1

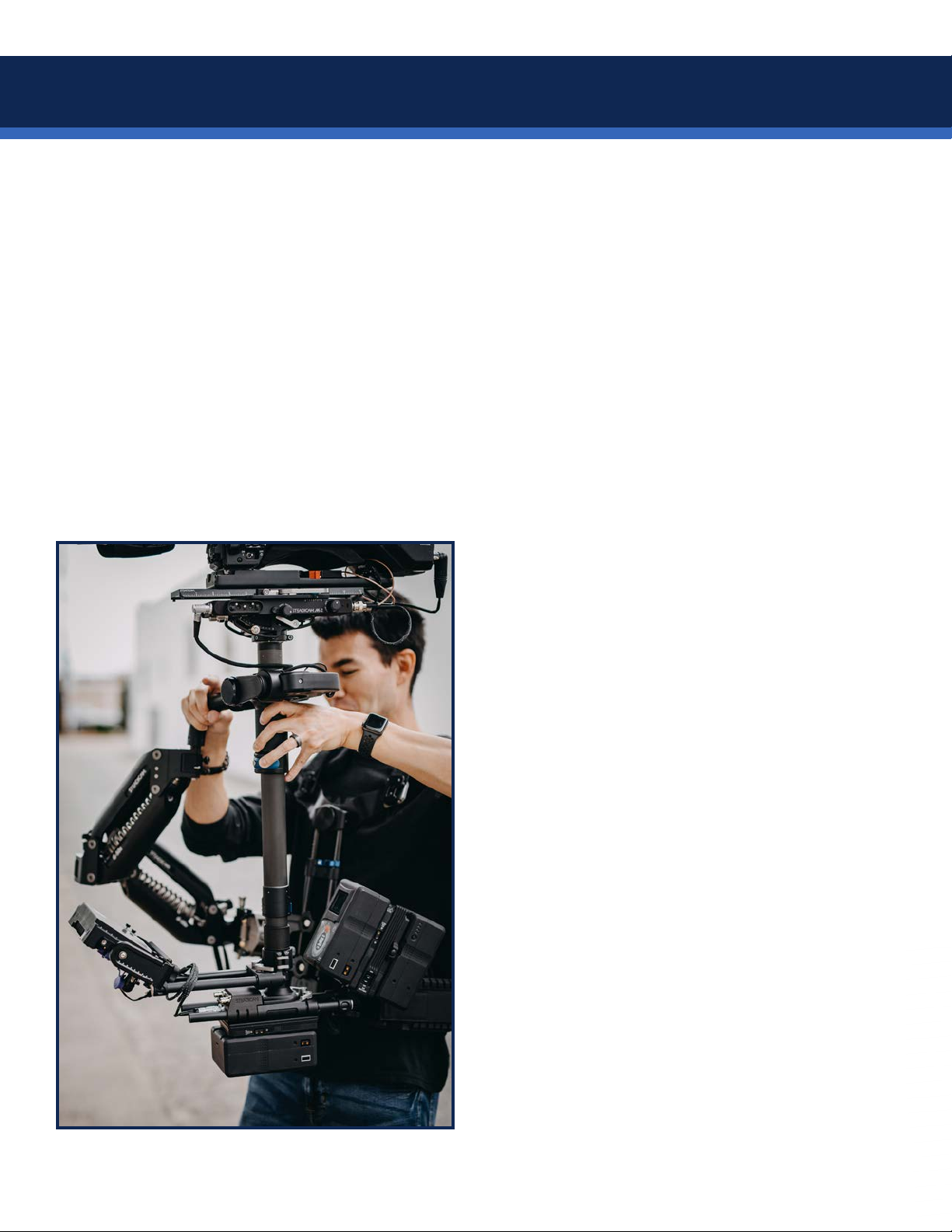

The Steadicam®Volt™

Working with the sled’s inertia and neutral balance, the Volt generates an “articial bottom-heaviness” to

keep the horizon level and headroom stable. With Volt, the operator can concentrate on precise framing,

timing, navigating, and other more interesting aspects of operating.

The strength of the roll and tilt assistance may be individually ne-tuned to suit the operator’s

preferences, and easily adjusted for different shots. The assistance can feel like operating a sled with a

very long drop time – easy to tilt or roll – to full gyro-simulation, with the sled locked hard to the horizon

in roll, or tilt, or both.

Because the sled is always balanced neutrally top-to-bottom, all pendular effects from acceleration and

deceleration are eliminated. Plus, there is no re-balancing needed when switching to low mode!

Trunnion motor

and belt

The Volt also allows behaviors that were impossible

before. Like “friction mode” which emulates a uid

head with tilt hold and a xed horizon, bringing

you new control options for each and every shot.

In use, the Volt is completely transparent to the

operator, and it feels exactly like regular Steadicam

operating – with perfect horizons. The operator is

always in full and direct control of framing, and can

easily override the Volt’s assistance.

This user guide is organized to get you up and

running quickly; with components and operating

up rst, then how-to install the popular complete

M-2 Volt gimbal kit onto a sled. Further back, we

show step-by-step installation of Volt components

onto any gimbal, and nally, the factory upgrade

steps for older gimbals, should you be so inclined.

Welcome to the future of professional Steadicam

operating!

Introduction