Provide an external guide or support.

On request: Special designs available on request. Toothed

plastic racks (modules 0.5 to 1.0) are available for the rotary

dampers with pinions.

Rotary Damper FRT-E2 (continuous rotation)

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

4

Warranty

Fundamentally, all modifications to the product by third parties

lead to exclusion from the warranty.

Obvious defects must be reported to the vendor in writing immedi-

ately after delivery, no later than one week, but in any case before

processing or installation, otherwise the assertion of a warranty

claim is excluded. A timely dispatch is sufficient to keep the term.

The vendor is to be given an opportunity to check on site. If the

complaint is justified the vendor offers warranty by repair or re-

placement at its own discretion. If the rectification fails, the buyer

may choose to demand reduction of payment or cancellation of

the contract. If there is only a minor lack of conformity, particularly

with only minor defects, the buyer nevertheless has a right of

withdrawal.

If, after failed rectification, the buyer chooses to cancel the

contract due to a defect of title or material defect, they are not

entitled to additionally claim for damages.

If, after failed fulfilment, the buyer chooses compensation, the

goods remain with the buyer, if this is reasonable. The compen-

sation is limited to the difference between the purchase price and

the value of the defective item. This does not apply if the vendor

maliciously causes the breach of contract.

The quality of the goods is only considered as agreed upon with

the product description of the vendor. Public statements, claims

or advertising of the manufacturer do not represent an additional

contractual specification of quality of the goods.

If the buyer receives defective mounting instructions, the buyer

is only obligated to deliver defect-free mounting instructions and

only if the defect to the mounting instructions prevents proper

mounting.

The warranty period is two years and begins upon completion.

Exchange and return of custom products are fundamentally

excluded. The factory conditions of the manufacturing factory

apply to parts not manufactured and processed by the vendor,

which can be viewed by the orderer at the vendor at any time.

Construction and installation parts are delivered according to the

present standard of engineering.

Manufacturer's declaration as part of the EC Machinery Directive 2006/42/EC

We hereby declare that the model of industrial shock absorbers, industrial gas springs, hydraulic dampers, rotary dampers and profile

dampers or individual positions thereof are intended for installation in a machine in the execution delivered by us. Its commissioning

is forbidden until such a time that it is established that the machine, into which the elements above are to be fitted, meets the regula-

tions of the EC Directive version 2006/42/EC of 17 May 2006.

The products listed above are not autonomous or incomplete machines and do not fall under the Machinery Directive 2006/42/EC.

Applied harmonised standards are EN 983 and DIN EN 60204, in particular.

This declaration is not an assurance of properties in the sense of the product liability law. The safety information of the product

information should be observed.

Jürgen Roland Langenfeld, 11.09.2013

(Executive Director)

Manufacturer's declarationExpected service life

ACE rotary dampers are generally tested for a lifetime of 50,000

cycles with a max. speed of 50 rpm and a max. cycle number of

10/min. After this the dampers still have approx. 80 % of their

original damping torque. Depending on use the service life can

be significantly longer or shorter. In practice significantly longer

lifetimes have been achieved.

Rotary Damper FRT-E2 (continuous rotation)

Manual

This manual suits for next models

7

Popular Fire And Smoke Damper manuals by other brands

Swegon

Swegon actionair DWFX-C installation guide

EKOVENT

EKOVENT EKO-SRBG1 Installation and maintenance instructions

mercor

mercor mcr PL1 Technical and Operational Documentation

BSB

BSB FD-C Installation, operating, & maintenance instructions

Greenheck

Greenheck FSD Series Installation, operation and maintenance manual

SMAY

SMAY KTM installation manual

Metal Fab

Metal Fab MFD installation instructions

Greenheck

Greenheck FD Series Installation, operation and maintenance instructions

aldes

aldes Minisone Assembly instructions

System air

System air SAVE VTC 700 Replacement instructions

Nailor

Nailor CVR Series Installation, operation & maintenance manual

Lindab

Lindab SKMTR Mounting instruction