Start italiana XMT User manual

INSTALLATION

MANUAL

XMT

MAGNETOSTRICTIVE

LEVEL PROBE

XMT rev.03 2015-04 - ENG

2

INDEX

INDEX...........................................................................................................................................................................................................................................2

REVISION INDEX........................................................................................................................................................................................................................2

INTRODUCTION ........................................................................................................................................................................................................................3

GENERAL WARNINGS ..............................................................................................................................................................................................................3

DESCRIPTION.............................................................................................................................................................................................................................4

MAIN COMPONENTS ..............................................................................................................................................................................................................5

MECHANICAL INSTALLATION ...............................................................................................................................................................................................6

INSTALLATION PROCEDURE..................................................................................................................................................................................................6

ELECTRICAL CONNECTION....................................................................................................................................................................................................8

EXTERNAL INSTALLATION SCHEME.....................................................................................................................................................................................9

RS485 BUS CONNECTION: ................................................................................................................................................................................................... 10

MARKING AND SERIAL NUMBER ......................................................................................................................................................................................... 11

ELECTRONIC BOARD ............................................................................................................................................................................................................. 12

ATEX CERTIFICATE AND CESI NOTIFICATION ................................................................................................................................................................. 13

REVISION INDEX

DATE

REVISION NUMBER

DESCRIPTION

0

INITIAL RELEASE

09/2011

1

General revision

09/2014

2

General amendments and layout revision

04/2015

3

Notification

This product complies with EU Directive 2012/19/UE.

The crossed-bin symbol fixed on the device indicates that the product, at the end of its useful life, should be

disposed of separately from household waste, must be taken to a collection point for electrical and electronic

equipment.

Nota: Start italiana Srl, in respect of its quality duty may modify its production and data shown into this manual. This

manual cannot be copied, neither partially, without authorization.

XMT rev.03 2015-04 - ENG

3

INTRODUCTION

This manual gives all the installation and use instructions for XMT level probes.

GENERAL WARNINGS

Before the installation and use of the equipment please carefully read the instructions given into this manual.

The manufacturer is not responsible of any possible operation not mentioned into this manual.

Any failure or faulty operation would occur to the equipment, please refer to the authorized personnel for maintenance

or directly to the manufacturer only.

The manufacturer refuses all responsibility for any eventual injury and/or damage to things caused to the non-

observance of the safety regulations.

The assigned personnel is required to know all the safety regulations relative to the hereby described equipment.

Any doubt may occur about the equipment running please refer to the authorized personnel for maintenance or

directly to the manufacturer.

Tampering releases the manufacturer from any responsibility in front of the competent authority.

This product is used in fuel tanks and in hazardous areas for risk of explosion and fire. Subterranean leakages of the fuel

tanks may cause serious damages to environment and injury.

XMT rev.03 2015-04 - ENG

4

DESCRIPTION

The magnetostrictive level transmitters are based on the principle named Wiedemann effect and enable continuous

and highly accurate reading of liquids’ level.

The XMT level transmitter consists of a microprocessor based electronic circuit placed inside one aluminum case

head and a stainless steel shaft containing a wave guide placed inside the tank.

An high frequency electric impulse is transmitted through the electronic device. At the matching point with the

magnetic field generated by the permanent magnet placed inside the float, a mechanical impulse is generated thanks to

the magnetostrictive torsional strain. The mechanical impulse spreads through the wave guide to the speed of sound up to

the sensor in the measuring head. The timing between the transmission of the going impulse and the return impulse define

exactly the position of the floats.

Main features

Measurable product

Diesel, fuel, propane (GPL), water

According to the float

Accuracy

± 0,5 mm probe with serial output

Resolution

0,1 mm

Repeatability

± 0,1 mm probe with serial output

Supply

9-30Vcc

Absorpion

< 50 mA

Temperature accuracy

± 0,5°C

Temperature measuring range

-45°C ÷ +130°C

Ambience temperature

-20°C ÷ +60°C

INERIS Exd execution

II 1/2 GD Ex d IIA T6 Ex tD A21 IP66/68

Technical features

Body

Ø 110 mm

Float

Ø 50 mm (other dimensions on demand)

Shaft

Ø 16 mm

Measurable height

500 ÷ 6000 mm

XMT rev.03 2015-04 - ENG

5

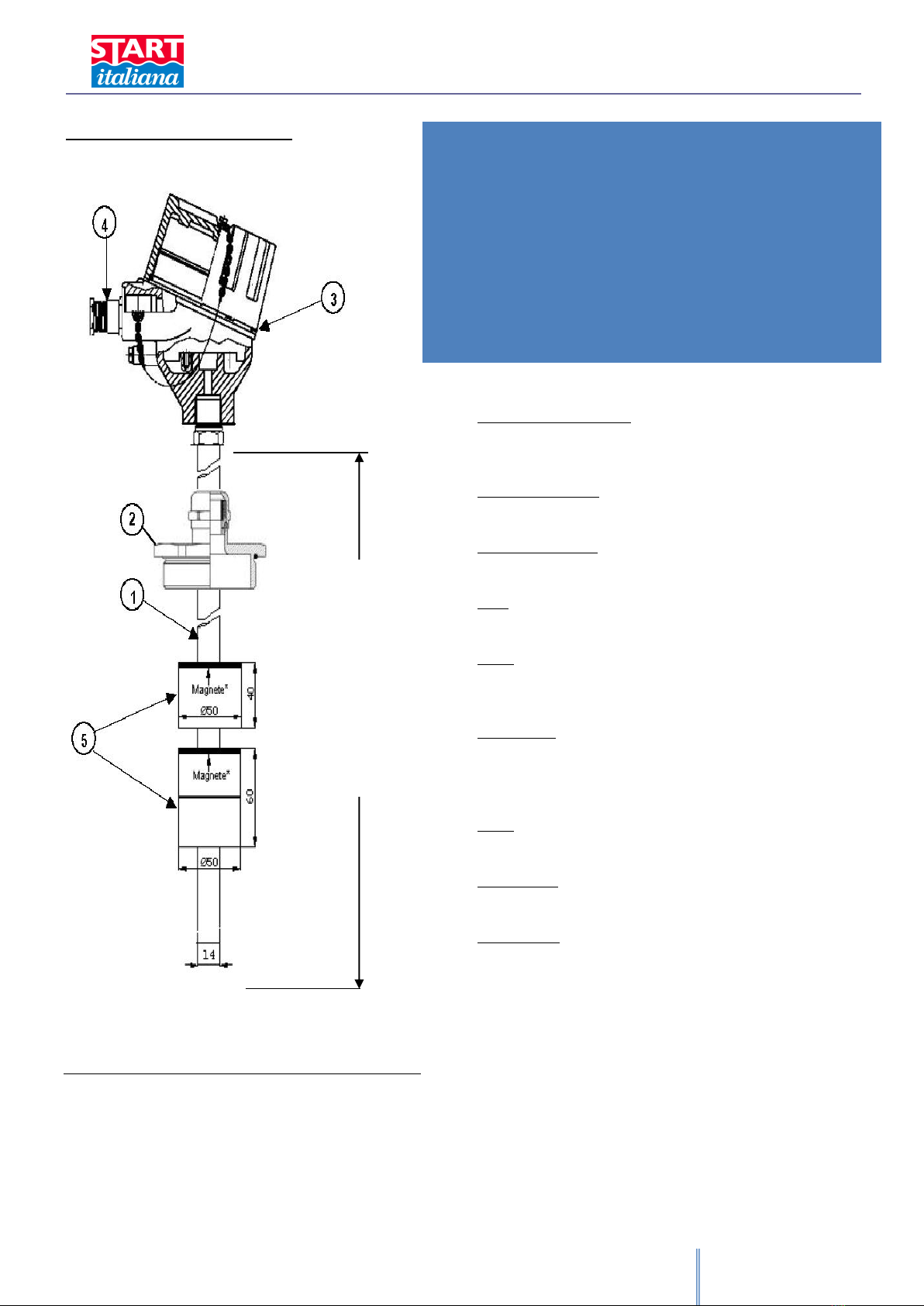

MAIN COMPONENTS

1 Stainless steel shaft AISI 304 - Length from 200 to 6.000 mm

2 Sliding nipple 2” F gas nickel plated brass

3 Die-casted aluminium case IP68

4 Cable gland EExd ½”NPT IP68

5 Floats

Shaft length L . mm……….

Tank standard connection:

Adjustable threaded 3/4”NPT-2”M Gas

Special ones on demand

Electrical connection:

Cable gland EExd ½”NPT IP68

Guide shaft AISI 304:

Diam. 16X2

Case:

Explosion proof IP68 in painted aluminum

Floats:

Foam PVC with closed cells and no-sticking flaps Diam. 50mm

Other materials and dimensions on demand

Temperature:

Liquid: -45°C + 130°C

Head: -25°C + 85°C

ATEX version: -25°C + 60°C

Cable:

Double shielding, twisted, hydrocarbur resistant, 10mm sheath

Power supply:

External supply 9-30 Vdc

Power output:

- RS 485 serial output

- Conversion board from RS485 protocol to 4-20 mA is

available (4 wires technology). In this case only the product

level will be converted into 4-20mA.

XMT rev.03 2015-04 - ENG

6

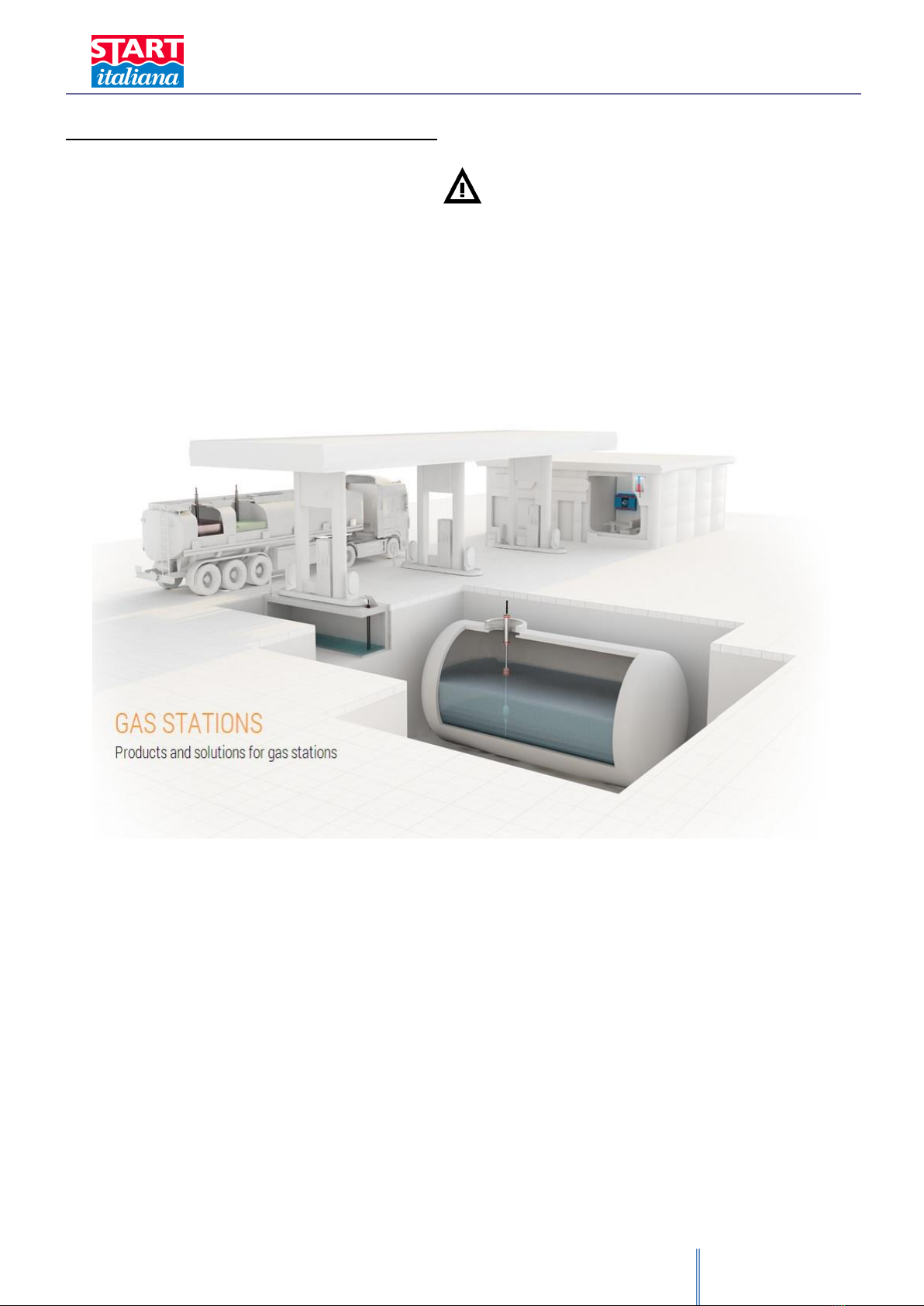

MECHANICAL INSTALLATION

If mixed with air, the flammable vapors may cause explosion. Hazardous areas may be originated therefore by the

presence of gas or vapors.

Explosions or fire may cause damages, even lethal.

The magnetostrictive probe can be installed in hazardous areas.

INSTALLATION PROCEDURE

The XMT magnetostrictive level probe is supplied into carton package of one or two pieces. We recommend to check

packing integrity.

1. When removing from original packing please pay attention not to bend the stainless steel men-hole reminding that

it is an electronic device.

2. The standard version of level probe XMT is supplied with a sliding 2” gas M fitting and the assembled floats enable

to easily shift into 2” connection. This makes the probe insertion inside the tank easier,this means that no part of

the probe must be disassembled for tank insertion operation.

3. The probe must be placed as much as possible in the center of the tank, it must be far from the product loading.

4. The probe must be assembled by keeping the body as high as possible in order to avoid its flooding.

5. It is recommended to use a 2” riser outside the tank to protect it mechanically.

6. Before introducing the probe inside the tank please check the correct floats positioning and clamping of the shaft

end.

7. Carefully unpack the level probe and insert it inside the tank.

8. Insert the probe in the 2” G-F tank gate and make it reach the floor with care then raise it of at least 10mm, this

will avoid bending of the shaft in case loading operation make tank deforming.

9. The level probe must be placed in vertical position inside the tank. The shaft inside the tank must not be either

folded or blended and must not be subjected to impact or stress.

10. Tighten the adjustable fitting until full clamping on the shaft. Connect probe cable to the plant as described

afterwards.

11. Connect sensors as described into “Electrical connection “section.

XMT rev.03 2015-04 - ENG

7

IMPORTANT: if the probe is installed without leaving at least 10mm space from the bottom of the tank and blocked on the

top with a sliding connection, any deformation of the tank that occurs will bend the probe compromising the correct

functionality.

Riser 2” as reinforce for the shaft

external off the tank. Keep the sliding

connection as near as possible to the

head.

At least 10 mm from the bottom

XMT rev.03 2015-04 - ENG

8

ELECTRICAL CONNECTION

In case of hydrocarbour vapor use anti-sparks tools

The installation must be realized by specialized people

Respect the safety rules

Read carefully the instruction given into this manual

The manufacturer is not responsible for any damage and/or supplementary costs due to the missing respect of the

supplied instructions.

The probe is supplied with 2 m of cable (1) connected through an ex-proof cable gland (2) to the probe head.

This cable must be connected to the back bone using an ex-proof junction box and an ex-proof cable gland.

It is recommended not to cut the cable for an easy extraction of the probe from the tank in case of maintenance.

It is recommended the usage of junction box JB IP68 Exd supplied by Start Italiana under request.

WARNING: the supplied 3 mt cable is moulded inside the probe head with special compound to improve the water proof;

its removal compromises the probe functioning, and affect the guarantee and the ATEX certification.

Insert the cable into the console in the locking joint (4).

The cable inside the locking joint must be without external rubber isolation.

Perform the electrical connections into the junction box as shown by the electrical scheme below.

After having tested the good functioning of the system, the locking joint must be filled with resin to avoid the

eventual hydrocarbon vapor infiltrations.

Note A

Installation made in compliance with CEI 64-8 and CEI EN 60079-14 standards.

Note B

Use cable compliant with regulation in force in the country of installation.

64-8 Electrical installations with nominal voltage not higher than 1000 Vac and 1500 Vdc. 60079-14 (1998) Classif.CEI 31-33 “Electrical costructions for

explosive area for gas presence” Part 14: Electricla installation in ex-proof area for gas presence (excluded mines).

XMT rev.03 2015-04 - ENG

9

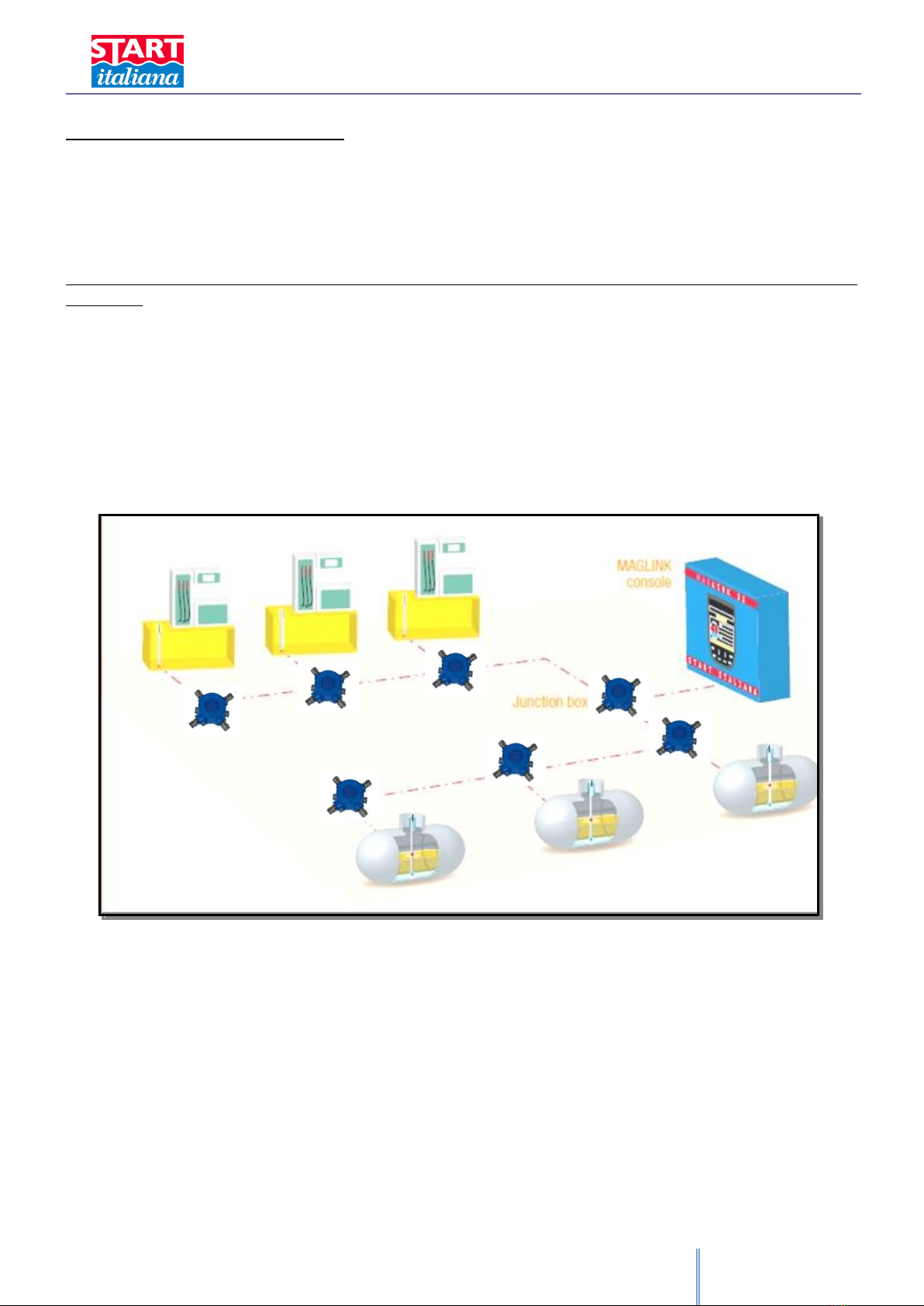

EXTERNAL INSTALLATION SCHEME

The installation must be realized by specialized people

Respect the safety rules

Read carefully the instruction given into this manual

The manufacturer is not responsible for any damage and/or supplementary costs due to the missing respect of the

supplied instructions.

Note A

Installation made in compliance with CEI 64-8 and CEI EN 60079-14 standards.

Note B

Use cable compliant with regulation in force in the country of installation.

64-8 Electrical installations with nominal voltage not higher than 1000 Vac and 1500 Vdc.

60079-14 (1998) Classification CEI 31-33 “Electrical constructions for explosive area for gas presence”

Part 14: Electric installation in ex-proof area for gas presence (excluded mines).

XMT rev.03 2015-04 - ENG

10

RS485 BUS CONNECTION:

Standard connection scheme of the probes to the bus RS485. Every probe is connected in parallel. If possible please

use Start Italiana’s IP68 shunt boxes already equipped with connecting terminal.

The 4 wires cable has always red-brown-blue-white colors.

Connect to the terminal the same color type: red-red, white-white, etc.

Shielded cables have all to be connected in parallel as a fifth wire and connected to the earth into the office using a protected

ground tap.

Any possible double wall and sump sensors will need the same connection on the same bus.

For connection and programming of the consoles please refer to the manual provided together with the device.

XMT rev.03 2015-04 - ENG

11

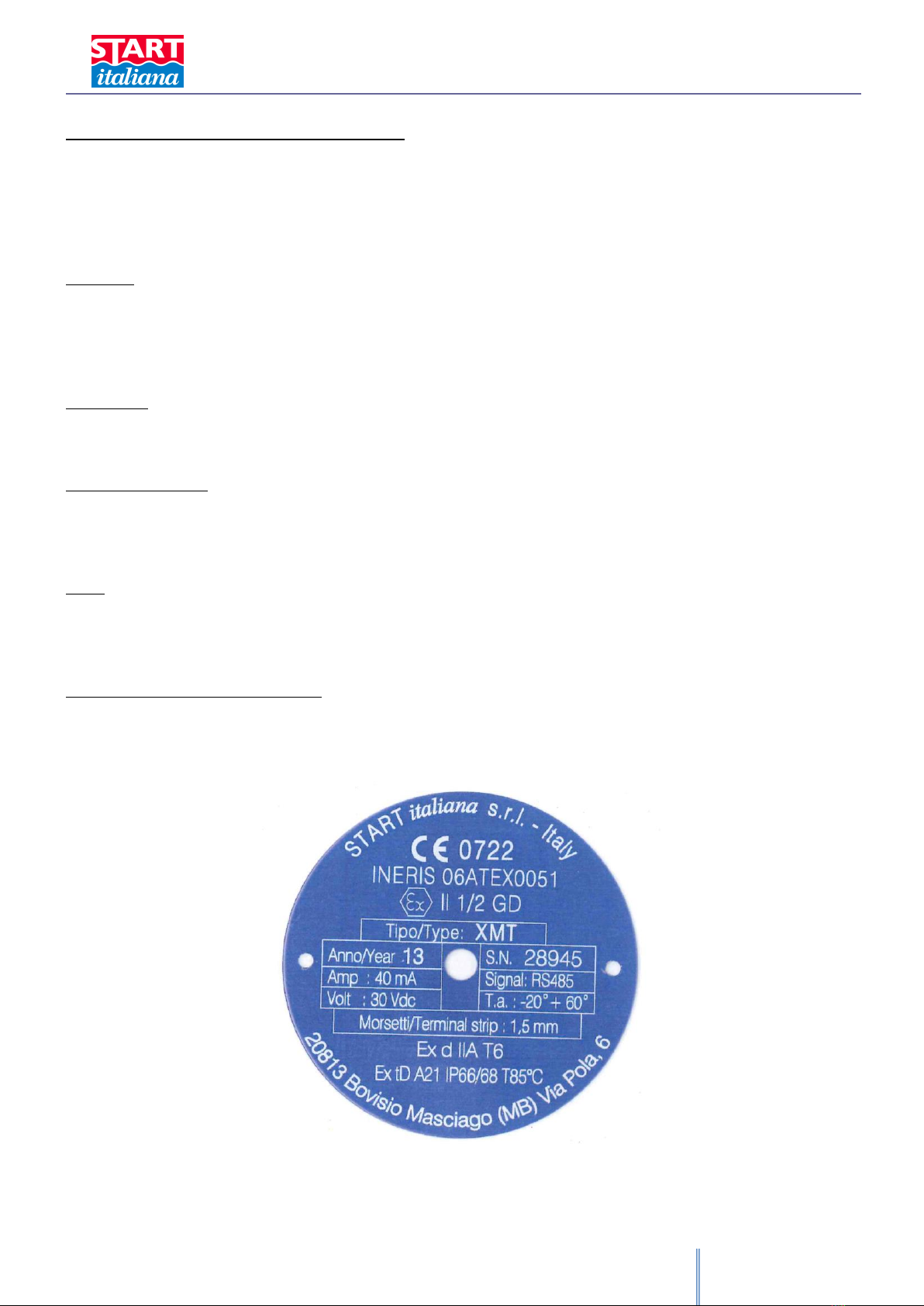

MARKING AND SERIAL NUMBER

Every probe has a unique identification serial number (S.N.) which is also the ID Address of the probe.

Take note of the S.N. (ID address), it will be required during system recognizement through the set-up Software.

On the cap head there is a metallic label with laser marking which is showing the following information:

MARKING:

Manufacturer: START ITALIANA SRL –20813 Bovisio Masciago (MB) - Italy

Type: XMT-XCR-XLR-DGM

CE e O.N.: 0722

Group: II ½ GD

EXECUTION:

EEx d IIC T6 IP66/68 T 85° for level probes with /titanium/hastelloy float

EEx d IIA T6 IP66/68 T 85° for level probes with PVC float

LABORATORY: INERIS

A nom: …

N° certificate: …..

V max: …

Signal

S.N. and probe address

T.a.: -20° +60°

Year of manufacture:

FUSION MARKING ON THE CAP HEAD:

Keep cover tight when circuits alive

XMT rev.03 2015-04 - ENG

12

ELECTRONIC BOARD

Pos

Component

1

Power supply 12-30V 2,1

RED

2

RX

BROWN

3

TX

BLUE

4

0 V

WHITE

Probe 1

Probe 2

Max no. of probes: 32

Brown

Blue

White

Red

4 = White

3 = Blue

2 = Brown

1 = Red

4 = White

3 = Blue

2 = Brown

1 = Red

XMT rev.03 2015-04 - ENG

13

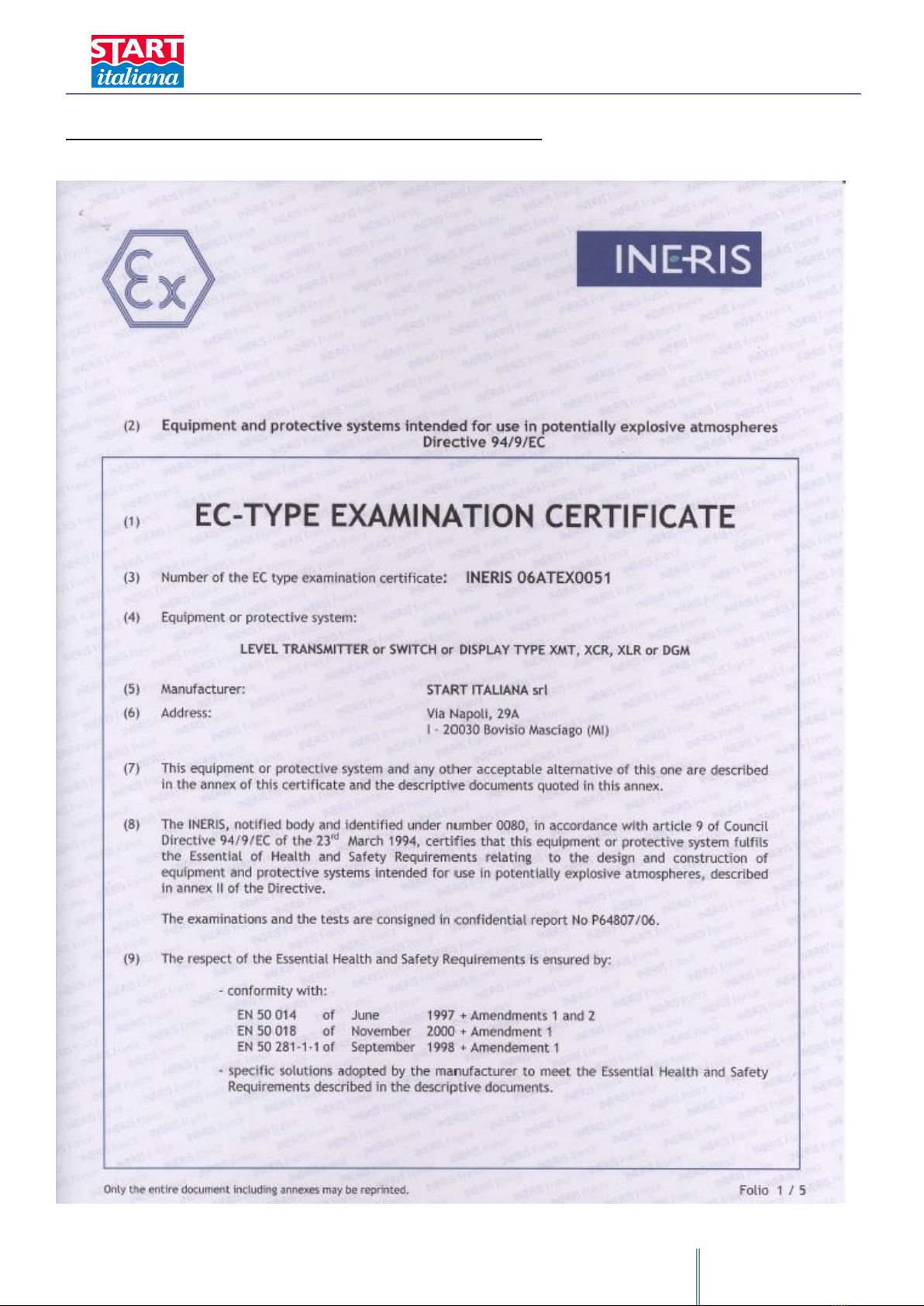

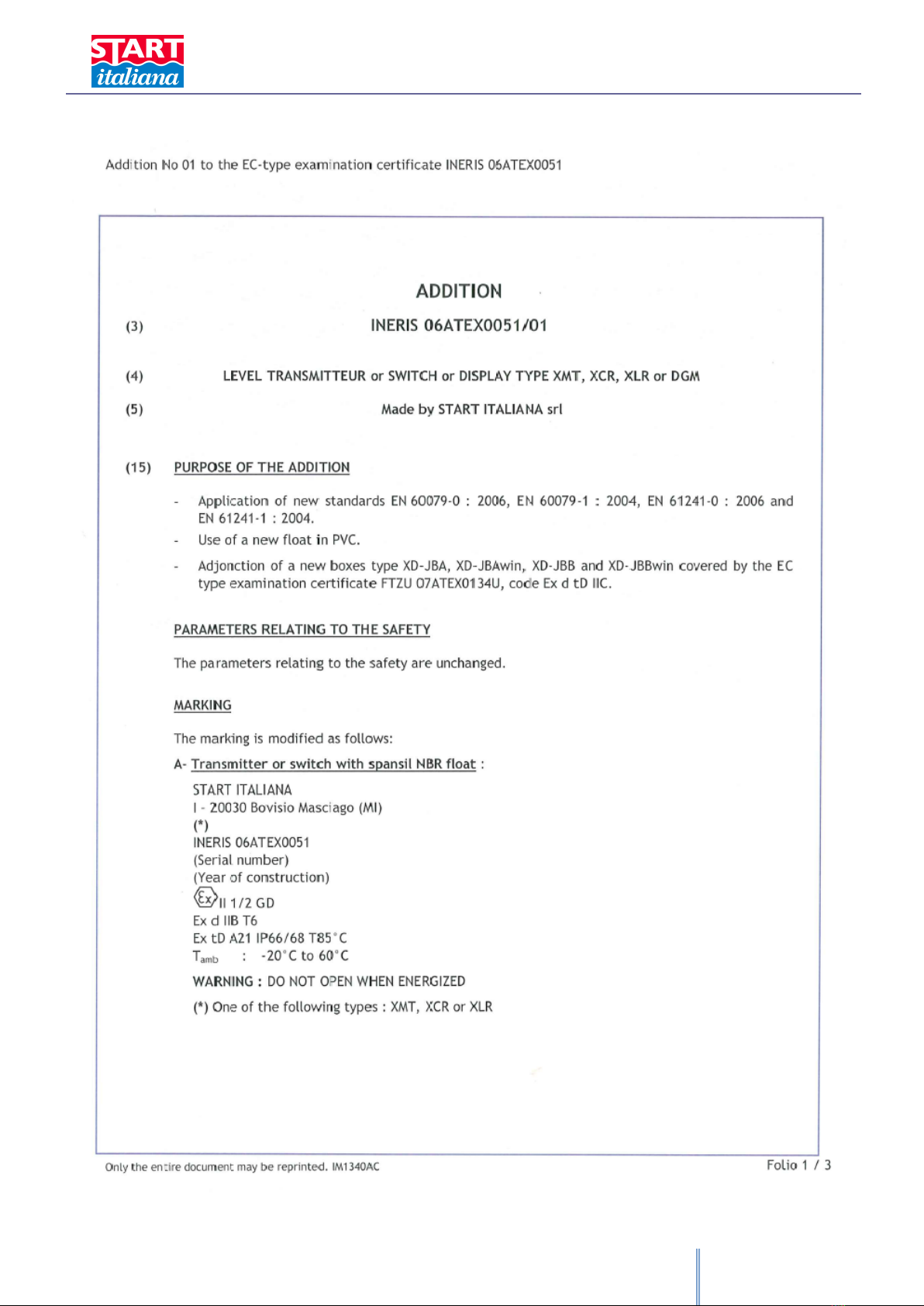

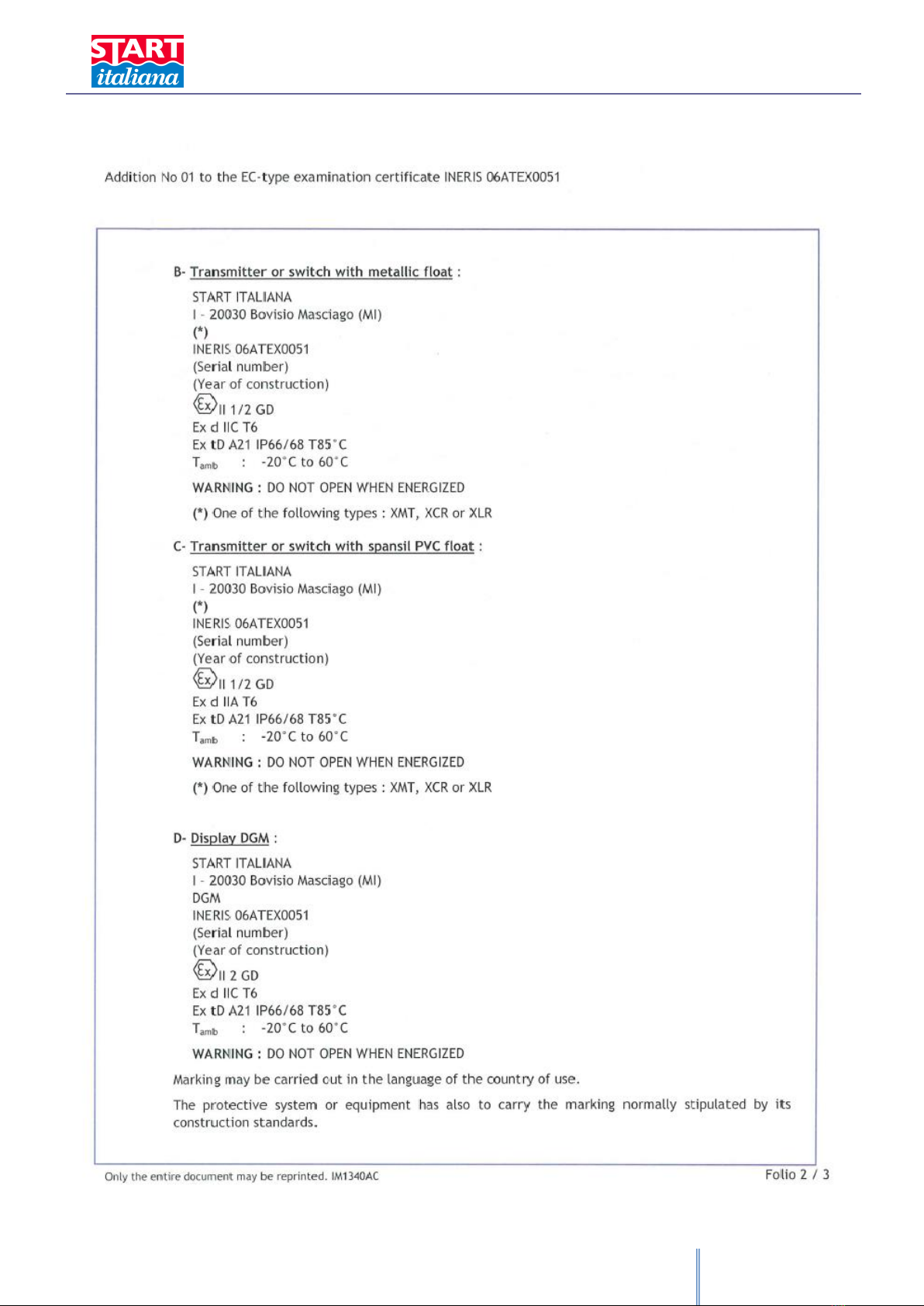

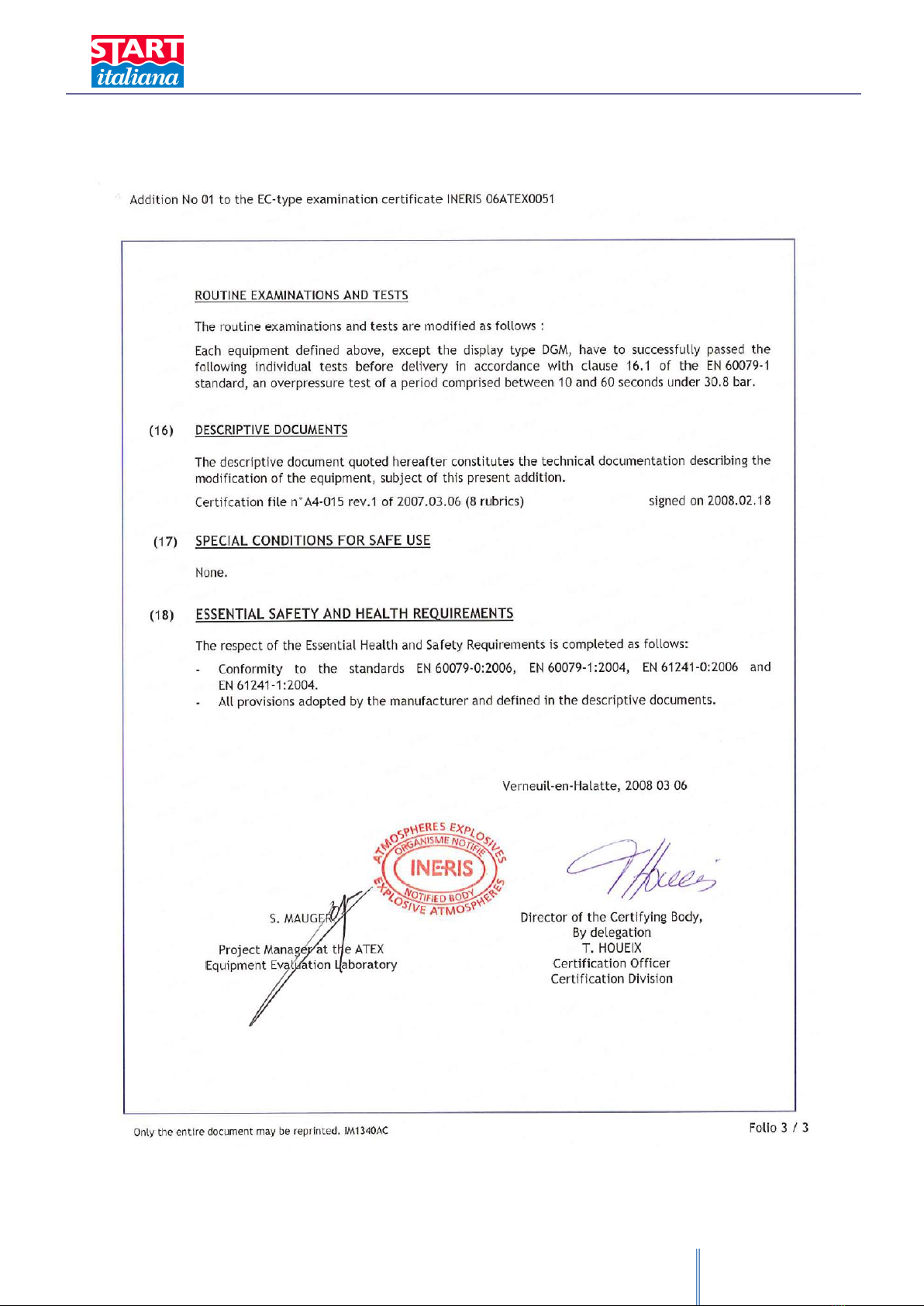

ATEX CERTIFICATE AND CESI NOTIFICATION

XMT rev.03 2015-04 - ENG

14

XMT rev.03 2015-04 - ENG

15

XMT rev.03 2015-04 - ENG

16

XMT rev.03 2015-04 - ENG

17

XMT rev.03 2015-04 - ENG

18

XMT rev.03 2015-04 - ENG

19

XMT rev.03 2015-04 - ENG

20

Table of contents

Other Start italiana Measuring Instrument manuals