Stahl ET 6-A Series User manual

Installation Manual

SERIES 300 Operator Interfaces

SERIES 400 Panel PC

SERIES 500 Thin Clients

Device platform EAGLE

ET-xx6 / MT-xx6

HW-Rev. ET-xx6-A-FX: 03.00.12

HW-Rev. ET-xx6-A-TX: 03.00.22

HW-Rev. ET-xx6-A-FX-BT: 03.00.16

HW-Rev. ET-xx6-A-TX-BT: 03.00.26

HW-Rev. ET-3x6-A-FX-BS: 03.00.17

HW-Rev. ET-3x6-A-TX-BS: 03.00.27

Installation Manual version: 01.00.02

Issue date: 23.07.2018

Installation Manual ET-/MT-xx6 Publisher

Page 2 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

Publisher

Publisher and copyright holder:

R. STAHL HMI Systems GmbH

Adolf-Grimme-Allee 8

D 50829 Cologne

Registered place of business: Cologne

Court of registration: District court Cologne, HRB 30512

VAT number: DE 812 454 820

Phone: (switchboard) +49 (0) 221 76 806 - 1000

(hotline) - 5000

Fax: - 4100

(hotline) support@stahl-hmi.de

All rights reserved.

This document may not be reproduced in whole or in part except with the written consent

of the publisher.

This document may be subject to change (dates, dimensions, weight, constructions,

drawings, images).

Any warranty claims are limited to the right to demand amendments. Liability for any damage that

might result from the contents of these instructions or all other documentation is limited to clear

cases of premeditation.

We reserve the right to change our products and their specifications at any time, provided it is in

the interest of technical progress. The information in the current manual (online or on CD / DVD /

USB stick) or in the operating instructions included in the delivery applies.

Trademark

The terms and names used in this document are registered trademarks and / or products of the

companies in question.

Copyright © 2018 by R. STAHL HMI Systems GmbH. Subject to alterations.

Installation Manual ET-/MT-xx6 Table of contents

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 3 of 23

Table of contents

Description Page

Publisher 2

Table of contents 3

1Intended use and location 4

2Warning 4

2.1 Touch operation 4

3Enclosure types 5

4Versions mounted on stand or elbow 6

5Mounting 7

5.1 Mounting options 7

5.2 Recommended mounting type 8

5.3 Assembly notes 9

6Tools 9

7Mechanical Installation 9

7.1 Dimensions 10

7.2 Stand mounting 12

7.2.1 View 12

7.2.2 MPFL Stand 12

7.2.3 Mounting –Step by step 13

8Electrical Installation 19

8.1 Connection of the X1 power supply 19

8.2 Stand or enclosure equipotential bonding / earthing 19

8.3 Ethernet interface TX / FX 20

8.3.1 Ethernet interface copper connection TX (X11) 20

8.3.2 Ethernet optical fiber interface FX (X10) 21

9Release notes 22

Installation Manual ET-/MT-xx6 Intended use and location

Page 4 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

1 Intended use and location

The ET-/MT-xx6-A-* HMI devices with the EAGLE device platform are equipment for installation

in hazardous areas and can be operated in zones 1, 2, 21 and 22 according to ATEX Directive.

All HMI devices have a modular structure, which makes changes and maintenance easy. They

can be integrated into control cabinets or panels, etc.

2 Warning

2.1 Touch operation

Incorrect / phantom operation:

Incorrect operation of the touch screen may result in accidental functions and errors. The device

will then be unable to execute functions, may execute them incorrectly or in a way not intended.

- Do not realise safety-relevant functions via the touch screen

- Avoid accidental multi-touches

- Do not touch the touch screen across a large area

- Use a touch pen only for the capacitive touch screen

- Before operating the device, thoroughly acquaint yourself with the multi-touch functions of

the operating system and the application

- Switch off the device for cleaning and maintenance

Conductive liquids on thetouch screen can result in incorrect or phantom operations.This applies

in particular to salt water.

- Avoid contamination of the touch screen surface with salt water

Protect the device against rain, snow and splashes, since excessive amounts of standing or

running water will disrupt operation and may cause erratic cursor movement.

This protection can be achieved by using a canopy or some other protective roof-type

construction. Offshore, strong winds, saltwater and rain will have to also be taken into

consideration.

Touch screen damage:

Only touch the touch screen with your finger or a suitable pen.

- Do not touch the screen with pointed or sharp instruments as this may damage the touch

screen, substantially reduce its service life or result in total black-out

Foil membrane blistering / air-pockets:

Extreme ambient conditions (high humidity, temperature) may, in rare cases, result in blistering

or air-pockets underneath the foil touch screen. This does not impede functionality and is a purely

optical phenomenon.

Installation Manual ET-/MT-xx6 Enclosure types

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 5 of 23

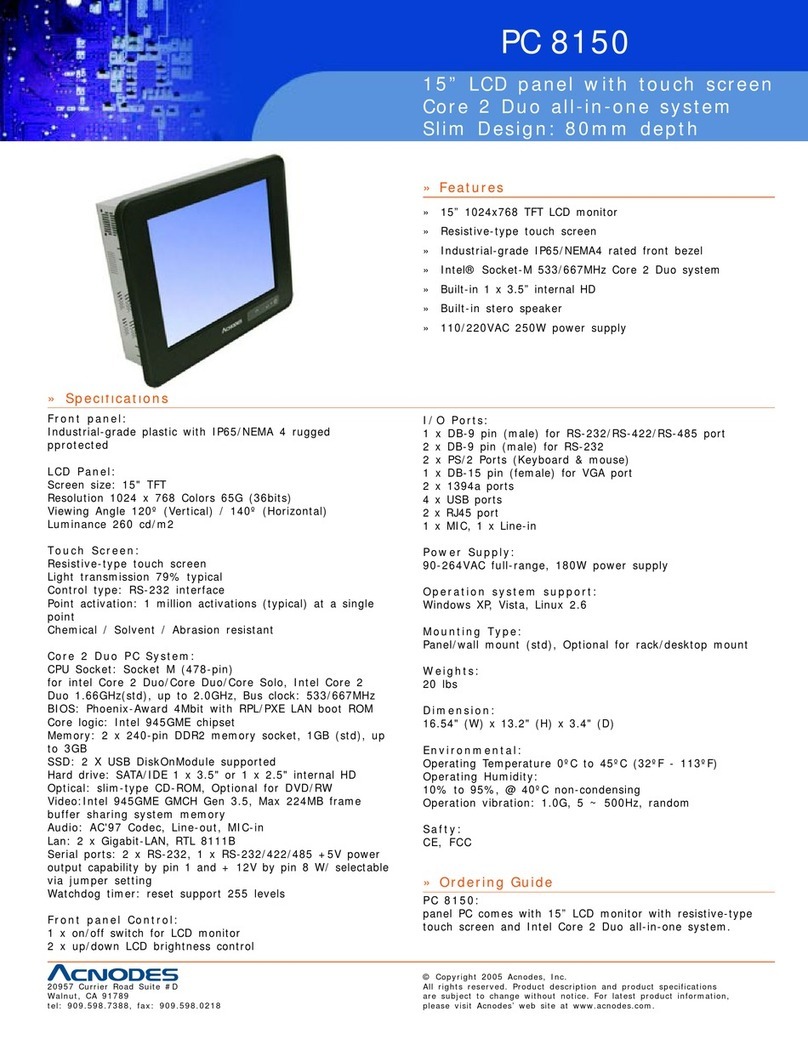

3 Enclosure types

HSG-xx6-VxA-FR HSG-xx6-VxA-CFR

with front door as standard with front door for cleanroom

HSG-xx6-VxA-BD HSG-xx6-VxA-FRS

with rear door (Backdoor) wall mounting

for 10.4" and 15" panel-mount devices only

Installation Manual ET-/MT-xx6 Versions mounted on stand or elbow

Page 6 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

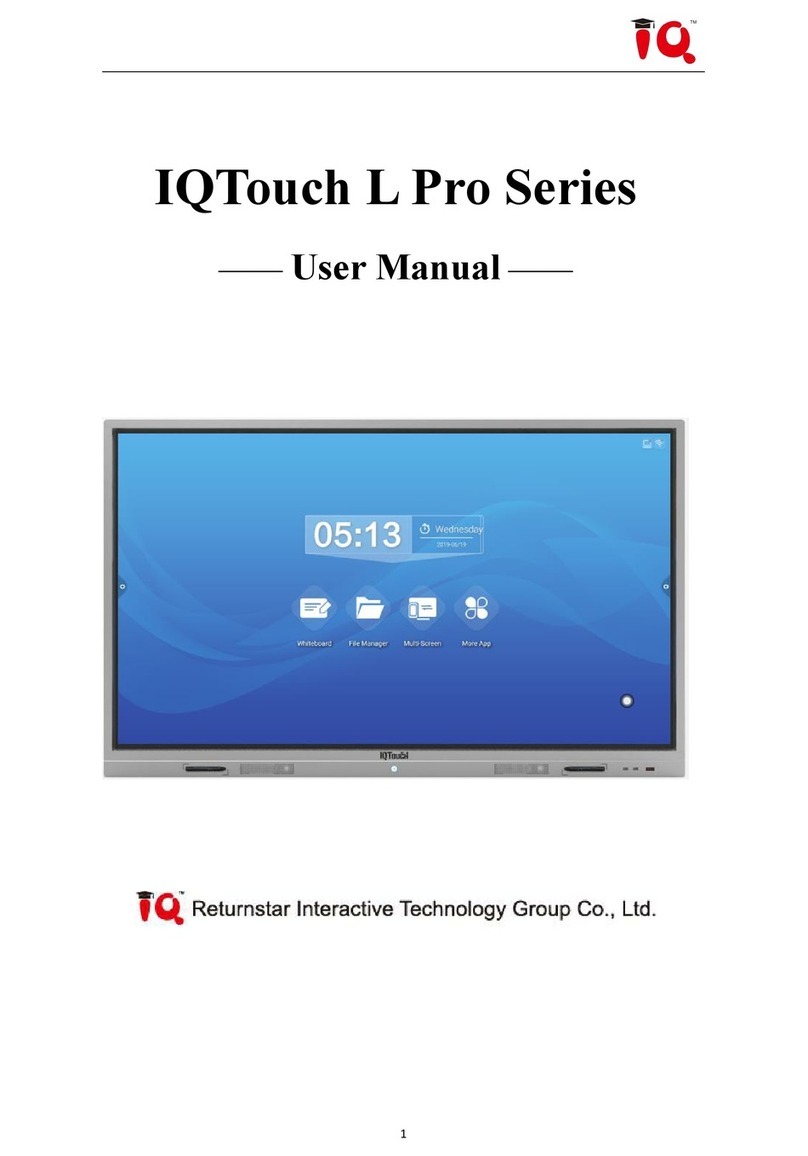

4 Versions mounted on stand or elbow

mounted upright on elbow

mounted hanging from elbow

MPFL stand

Installation Manual ET-/MT-xx6 Mounting

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 7 of 23

5 Mounting

In regards of different applications and ambient conditions we recommend following installation

types:

5.1 Mounting options

Mounted on stand

Ceiling mounting

Elbow upright mounting

Mounted hanging from elbow

Wall mounting (for 10.4" and 15" panel-mount devices only)

Installation Manual ET-/MT-xx6 Mounting

Page 8 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

5.2 Recommended mounting type

The following recommended mounting types are the result of trying out many different types over

the years. Please follow these recommendations to ensure the optimum mounting type for your

device.

Before deciding on how to mount the device you need to check the vibration and shock conditions.

We cannot accept any responsibility if you select an unsuitable mounting type that results in

damage or failure of the device.

Conditions present at the

point of installation

Mounting / installation type

Recommendation

No vibration and no

shocks

Mounting on stand, with /

without external

keyboard

No restriction

Ceiling mount with

MPFL stand with /

without external

keyboard

No restriction

Mounted on elbow

standing with / without

external keyboard

No restriction

Mounted on elbow

hanging with / without

external keyboard

No restriction

Wall mounting

with / without external

keyboard

No restriction

Vibration sinusoidal

acc. to IEC 60068-2-6 and

DNV Certification No. 2.4:

5 … 13.2 Hz: ±1 mm

13.2 … 100 Hz: ±0.7 g

X, Y, Z axes

acc. to IEC 60068-2-6:

10 Hz, 1 g

450 Hz, 1 g

Change cycle 1 oct/min

Operating mode 1.2

X, Y, Z axes

Mounting on stand, with /

without external

keyboard

Not recommended

Ceiling mounting with

MPFL stand, with /

without external

keyboard

Not recommended

Mounted on elbow

standing with / without

external keyboard

Not recommended

Mounted on elbow

hanging, with / without

external keyboard

Not recommended

Wall mounting

with / without external

keyboard

No restriction

Installation Manual ET-/MT-xx6 Tools

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 9 of 23

5.3 Assembly notes

The tightening torques for the cable glands depend on the cables and wires used. This

means the user has to determine the required torques.

The stand / wall bracket must be mounted with at least 4 fastening points. The type of wall

fixing used must be suitable for the wall material.

6 Tools

1x side cutter

1x wire stripping knife

1x wire stripper

1x spanner AF 10

1x spanner AF 13

1x spanner AF 14

1x spanner AF 24

1x spanner AF 30

1x Phillips screwdriver size 1

1x Phillips screwdriver size 2

1x flat-bladed screwdriver 2.5 mm

1x Allen key 5 mm

Mounting the stand or wall-mounting will require other tools not

specified here.

7 Mechanical Installation

Always have two people mount the devices.

CAUTION

NOTE

Installation Manual ET-/MT-xx6 Mechanical Installation

Page 10 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

7.1 Dimensions

Dimensions in mm. HSG-xx6-VxA-FR

Device

A

B

C

D

E

F

G

H

I

ET-/MT-x06

ET-/MT-x16

ET-/MT-x36

625

516

190

720

304

400

78

34°

270

ET-/MT-x56

740

568

190

720

304

400

78

34°

270

HSG-xx6-VxA-CFR

Device

A

B

C

D

E

F

G

H

I

ET-/MT-x06

ET-/MT-x16

ET-/MT-x36

625

542

190

720

304

406

78

34°

270

ET-/MT-x56

720

627

190

720

304

406

78

34°

270

Installation Manual ET-/MT-xx6 Mechanical Installation

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 11 of 23

HSG-xx6-VxA-BD

Device

A

B

C

D

E

F

G

H

I

ET-/MT-x06

ET-/MT-x16

ET-/MT-x36

625

542

195

720

304

442

78

34°

270

ET-/MT-x56

740

568

195

720

304

442

78

34°

270

HSG-xx6-VxA-FRS

X

Mounting tongue for wall mounting

*a

Alternative mounting position of the mounting tongues

Choose suitable mounting screws, rawlplugs and bolts depending on

the actual local requirements and possibilities.

Enclosure dimensions

A

B

C

560

435

190

Mounting tongue dimensions

A

B

C

D

E

F

30

55

35

10.5

10.5

18

NOTE

Installation Manual ET-/MT-xx6 Mechanical Installation

Page 12 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

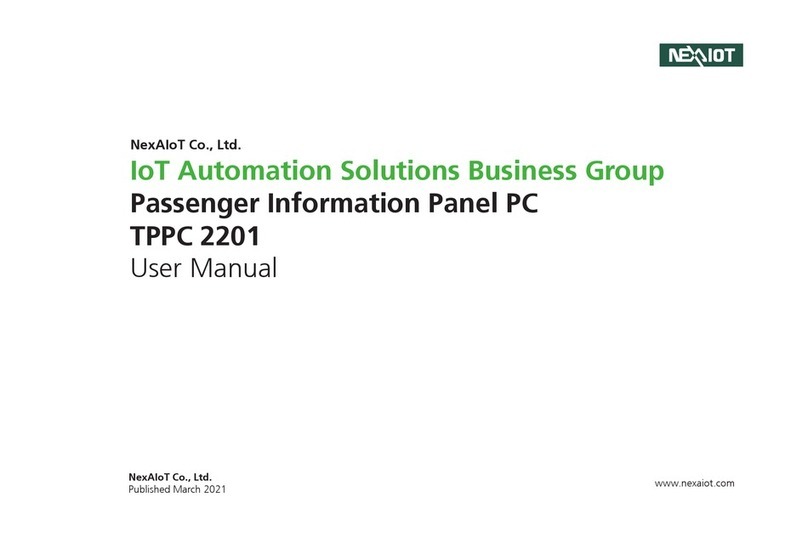

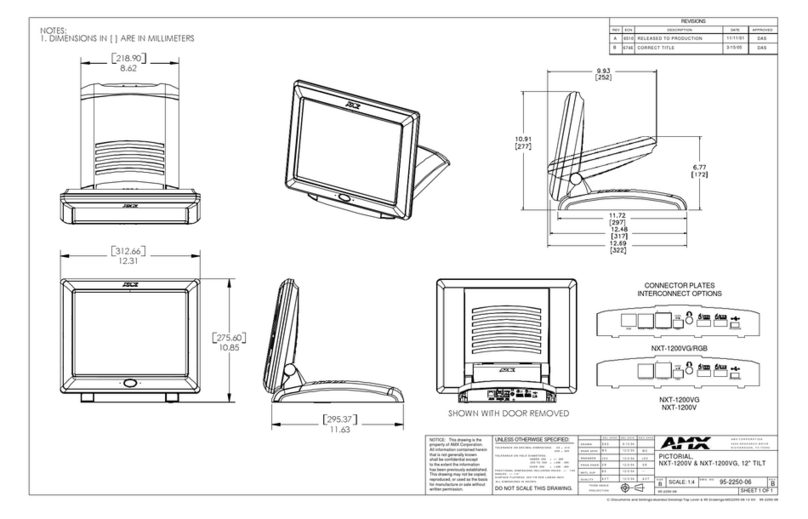

7.2 Stand mounting

7.2.1 View

7.2.2 MPFL Stand

Dimensions in mm.

Stand

A

B

C

D

E

F

G

H

1216

265

200

135

20

101

Ø 60.3

Ø 88.9

Cable glands

Gl1

Gl2

Gl3

M25 x 1.5

M25 x 1.5

M20 x 1.5

Installation Manual ET-/MT-xx6 Mechanical Installation

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 13 of 23

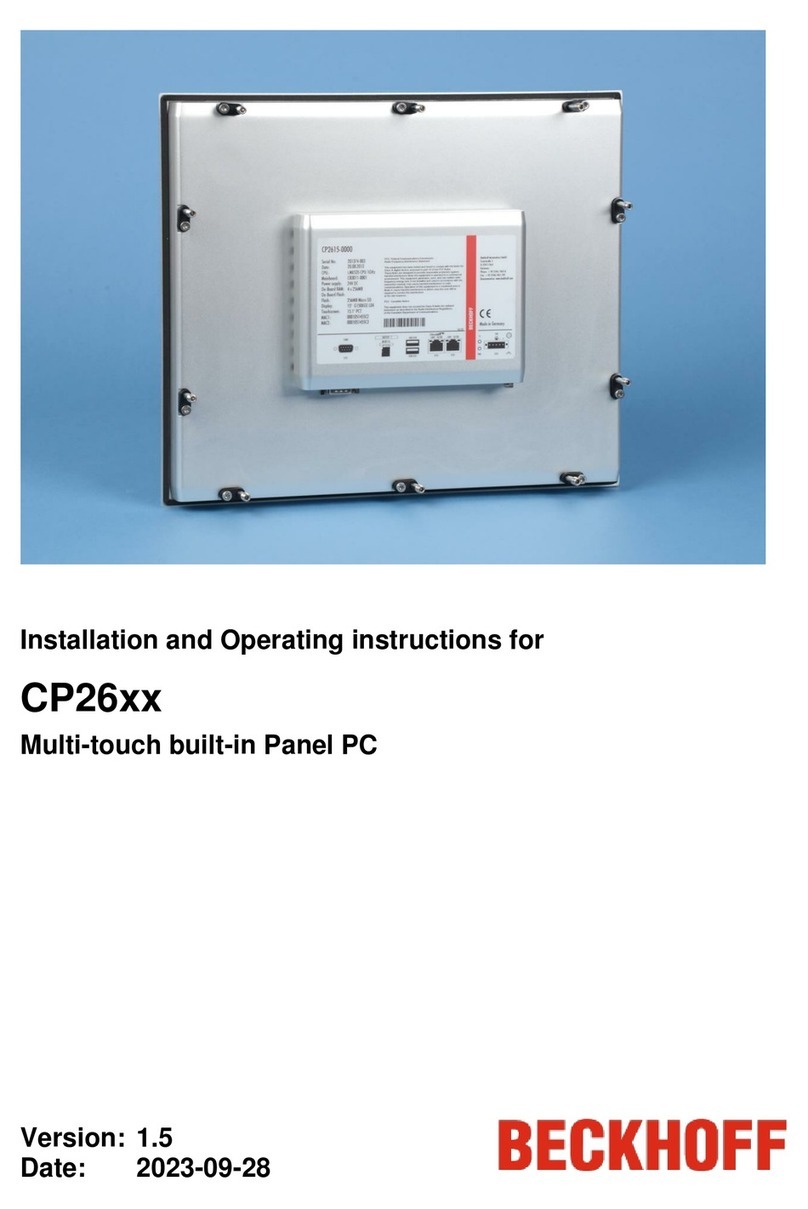

7.2.3 Mounting –Step by step

Choose suitable mounting screws, rawlplugs and bolts depending on

the actual local requirements and possibilities.

Earthing of stand

8x Ø16

See dimensions "stand"

2

1

NOTE

(See 8.1 Connection of power supply)

Installation Manual ET-/MT-xx6 Mechanical Installation

Page 14 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

A mounting holes, for hanging mount

B mounting holes, for upright mount

3 enclosure operating device

D mounting holes in the enclosure of the operating device

Coupling (pre-mounted)

3

Installation Manual ET-/MT-xx6 Mechanical Installation

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 15 of 23

C M6 Allen screw

E mounting coupling

F stand / wall bracket

or

4

5

Installation Manual ET-/MT-xx6 Mechanical Installation

Page 16 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

6

7

tighten all 4 screws with a torque of 10 Nm

Installation Manual ET-/MT-xx6 Mechanical Installation

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 17 of 23

*1

Connection bolt for equipotential bonding. Already wired to the multiple connection (*2)

in operator stations (OS).

8

Installation Manual ET-/MT-xx6 Mechanical Installation

Page 18 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

FRS enclosure

*1

Connection bolt for equipotential bonding. Already wired in operator stations (OS).

*2

Connection for equipotential bonding. See 8.1 Connection power supply

8a

Installation Manual ET-/MT-xx6 Electrical Installation

R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018 Page 19 of 23

8 Electrical Installation

8.1 Connection of the X1 power supply

Pin

Signal name

Description

1

+24 VDC

Power supply +24 VDC

2

3

Earth

Power supply 0 VDC

4

8.2 Stand or enclosure equipotential bonding / earthing

see 7.2.3 step 2

1

=

Stand mounting plate

2

=

Washer 2x

3

=

Toothed washer

4

=

Hexagon screw M6x16

5

=

Split washer

6

=

Cable lug with eyelet

9

10

Installation Manual ET-/MT-xx6 Electrical Installation

Page 20 of 23 R. STAHL HMI Systems GmbH / IM_ET_MT-xx6_en_V_01_00_02.docx / 23.07.2018

8.3 Ethernet interface TX / FX

8.3.1 Ethernet interface copper connection TX (X11)

Yellow

Orange

White

Blue

Pin

Signal

Colour

Note

Connection

1

Tx+

Yellow

twist

100Base-TX interface

2

Tx-

Orange

3

Rx+

White

4

Rx-

Blue

11

twist

shielding

clamping

bracket

e.g. cable:

VB-TP-CAT5-Exe-RJ45-Patch

correct

wrong

This manual suits for next models

10

Table of contents

Other Stahl Touch Panel manuals