Stat Fax 303 Plus User manual

Copyright 2001 Doc 303 Revised 04/2007 Rev. J

Stat Fax®303 Plus

Operator’s Manual

TABLE OF CONTENTS

1.0 Introduction........................................................................................................................................... 1

1.1 Applications ...................................................................................................................................... 1

1.1.1 Intended Use .............................................................................................................................. 1

1.1.2 Summary of the Instrument ....................................................................................................... 1

1.2 Principles of Operation ..................................................................................................................... 2

1.3 Warning Markings ............................................................................................................................ 3

1.3.1 Safety Symbols .......................................................................................................................... 3

1.3.2 Safety Terms .............................................................................................................................. 3

1.4 Safety Precautions............................................................................................................................. 4

1.5 Installation......................................................................................................................................... 6

1.5.1 General Installation.................................................................................................................... 6

1.5.2 Serial Port................................................................................................................................... 7

1.5.3 Internal Printer ........................................................................................................................... 8

1.5.4 Check-out Procedure.................................................................................................................. 8

1.6 Major Parts and Controls .................................................................................................................. 9

1.7 Keyboard Functions........................................................................................................................ 10

1.8 Specifications.................................................................................................................................. 12

2.0 Operating Procedures.......................................................................................................................... 15

2.1 General Selections .......................................................................................................................... 15

2.1.1 Selecting a Strip Format........................................................................................................... 16

2.1.2 Selecting a Mode...................................................................................................................... 17

2.1.3 Quitting a Mode ....................................................................................................................... 18

2.1.4 Selecting Filters ....................................................................................................................... 18

2.1.5 Selecting a Blank ..................................................................................................................... 19

2.1.6 Selecting Duplicates................................................................................................................. 19

2.1.7 Unit Codes ............................................................................................................................... 20

2.1.8 Selecting Cutoff Interpretations............................................................................................... 20

2.1.9 Selecting Control Options........................................................................................................ 21

2.1.10 Selecting an END location..................................................................................................... 22

2.1.11 Strip Carrier Loading and Positioning ................................................................................... 22

2.2 Calculation Programs...................................................................................................................... 23

2.2.1 Absorbance Mode .................................................................................................................... 23

2.2.2 Calibrator (Single Standard) Mode.......................................................................................... 23

2.2.3 Cutoff Mode............................................................................................................................. 24

2.2.4 Cutoff Control Mode (C/O Control)........................................................................................ 26

2.2.4 Regression Mode ..................................................................................................................... 28

2.2.6 Point-to-Point Mode................................................................................................................. 30

2.2.7 % Absorbance Multi-Point Mode ............................................................................................ 31

2.2.8 Uptake Mode............................................................................................................................ 32

2.3 User Test Menu............................................................................................................................... 32

2.3.1 Storing a Test ........................................................................................................................... 32

2.3.2 Deleting a Test ......................................................................................................................... 33

2.3.3 Recalling a Test........................................................................................................................ 33

2.4 Special Features .............................................................................................................................. 34

2.4.1 Clock and Calendar.................................................................................................................. 34

2.4.2 Lamp Saver .............................................................................................................................. 34

2.4.3 Flags and Error Messages ........................................................................................................ 34

2.4.4 Differential Absorbances ......................................................................................................... 35

2.4.5 Calibration and Linearity ......................................................................................................... 36

3.0 Additional Tips and Information ........................................................................................................ 37

3.1 Restoring Electronic Calibration..................................................................................................... 37

3.2 Operating Precautions..................................................................................................................... 37

3.3 Maintenance.................................................................................................................................... 38

3.4 Troubleshooting .............................................................................................................................. 39

3.5 References....................................................................................................................................... 41

4.0 Appendices.......................................................................................................................................... 43

4.1 Appendix 1: Dri-Dye®Check Strips.............................................................................................. 44

4.2 Appendix 2: Test Log ..................................................................................................................... 45

4.3 Appendix 3: Sample Printouts ........................................................................................................ 46

4.4 Appendix 4: Contact Information ................................................................................................... 48

Awareness Technology, Inc. Stat Fax 303 Plus Operator’s Manual Rev. J 1

1.0 INTRODUCTION

1.1 Applications

1.1.1 Intended Use

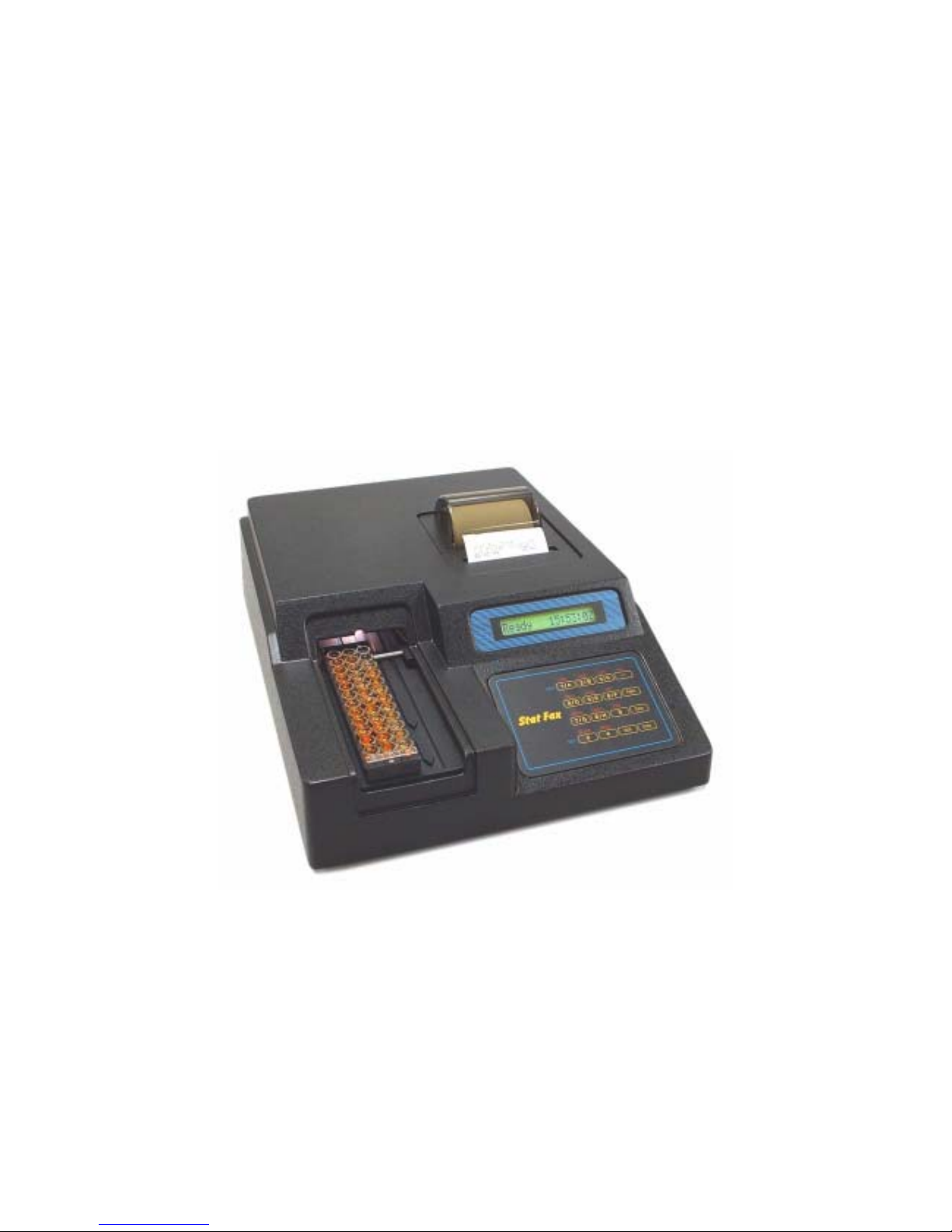

This microstrip reader is a laboratory instrument intended for in-vitro diagnostic use. It is a

compact, microprocessor-controlled, photometer system designed to read and calculate the

results of endpoint colorimetric assays, which are read in microtiter strips. This general purpose

instrument is intended to be used by trained laboratory professionals.

1.1.2 Summary of the Instrument

The instrument reads monochromatically or bichromatically, and has 3 models; a four filter model

(405, 450, 492, and 630 nm), a six-filter UV model (405,450,492,630,545, and 340nm), and a 6-

filter VIS model (405,450,492,630,600, and 545 nm). Substitute wavelengths in the range of 340

nm to 700 nm are also available on specially ordered models. It is designed to accept many

single column microstrips up to 12 wells in length, as well as break-apart wells, whether the wells

have flat- or round bottoms. An accessory carrier is available for use with dual column 2x8-well

strips and single-column 8 well strips. The user need only position the carrier to the desired row;

the instrument automatically positions the strips, reads absorbances, calculates concentrations,

and prints results. It comes with a built-in thermal graphics printer with the capability to plot

standard curves.

Besides providing absorbance readings, this instrument also offers pre-programmed modes for

performing the most commonly used calculations, multiple convenience features, and user

programmable memory to further facilitate testing.

Preprogrammed Modes

The reader is programmed with many keyboard-selectable general purpose programs. Each

mode is self-prompting, to reduce error and simplify operation. The general purpose programs

include absorbance, single point calibration, cutoff determination, multi-point linear and log-logit

regressions and point-to-point connections, multi-point % absorbance calculations, and an

uptake mode. Each mode is described in detail in section 2.2-Calculation Programs. These

calculation modes have been selected to facilitate the performance of enzyme immuno assays,

drug levels, and other similar tests.

Convenience Features

Multiple convenience features include automatic blanking options and the ability to indicate the

locations of positive and negative controls and to enter control acceptance criteria for automatic

comparisons, to select positive and negative interpretations based on concentration value, and

to edit out discrepant duplicates with automatic reread and recalculation. Instructions for each of

these modes and convenience features are provided in this manual.

2 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

User Programmable Memory

User-programmable memory allows the operator to store test protocols, recall tests by number,

and delete unwanted tests from a user-generated test menu. Instructions for using this memory

are given in section 2.3.3-Recalling a Test.

Besides quick, accurate, and reproducible results, the instrument offers maintenance-free and

easy operation, versatility, and economy. A stable factory-calibrated durable design, with a timed

lamp saving feature, further assures the reliability of this instrument.

1.2 Principles of Operation

Light energy from an overhead lamp is focused by a lens, directed through an aperture, and then

passed vertically through the sample. Below the sample, a continuously rotating wheel positions

the filters so that readings can be taken very quickly at both the primary and differential

wavelengths. Use of bichromatic differential absorbance values corrects for optical imperfections

in the plastic wells, differences in well meniscus, turbidity, and lamp variation. A photo detector

converts transmitted light energy into electrical signals, which are amplified and interpreted.

4 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

1.4 Safety Precautions

To assure operator safety and prolong the life of your instrument, carefully follow all instructions

outlined below.

Read Instructions

Review the following safety precautions to avoid injury and prevent damage to this instrument or

any products connected to it. To avoid potential hazards, use this instrument only as specified.

For best results, familiarize yourself with the instrument and its capabilities before attempting any

clinical diagnostic tests. Refer any questions to your instrument service provider.

Servicing

There are no user-serviceable parts inside the instrument. Refer servicing to qualified service

personnel. Use only factory authorized parts. Failure to do so may void the warranty.

Personal Protective Equipment

Many diagnostic assays utilize materials which are potentially biohazardous. Always wear

protective apparel and eye protection while using this instrument.

Follow Operating Instructions

Do not use the instrument in a manner not specified by the manual or the protection provided by

the instrument may be impaired.

Use Proper Power Cord

Use only the power cord specified for this product and certified for the country of use.

Ground the Product

This product is grounded through the grounding conductor of the power cord. To avoid electric

shock, the grounding conductor must be connected to earth ground. An alternate method is to

attach a ground strap from the external grounding terminal on the rear panel of the instrument to

a suitable ground such as to a grounded pipe or some metal surface to earth ground.

Observe All Terminal Ratings

To avoid fire or shock hazard, observe all ratings and markings on the instrument. Consult this

manual for further ratings information before making connections to the instrument.

Install as Directed

The Microstrip Reader should be installed on a sturdy, level surface capable of supporting the

instrument’s weight of 13 lbs (5.9 kg) safely for safety and ventilation purposes. The mounting

surface should be free of vibrations.

Provide Proper Ventilation

Refer to the installation instructions for details on installing the product so it has proper

ventilation. The instrument should be surrounded by the following clearances: 8 cm around

perimeter of unit and 8 cm on top.

Do Not Operate Without Covers

Do not operate this instrument with covers and panels removed.

6 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

1.5 Installation

1.5.1 General Installation

Unpack Instrument

Carefully unpack the instrument, removing it from its plastic bag. Report any damage to your

freight carrier at once. The box should also contain the Owner’s Manual and a serial cable.

NOTE: Retain the original packing material for future use in the event that the instrument is

shipped to another location or returned for service.

Instrument Mounting and Use

Place the instrument on a flat working surface capable of safely supporting the weight of the

instrument (approx. 21 lbs, 9.5 kg). Excessive vibration during reading may cause poor

repeatability; thus, a sturdy working surface is required. A clearance of at least 3 inches (8cm)

around the instrument is required to assure optimal ventilation. It is recommended that the

instrument be operated within an ambient temperature range of 18-35°C and humidity of less

than 80%.

Power Switch Position

When installing the power cord or if changing the setting on the voltage select switch the unit

should be turned off. Look at the rear panel of the instrument to check that the power switch is

in the Off position.

Power Cord Requirements

Use only the power cord specified for this product and certified for the country of use. For 110-

120 V units used inside the US use a UL listed cord set consisting of a minimum 18 AWG, Type

SVT or SJT three conductor cord, maximum 3 meters (10 feet) in length, rated 10 A, 125 V, with

a parallel blade, grounding type attachment plug.

For 220-240 V units used inside the US use a UL listed cord as above, except rated 250 V, with

a tandem blade, grounding type attachment plug. The cord set provided by the manufacturer

meets these requirements.

Safety Grounding

Do not alter or defeat the safety grounding methods provided. To avoid the risk of electric shock,

the third prong of the AC power plug must be connected to conductive parts internal to the

equipment. Internal fasteners to grounding points are marked by the IEC 417 symbol 5019

. DO NOT loosen or remove these fasteners or connections. An alternate method of

grounding is provided by connecting the grounding terminal located on the rear panel, to a

suitable ground.

To avoid electric shock, the power cord protection ground conductor must be connected to

ground.

Awareness Technology, Inc. Stat Fax 303 Plus Operator’s Manual Rev. J 7

Voltage Select Switch

Locate the voltage select switch on the rear panel. This is a 2-position slide switch that will

configure the instrument to accept either 230V or 115V input. Do not connect equipment to the

power supply before changing the line voltage selection switch.

Warning: To prevent permanent damage to the instrument, this switch must be set

for the appropriate input voltage before powering up.

When you can see the 230V label, the instrument is set for 230V input. If you plug the

instrument into an 115V power supply while 230V is selected, the instrument will have

insufficient operating power.

To select 115V input, insert a straight screwdriver blade (or similar instrument) into the slot on

the switch, and slide it into its alternate position. Upon sliding the switch, you will see the 115V

label appear.

Warning: If the instrument is configured to accept 115V and you plug it into a 230V

power supply, the fuses will blow and permanent damage to the electronics may result.

Assure Clean Power Availability

The circuit used should be substantially free of large voltage transients (Kilovolt amp loads) such

as large pumps, large centrifuges, refrigerators and freezers, air conditioners, large autoclaves,

ovens, and dryers. The instrument may fail to operate normally if the power supply is

interrupted. If this occurs, turn the instrument off for a moment. When you turn the instrument

back on, it will resume normal operation, but a standard curve which was not stored in

nonvolatile memory will be lost.

Fuse Requirements

The fuses are located internally in the instrument; there are two fuses, fusing both sides of the

main power supply. Fuse failure is a very rare occurrence and should indicate malfunction of the

equipment requiring service by qualified personnel.

The fuses used within this instrument are 1/2 Amp T rated (slow blow), 250 V. Cartridge size is

3AG or size “0”, dimensions 1/4 x 1-1/4” (6.3 x 32 mm). For continued protection against risk of

fire, use the same fuse for either 115 or 230 V line voltage selection. Disconnect power cord

from mains supply before replacing fuses.

1.5.2 Serial Port

The serial port on the back of the instrument echoes the data shown on the internal printer,

except for data printed in graphical mode (i.e., standard curve plots). You may use the serial

port with the strip reader to output to a PC, but this will require a cable and software not provided

with the reader. Contact your dealer for the appropriate cable. Remember that the microstrip

reader only sends data out. It does not accept any input from the external equipment.

The serial connector of the reader is located on the right side of the rear panel. Interface: “DB-

9P” is configured for data terminal equipment (“D” connector with 9 male pin contacts.) Pin 1 is

ground, Pin 2 is the transmit data output.

8 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

Data is transmitted at 2400 baud, with 1 start bit, 1 stop bit, 8 data bits in ASCII Code, and no

parity bit (RS-232 signal levels).

With both the reader and the receiving equipment turned off, plug in both ends of the cable.

Then turn the receiving equipment on. Finally, turn on the strip reader. It is important to have the

receiving equipment ready before starting up the strip reader so that data will not be lost.

1.5.3 Internal Printer

If there is no paper in the printer, install a new roll of paper as follows:

How to install a roll of paper:

Remove the paper cover by pinching its sides together and pulling up. Unroll about 10 inches

(25cm) of paper, and place the roll on the table behind the instrument. A ragged edge or

wrinkled paper will be difficult to load and could cause a paper jam. Feed a clean cut edge of the

paper from the back, into the printer, along the top edge of the metal guide inside the printer

paper well. Feed slightly more than 1 inch (3 cm) of paper in, then press the PAPER key several

times to automatically feed the paper through the printer. You will see the paper feed up through

the paper slot in front. If you have difficulty, cut a new straight edge before trying again. Drop the

roll of paper into the printer paper well in back, spooling up any loose paper. Replace the paper

cover by pinching its sides together and placing it down over the roll of paper. Use of the paper

cover is optional for holding the paper down into the printer paper well.

1.5.4 Check-out Procedure

After installation and each time you start up the instrument, perform the following instrument

checkout procedure. If any portion of the procedure does not check out properly, contact your

dealer to arrange for assistance.

Turn the power switch on. The printer should print the instrument name and “:X,” where X is the

software revision level. Then the time and date will print. If they are not correct, see section

2.4.1, Clock and Calendar, for setting time and date. Look for “Ready” and the correct time in the

display. Press the ABS key. Look into the strip track for light, indicating that the lamp is lit. See

“ABSORBANCE MODE” displayed and printed. The instrument will then display “SELECT

FILTER”. Select 405-630nm. Then see “Set Carrier” in the display. Now load the empty carrier

over the carrier bar and press the BLANK key and the ENTER key. The instrument will read air.

Check that the carrier moves in and back out of the instrument. Check that all 8 or 12 of the

readings are 0.000 ± 0.005A. Poor repeatability of the absorbance readings for air indicates

possible electronic problems.

Awareness Technology, Inc. Stat Fax 303 Plus Operator’s Manual Rev. J 9

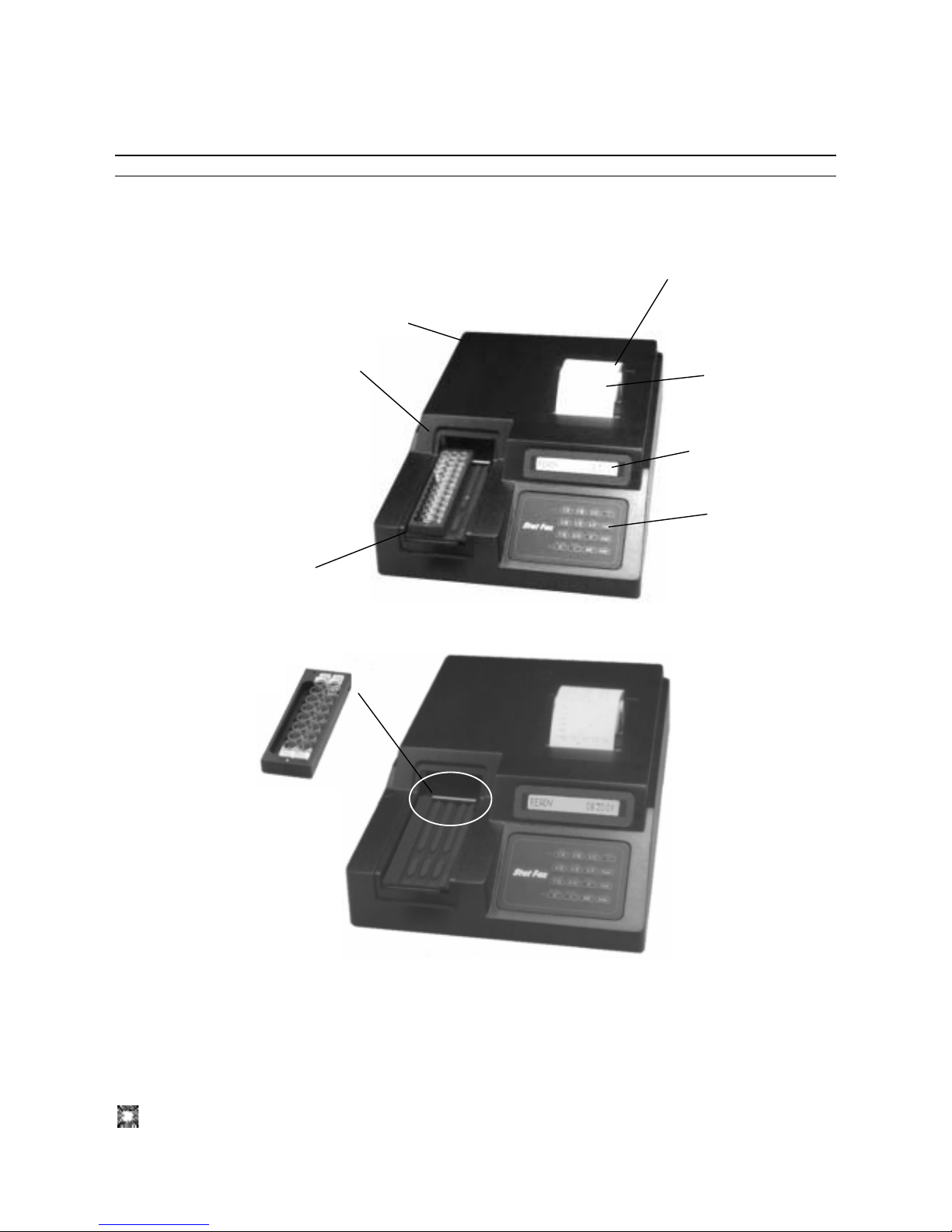

1.6 Major Parts and Controls

The following labeled sketches will help you to locate and identify the major parts of the

microstrip reader. More details on the operation of each feature are provided in section 2,

Operating Procedures. The voltage select switch is on the base. The power switch and serial

connector are on the rear panel.

Cover

Optical system

(under cover)

Printer paper well

(with paper roll cover)

Printer paper slot

Alpha-numeric display

Carrier track

(with carrier)

Keyboard

Place carrier groove

over bar

10 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

1.7 Keyboard Functions

T

h

e

B

L

A

N

K

The numeral keys serve several functions. As numbers, they are used to enter test parameters,

and to make filter selections. Any key serving multiple functions will respond to the displayed

request for information.

ABS, STND, CUT, MULT, %ABS, and UPT, are the keys used to select a mode of operation.

ABS stands for Absorbance Mode.

STND stands for Calibrator (Single Standard) Mode.

CUT stands for Cutoff Mode and offers two choices: Cutoff Control, and Cutoff mode with

Reverse Cutoff option.

MULT stands for Multi-Standard Mode and offers two choices: regression (including linear, log,

and log-logit), and point-to-point connection.

%ABS stands for Percent Absorbance Multi-Point Mode.

UPT stands for Uptake Mode.

Pressing the INTRP key causes the reader to ask for positive and negative cutoff points to be

used for automatic sample interpretation.

Pressing the CNTRL key causes the reader to ask for the locations and acceptance criteria of

high and low controls to be used for automatic labeling.

The ENTER key is used to tell the instrument when

you are finished entering information

The AUX ke

y

is used to turn the lam

p

on and off.

The CLEAR key is used to erase a typing error

when information is being entered by keyboard.

Pressin

g

twice

q

uits the mode.

The PAPER key advances the printer paper

f

o

rw

a

r

d

o

n

e

lin

e

eac

h

t

im

e

i

t

i

s

p

r

essed

.

The ALT key is used to enter a negative sign and

to access a list of alternate functions such as

saving and deleting tests, setting the clock, and

c

h

oos

in

g

8

o

r 12 w

e

ll

st

ri

ps

.

The MENU key is used to access tests stored in the It is

also used to enter a decimal point for numeric entries.

The BLAN

K

key allows automatic blank

on well A-1 in the ABS Mode.

Awareness Technology, Inc. Stat Fax 303 Plus Operator’s Manual Rev. J 11

The END key allows the user to select the total number of wells to read and print.

The key assignments for the filters are as follows:

For all models: key 1 is 405nm, key 2 is 450nm, key 3 is 492nm, key 4 is 630nm

6 filter UV: key 5 is 545nm, key 6 is 340nm

6 filter VIS: key 5 is 600nm, key 6 is 545nm

The 1 and 0 keys are also used to answer YES and NO questions.

12 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

1.8 Specifications

Photometric

Linear Measurement Range ......................0.00 to 3.0 Absorbance Units (A)

Photometric Accuracy ................................± (1% of the reading + 0.01 A) from 0 to 1.5A

................................................................... ± (2% of the reading + 0.01 A) from 1.5 to 3.0A

Stability ......................................................Drift of no more than 0.005A in 8 hours

Warm up Time ...........................................45 seconds, built-in

Light Source...............................................Tungsten Lamp

Standard Wavelengths...............................Standard: 405, 450, 492, 630nm

Six Filter UV: 405, 450, 492, 630, 545, and 340 nm

Six Filter VIS: 405, 450, 492, 630, 600, and 545 nm

Type of Filter ..............................................3-cavity hard coat interference filter, 10nm half band

pass typical

Vessel ........................................................Single, double, or break apart strips, up to 12 wells

long,

3 strip loading capacity

Electronic and Software

Speed ........................................................Reads, calculates and prints results for up to 12 wells

in about 30 seconds

Display .......................................................LCD, 16” characters, 5x7 dot matrix

Internal Printer ...........................................Thermal, dot matrix, 20 characters per line

Keyboard ...................................................16-key, membrane switch, 4X4

Calculation Modes .....................................Single point calibration, Multi-point calibration with

regression or point-to-point curve fit, cutoff, cutoff

control, % Absorbance Multi-Point, Uptake.

Serial Port ..................................................Output only, 2400 Baud, 1 start bit, 8 data, 1 stop, no

parity, no handshake

Power Source ............................................Switch selectable power supply (115V or 230V

indicated)

Voltage Source 110-120/220-240 VAC from 50 to 60

Hz, CAT II

Power consumption is less than 50 Watts

Fuse: two 1/2A, T rating, 250V, 3AG type fuse

All power cords must be approved for the country of

use

Certifications and Compliances .............NRTL Listed Standard UL -61010A-1, Electrical

Equipment for Laboratory Use.

CE Certificate of Conformity. Conforms to the

following standards: EN 61010-1, EN 61326, following

the provisions of the 98/79/EC IVD directive

Physical

Enclosure...................................................ABS Plastic cover with metal base

Dimensions .............................................Approx. 9”x 12” x 3”, (23 x 30 x 8 cm) 13 lbs (5.9 Kg)

Awareness Technology, Inc. Stat Fax 303 Plus Operator’s Manual Rev. J 13

Environmental Conditions for Safe Operation

Indoor use

Altitude up to 2000m

Temperature 5ºC to 40ºC (Although it may be safe to

operate in these conditions, it may not be suitable for

the performance of your tests; check with your

supplier.)

Humidity 80% for temperature up to 31ºC, decreasing

linearity to 50% humidity at 40ºC

Mains supply voltage fluctuations not to exceed ±

10% of nominal voltage

Recommended Environmental Conditions

Recommended Operating Temperature ....18-35ºC

Recommended Operating Humidity ...........Less than 80%

Optional Accessories

Available from your dealer .........................DRI-DYE Check Strips for instrument QC,

replacement lamps, fuses, thermal paper, serial cable

Design and instrument specifications are subject to change without notice.

14 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

Notes:

Awareness Technology, Inc. Stat Fax 303 Plus Operator’s Manual Rev. J 15

2.0 OPERATING PROCEDURES

When reading microstrips, the instrument must be programmed to calculate and to label wells

and results according to the operator’s specifications. For test procedures with many entries, it is

recommended that inexperienced operators prepare a list of their selections before beginning

operation.

Alternately, these tests can be stored in non-volatile memory to reduce set up requirements to a

single step for subsequent uses. When tests are recalled from the user menu, all of the general

selections will have been predetermined. Section 2.1 provides information about making general

selections such as mode, filter, blank, duplicates, cutoffs, and controls. Section 2.2 follows with

mode-specific instructions for each of the general purpose calculation programs. Section 2.3

explains how to create and use your own test menu (stored in nonvolatile memory). Finally,

Section 2.4 provides specific details on the operation of additional special features (i.e. clock and

calendar, lamp saver, etc.).

2.1 General Selections

Although many features are available to aid the user, this instrument may be operated very

simply in most modes by bypassing optional features.

For every test, the instrument will require a mode selection and filter choices. Thereafter, only

those questions that pertain to the calculation mode selected will be asked. In the absorbance

mode, for example, there are no further selections required.

Here is a list of questions to review before beginning a test:

1. What strip length will be used? (8 wells or 12 wells)

2. What strip type will be used? (e.g., break apart)

3. What calculating program will be used?

4. What filters are optimal? (operating and differential wavelengths)

5. Is a blank required? Desired?

6. What is the calibrator value(s)?

7. Will blanks, calibrators and/or specimens be read singly, or in duplicate?

8. Will locations of 1 or more controls be marked? If so, you will need to indicate row and strip

number for each.

9. Will control acceptance criteria be entered for automatic comparison? If so, what are the

limits?

10. Will a cutoff value be used to label any samples as positive? (If so, the value which begins

the positive range will be required.)

11. Will a cutoff value be used to indicate negative samples or define an equivocal zone? If so,

results less than what cutoff should be labeled as negative?

12. Will you be running partial strips? If so, you may want to assign an END location.

16 Stat Fax 303 Plus Operator’s Manual Rev. J Awareness Technology, Inc.

13. Will this test be stored? If so, you must remember to store it before you cancel the mode.

14. For modes using duplicate calibrators, the instrument will ask you if you accept the standard

curve before proceeding. What criteria will be used to determine “bad curves?” Then, you will

be asked which points you wish to delete. Again, some preestablished criteria for selecting

“bad points” and perhaps a maximum number of acceptable deletions might be needed.

NOTES:

1. For the purposes of this manual, the terms “standard(s)” and “calibrator(s)” are used

interchangeably to designate reference materials of known concentrations. The terms

“specimen(s)” and “sample(s)” are also used interchangeably to mean materials of unknown

concentrations.

2. Pressing the ENTER key will bypass many unwanted options.

To begin, turn the instrument on and perform the Check Out Procedure (Section 1.4.5). When it

is finished, the instrument will display “Set Carrier”. Press the CLEAR key twice to cancel the

Check Out. See “Ready” and the time in the display.

If you do not wish to perform the Check Out, turn the instrument on and see “Ready” and the

time in the display. The lamp will warm up for 45 seconds. During this time, you may begin

making your selections. If the lamp warm up is not completed by the time you press the ENTER

key to read the first strip, the display will indicate “LAMP WARM UP 00” where 00 represents

the number of seconds remaining. When the instrument is ready, a double beep will be heard,

and the instrument will begin reading.

GENERAL OPERATION TIPS:

• Wipe any dust or fingerprints from the bottoms of the strips before using.

• Do not read strips that contain bubbles or condensation.

• Use the same volume for the blank as you use for the samples.

2.1.1 Selecting a Strip Format

Microstrips are typically either 8 or 12 wells in length. Using the keyboard, this instrument can be

configured for reading and labeling either type of strip. When using the standard 12-well carrier,

you may still select either strip format.

First, press the ALT key. ALT stands for alternate functions. You can use this key to access

several functions, including changing the strip type. The first display is “SAVE TEST Y/N”.

Respond by pressing the NO key. Next you will see “STRIP TYPE Y/N”. This time, answer with

the YES key.

The display will ask “8 WELLS Y/N”. If you want to read 8 well strips, answer YES and see “8

Well Strips (A-H)” printed. If you want to read 12 well strips, press NO and see “12 Well Strips

1-12” printed. The display will return to “Ready”.

You may change between reading 8 well strips and 12 well strips via the ALT key whenever the

display indicates “Ready”.

If a test is stored in the test menu, the strip type will also be saved.

Table of contents

Popular Laboratory Equipment manuals by other brands

Faro

Faro SK07 Series instruction manual

Agilent Technologies

Agilent Technologies UHV-24 user manual

Fisher Scientific

Fisher Scientific Isotemp 20LFEEFSA Instruction and operation manual

ECD

ECD SmartDRY SD Series Setup and operation manual

IKA

IKA RW20 digital operating instructions

SDL Atlas

SDL Atlas QuickWash Plus instruction manual

Teledyne

Teledyne Platinum Pocket guide

Apera Instruments

Apera Instruments 201DJ-C user manual

Ihlas Ev Aletleri

Ihlas Ev Aletleri aura Cebilion iflow 101IFL user manual

TMC

TMC STACIS 2100 Installation & operation manual

Beckman Coulter

Beckman Coulter CytoFLEX Instructions for use

Bluescience

Bluescience Pro installation instructions