5

5

ENGLISH

The device has been designed to clean surfaces and

objects in the elements, tools, vehicles and boats. With

special accessories can be mixed for the cleaning

products recommended by STAYER, unclogging pipes

and loosen rust or paint.

This product is not suitable for industrial use. Regulatory

use also involves the use at an ambient temperature

between 5 ° C and 50 ° C.

This manual includes instructions on

proper installation and safe use of

machinery. It is very important to read

carefully these instructions.

1. List of contents Page

2. Special safety instructions...................................12

3. Machine-specific Safety Warnings.......................13

3.1. Placing or fixing the tool........................................13

3.2. Assembling..........................................................13

3.3. Electrical connection............................................13

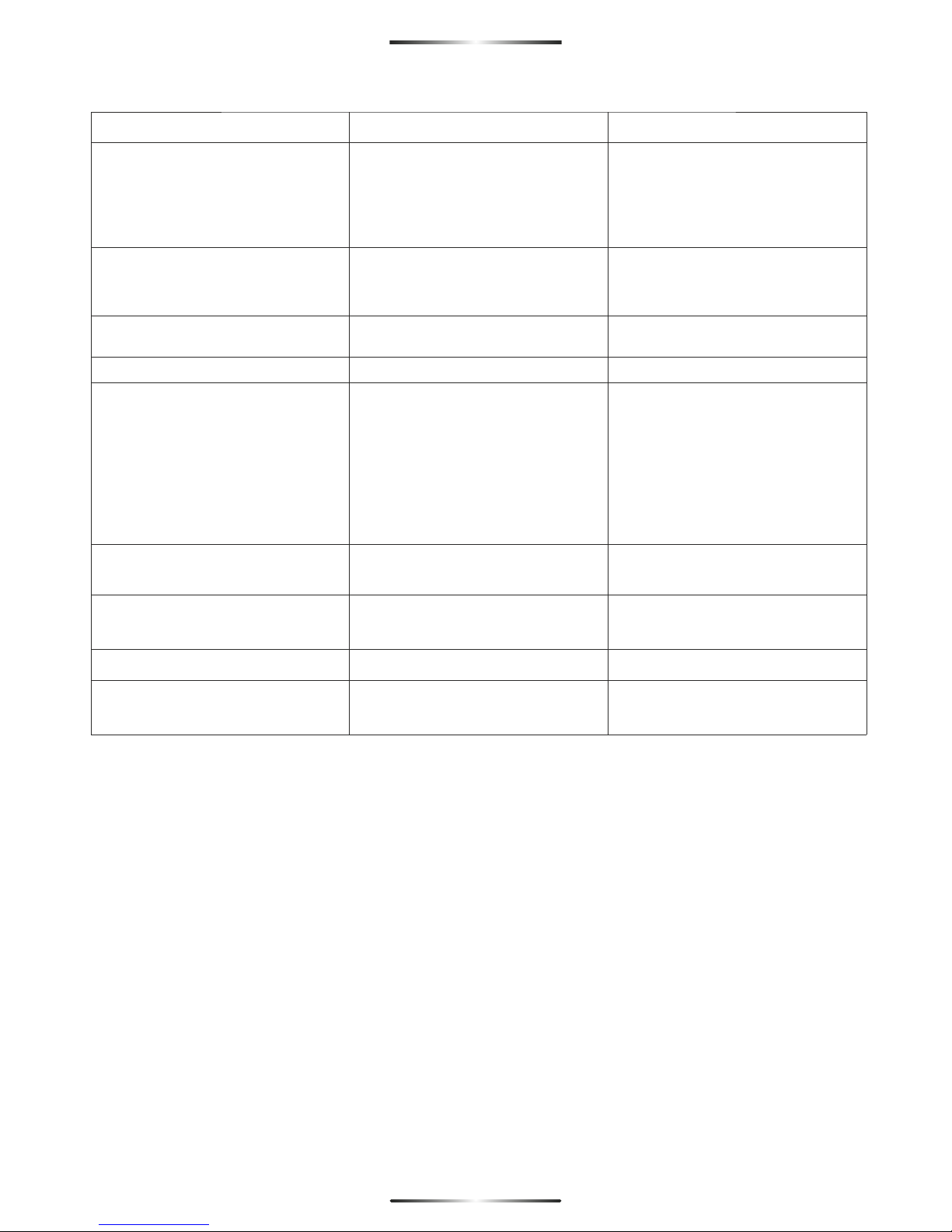

3.4. Illustrated description...........................................13

4. Operating instructions..........................................13

4.1. Placement and testing..........................................13

4.2. Instructions for use...............................................14

5. Maintenance instructions.....................................14

5.1. Cleaning, maintaining, lubricating, sharpening.....14

5.2. Repair service......................................................15

5.3. Guarantee............................................................15

6. Legal Regulations.................................................15

6.1. Technical features................................................15

6.2. EC Declaration of Conformity...............................15

2. Machine-specific Safety Warnings

Before start-up please read these instructions!

Before using the machine please read the

operating instructions for your unit and

comply in particular with these safety

instructions. Please keep the instructions

safe for later use.

The warning and information signs

attached to the unit provide important

information for safe operation.

Apart from the information in the operating

instructions comply with the general safety

regulations and regulations for the prevention of

accidents.

Machine not suitable for connection to the

potable water mains.

Never direct the water jet at

people, animals, the unit or

electric components.

Power suply

The voltage indicated on the rating plate must correspond

to the voltage of the power source.

Class 1 units may only be connected to properly earthed

power sources.

This equipment is only connected into a socket which is

protected by a circuit-breaker that would be actuated by a

30 mA residual current. If an extension cord is used, the

plug and socket must be of a water tight construction.

Warning. Inadequate extension cords can be

dangerous. Never touch the mains plug with wet

hands.

Do not run over, crush or pull the power supply cable or

extension lead, otherwise it may be damaged. Protect the

cable from heat, oil and sharp edges.

The extension lead must have a cross section in

accordance with the operating instructions and be

protected against splashed water. The connection must

not be in water.

Water connection

Comply with the regulations of your water supply

company.

All connecting hoses must have properly sealed joints.

The high-pressure hose must not be damaged (danger of

bursting). A damaged high-pressure hose must be

replaced immediately. Only use hoses and connections

recommended by the manufacturer.

Application

Before use, check that the unit and operating equipment

are in perfect condition and are safe to operate. Do not use

the unit if it is not in perfect condition.

Never draw in solvent-containing liquids, undiluted acids

or solvents! This includes petrol, paint thinners heating oil.

The sprayed vapour is highly flammable, explosive and

toxic; also acetone, undiluted acids and solvents as these

corrode the materials used on the unit.

The appropriate safety regulations must be observed

when using the unit in dangerous area (e.g. petrol

stations). It is forbidden to operate the unit in

potentially explosive locations.

The gun trigger must not be jammed in the “ON” position

during operation.

Suitable protective clothing must be worn if necessary to

protect against splashing from some parts.

Vehicle tyres/tyre valves may only be cleaned from a

minimum distance of 30 cm, otherwise the vehicle

tyre/tyre valve could be damaged by the high-pressure jet.

The first indication of this is a discoloration of the tyre.

Damaged vehicle tyres/tyre valves can be deadly

dangerous.

Materials containing asbestos and other materials which

contain substances which are hazardous to your health

must not be sprayed.

Only use detergents which have been approved by the

manufacturer of the unit.

!

High pressure jets can be dangerous if

subject to misuse.

!