Stahl SHARK 400 Series User manual

Operating Instructions

SHARK Device Platform

ET-xx8 / MT-xx8

Series 400 Panel PCs

Series 500 Thin Clients

Series 600 KVM Systems

Doc. no.: 20141870000

HW-Rev. ET-/MT-4x8: 01.01.04

HW-Rev. ET-/MT-5x8: 01.01.04

HW-Rev. ET-/MT-6x8: 01.01.03

Operating Instructions Version: 01.02.03

Issue: 10.03.2021

Order number: 241589

Operating Instructions ET-xx8 / MT-xx8 Table of contents

Page 2 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

Table of contents

Description Page

Table of contents 2

1General information 7

1.1 Manufacturer 7

1.2 Legal notice 7

1.2.1 Trademark 7

1.2.2 Disclaimer 7

1.3 About these Operating Instructions 8

1.3.1 Target group 8

1.3.2 How to use this manual 8

1.3.3 Application 8

1.4 Further documents 8

1.5 Conformity with standards and regulations 9

1.5.1 Certificates 9

1.5.2 Approvals 9

1.5.3 Summary of applied standards 10

1.5.3.1 ATEX / IECEx ET-xx8 10

1.5.3.2 ATEX / IECEx MT-xx8 10

1.5.3.3 EMC directive 2014/30/EU 10

1.5.3.4 Radio equipment directive 2014/53/EU 10

1.5.3.5 Low voltage directive 2014/35/EU 10

1.5.3.6 RoHS directive 2011/65/EU 11

1.5.3.7 FM USA 11

1.5.3.8 FM Canada 11

1.5.3.9 EAC 12

2Explanation of symbols 13

2.1 Symbols used in these Operating Instructions 13

2.2 Warning notes 13

2.3 Symbols on the device 14

3Safety 15

3.1 Intended use 15

3.2 Predictable improper use 16

3.3 Personnel qualification 16

3.4 Special conditions of use 17

3.5 Residual risks 18

3.5.1 Explosion hazard 18

3.5.2 Risk of injury 19

3.5.3 Device damage 20

3.6 Industrial Security 20

4Function and device design 21

4.1 Features and versions 21

4.1.1 Options 21

4.1.2 Display 21

4.1.3 Outdoor Installation 21

4.1.4 Card reader for access control 21

Table of contents Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 3 of 84

4.1.5 Other features 22

4.1.6 Accessories 22

4.2 Device design 22

4.3 Dimensions 23

4.3.1 Front: 23

4.3.2 Page - VESA 200 Standard 23

4.3.3 Page - VESA 200 Top Connect 23

4.4 Terminal boxes 24

4.4.1 VESA 200 Standard 24

4.4.2 VESA 200 Top Connect 24

4.5 Operating elements 25

4.5.1 ET-/MT-x38 (15") 25

4.5.2 ET-/MT-x98 (21.5") 25

4.6 LED status display 25

4.7 Markings on the device 26

4.7.1 Position 26

4.7.2 Design of a type label (taking the field system type label

as an example) 26

4.7.3 Display module type key code 27

4.7.4 Type key code E-box module SERIES 400 / 500 28

4.7.5 Type key code E-box module SERIES 600 30

4.8 Approval label 31

4.8.1 Ex classification ATEX / IECEx 31

4.8.2 Ex classification EAC 31

4.8.3 Ex classification FM USA 32

4.8.4 Ex classification FM Canada 32

4.8.5 Ex classification CCC China 33

4.8.6 Ex classification CNEX China 33

4.8.7 Ex classification PESO 33

5Operating systems and drivers 34

5.1 UPDD touch driver 34

5.2 Up to Windows 7 34

5.2.1 Licensing issues 34

5.3 Windows® 10 IoT Enterprise 2019 LTSC operating system 34

5.3.1 Recovery 34

5.3.2 Proprietary Windows installations and drivers 34

5.4 Data back-up 35

5.4.1 Recovery Stick 35

5.4.2 Back-up 35

5.4.3 Switching off / closing down 35

5.4.4 Loss of data 35

5.5 License sticker 36

6Transport and storage 37

7Unpacking 37

8Mounting and installation 38

8.1 Note on mounting and installation 38

8.2 Requirements for site of installation 38

Operating Instructions ET-xx8 / MT-xx8 Table of contents

Page 4 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

8.3 Mounting types 38

8.4 Panel mount with xx8 Mounting-Kit 39

8.5 Installation 40

8.5.1 General information on electric connection 40

8.5.2 Connecting device to power supply 40

8.5.3 Grounding the device 41

8.5.4 Connecting data cable 41

8.5.5 Mounting the cover of the terminal boxes 41

8.5.6 Connecting associated equipment 41

8.5.7 Cable glands 42

8.5.8 Electric connections of interfaces X1 ... X9 and X31 ... X35 43

8.5.9 Details for electrical connection of Interface X10 43

8.6 Using USB interfaces 44

9Initial start-up 45

10 (Re-) Commissioning 45

11 Operation 46

11.1 Operating the touch display 46

11.2 Switching the device on and off 47

11.2.1 Without optional on/off switch 47

11.2.2 With optional on/off switch (for SERIES 400 and 500 only) 47

11.3 Teaming function 47

12 Maintenance, overhaul and repair 48

12.1 Changing the battery 48

12.2 Servicing 48

12.3 Maintenance 49

12.4 Repair 49

12.4.1 Mounting / dismounting the modules 49

13 Returning the device 50

14 Cleaning 50

15 Disposal 50

16 Accessories 50

17 Appendix A 51

17.1 Technical data 51

17.1.1 General 51

17.1.2 Electrical data 51

17.1.3 Display 52

17.1.4 Ambient conditions 52

17.1.5 Mounting 53

17.1.6 Mechanical data VESA 200 Standard 53

17.1.7 Mechanical data VESA 200 Top Connect 54

17.2 Additional data for SERIES 400 / 500 54

17.2.1 General 54

17.2.2 Electrical data 54

17.2.3 Interfaces 55

17.3Additional data for SERIES 600 KVM Systems 55

17.3.1 General 55

17.3.2 Electrical data 55

Table of contents Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 5 of 84

17.3.3 Interfaces 56

17.4 Transponder media table 56

17.5 Overview Hardware Revision ET-xx8 / MT-xx8 57

18 Appendix B 58

18.1 Connection values 58

18.2 Intrinsically safe interfaces (Ex ia) 58

18.2.1 X30 PB –on/off switch 58

18.2.2 X31 - Fan 58

18.2.3 X32 –Barcode / card reader 58

18.2.4 X33 / X34 –USB KB/M 60

18.2.5 X35 –USB 60

18.2.6 X36 / X37 –RF1 / RF2 60

18.3 Bluetooth –B1 61

18.4 RFID reader interface –RF1, RF2 61

18.5 Inherently safe optical interfaces (Ex op is) 61

18.5.1 X20 / X21 –FO 1 / FO 2 type FX 61

18.5.2 X20 / X21 –FO 1 / FO 2 type SX 61

18.5.3 X20 / X21 –FO 1 / FO 2 type LX 61

18.5.4 X22 –FO 3 type OSX 61

18.5.5 X22 –FO 3 type OLX 61

18.6 Non intrinsically safe interfaces (Ex e) 62

18.6.1 X1 –Power supply 62

18.6.2 X2 / X3 –copper1 / copper2 62

18.6.3 X4 –DC out 62

18.6.4 X5 –CAN 62

18.6.5 X6 –USB 62

18.6.6 X7 –RSxxx 62

18.6.7 X8 62

18.6.8 X9 –Audio / Video 62

18.6.9 X10 –SATA 62

19 Appendix C 63

19.1 Connection overview terminal assignment 63

19.1.1 Ex e terminal box / terminals 63

19.1.2 Ex i terminal box / terminals 65

20 Appendix D 67

20.1 Variation of operating temperature range 67

21 Appendix E 69

21.1 Disposal / Restricted substances 69

21.1.1 Declaration of substances and restricted substances 69

21.1.1.1 Declarable substance groups 69

21.1.1.2 ROHS directive 2011/65/EC 70

21.1.1.3 IMO Resolution MEPC.269(68) 70

22 Appendix F 71

22.1 Defective pixels 71

22.1.1 Terminology 71

22.1.2 Display specification 72

23 Appendix G 73

Operating Instructions ET-xx8 / MT-xx8 Table of contents

Page 6 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

23.1 Panel mount with xx8 Mounting-Kit 73

23.2 Control Drawing –FM USA / Canada 74

24 Attachment H 77

24.1 Declarations of EC conformity 77

24.1.1 EU 77

24.1.1.1 ET-xx8 77

24.1.1.2 MT-xx8 78

24.1.2 RCM 79

24.1.3 EAC 81

25 Appendix I 83

25.1 Release notes 83

General information Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 7 of 84

1 General information

1.1 Manufacturer

R. STAHL HMI Systems GmbH

Adolf-Grimme-Allee 8

50829 Köln

Germany

Sales Support

Telephone:

+49 221 768 06 –1000

E-mail:

sales.dehm@r-stahl.com

Technical Support

Telephone:

+49 221 768 06 –5000

E-mail:

support.dehm@r-stahl.com

General

Fax:

+49 221 768 06 –4100

Internet:

r-stahl.com

1.2 Legal notice

1.2.1 Trademark

The terms and names used in this document are registered trademarks and / or products of the

companies in question.

1.2.2 Disclaimer

All rights reserved.

This document may not be reproduced in whole or in part except with the written consent

of the publisher.

This document may be subject to change without notice.

Any warranty claims are limited to the right to demand amendments. Liability for any damage that

might result from the contents of these instructions or all other documentation is limited to clear

cases of premeditation.

We reserve the right to amend our products and their specifications at any time, provided it is in

the interest of technical progress. The information in the current manual (online or on CD / DVD /

USB-stick) or in the operating instructions included in the delivery applies.

Operating Instructions ET-xx8 / MT-xx8 General information

Page 8 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

1.3 About these Operating Instructions

1.3.1 Target group

These operating instructions are intended for the following groups of people:

Project engineers

Electricians and fitters

Operators

Operating staff

Maintenance staff

1.3.2 How to use this manual

Read these operating instructions, especially the safety notes, carefully before use.

Take note of all other applicable documents (see also chapter 1.4 Further documents).

Keep the operating instructions throughout the service life of the device.

Make the operating instructions accessible to operating and maintenance staff at all times.

Pass the operating instructions on to each subsequent owner or user of the device.

Update the operating instructions every time R. STAHL issues an amendment.

1.3.3 Application

Operating Instructions

version:

01.02.03

Hardware revision:

ET-/MT-4x8: 01.01.04

ET-/MT-5x8: 01.01.04

ET-/MT-6x8: 01.01.03

The following operating instructions apply to the following systems:

ET-xx8 / MT-xx8

SERIES 400 Panel PC

SERIES 500 Thin Clients

SERIES 600 KVM Systems

The original instructions are the German edition.

They are legally binding in all legal affairs.

1.4 Further documents

Installation Manual ET-/MT-xx8 (IM_ET_MT-xx8)

Installation Manual Top Connect ET-/MT-xx8 (IM_Top-Connect_xx8)

Installation Manual Mounting-Kit xx8 (IM_Mounting-Kit_xx8)

Installation Manual Module exchange xx8 (IM_Module_exchange_xx8)

Compilation of Certificates xx8 (CE_ET_MT-xx8)

For documents in other languages see r-stahl.com.

General information Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 9 of 84

1.5 Conformity with standards and regulations

1.5.1 Certificates

Certificates and EC Declaration of Conformity: r-stahl.com

The device has IECEx approval. See IECEx homepage: http://iecex.iec.ch/ to view the

certificate

Further national certificates can be downloaded via the following link:

https://r-stahl.com/de/global/support/downloads/

1.5.2 Approvals

The following approvals are valid for all devices:

Synonym

Scope of validity

Certificate number

CE / ATEX

Europe

BVS 14 ATEX E 134 X

IECEx

Global

BVS 14.0116X

EAC

Russia

TC RU C-DE.ME92.B.00843

EACЭN RU Д–DEPA01.B.27604/20

NEC

USA

FM 16 US 0278 X

CEC

Canada

FM 16 CA 0141 X

CCC

China

2020312309000286

CNEX

CNEx17.2233X

Synonym

Scope of validity

Device

Certificate number

PESO

India

ET-xx8

A/P/HQ/TN/104/5747 (P436617)

CCE identification number

P436617/1

MT-xx8

Certificate number

A/P/HQ/TN/104/5750 (P436574)

CCE identification number

P436574/1

Synonym

Scope of validity

Note

RCM

Australia

according to declaration of conformity

The following approvals are only valid for the SERIES 400 Panel PCs and the SERIES 500 Thin

Clients:

Synonym

Scope of validity

Certificate number

ABS

Marine / ship approval

17-HG1687000-PDA

DNV / GL

Marine / ship approval

TAA00001E6

Operating Instructions ET-xx8 / MT-xx8 General information

Page 10 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

1.5.3 Summary of applied standards

1.5.3.1 ATEX / IECEx ET-xx8

Standard

Classification

IEC 60079-0: 2012 + A1 : 2013

General requirements

IEC 60079-5: 2015

Protection by powder filling "q"

IEC 60079-7: 2015

Protection by increased safety "e"

IEC 60079-11: 2012

Protection by intrinsic safety "i"

IEC 60079-28: 2015

Optical radiation “op is”

IEC 60079-31: 2014

Protected by enclosures "t" (dust)

The product corresponds to requirements from:

EN IEC 60079-0 : 2018

General requirements

EN IEC 60079-7 : 2015 + A1 : 2018

Protection by increased safety "e"

1.5.3.2 ATEX / IECEx MT-xx8

Standard

Classification

IEC 60079-0: 2012 + A1 : 2013

General requirements

IEC 60079-5: 2015

Protection by powder filling "q"

IEC 60079-7: 2015

Protection by increased safety "e"

IEC 60079-11: 2012

Protection by intrinsic safety "i"

IEC 60079-15: 2010

Type of protection "n"

IEC 60079-28: 2015

Optical radiation “op is”

IEC 60079-31: 2013

Protected by enclosures "t" (dust)

The product corresponds to requirements from:

EN IEC 60079-0 : 2018

General requirements

EN IEC 60079-7 : 2015 + A1 : 2018

Protection by increased safety "e"

EN IEC 60079-15: 2020

Type of protection "n"

1.5.3.3 EMC directive 2014/30/EU

Standard

Classification

EN 61000-6-2 : 2005 + AC : 2005

Immunity

EN 61000-6-4 : 2007 + A1 : 2011

Emission

1.5.3.4 Radio equipment directive 2014/53/EU

Standard

Classification

ETSI EN 300328 V2.1.1 : 2016

Wideband transmission systems –data

transmission equipment operating in the

2.4 GHz ISM band

1.5.3.5 Low voltage directive 2014/35/EU

Standard

Classification

EN 62368-1 : 2016

IEC 62368-1 : 2014

Audio / video, information and communication

technology equipment –safety requirements

General information Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 11 of 84

1.5.3.6 RoHS directive 2011/65/EU

Standard

Classification

EN IEC 63000 : 2018

Technical documentation for the assessment

of electrical and electronic products with

respect to the restriction of hazardous

substances

1.5.3.7 FM USA

Standard

Classification

FM Class 3600: 2011

Electric equipment for use in hazardous areas

- general requirements

FM Class 3616: 2011

Dust explosion protection electric equipment -

general requirement

FM Class 3810: 2005

Electric equipment for the operation of

measuring, control and laboratory equipment

ANSI/ISA 60079-0: 2013

General requirements

ANSI/UL 60079-5: 2016

Protection by powder filling "q"

ANSI/UL 60079-7: 2017

Protection by increased safety "e"

ANSI/ISA 60079-11: 2014

Protection by intrinsic safety "i"

ANSI/ISA 60079-15: 2013

Type of protection "n"

ANSI/ISA 60079-28: 2013

Optical radiation “op is”

ANSI/UL 60079-31: 2015

Protected by enclosures "t" (dust)

ANSI/IEC 60529: 2004

Degrees of protection provided by enclosure

(IP code)

1.5.3.8 FM Canada

Standard

Classification

CAN/CSA-C22.2 No. 60079-0: 2015

General requirements

CAN/CSA-C22.2 No. 60079-5: 2016

Protection by powder filling "q"

CAN/CSA-C22.2 No. 60079-7: 2016

Protection by increased safety "e"

CAN/CSA-C22.2 No. 60079-11: 2014

Protection by intrinsic safety "i"

CAN/CSA-C22.2 No. 60079-15: 2016

Type of protection "n"

CAN/CSA-C22.2 No. 60079-31: 2015

Protected by enclosures "t" (dust)

CAN/CSA-C22.2 No. 60529: 2016

Degrees of protection provided by enclosure

(IP code)

CAN/CSA-C22.2 No. 61010-1: 2004

Safety regulations for electric measuring,

control and laboratory equipment - general

requirements

Operating Instructions ET-xx8 / MT-xx8 General information

Page 12 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

1.5.3.9 EAC

Standard

Classification

ГОСТ 31610.0-2014 / IEC 60079-0 : 2011

General requirements

ГОСТ Р МЭК 60079-5-2012

Protection by powder filling "q"

ГОСТ Р МЭК 60079-7-2012

Protection by increased safety "e"

ГОСТ 31610.11-2014 / IEC 60079-11 : 2011

Protection by intrinsic safety "i"

ГОСТ 31610.15-2014 / IEC 60079-15 : 2010

Type of protection "n"

ГОСТ Р МЭК 60079-31-2010

Protected by enclosures "t" (dust)

ГОСТ 31610.28-2012 / IEC 60079-28 : 2006

Optical radiation “op is”

GB3836.1-2010

General requirements

GB3836.3-2010

Protection by increased safety "e"

GB3836.4-2010

Protection by intrinsic safety "i"

GB3836.7-2004

Protection by powder filling "q"

GB3836.8-2014

Type of protection "n"

IEC 60079-28 : 2015

Optical radiation “op is”

IEC 60079-31 : 2013

Protected by enclosures "t" (dust)

Explanation of symbols Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 13 of 84

2 Explanation of symbols

2.1 Symbols used in these Operating Instructions

Symbol

Meaning

Handy hint for making work easier, important note

Reference to another chapter, another section, another documentation or a web

page.

2.2 Warning notes

Dangerous situation which can result in fatal or severe, life-changing

injuries if the safety measures are not complied with.

Dangerous situation which can result in severe injuries if the safety

measures are not complied with.

Dangerous situation which can result in minor injuries if the safety

measures are not complied with.

Dangerous situation which can result in material damage if the safety

measures are not complied with.

Symbol

Meaning

Burn hazard

Laser radiation hazard

DANGER

WARNING

CAUTION

NOTE

Operating Instructions ET-xx8 / MT-xx8 Explanation of symbols

Page 14 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

2.3 Symbols on the device

Symbol

Meaning

Device certified for hazardous areas according to ATEX directive.

Device marking according to EU directive

0158

ID number of monitoring body

Marking according to WEEE directive 2012/19/EU

Marking for device approval in Eurasian Economic Union

Marking according to FM (Factory Mutual) for approval in North America

C stands for Canada

US stands for United States

Warning - important information

Warning of hazardous voltage

Connection for equipotential bonding

Safety Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 15 of 84

3 Safety

The device has beenmanufactured according to the state of the art of technology while observing

recognised safety-related rules. When using the device, it is nevertheless possible for hazards to

occur to life and limb of the user or third parties or for the device, environment or material assets

to be compromised.

Only use the device under the following conditions:

If it is not damaged

As intended, while remaining aware of safety and hazards

In accordance with these Operating Instructions

3.1 Intended use

The Series xx8 Shark device platform HMIs are operator stations suitable for industrialproduction

in hazardous areas.

Depending on their version, the devices are certified for the following hazardous areas:

Series xx8

Hazardous area

Directive

ET

Zone 1, 2, 21 and 22 (EPL Gb, Db)

Class I, Zone 1 & 2; Class I, Division 2; Zone

21 & 22

ATEX directive, IEC and

Canadian requirements

Class II, Division 2

acc. to American

requirements

MT

Zone 2 and 22 (EPL Gc, Dc) Class I,

Zone 2, Class I, Division 2, Zone 22

ATEX directive, IEC and

Canadian requirements

Class II, Division 2

acc. to American

requirements

The SHARK device platform has been designed with particular focus on the harsh conditions

prevalent in the oil and gas industry. The device can be used indoors as well as in outdoor areas.

It is shock, vibration, saltwater and salt-spray proof.

The approved operating temperature ranges depend on the version:

Standard: from -10 °C to +65 °C

Outdoor installation (with integrated heater): from -40 °C to +65 °C

Depending on their configuration, the following versions with the SHARK device platform are

available:

Panel PC - SERIES 400

Thin Clients - SERIES 500

KVM Systems (Keyboard - Video - Mouse) - SERIES 600

Operating Instructions ET-xx8 / MT-xx8 Safety

Page 16 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

The SHARK device platform consists of a display and an E-Box module that are mounted

together. The display module generally consists of all display components, whereas the E-Box

module generally consists of the other electronic parts.

The device platform communicates with automation systems and distributed control systems via

Ethernet, WLAN or serial interfaces, and has additional interfaces for peripherals such as

keyboards, pointing devices, RFID readers, barcode readers for material inventory or EM-STOP

switches.

The device is not a panel-mount module. For applications that require degree of protection Ex e,

Ex p or Ex tb, the device must be mounted together with the "xx8 Mounting-Kit".

Two terminal boxes for Ex e and Ex ia circuits are available for the connection of all external

cables.

"Intended use" includes complying with these Operating Instructions and the other applicable

documents, such as the data sheet. All other uses are only considered to be intended after being

approved by R. STAHL.

3.2 Predictable improper use

The device may only be installed and connected by specifically trained personnel.

3.3 Personnel qualification

Qualified specialist personnel is required to perform the activities described in these Operating

Instructions. This primarily applies to work in the following areas:

Product selection and project engineering

Mounting / dismounting the device

Installation

Commissioning

Maintenance, cleaning

Specialists who perform these tasks must have a level of knowledge that meets applicable

national or equivalent country-specific standards and regulations. Additional knowledge is

required for any activity in hazardous areas !

R. STAHL recommends having a level of knowledge equal to that described in the following

standards:

IEC/EN 60079-14 (Electrical installations design, selection and erection)

IEC/EN 60079-17 (Electrical installations, inspections and maintenance)

IEC/EN 60079-19 (Equipment repair, overhaul and reclamation)

Safety Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 17 of 84

3.4 Special conditions of use

The intrinsically safe circuits are earthed. Equipotential bonding is required for the entire

intrinsically safe circuits.

Devices with wireless interface

Type feature for devices with wireless interface:

W02, W05, W22, W55 or W25

Maximum transmission power of antenna

2 W (group IIC)

Connection terminal for antenna:

X36 and X37

The maximum transmission power is the result of: antenna gain, power loss in the cable and

transmission power of the transmitter (X36 / X37), according to the data in these operating

instructions.

The intrinsically safe circuits at terminals X36 and X37 are earthed. When connecting external

antennae, please note the following earthing requirements for intrinsically safe circuits:

EN 60079-14 of the National Electrical Code ANSI/NFPA 70

Canadian Electric Code CSA C22.1

Requirements for plug connectors and switches

The covers of the terminal boxes are fitted with cable entries and blind plugs. As an option, they

may be fitted with plug connectors and switches.

The devices must be certified individually for the respective type of protection and also have IP66.

Panel mount with xx8 Mounting-Kit

The devices can be mounted inside an enclosure with a suitable cut-out with the aid of fixing

frame kits (xx8 Mounting-Kit). Where degree of protection Ex e, Ex p or Ex tb is required, the

device must be mounted with a xx8 Mounting-Kit mounting frame (see chapter 8.4 Panel mount

with xx8 Mounting-Kit).

Operating Instructions ET-xx8 / MT-xx8 Safety

Page 18 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

3.5 Residual risks

3.5.1 Explosion hazard

Despite the device's state-of-the-art design, explosion hazards cannot be entirely eliminated in

hazardous areas.

Perform all work steps in hazardous areas with the utmost care at all times !

Possible hazards ("residual risks") can be categorised according to the following causes:

Mechanical damage

The device may become damaged during transport, mounting or commissioning. This kind of

damage may, for example, render the device's explosion protection partially or completely

ineffective. This may result in explosions causing serious or even fatal injury.

Do not commission a damaged device.

Only transport the device in special transport packaging that reliably protects the device

from external influences. Observe the ambient conditions when selecting the transport

packaging (see chapter 17.1 Technical data).

Do not place any loads on the device.

Check the packaging and the device for damage. Immediately report any damage to

R. STAHL.

Store the device ideally in its original packaging in a dry place (with no condensation), and

make sure that it is stable and protected against the effects of vibrations and knocks.

Do not damage the device or seals during its installation.

Excessive heat or electrostatic charge

Operate the device only within the prescribed operating conditions (see chapter

4.7 Markings on the device and chapter 17.1 Technical data).

Mount and install the device in such a way that it is always operated within the permissible

temperature range.

Do not use the device in strong charge-generating environments.

Avoid friction and flow of particle streams.

R. STAHL recommends you equip devices used outdoors or exposed to the elements with

a protective roof or wall.

Regularly inspect the device for a material change. If you spot any changes, test or replace

the device.

Do not paint or repaint the device yourself. Do not have the paintwork touched up byanyone

other than the manufacturer.

Comply with the area specification of EN/IEC 60079-0 when fitting additional plastic

adhesive labels.

Clean the device with a damp cloth only.

Do not cover the display with protective foil.

Safety Operating Instructions ET-xx8 / MT-xx8

R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021 Page 19 of 84

Improper mounting, installation, commissioning, maintenance or cleaning

Basic work such as installation, commissioning, maintenance or cleaning of the device must

always be performed in accordance with the applicable national regulations of the country of use

and only by qualified persons. Otherwise, the explosion protection may be rendered ineffective.

This may result in explosions causing serious or even fatal injury.

Have the assembly, installation, commissioning and maintenance work performed by

qualified and authorised persons only (see chapter 3.3 Personnel qualification).

Prior to commissioning, check the device is mounted correctly (see chapter 8 Mounting and

installation).

Electrical circuits with Ex i type of protectionmay no longer be operated as electrical circuits

with this type of protection after being operated with electrical circuits with other types of

protection.

Even when used in Zones 2 and 22, intrinsically safe devices of Zones 0, 1, 20 and 21 can

be connected to the intrinsically safe signal circuits.

Only connect the device to equipment which does not carry voltages higher than 250 VAC

(50 - 60 Hz).

Connect Ex i devices only to intrinsically safe terminals.

In hazardous areas, always switch the electrical circuits and devices to a de-energised state

before disconnecting or connecting and when mounting / dismounting.

Do not change or modify the device.

Any repair on the device is to be performed by R. STAHL only.

Gently clean the device with a damp cloth only –do not use scratching, abrasive or

aggressive cleaning agents or solutions.

Never clean the device with a strong water jet, such as a pressure washer !

3.5.2 Risk of injury

Falling devices or components

The heavy device or components can fall during transport and mounting, causing severe injury to

persons in the form of bruises and contusions.

Use transporting and lifting equipment suitable for the size and weight of the device when

transporting and mounting it.

Observe the weight and the maximum load-bearing capacity of the device; see

specifications on the shipping label or on the packaging.

Use suitable mounting materials for mounting.

Electric shock

During operation and maintenance, high voltage isat timesapplied to the device. Because of this,

the device must be de-energised during installation. Persons coming into contact with electrical

lines carrying excessively high voltage can suffer severe electric shocks and, consequently,

injuries.

Only connect electrical circuits to suitable terminals.

Operating Instructions ET-xx8 / MT-xx8 Safety

Page 20 of 84 R. STAHL HMI Systems GmbH / OI_ET_MT-xx8_en_V_01_02_03.docx / 10.03.2021

3.5.3 Device damage

As a result of unsuitable operating conditions or careless contact the device or individual

components may be damaged so significantly that the device does not operate correctly or fails

completely.

Do not subject the device to external heat sources or direct sunshine. Ensure that the

maximum ambient temperature is never exceeded.

Do not open the enclosure. The enclosure has been sealed permanently.

3.6 Industrial Security

Our products with Industrial Security functions support the secure operation of plants, systems

and equipment. Protection against cyber threats requires an all-encompassing Industrial Security

concept. The key to a successful concept is integrated implementation, continuous maintenance

and state-of-the-art technology. This is the responsibility of the plant operator.

The following are key issues for effective industrial security concepts:

Prevention of unauthorised access to plants, systems, equipment and networks

Systems, equipment and components should only be connected to the company intranet or

the internet if and when required

Employ protective measures such as firewalls and network segmentation

Only use the latest software product versions

Carry out software updates as soon as new updates are available

Use standard user accounts for regular operation

Use secure passwords

Appropriate safeguarding of administrator accounts

Application of security guidelines

Other measures to be taken as required

R. STAHL is constantly working on enhancing its products, thereby contributing to plant security

and to minimizing the risk of cyber threats.

This manual suits for next models

14

Table of contents

Other Stahl Touch Panel manuals

Popular Touch Panel manuals by other brands

Extron electronics

Extron electronics TouchLink TLP Pro 725C Series Setup guide

Beckhoff

Beckhoff CP32-2 Series manual

Vimar

Vimar 01422 quick start guide

Harman

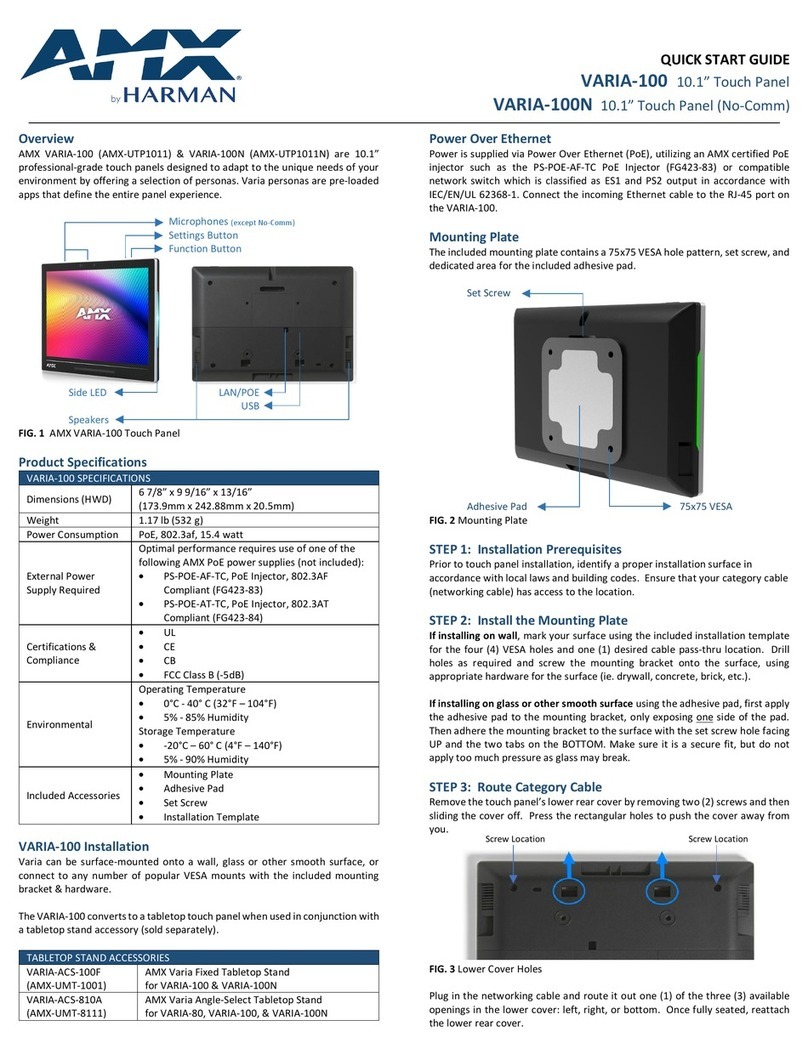

Harman AMX VARIA-100N quick start guide

AMX

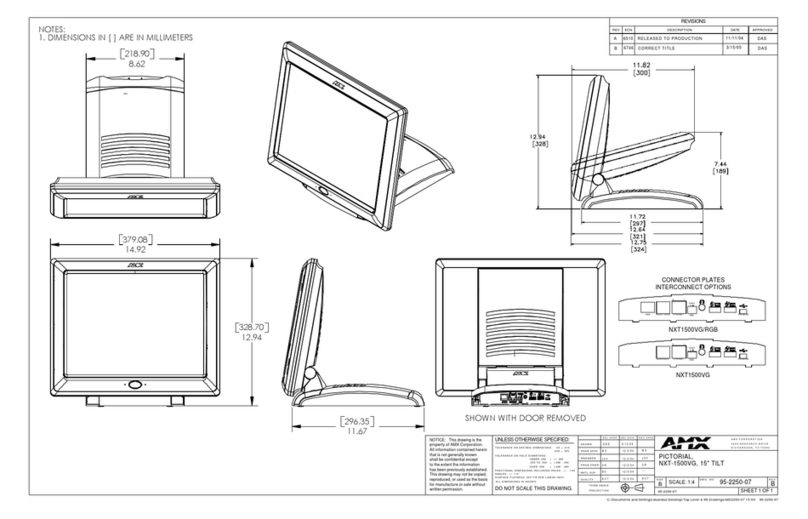

AMX Modero NXT-1500VG Dimension Guide

Grossenbacher Systeme

Grossenbacher Systeme WebPanel WP-284 Series operating instructions

Autonics

Autonics GP Series Solution guide

M2I

M2I TOPR Series Hardware manual

Premio

Premio VIO-100-PC100-J1900 Series user manual

HEIDENHAIN

HEIDENHAIN ND 5023 installation instructions

Avalue Technology

Avalue Technology AID-173SBT Quick reference guide

Next Wave CNC

Next Wave CNC LCD Pendant owner's manual