1. CLEARANCES REQUIRED BETWEEN FIRE

DAMPER SLEEVES AND WALL/FLOOR

OPENINGS

Fire damper and sleeve assemblies expand during periods

of intense heat. Therefore it is essential that openings in

walls or floors be larger than the fire damper and sleeve

assembly to allow for this expansion. Minimum clearances

required between the outside of fire damper sleeve

assemblies and wall/floor openings are:

• Galvanized steel fire dampers and sleeves: 1

/8 in. per foot

of damper width and height with a minimum clearance of

1

/4 in. Recommended clearances, for width and/or height

dimensions of:

1) 48 in. or less: 1

/2 in. clearance

2) More than 48 in. and 96 in. or less: 1 in. clearance

3) More than 96 in.: 11

/2 in. clearance

• Stainless steel fire dampers and stainless steel or

galvanized sleeves: 3/16 in. per foot of damper width and

height with a minimum clearance of 1

/4 in., maximum of 2

in. Recommended clearances, for width and/or height

dimensions of:

1) 48 in. or less: 3/4 in. clearance

2) More than 48 in. and 96 in. or less: 11

/2 in.

clearance

3) More than 96 in.: 2 in. clearance

These are total clearances (ignoring fastener heads) and

do not need to be equally spaced around the damper.

Refer to Section 4 and Figure 6 for additional installation

considerations.

Example: A 12 in. x 12 in. damper would require a

minimum clearance of 1

/4 in.

A 48 in. x 12 in. damper would require a

minimum clearance of 1

/2 in. on width and

1

/4 in. on height.

2

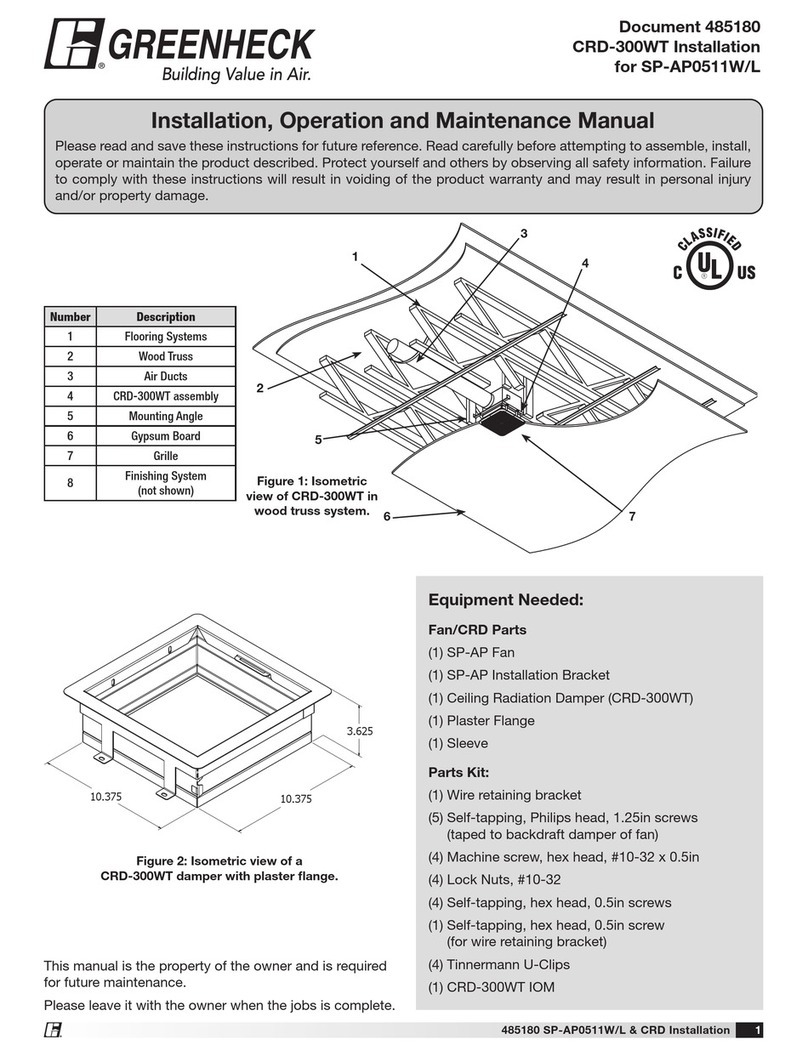

2. GAUGES AND LENGTHS OF FIRE DAMPER

SLEEVES

All fire dampers must be installed in a steel sleeve of the

required gauge and length. See Table 1 for required

minimum sleeve gauges. Maximum sleeve thickness is 10

gauge. Sleeve inside dimensions must equal damper outside

dimensions.

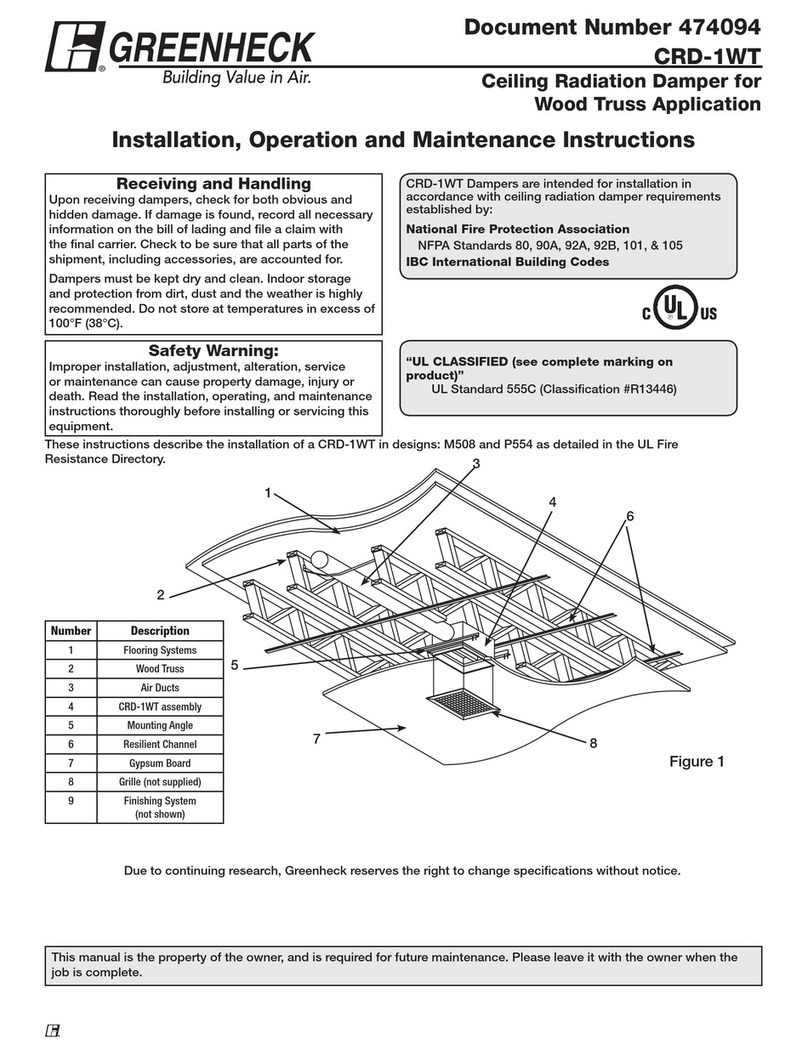

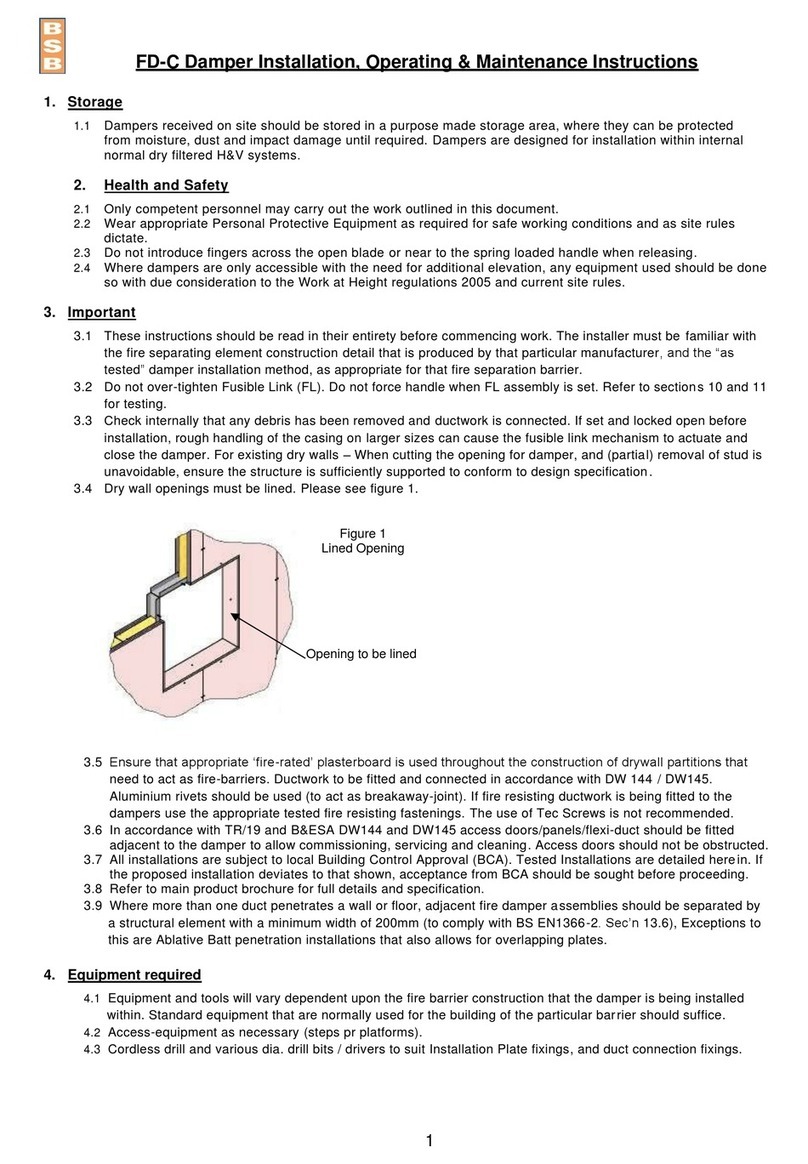

Sleeves shall extend a maximum of 6 in. beyond the wall or

floor opening on each side (see Figure 1). When an access

door is incorporated as a part of sleeve, the sleeve may

extend a maximum of 16 in. beyond the wall or floor opening

on the access door side.

3. ATTACHING FIRE DAMPERS TO SLEEVES

Fire dampers must be attached to sleeves as shown in

Figure 5. All four sides of the damper frame must be

attached to the sleeve with one row of attachments on each

side of the blade channel. Attachments must be spaced a

maximum of 6 in. on centers and a maximum of 2 in. from

corners. A minimum of 4 attachments (2 on each side of the

blade channel ) per side ( 16 per damper ) are required. One of

the methods of attachment shown below must be used.

• tack or spot welds

• #10 sheet metal screws

•1

/4 in. bolts and nuts

•3/16 in. steel pop rivets

4. SECURING FIRE DAMPER AND SLEEVES TO WALL

AND FLOOR OPENINGS.

Fire damper and sleeve assemblies must be installed in wall

and floor openings using retaining angles on each side of the

wall or floor as described below:

• Retaining angles must be a minimum of 16 gauge steel with

minimum 11

/2 in. x 11

/2 in. legs. For dampers with height

greater than 48 in., retaining angles must be a minimum of

16 gauge steel with minimum 11

/2 in. x 21

/2 in. legs.

• Retaining angles must be attached to

the sleeve using the procedures and

methods described in Section 3. The

angles must be attached to all 4 sides of

the sleeve with butt joints at each corner.

A minimum of two attachments are

required on each side, top and bottom.

The angles need not be attached to each

other at the corners.

• Retaining angles must completely

cover the clearance space between the

sleeve and the wall/floor opening, plus

overlap the wall/floor a minimum of 1 in.

This coverage includes all corners (see

Figure 6).

• Retaining angles should not be

fastened to the wall/floor material. The

angles should only sandwich the wall/floor

and allow for damper/sleeve expansion

during periods of intense heat.

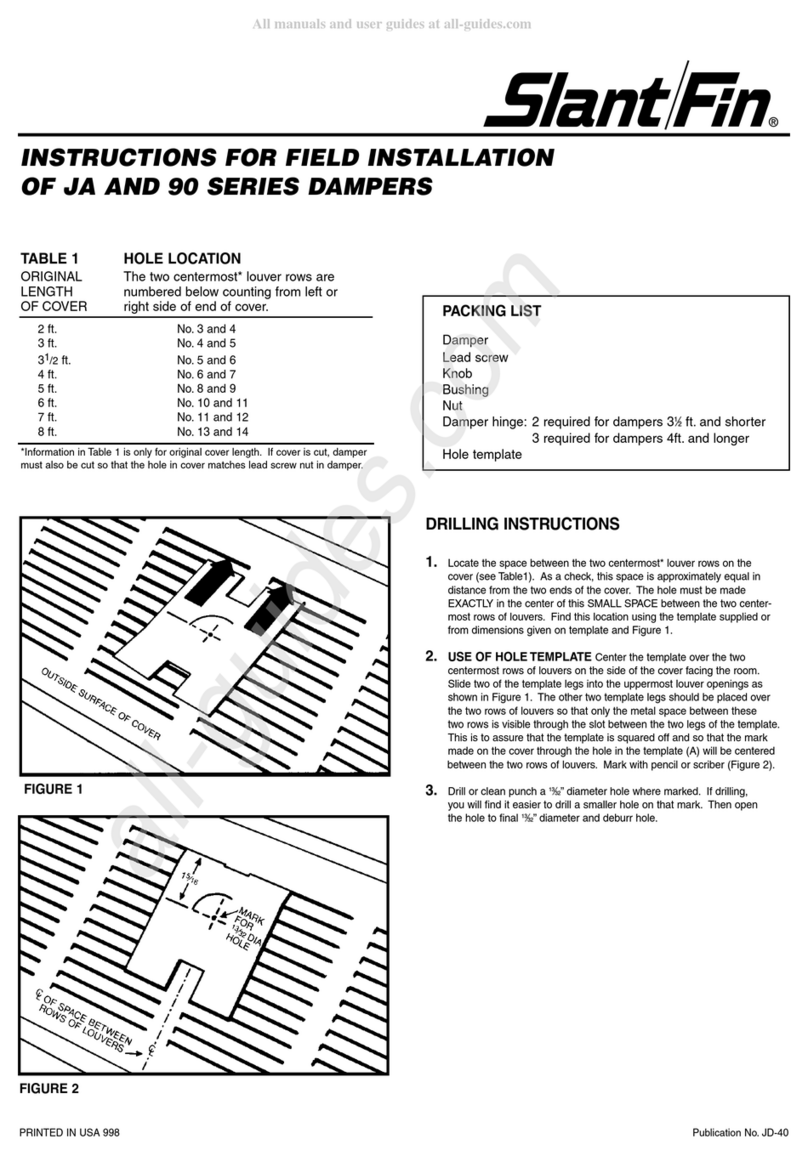

MINIMUM SLEEVE THICKNESS FOR FIRE DAMPERS

Type of Duct to Duct Duct Dimension Sleeve Gauge

Sleeve Connection

Rigid Round 24 in. max. diameter

Rectangular 36 in. max. width or 16 (.060 in.)

24 in. max. height

Rigid Round over 24 in. diameter

Rectangular over 36 in. width or 14 (.075 in.)

over 24 in. height

Breakaway Round or 12 in. wide and under 26 (.018 in.)

(or no duct) Rectangular 13 in. - 30 in. wide 24 (.024 in.)

31 in. - 54 in. wide 22 (.030 in.)

55 in. - 84 in. wide 20 (.036 in.)

85 in. wide and over 18 (.048 in.)

Important Note:

Sleeve thickness must not be less than the gauge of the connecting duct.

U.L. Standard 555 requires all ducts to terminate at the fire damper sleeves or the damper frames.

Table 1: Minimum sleeve thickness for fire dampers.

These instructions apply to 11

/2and 3 hour rated fire dampers mounted (blades must be horizontal) in masonry, block or stud walls

and concrete floors. Specific requirements in these instructions are mandatory. These instructions meet the requirements of UL 555.

Installation shall comply with the requirements of NFPA 90A Standard for the Installation of Air Conditioning and Ventilating

Systems. U.L. listing R13317, California State Fire Marshal listings 3225-0981:102 & 3225-0981:107, and New York City

BSA/MEA listing 260-91-M apply to these dampers.