Introduction 4

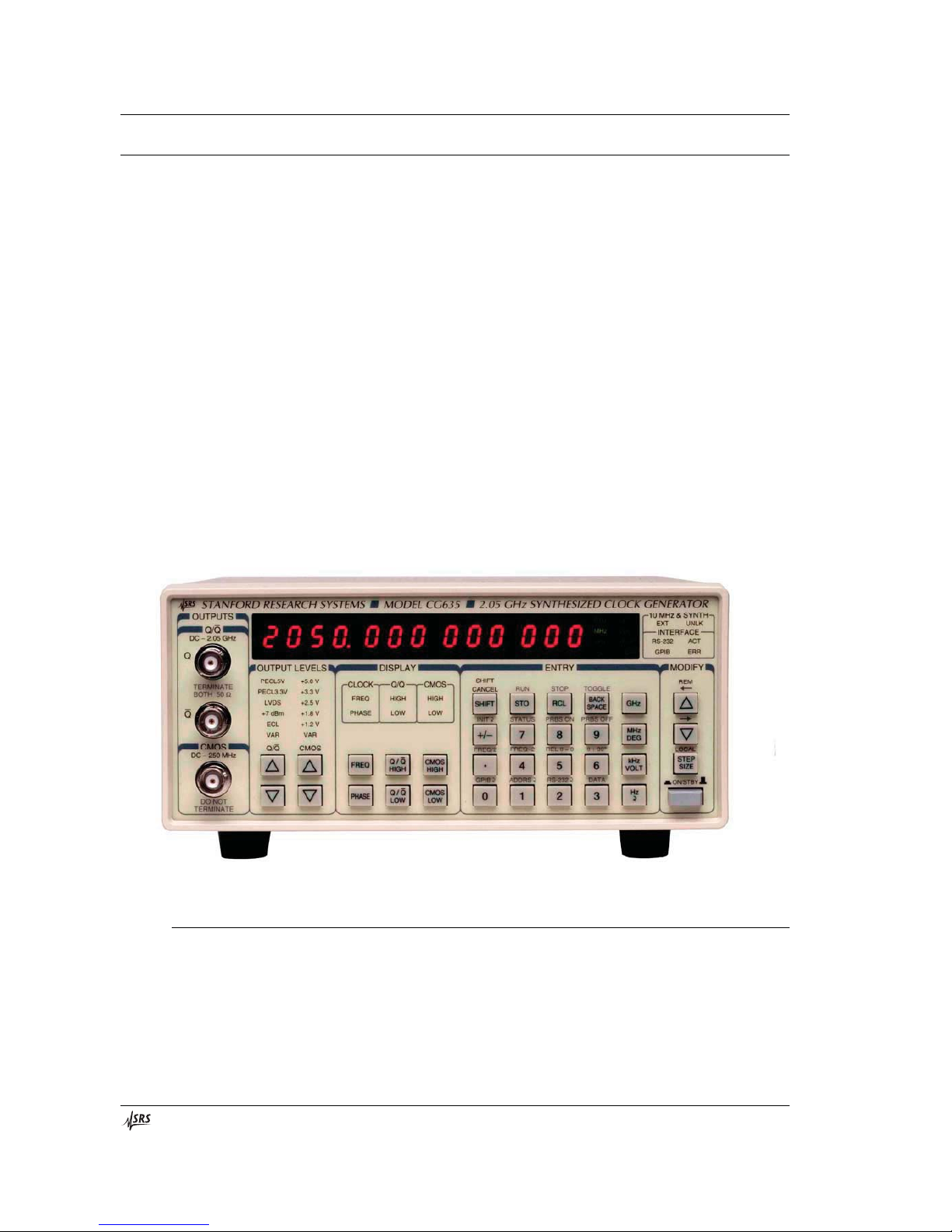

CG635 Synthesized Clock Generator

Display

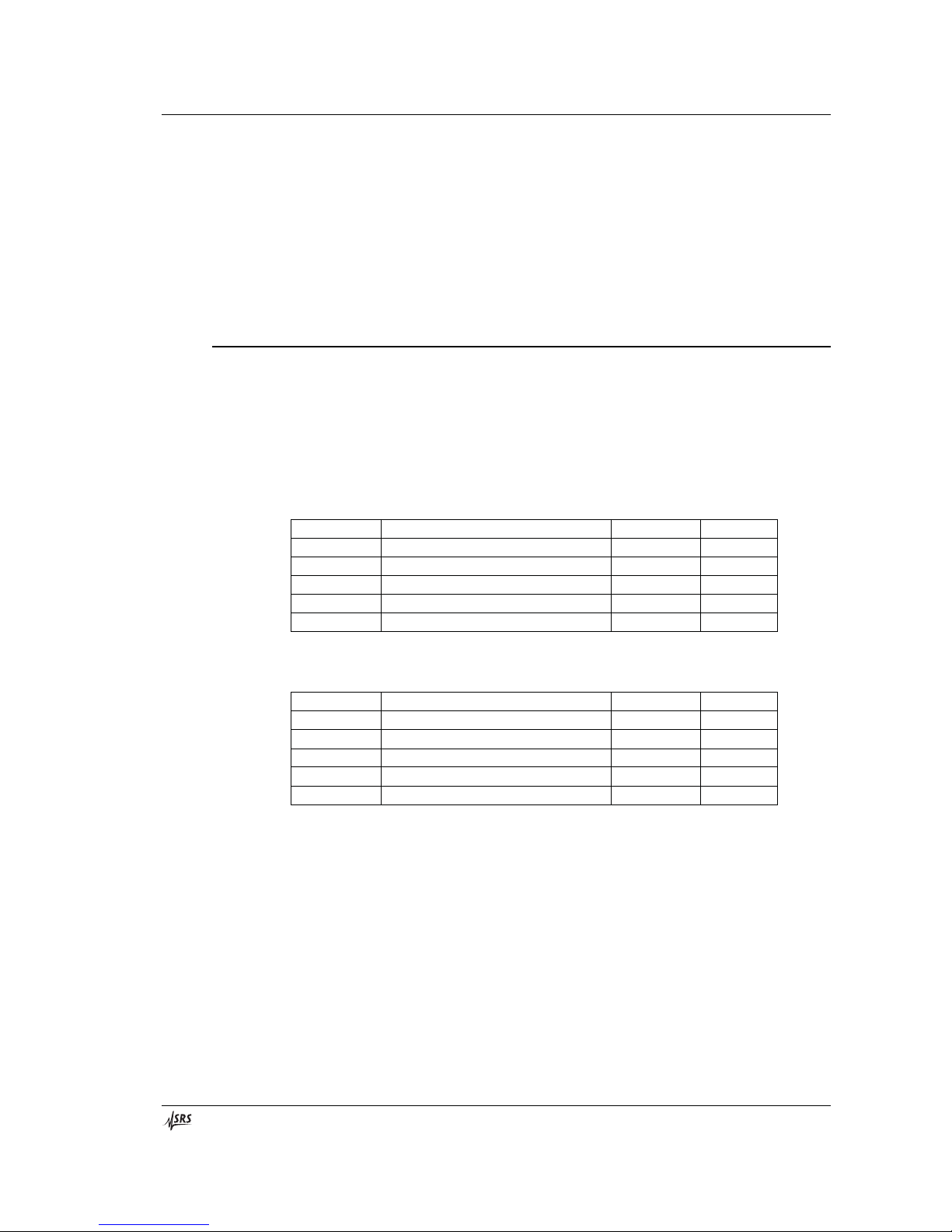

The DISPLAY section allows the user to select which values are reported in the main

front panel display. The LEDs in the display section indicate what is currently being

displayed or edited. The meaning of the LEDs and keys are summarized in Table 3.

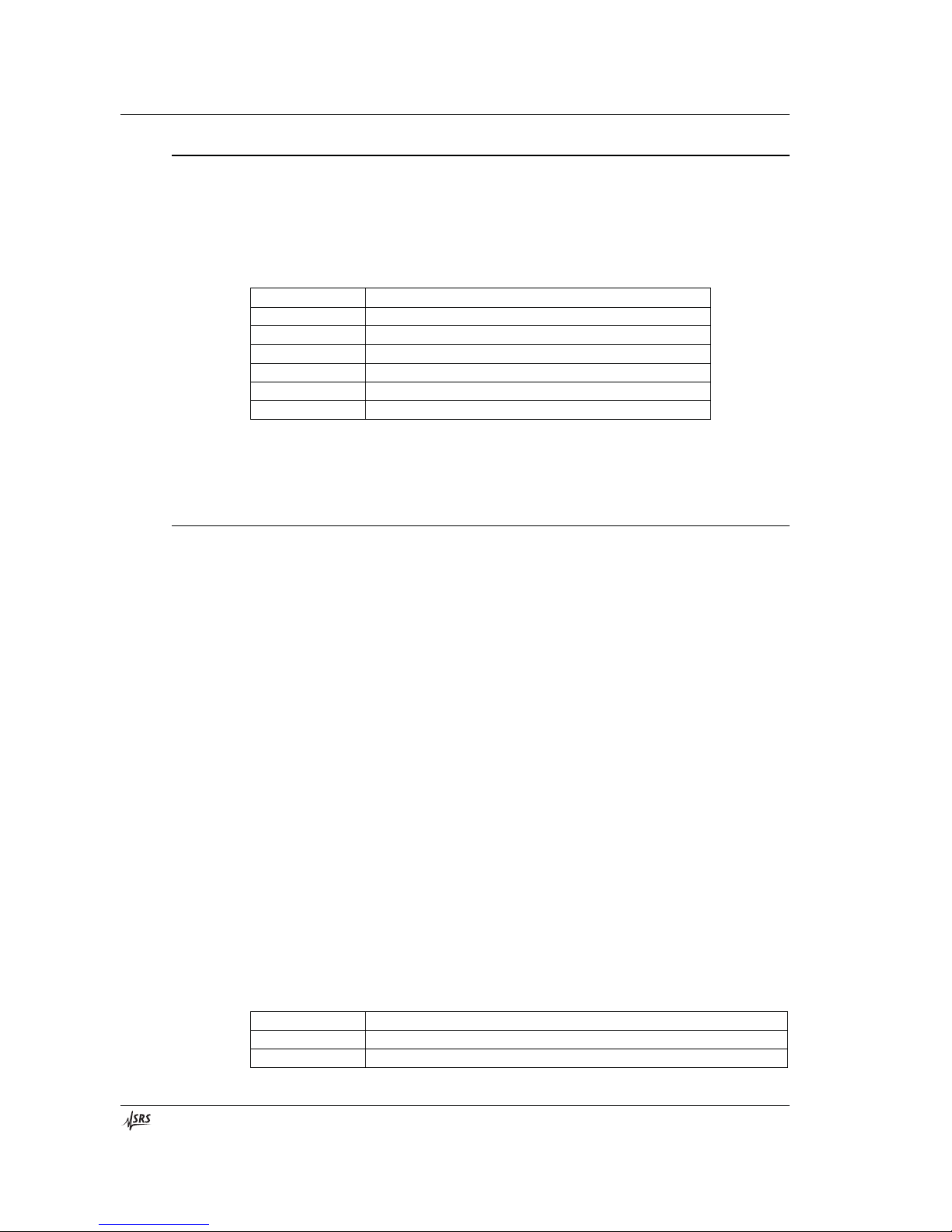

Table 3: DISPLAY Section Keys

Label Value Shown in Main Display When Pressed

FREQ Current frequency

PHASE Current phase

Q / Q¯ HIGH Voltage for a Q / Q¯ logic high state

Q / Q¯ LOW Voltage for a Q / Q¯ logiclowstate

CMOS HIGH Voltage for a CMOS logic high state

CMOS LOW Voltage for a CMOS logic low state

The keys are used to change the main display to the indicated item. Pressing ‘FREQ’, for

example, will cause the CG635 to display the current frequency. The FREQ LED will

turn on, indicating that the current display is frequency.

Entry

Numeric Entry

The ENTRY section is used to modify the current settings of the CG635. In most cases,

the currently displayed item can be changed by entering a new value with the numeric

keys, and pressing an appropriate units key to complete the entry. For example, if the

frequency is currently being displayed, pressing the keys ‘1’, ‘MHz’, sequentially will

change the frequency to 1 MHz. Similarly, if the CMOS HIGH voltage is displayed,

pressing the keys ‘2’, ‘.’, ‘1’, ‘VOLT’ will set the CMOS logic high voltage to 2.1 VDC.

Store and Recall Settings

The ‘STO’ and ‘RCL’ keys are for storing and recalling instrument settings, respectively.

The instrument saves the frequency, phase, Q / Q¯ and CMOS output levels, all the

associated step sizes, the run/stop state, the PRBS state, and the current display. Up to ten

different instrument settings may be stored in the locations 0 to 9. To save the current

settings to location 5, press the keys ‘STO’, ‘5’, ‘Hz’, sequentially. To recall instrument

settings from location 5, press the keys ‘RCL’, ‘5’, ‘Hz’ sequentially.

Secondary Functions

Many of the keys have secondary functions associated with them. The names of these

functions are printed above the key. The ‘4’ key, for example, has FREQx2 above it. The

meaning of the secondary functions is summarized in Table 4.

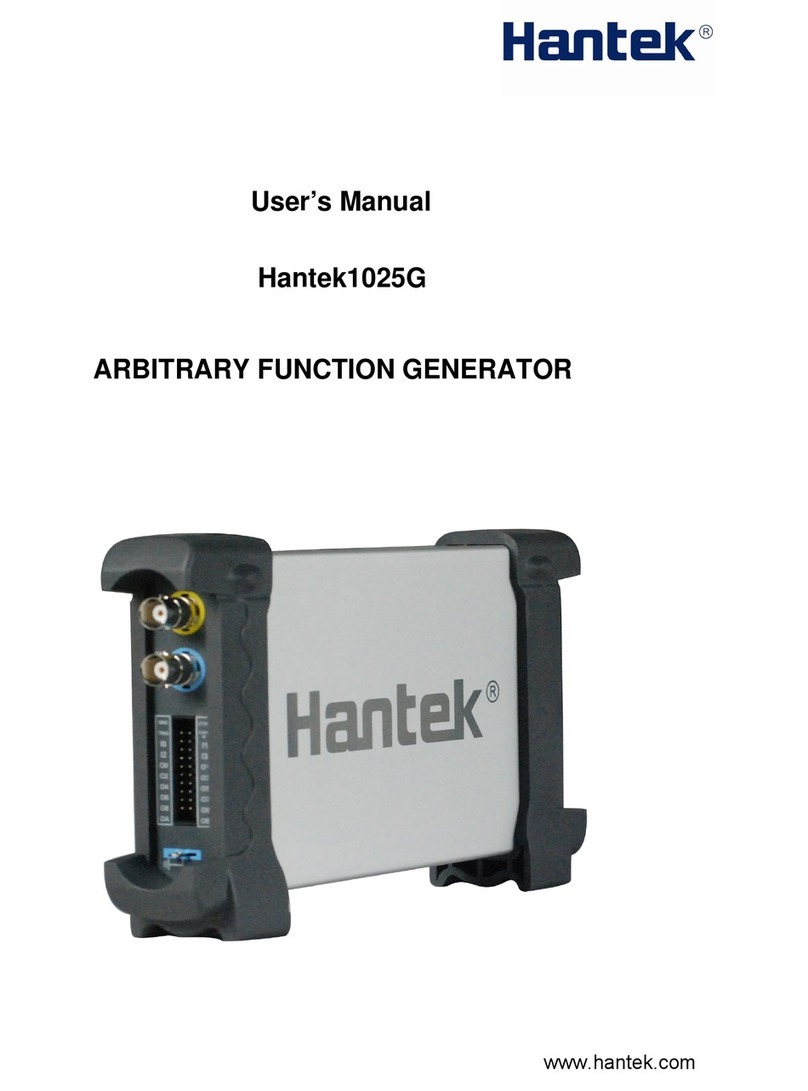

Table 4: Secondary Functions

Label Function Description

RUN Enables the output. Drives the output at the current frequency.

STOP Stops the output. Forces the output to a logic low state.