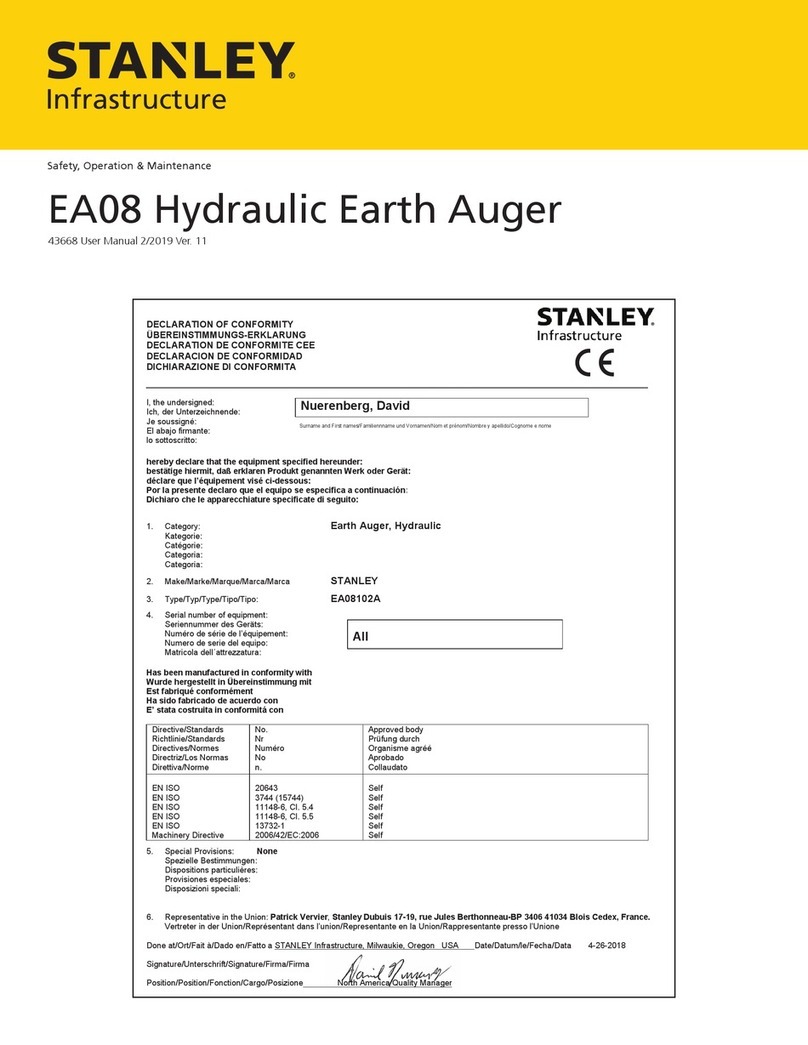

6 ► EA08 User Manual

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the

hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

STANLEY hydraulic tools. They are:

Certi ed non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certifi ed non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid

reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used

near electrical conductors.

Fabric-braided (not certi ed or labeled non-conductive) — constructed of thermoplastic or synthetic rubber

inner tube, synthetic ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover.

This hose is not certifi ed non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from STANLEY. DO

NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your STANLEY Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

(Shown smaller than actual size)

SIDE 1

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSEAND FITTING

WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND TEST

HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY

DEPARTMENT INSTRUCTIONS.

SEE OTHER SIDE

SIDE 2

DO NOT REMOVE THIS TAG

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

AND SEVERE PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAM-

AGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

SEE OTHER SIDE

DANGER

DO NOT REMOVE THIS TAG

DANGER

(Shown smaller than actual size)

SIDE 2

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

DANGER

DO NOT REMOVE THIS TAG

DANGER

SIDE 1

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELEC-

TRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

DANGER

SEE OTHER SIDE SEE OTHER SIDE

SAFETY TAG P/N 15875 (Shown smaller then actual size)

DANGERDANGER

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CER-

TIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC

TOOLS ON OR NEAR ELECTRICAL LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE

HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE

SHOULD BE REGULARLY TESTED FOR ELECTRIC CUR-

RENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY

DEPARTMENT INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJEC-

TION INTO THE BODY OR CAUSE OTHER SEVERE

PERSONAL INJURY.

A. DO NOT EXCEED SPECIFIED FLOW AND PRESSURE

FOR THIS TOOL. EXCESS FLOW OR PRESSURE MAY

CAUSE A LEAK OR BURST.

B. DO NOT EXCEED RATED WORKING PRESSURE OF

HYDRAULIC HOSE USED WITH THIS TOOL. EXCESS

PRESSURE MAY CAUSE A LEAK OR BURST.

C. CHECK TOOL HOSE COUPLERS AND CONNECTORS

DAILY FOR LEAKS. DO NOT FEEL FOR LEAKS WITH

YOUR HANDS. CONTACT WITH A LEAK MAY RESULT

IN SEVERE PERSONAL INJURY.

IMPORTANT

D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO

NOT ABUSE HOSE. DO NOT USE KINKED, TORN OR

DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CON-

NECTED TO THE TOOL BEFORE PRESSURING SYSTEM.

SYSTEM PRESSURE HOSE MUST ALWAYS BE CON-

NECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT.

REVERSING CONNECTIONS MAY CAUSE REVERSE

TOOL OPERATION WHICH CAN RESULT IN SEVERE

PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSED-

CENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN

LOSS OF OTHER HYDRAULIC FUNCTIONS POWERED BY

THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA.

KEEP BYSTANDERS CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PRO-

TECTION.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE,

ALL TOOL REPAIR MAINTENANCE AND SERVICE MUST

ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY

TRAINED PERSONNEL.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

The safety tag (P/N 15875) at right is

attached to the tool when shipped from

the factory. Read and understand the

safety instructions listed on this tag before

removal. We suggest you retain this tag and

attach it to the tool when not in use.

NOTE:

THE INFORMATION LISTED

ON THE STICKERS SHOWN,

MUST BE LEGIBLE AT ALL

TIMES.

REPLACE DECALS IF

THEY BECOME WORN OR

DAMAGED. REPLACEMENTS

ARE AVAILABLE FROM

YOUR LOCAL STANLEY

DISTRIBUTOR.

11207

CIRCUIT D DECAL

28323

CE DECAL

23139

NAME TAG 11206

CIRCUIT C STICKER

CALL BEFORE

YOU DIG

39423

COMPOSITE DECAL

66409

SOUND POWER DECAL

39424

WARNING DECAL

WARNING

TOOL STICKERS & TAGS