(2)

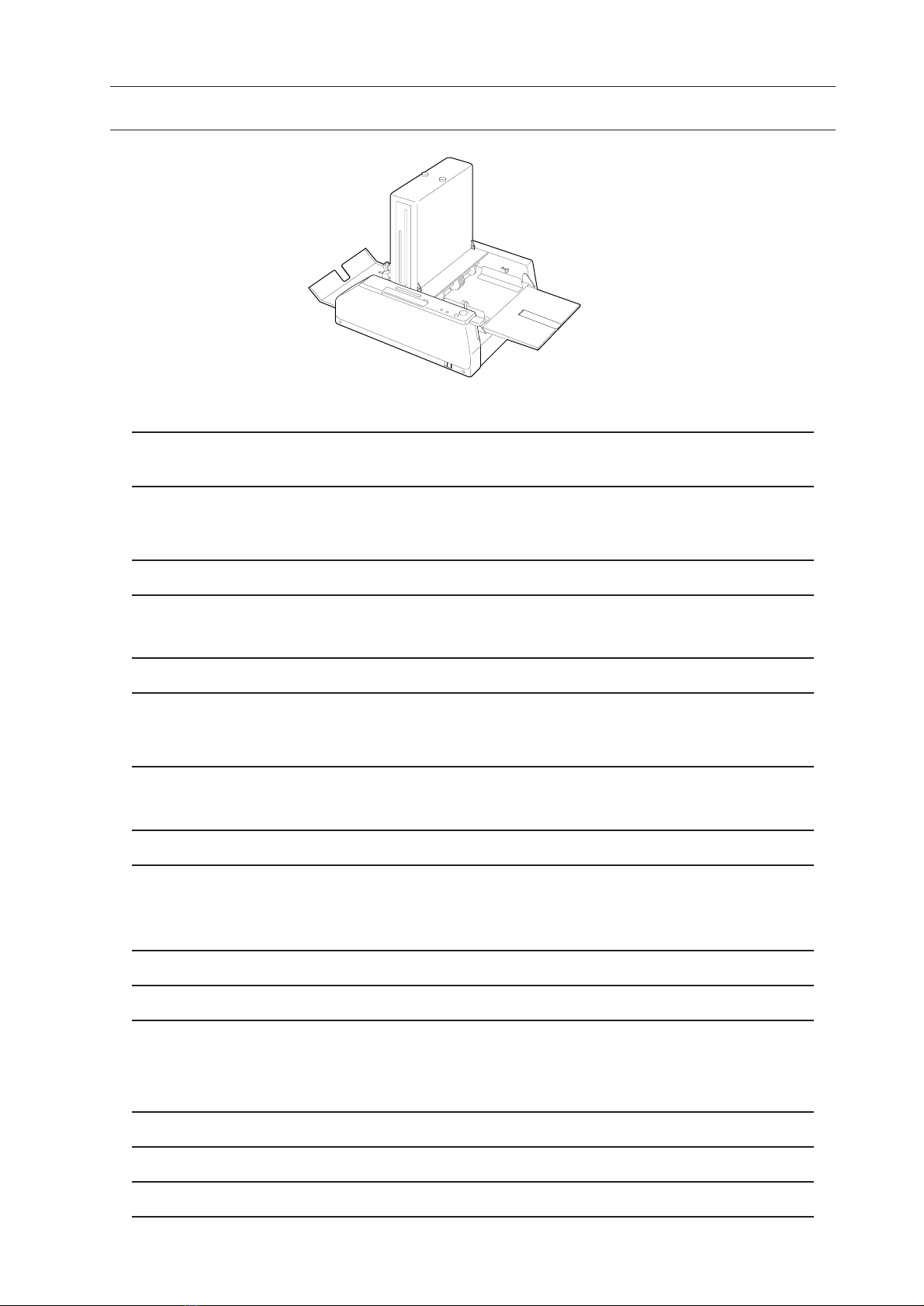

2. Operation Overview

1. Turn on power switch.

1st and 2nd stoppers move to home position

automatically. Then stoppers moves accord-

ing to fold pattern and sheet size memorized

at previous operation. When feed tray lever

rises at that time, motor, fold roller and

delivery belts will rotate. When feed tray

lever lowers, motor does not rotate.

2. Push feed tray lever down.

Motor will stop about 0.5 minute later.

3. Pile sheets into feed tray and select fold

pattern with folding pattern select button.

Stoppers move to set position according to

fold pattern. Deflector is activated only

when single fold pattern is selected.

4. Push feed tray lever up.

Motor will rotate.

5. Press test feed button.

- Clutch will be activated and feed roller

will make 1 turn and a sheet is fed.

- If sheet is not piled on feed tray, motor

will stop.

6. Press start/stop button.

- Clutch will be activated and a sheet will be

fed continuously or sheets will be fed con-

tinuously with some intervals (only accor-

dion fold and short fold).

7. Sheet feeding stops.

- Clutch will be off and only feed roller

stops when start/stop button is pressed.

- Clutch will be off and feed roller stops and

motor stops when feed tray lever is lowered.

- Feed roller stops when counter reaches

input number in the case of preset counter is

used.

- Feed roller stops when sheets run out on

feed tray.

Display Indication

" Please wait"

"Set Delivery Roller"

"0 / 0"

"Set Delivery Roller"

"0 / 0"

"0 / 0"

"0 / 0"

"1 / 0"

"Empty Tray"

"1 / 0"

Count Up

"50 / 0"

"0 / 50 Preset Stop"