StatSpin ThermoBrite S500-12 User manual

T

T

Th

h

he

e

er

r

rm

m

mo

o

oB

B

Br

r

ri

i

it

t

te

e

e

Service Manual

Service Manual

ThermoBrite

Model Number S500-12/S500-24

FOR IN VITRO DIAGNOSTIC USE

StatSpin is a registered trademark of StatSpin Inc., a Subsidiary of IRIS International, Inc.

Copyright 2004

Printed in U.S.A.

i

Table of Contents

Table of Contents............................................................................................................ i

How to use this manual.....................................................................................iii

Section 1.............................................................................................................1

Safety................................................................................................................................. 1

Before you Begin...................................................................................................... 1

Install System............................................................................................................ 1

Connect Power ......................................................................................................... 1

Section 2.............................................................................................................2

System Overview ........................................................................................................... 2

Principle and Intended Use .................................................................................... 2

Symbols and Definitions.......................................................................................... 2

Symbols and Definitions (cont.) ............................................................................. 3

Display Abbreviations .............................................................................................. 3

Audible Indicators - NORMAL ................................................................................ 3

Audible Indicators - ERROR................................................................................... 3

Error Messages ........................................................................................................ 4

Section 3.............................................................................................................5

Operating Instructions.................................................................................................. 5

Opening and Closing the Lid .................................................................................. 5

Turning Unit On ........................................................................................................ 5

Run a Denaturation and Hybridization Program ................................................. 5

Abort Program in Process....................................................................................... 7

Slide Installation ....................................................................................................... 7

Humidity Control Cards ........................................................................................... 7

Predefined Limits...................................................................................................... 7

Section 4.............................................................................................................8

Specifications ................................................................................................................. 8

Table........................................................................................................................... 8

Section 5.............................................................................................................9

Theory of Operation ...................................................................................................... 9

Overview.................................................................................................................... 9

Data Acquisition........................................................................................................ 9

Calibration ................................................................................................................. 9

PID............................................................................................................................ 10

Section 6...........................................................................................................11

Alignment....................................................................................................................... 11

Materials .................................................................................................................. 11

Workstation Setup.................................................................................................. 11

Procedure ................................................................................................................ 11

Calibration ............................................................................................................... 12

Testing ..................................................................................................................... 13

Section 7...........................................................................................................15

Programming................................................................................................................. 15

ii

Overview.................................................................................................................. 15

Character Selection ............................................................................................... 15

Creating a Denaturation and Hybridization Program (Denat & Hyb) ............. 15

Section 8...........................................................................................................16

Schematic....................................................................................................................... 16

Block Diagram ........................................................................................................ 16

Main PCB................................................................................................................. 17

Main PCB................................................................................................................. 18

Section 9...........................................................................................................19

Disassembly .................................................................................................................. 19

Heater Assembly .................................................................................................... 19

Housing Assembly ................................................................................................. 20

Section 10 .........................................................................................................21

Troubleshooting........................................................................................................... 21

Section 11 .........................................................................................................22

Exploded View .............................................................................................................. 22

ThermoBrite............................................................................................................. 22

Part Numbers.......................................................................................................... 23

iii

How to use this manual

This manual along with information contained on product labels should provide you with all the

information you need to operate and maintain the ThermoBrite.

Notes appear in italics to highlight information. When the information requires special attention, a

caution symbol appears next to the italicized text.

Please pay close attention to the instructions that accompany the notes and symbols as well as the

standard laboratory practices outlined by your facility and local regulatory agencies. The table below

lists all the CAUTIONS / WARNINGS for the ThermoBrite.

WARNING – Plug the instrument into a properly grounded outlet supplying the

voltage and frequency indicated on the serial number label.

CAUTION – Unplug the ThermoBrite from the wall outlet before performing

maintenance.

WARNING – Do not expose ThermoBrite to strong or concentrated acids, bases,

esters, aromatic or halogenated hydrocarbons, ketones or strong oxidizing agents.

CAUTION - Universal Precautions should be followed on all specimens, regardless

of whether a specimen is known to contain an infectious agent. (See references)

CAUTION –Risk of electric shock: The instrument contains no user serviceable

parts. Removal of housing will expose potentially lethal voltage. Refer service to

qualified service personnel.

CAUTION – Hot Surface: The interior surface of the instrument may be HOT, use

caution to avoid potential burn.

Please use the system as intended. Improper use of the ThermoBrite may cause damage to the

system, inaccurate results, or potentially void warranties.

1

Section 1

Safety

Before you Begin

READ ALL PRODUCT MANUALS AND CONSULT WITH TRAINED PERSONNEL BEFORE

ATTEMPTING TO OPERATE OR SERVICE THIS INSTRUMENT.

HAZARDS AND OPERATIONAL PRECAUTIONS AND LIMITATIONS

WARNINGS, CAUTIONS and IMPORTATANT alert you as follows:

WARNING - Might cause injury.

CAUTION - Might cause damage to the instrument.

IMPORTANT - Might cause misleading results

CAUTION: System integrity might be compromised and operational failures might occur if:

This equipment is used in a manner other than specified. Operate the instrument as

instructed in the Product Manuals.

You introduce software that is not authorized by StatSpin into the instrument. Only operate

your system with software authorized by StatSpin.

You install software that is not an original copyrighted version. Only use software that is an

original copyrighted version to prevent virus contamination.

IMPORTANT: StatSpin urges its customers to comply with all national health and safety standards

such as the use of barrier protection. This may include, but it is not limited to protective eyewear,

gloves and suitable laboratory attire when operating or maintaining this or any other automated

laboratory analyzer.

Install System

1. Place the ThermoBrite on a level surface suitable for laboratory instrumentation.

2. ThermoBrite has an intake fan located on bottom, assure no obstruction exist on intake.

3. Ensure the ThermoBrite is placed at least 12” (0.3048m) from the wall to allow for proper

cooling.

4. Position the ThermoBrite away from direct sunlight and sources of heat or cold.

5. Verify voltage requirements located on serial number label on the rear of instrument.

Connect Power

Plug the instrument into a grounded outlet supplying the voltage and frequency indicated on the

serial number label.

Main power switch is located on the rear of the instrument, next to the line cord power entry

module.

2

Section 2

System Overview

Principle and Intended Use

For in vitro diagnostic use for denaturation/hybridization for slide-based FISH procedures.

The ThermoBrite is a microprocessor controlled small bench top hot plate with lid. The ThermoBrite

allows storage of 40 programs, three operating modes, fixed temperature, Hybridization only or

Denaturing and Hybridization. Capacity for twelve slides and a maximum temperature of 99°C. The

instrument is UL / CUL listed and CE marked.

Symbols and Definitions

Up Move cursor up; Enter character A-Z for program

name

Down Move cursor down; Enter character A-Z for

program name

Enter Accept or Enter

Backspace Move cursor back or previous screen

Stop End a program in process

0-9 Enter numeric values for time and temperature or

for program name

REF Product/Reference

Number

Indicates the StatSpin product/catalog number

Caution Statement of caution/warning, read instruction

carefully

Temperature

limitation

Indicates storage requirements range

EC Representative European Community Authorized Representative

IVD

For in vitro

diagnostic use

Clarifies for use as in vitro diagnostic use only

Non-sterile Indicates non-sterile product

S N Serial Number Indicates instrument serial number code

Consult

Instructions

Consult instruction manual for further explanation

IVD

8

3

Symbols and Definitions (cont.)

Manufactured By Indicates Manufacturer of the Device

Electric Shock Indicates a potential risk of electrical shock

Biohazard Universal Precautions should be followed at all times

Hot Surface Use caution to avoid burn

Display Abbreviations

Display Abbreviations

PGM Program

Denat & Hyb Denaturation & Hybridization

Denat Temp Denaturation Temperature

Denat Time Denaturation Time

Hyb Temp Hybridization Temperature

Hyb Time Hybridization Time

Hyb Only Hybridization Only

Fixed Temp/Fxd Fixed Temperature

Audible Indicators - NORMAL

Single beep: All legal keystrokes.

Two quick beeps: Upon accepting a field and cursor has moved to next field.

Five beeps: Completion of process.

Audible Indicators – ERROR

Three short beeps: Entering of illegal or non-functioning keystrokes.

Low tone beep: Attempt to enter a value out of acceptable range.

Continuous beep: Instrument is not performing within acceptable range or program

condition. Turn off main power and restart. If beep continues,

discontinue use and contact service.

4

Error Messages

Instrument cannot achieve a set temperature by heating within 10 minutes an error message appears to inform user to

turn unit off and call service. A constant beep will sound.

If the instrument cannot measure the temperature, the software will automatically turn off the heating. An error message

will appear to inform the user to turn off the unit and call service. A constant beep will sound.

Instrument cannot achieve a set temperature by heating within 10 minutes an error message appears to inform user to

turn unit off and call service. A constant beep will sound.

High ambient temperature condition:

The instrument will attempt to achieve process set temperatures. However, if the cooling fan cannot achieve the

set temperature within 10 minutes, an error message will appear to inform the user that the ambient temperature is

high. A constant beep will sound. The counter will continue to count. The present temperature will be displayed.

Hitting the “Stop” button will allow the user to abort the process. A new screen will be displayed asking user if they

are sure they want to abort.

Please Wait

Cooling to XXX --°C

Present Temp: --°C

If the ambient temperature changes during a process and causes the instrument process set temperature to change

beyond the +/- 1°Cspecification for more than 2 minutes, a message will appear to inform the user that the

ambient temperature is high. A constant beep will sound. The counter will continue to count. The present

temperature will be displayed. Hitting the “Stop” button will allow user to abort the process. A new screen will be

displayed asking user if they are sure they want to abort.

If the ambient temperature changes after a process is completed, but before the user removes the slides and

causes the instrument process set temperature to change beyond the +/- 1°Cspecification for more than 2

minutes a message will appear to inform the user that the ambient temperature is high. A constant beep will sound.

The counter will continue to count. The present temperature will be displayed. Hitting the “Stop” button will allow

user to abort the process. A new screen will be displayed asking user if they are sure they want to abort.

Note: If 40 programs have been created or edited the software will blank out the “Create” mode on the main menu

screen. This will only allow users to edit existing programs.

SYSTEM ERROR!

TURN UNIT OFF!

CALL SERVICE

Please Wait

Cooling to XXX --°C

Ambient Temp High!

PGM -- namexxxxxx

“Ambient Temp High!”

Hyb --°C --:--

Present Temp: --°C

PGM -- namexxxxxx

“Ambient Temp High!”

Reset Timer 00:00:00

End PGM/Main Menu

PGM -- namexxxxxx

“Ambient Temp High!”

Total Hyb Time --:--

End PGM/Main Menu

Run a PGM

Edit a PGM

Present Temp: --°C

5

Section 3

Operating Instructions

Opening and Closing the Lid

The platen may be hot. Use caution and check temperature on display before handling slides. Improper

precaution can cause a burn.

Depressions located on either side of the lid allow user to simply lift lid into position. The lid should offer

some resistance when opening. To close, reverse process. Assure front is completely down and no

obstructions prevent gasket seal from sealing on housing base.

Turning Unit On

The ThermoBrite main power switch is located on the rear panel. Assure unit is plugged into a grounded

outlet. Move switch to on position. Instrument will beep to announce power has been turned on, fan will

start and the Main Menu will come up onto the display.

I = ON O=OFF

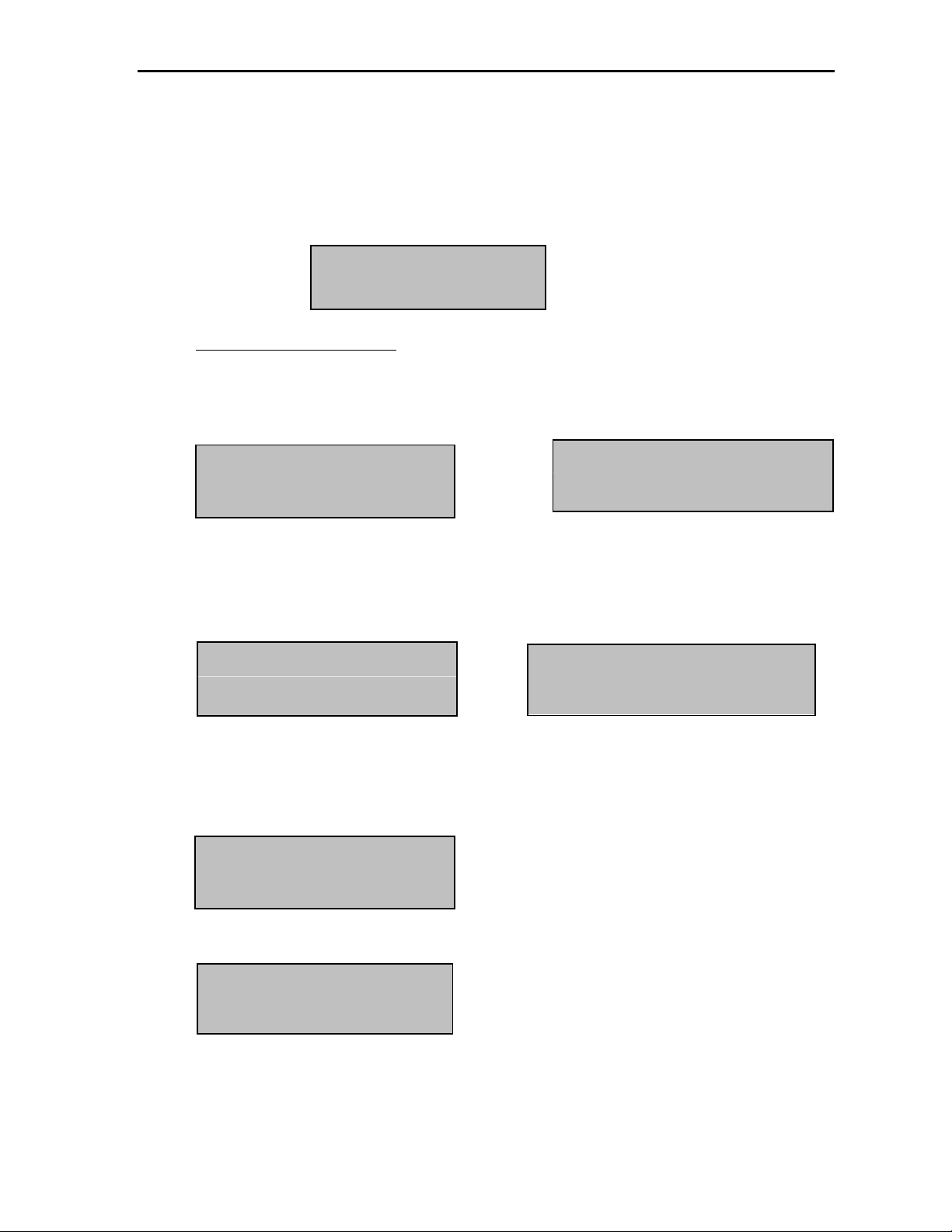

Run a Denaturation and Hybridization Program

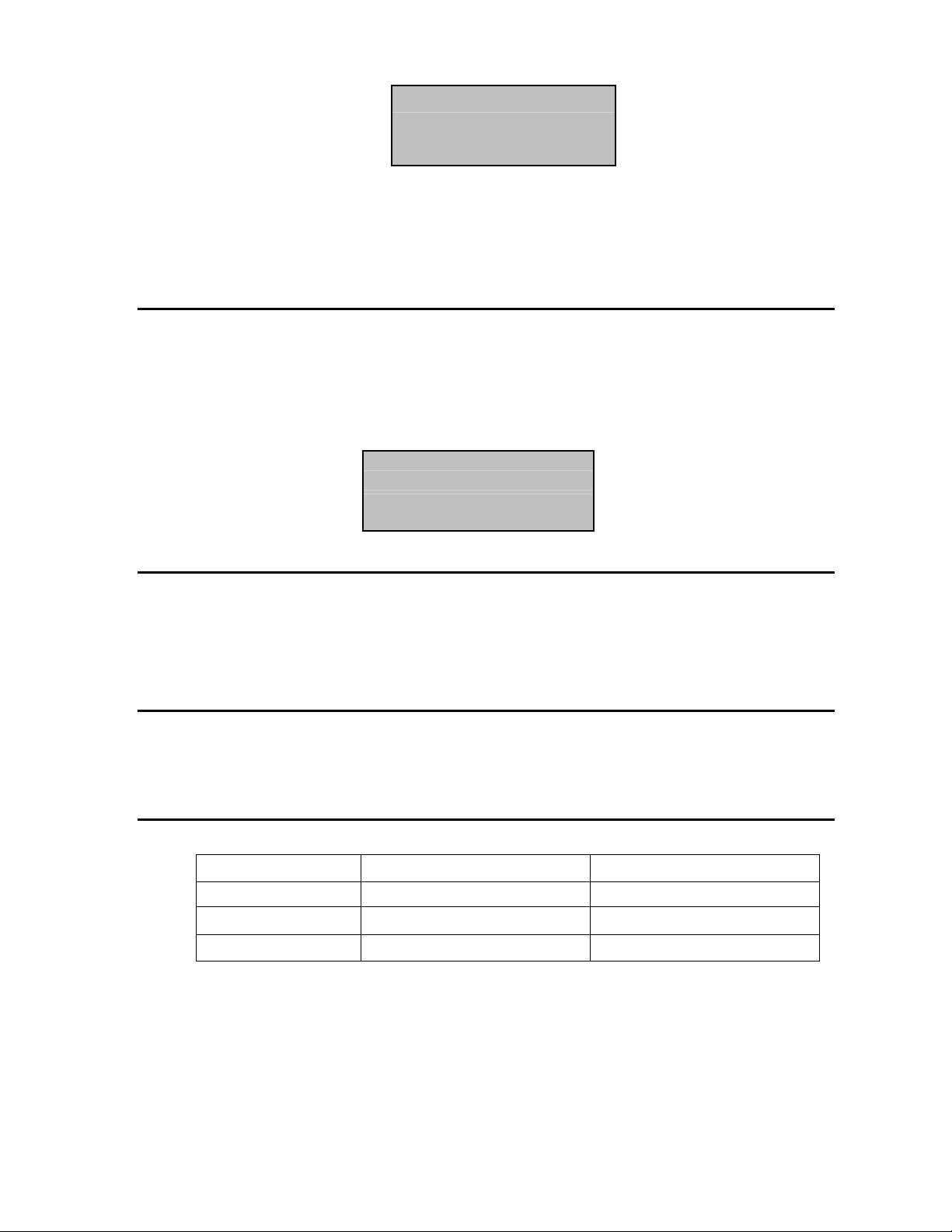

Turn unit on and wait for the Main Menu screen. Cursor highlights “Run a PGM” line.

Press “Enter” button to accept.

With the arrow keys scroll through program numbers 1 to 40 / program names. If no programs have been

saved advance to programming section of this handbook. To accept, press “Enter” button.

Display will confirm PGM number/name and Denat & Hyb times and temperatures. Cursor highlights “Run

PGM” line. Press “Enter” button to accept.

Hyb Only Denat & Hyb Fxd Temp

PGM 01 Her2

82°C :05; 45°C 16:00

Run PGM

Main Menu

The display prompts to “Add Slides and Close Lid”. Before adding slides, insert two Humidity Cards into the

inside lid. After card insertion saturate with distilled water or equivalent (see Humidity Control Cards).

Cursor highlights “Start” line. Press “Enter” button to run the program.

(To return to the Main Menu, move the cursor to highlight “Main Menu” line and press “Enter” button).

Run a PGM

Edit a PGM

Create a PGM

Present Temp: 37°C

PGM 02 EBV

Hyb: 55°C 01:30

Run PGM

Main Menu

PGM 03 Appl

Fixed: 65°C

Run PGM

Main Menu

PGM 03 Appl

Add Slides - Close Lid

Start

Main Menu

PGM 02 EBV

Add Slides - Close Lid

Start

Main Menu

PGM 01 Her2

Add Slides - Close Lid

Start

Main Menu

6

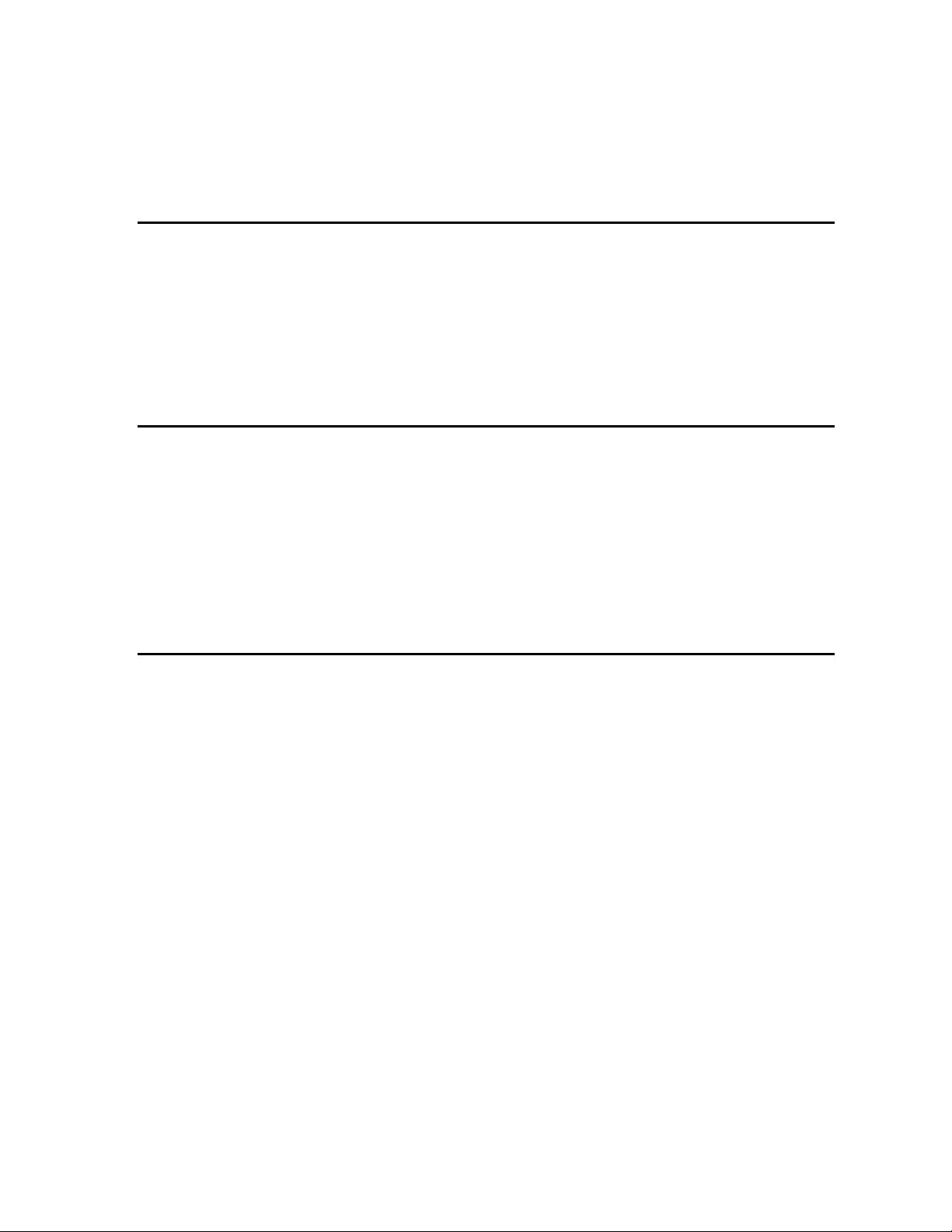

Denaturation and Hybridization:

Display indicates present temperature of the slides. Once temperature reaches denaturation set point, ThermoBrite will beep

twice and denaturation time will count down from the set time.

PGM 01 Her2

Denat in Process

Denat: 82°C 02:28

Present Temp: 82°C

The ThermoBritewill automatically cool to hybridization set temperature once denaturation is completed.

Please Wait

Cooling to Hyb 45°C

Present Temp: 58°C

Hybridization time will count down from the set time once temperature reaches hybridization set point.

Upon program completion ThermoBrite will beep five times and the display will show “PROCESS COMPLETE”. Hybridization

temperature will be maintained until “End PGM/Main Menu” is accepted by pressing “Enter” button. Before pressing

“Enter” button, remove slides for further processing. If “End PGM/Main Menu” is not accepted within the first minute of

program completion, hybridization time will start counting the total time at hybridization temperature.

PGM 01 Her2

PROCESS COMPLETE

Total Hyb Time 21:05

End PGM/Main Menu

Hybridization Only:

Upon program completion ThermoBrite will beep five times and the display will show “PROCESS COMPLETE”.

Hybridization temperature will be maintained until “End PGM/Main Menu” is accepted by pressing “Enter” button. Before

pressing “Enter” button, remove slides for further processing. If “End PGM/Main Menu” is not accepted within the first

minute of program completion, hybridization time will start counting the total time at hybridization temperature.

Fixed Temperature:

Display indicates present temperature of slides.

Please Wait

Heating to Fxd: 65°C

Present Temp: 30°C

Turn unit on and wait for the Main Menu screen. Cursor highlights “Run a PGM” line.

Timer counts elapsed time. (Pressing “Enter” button will reset timer to zero).

PGM 02 EBV

PROCESS COMPLETE

Total Hyb Time 02:15

End PGM/Main Menu

7

PGM 03 Appl

Fixed Temp: 65°C

Reset Timer 01:18:10

End PGM/Main Menu

Use Arrow keys to move to “End PGM/Main Menu” line and press “Enter” button to accept.

Note: If ambient temperature is programmed the fan will continually cycle until the program is

aborted.

Note: The temperature can be increased or decreased as the unit is running by using the up/down

arrows from the “Fixed Temp” line.

Abort Program in Process

To end a program in process press “STOP” button, three beeps will sound. Use arrows to move cursor to

“Yes” line and press “Enter” button to accept. (Program will continue to run until “Yes” or “No” has been

accepted)

Note: The ThermoBrite prompts, “Are You Sure?” This measure is to prevent accidental disruption of a

program in process.

ABORTING!!

Are You Sure?

No

Yes - Main Menu

Fan will turn on. If the slide temperature is above 37ºC, the fan will cool to 37ºC.

Slide Installation

When prompted simply lift lid and load slides onto plate. Frosted edge of the slide should hang over

edge. Move slide toward middle of plate butting edge into marked positions in slide locator.

Be sure slides rest into slide locator before closing lid. For optimum temperature uniformity, use

blank slides to fill all unused spaces before closing lid. This will allow maximum performance of the

ThermoBrite.

Humidity Control Cards

To replace cards, lift lid and remove. Slide card into slot positions, allow tabs in lid to support cards.

Do Not use paper towels or any other filter card in card positions, this may change the humidity and may

decrease the intensity of the probe, causing potential false negative results.

Predefined Limits

Program Mode Temperature Range Timer Limits

Denature 50ºC to 99ºC 0-30 minutes

Hybridization Room temp: 30ºC to 70ºC 0-99 hours

Fixed Temp Room temp: 30ºC to 99ºC 0-99 hours

8

Section 4

Specifications

Table

Product No. TS01 TS02

Model No. S500-12 S500-24

Capacity Up to 12 slides

Processing Time 0-100 hours

Number of Programs 40

Ramp Time 37 – 95ºC in less than 3 minutes

Cooling Time 95 - 45ºC in less than 6 minutes

Electrical 120 VAC @ 3.0 A 240 VAC @ 1.6A

Dimensions Depth 45.1 cm

Width 22.8 cm

Height 14.6 cm

Weight 8.5 kg

Environmental Indoor use

Altitude up to 2000m

Temperature 15ºC to 40ºC

Maximum relative humidity 80% for temperatures up to 15ºC decreasing

linearly to 50% relative humidity at 40ºC

Main supply voltage fluctuations not to exceed +/- 10% of the nominal

voltage

Transient over-voltages according to installation category II

Pollution degree 2

Specifications are subject to change without notice and at any time.

9

Section 5

Theory of Operation

Overview

The ThermoBrite is a programmable device that is used to control a plate upon which samples are placed to

precision temperatures. The device is required to move quickly between various set temperatures with little or no

overshoot and then remain at the set temperature within +-1 degree for any desired time. Heat is added to the

system by means of a resistive heating pad bonded to the plate and removed by controlling ambient air flow

through the device and under the plate. Plate temperatures are measured via an RTD embedded between the

heating pad and plate. The RTD is connected to analog circuitry which signal conditions the RTD resistance to

provide a voltage between 0 and 5 volts to a 12 bit analog to digital converter (ADC). The input voltages are scaled

for RTD temperatures of between 15 and 105 degrees C. A microprocessor based system acquires temperature

data via this ADC, conditions it with calibration data and uses the result to run a proportional, integral, derivative

(PID) control algorithm to meet temperature requirements. The rest of this document will describe the temperature

data acquisition, calibration data signal conditioning, and PID control processes in detail.

Data Acquisition

The system microprocessor, using an integrated timer starts and reads conversions from the 12 bit ADC every 2

mSecs. To provide some noise immunity the ADC interrupt handler sums 8 consecutive readings in an

accumulator. After the 8th reading the accumulator value is loaded into a globally accessible 16 bit integer for use

by other routines. This accumulator is also written to a 16 value array. The newest entry in the array minus the

oldest is also provided in a globally accessible 16 bit integer. This provides temperature rate information to other

routines (i.e. the change in ADC value over 256 mSecs), When the PID algorithm runs (see below) this raw ADC

data is converted to temperature and rate of change of temperature data via calibration data (see below)..

Calibration

An RTD changes in resistance with changing temperature with a roughly linear characteristic. This response is not

perfectly linear however and so to reduce temperature measurement errors and to account for initial tolerances in

the analog signal conditioning circuitry and the RTD itself, a calibration routine is provided. The calibration provides

for measured temperatures to be matched with ADC readings at 5 points along the temperature range of interest.

By having known temperatures at fixed points on the ADC curve the measured temperature can be calculated with

a linear interpolation between these points. This allows the RTD characteristic to be broken up into 4 shorter

segments so that the RTD transfer function can be modeled with a linear approximation over that short span without

introducing significant error. The calibration is done via the microprocessor serial port. The device is instructed to

control the temperature to various points along the usable range from low to high(i.e. 25, 35 ,55 ,75, and 95 C).

When the temperature stabilizes at each point the value of the actual temperature (as measured by an accurate

independent device) is input and the microprocessor also records the ADC reading and saves both values. After

completing all 5 points the microprocessor calculates the gain between points in degrees C/ADC count (i.e. gain[n-

1] = (Temp[n]-Temp[n-1])/(ADC[n]-ADC[n-1])). In normal operation the microprocessor uses this calibration data in

the following manner: For any given ADC value the microprocessor searches the list of calibration data to find the

point that has ADC value less than or equal to the measured value and for which the next higher point has ADC

value greater than the measured value. We will call these points m and m+1 where m is 0 to 3. The temperature is

then calculated as Temperature = ( Temp[m] + gain[m]*(ADC-ADC[m]) ). If the ADC value is lower than the lowest

cal point then the data from cal point 0 is used. If the ADC value is above the highest cal point (4) then the gain

between points 3 and 4 is used. The temperature rate information is calculated from the ADC rate information by

just multiplying by the gain currently used.

10

PID

The system uses a PID algorithm to get quick and precise control of temperatures over the usable range of the instrument. If

we define a temperature error (E) as the difference between the temperature setpoint and the measured temperature, a

standard PID control would involve the following equation:

Control = Pg*E + Ig*∫E *dt+Rg*dT/dt

Where: Pg is a constant (proportional gain)

Ig is a constant (integral gain)

∫E *dt is the integral of the error term E

Rg is a constant (rate gain) (typically negative)

dT/dt is the temperature rate of change in deg C/sec

Control is an analog value describing the amount of heat to put into or take out (if

negative) from the system

Since this device only has a microprocessor and not a Cray we approximate some of these values. As described above the

temperature rate of change is approximated by storing a rotating buffer of ADC values so that the change of ADC over

periods of 256 mSecs can be calculated. The integral value is approximated by summing the error, E, at a constant time

interval to an accumulator (i.e ΣE). . Additionally since we do not have an analog control that can adjust a continuous supply

of heat into the system we approximate that by converting the control output to a duty cycle of a control period. So for

example, as the temperature approaches the set temperature and the control value becomes small, the heat is applied for a

brief fraction of the control period. When the temperature is away from the set temperature the heat is applied for most or all

of the control period. Naturally the amount of heat that can be applied over a control period is capped at whatever the heating

element can provide full on. A negative output out of the PID means that cooling is required and this controls the fan in a

similar manner as the heater. The nominal cycle time for the heater is 500 mSecs and 1000 mSec for the fan. The PID

output gives a fraction of these values and as described above is capped at 100%.

The purpose of the terms in the PID is straightforward. The proportional term gives an output that tries to drive the control to

reduce the temperature error. So, for instance, as long as the temperature is below the set temperature, the proportional term

will ask for heat according to:

Control = Pg*E

Of course the problem with this is that if you reach the set temperature, the error E is 0 and the Control would no longer be

asking for heat. If there is any heat flow out of the system (to ambient surroundings) as there most certainly is, then the

proportional term is incapable of maintaining a zero error and will be stable at some value of E were heat into the system

matches that lost to the outside. Introduction of the integral term is thus required. Now as long as a nonzero error E exists,

the integrator value continues to grow, which causes the Control value to increase until enough heat is supplied to the system

to drive the temperature to the set temperature. If the temperature matches the set temperature the integrator ceases to

change since E is now zero. Thus the integrator can hold a value that keeps the Control supplying heat to match loses to the

surroundings:

Control = Pg*E + Pi*ΣE or when E=0 Control = Pi*ΣE

Unfortunately this configuration is inherently unstable. When the temperature is below the set temperature, the integrator will

grow of course in a direction to drive the temperature up. The integrator will always grow to a value that is greater than that

needed to stay at the set temperature. The only way that the integrator can reduce in value is for the temperature to cross

above the set temperature so that E becomes negative. In order that the temperature can be driven back down to the set

temperature the integrator will need to reduce to a value less than that required to hold the temperature constant and so the

temperature will drive cooler than the set temperature until the integrator can grow again. The result then is a temperature

that oscillates around the set temperature.

To eliminate this instability the rate term is added. As stated above, the rate gain constant is negative so that the effect of the

term is to produce a Control value that resists rate of change of temperature. So for example an increasing temperature

produces a negative rate term which tends to reduce the size of the positive Control value. This term then by resisting

changes in temperature reduces the amount of energy that is added to or removed from the system when the temperature is

below or above the set temperature (with the integrator changing accordingly) and the integrator cannot maintain a stable

oscillation around the set temperature. Now the stable condition (if the control constants are properly selected and the

system properties allow stability) is a steady temperature at the set temperature where E=0, the integrator holds the value

necessary to supply the amount of heat via the Control to match heat loss to the surroundings and since the temperature is

unchanging, has no rate term contribution.

11

Section 6

Alignment

Materials

IBM compatible computer w/min P3 1Ghz, 9pin serial port and Hyper Terminal software installed.

Standard 9-pin male to 9-pin female serial printer cable.

Hi-Pot tester, equipment

Cole-Parmer thermometer

RS232 adapter, equipment

Data Logger, equipment

Six Temperature Probes

Workstation Setup

Boot-up the workstation and go to Start/Programs/Accessories/Communication and select “Hyper Terminal”.

Perform the following in the Hyper Terminals’ main screen:

Select File/Properties and configure the port settings to:

9600 Bits per second

Data Bits is set to (8)

Parity is set to none

Stop Bits is set to (1)

Flow Control is none.

Procedure

Setting up the ThermoBrite to workstation

Note: If any of the following tests fail to perform correctly then test or tests will be repeated.

Unplug unit from outlet and turn on its side to expose bottom surface.

Locate and remove access panel.

Attach the RS-232’s adapter cable to J3 of the unit being tested.

Attach one end of the serial cable to the RS-232 adapter and the other end to the serial port on the

workstation.

Turn on the ThermoBrite unit and the message “Hello World” should appear on the computer screen.

Select “H” to access the help screen.

Note: This screen will provide a list of options.

Select “S” for sign on and choose either Dako for Hybridizer or StatSpin for ThermoBrite.

Select “L” to cycle through the languages and select the “English” version.

Press the “Esc” key.

Select “9” for the PID. Confirm the following items in Setup:

1) Prop gain: 30.0

2) Rate gain: 120.0

3) Int gain: 0.04

4) Heating int deadband: 2.0

5) Cooling int deadband: 4.0

12

6) Heating rate deadband: 15.0

7) Cooling rate deadband: 1.0

8) Intergrator max value: 1000.0

9) Heating cycle time 500 ms

A) Cooling cycle time 1000 ms

B) Duty cycle deadband 0.30

X) Ambient cycle time 2000 ms

Y) Ambient duty fraction 0.05

Z) Use offset: Yes

C) Setpoint: XX.X C

D) Defaults

S) Save new coefficients to NVRAM

Q) Quit

Select “Z” and turn off the Offset.

Select “S” to save to NVRAM.

Select “Q” to quit.

Select “P” for Program.

Select “E” to erase all programs.

Select “Y”.

Calibration

Power up Data Logger or Thermometer and insert one Temp probe w/slide into position 5 or 6 on the

ThermoBrite unit.

Close the cover and apply a ten-pound weight to the cover.

Note: The ten-pound weight is used to keep the glass slide with the temp probe attached, flat

against the heating plate.

Select “C” for Calibrate.

Read the temperature value on the Data Logger and input this value. Press the “Enter” key.

Select as Cal pt 0 (Calibration Point Zero).

Select “C” for Calibrate.

Enter 30.0°C and press the “Enter” key for a new set point.

Note: The unit will now start to heat up to 30.0°C. You should see the temperature

measurement from the unit “RTD” and Data Logger start to rise.

Once the RTD temp and Data Logger temperatures are stable, enter the data Logger temp into the computer

and select Cal pt 1.

Select “C” for Calibrate and enter 35.0°C. Press the “Enter” key for a new set point. Once the RTD and Data

Logger temperatures are stable, enter the Data logger’s value into the computer and select Cal pt 1.

Note: The value for the Data Logger should be exactly 35.0°C. If not then repeat this step.

Select “C” for Calibrate and enter 50.0°C. Press the “Enter” key for a new set point. Once the RTD and Data

Logger temperatures are stable, enter the Data logger’s value into the computer and select Cal pt 2.

Select “C” for Calibrate and enter 55.0°C. Press the “Enter” key for a new set point. Once the RTD and Data

Logger temperatures are stable, enter the Data logger’s value into the computer and select Cal pt 2.

Note: The value for the Data Logger should be exactly 55.0°C. If not then repeat this step.

Select “C” for Calibrate and enter 70.0°C. Press the “Enter” key for a new set point. Once the RTD and Data

Logger temperatures are stable, enter the Data logger’s value into the computer and select Cal pt 3.

Select “C” for Calibrate and enter 75.0°C. Press the “Enter” key for a new set point. Once the RTD and Data

Logger temperatures are stable, enter the Data logger’s value into the computer and select Cal pt 3.

Note: The value for the Data Logger should be exactly 75.0°C. If not then repeat this step.

13

Select “C” for Calibrate and enter 90.0°C. Press the “Enter” key for a new set point. Once the RTD and Data

Logger temperatures are stable, enter the Data logger’s value into the computer and select Cal pt 4.

Select “C” for Calibrate and enter 95.0°C. Press the “Enter” key for a new set point once the RTD and Data

Logger temperatures are stable, enter the Data logger’s value into the computer and select Cal pt 4.

Note: The value for the Data Logger should be exactly 95.0°C. If not then repeat this step.

Select “S” for Save. The alignment is complete.

Select “H” for the Help menu.

Select “9” for PID.

Select “Z” and turn on the Offset.

Select “S” to save to NVRAM.

Select “Q” to Quit.

Testing

Start a ThermoBrite test record by recording the Start Date, Serial #, and Instrument voltage.

Install the 6 temp probes w/slides onto the heater plate as per the layout on the ThermoBrite test record.

Close the cover and apply a ten-pound weight to the top of the cover.

Turn on the Data Logger.

Insure that the proper line cord is used (120v or 240v) and record the results on the test record.

Note: The voltage will be listed on the device serial number label.

Turn on the ThermoBrite unit.

The Name “DakoCytomation” (Hybridizer) or “StatSpin Inc.” (ThermoBrite) and the software revision will

appear on the display for a short time.

Note: The prompt screen will supersede this screen.

Record the software revision and “Boot” results on the test record.

Use the arrow keys to move the curser on the display and choose EDIT a program. Press the “Enter” key.

Choose program #1 and press the “Enter” key.

Choose FIXED for the type of program. Enter FIXED in the “Mode” section on the test record.

Type 0123456789 in the name field and record the results on the test record Beep and Keypad section.

Note: Each time the keypad is depressed a beep is sounded and all characters are displayed in

the display window.

Set temperature to 45.0°C and press the “Enter” key.

Choose run program and press the “Enter” key.

Choose program #1.

Note: The unit will heat to 45.0°C and then beep.

Start the timer on the unit being tested.

Note: The display in the unit will start to count up in seconds.

Check with a stopwatch for 30 seconds that the timer on the unit is correct.

Record the temperature readings at 2, 5, and 10-minute time intervals for the six probes.

Note: The 45.0°C test readings should be between 44.0°C and 46.0°C. The unit passes the test

if the readings are within range.

End the test by depressing the stop button.

Note: The fan should come an as the unit cools down. If the fan is running then check off the

Fan as passed on the test record.

Power off the unit after the it has cooled down to 37.0°C.

Turn the unit on and select “Edit” a program.

Note: The temperature will be set to 95.0°C.

Record the time it takes to get from 37.0°C to 95.0°C on the test record when the program starts to run.

14

Note: It will beep once it reaches 95.0°C.

Start the timer and record the temperature readings at 2, 5, and 10-minute intervals for the six probes.

Note: The 95.0°C test readings should be between 94.0°C and 96.0°C. The unit passes the test

if the readings are within range.

Depressing the Stop button and end the test.

Record the time it takes to cool down from 95.0°C to 45.0°C.

Watch the display to see if it remains legible (not to dim) during the cool down. Record the results within the

Display section of the test record.

Use a DC hi-pot tester and perform the Line Dielectric Voltage withstand/Grounding continuity Test. Record

the results on the test record.

Inspect assembly for blemishes record the results in Cosmetic section of the test record.

Verify that the UL, CE, Hot, and serial # labels are installed.

15

Section 7

Programming

Overview

ThermoBrite is capable of storing 40 different programs. Each program can be one of three program

types:

oDenaturation and Hybridization (Denat & Hyb),

oHybridization Only (Hyb Only) or

oFixed Temperature (Fixed Temp).

Select PGM Type

Denat & Hyb

Hyb Only

Fixed Temp

Programming is simple. Select program type, and follow screen prompts to enter run times and set

temperatures. ThermoBrite maintains set temperatures for duration of the processing.

Note: At end of program the display will show “Process Complete”. Temperature will be maintained and timer

will continue to run until End PGM/Main Menu is accepted by pressing “Enter” button.

Note: If all 40 program numbers have been used ”Create a PGM” line in the Main Menu will no longer appear.

An existing program must be edited, see “Editing a Program”.

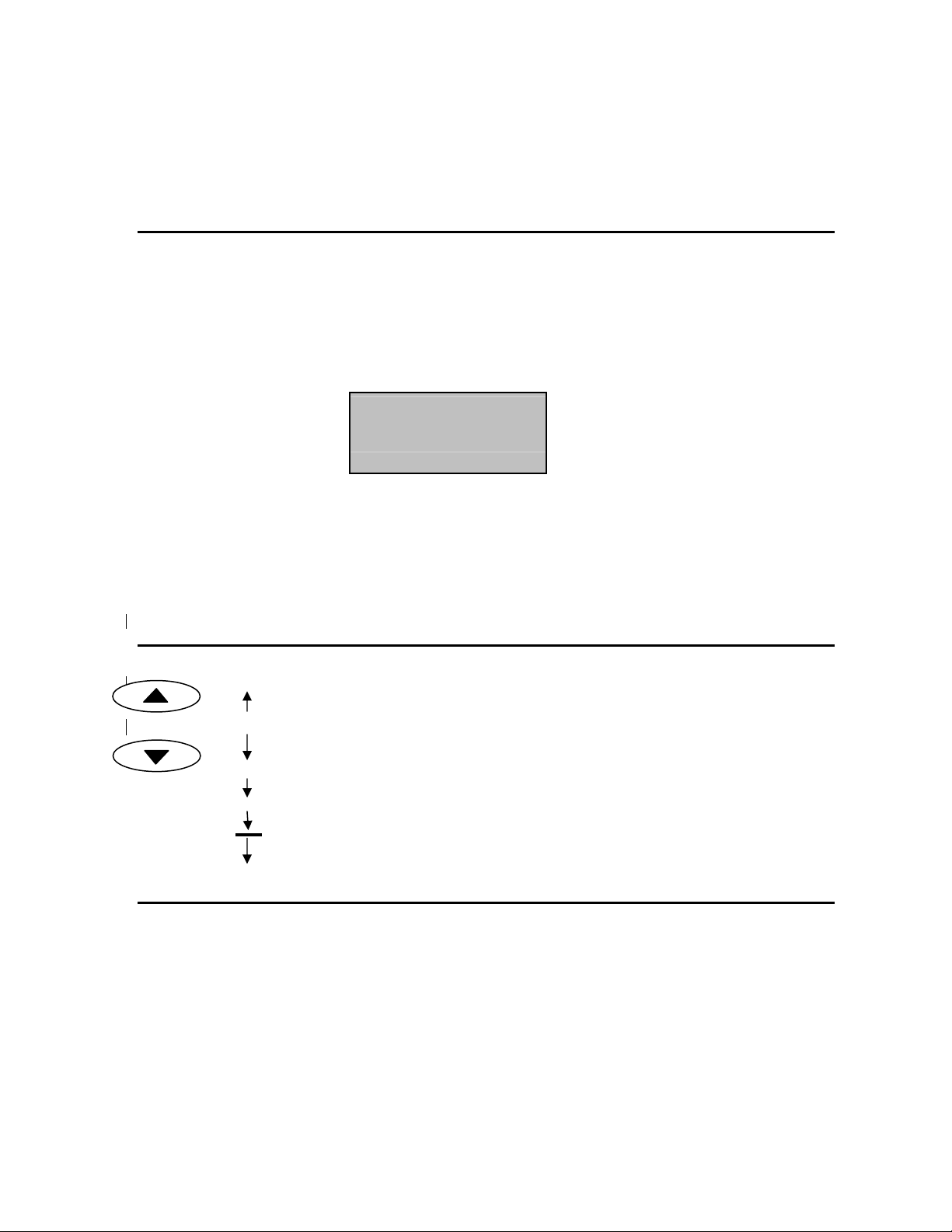

Character Selection

•ThermoBrite allows creating a program name. Cursor highlights the first name

character position.

•Use the arrow keys to move through character set and press “Enter” button to

accept the characters.

•All 10 character positions must be used and blank spaces are acceptable. Press

“Enter” button to accept blank characters.

•For numeric characters use keypad 0-9.

Creating a Denaturation and Hybridization Program (Denat & Hyb)

From the Main Screen, use the arrow keys to move cursor to “Create a PGM” and press “Enter” button to

accept.

Cursor highlights “Denat & Hyb” line; press “Enter” button to accept.

ThermoBrite will advance to the next available program number.

For specific programming instruction refer to units operators manual.

Z

A

“Blank”

•

Z

This manual suits for next models

3

Table of contents

Popular Laboratory Equipment manuals by other brands

Macherey-Nagel

Macherey-Nagel NANOCOLOR TIC-Ex manual

IKA

IKA IKA C 248 operating instructions

WONDFO

WONDFO Finecare FIA Meter Plus Operation manual

Thermo Scientific

Thermo Scientific 2032 Operating and maintenance manual

BC Northern Lights

BC Northern Lights Producer Technical manual

Thermo Scientific

Thermo Scientific NanoDrop One user guide

Leica

Leica CM3600 XP Instructions for use

NEW BRUNSWICK SCIENTIFIC

NEW BRUNSWICK SCIENTIFIC C-24 Guide to operations

Cell Guidance Systems

Cell Guidance Systems Exo-spin Mini-Columns user guide

Labnet

Labnet S0200 user manual

ELGA

ELGA PURELAB 7000 - US Quick start manual

BioChain

BioChain AnaPrep 12 Dx instruction manual