Steadicam X3 User manual

Steadicam X3

LIT-077200

X

Table of Contents

Introduction 1

X3 Components 2

Installation 3

Putting it on 5

Lift and Threads 7

Ride Adjustment 9

Goofy Setup 11

Other considerations 13

Maintenance 14

Contact Tiffen 15

The Tiffen Company

90 Oser Avenue

Hauppauge, NY 11788

Visit us at www.tiffen.com

1 2

Introduction Components

The Steadicam X3:

Building on the strength and versatility of the Fawcett Exovest, the Steadicam X3 expands

your ability to place the camera anywhere you wish. The additional 50% boom range over the

G-70X brings the Steadicam arm almost equal to the gripping range of most operators. You

now have nearly four feet of boom range to work with at all times! This translates to fewer

switches to low-mode or back to high mode for that special shot. And the lens can get higher

or lower than ever before.

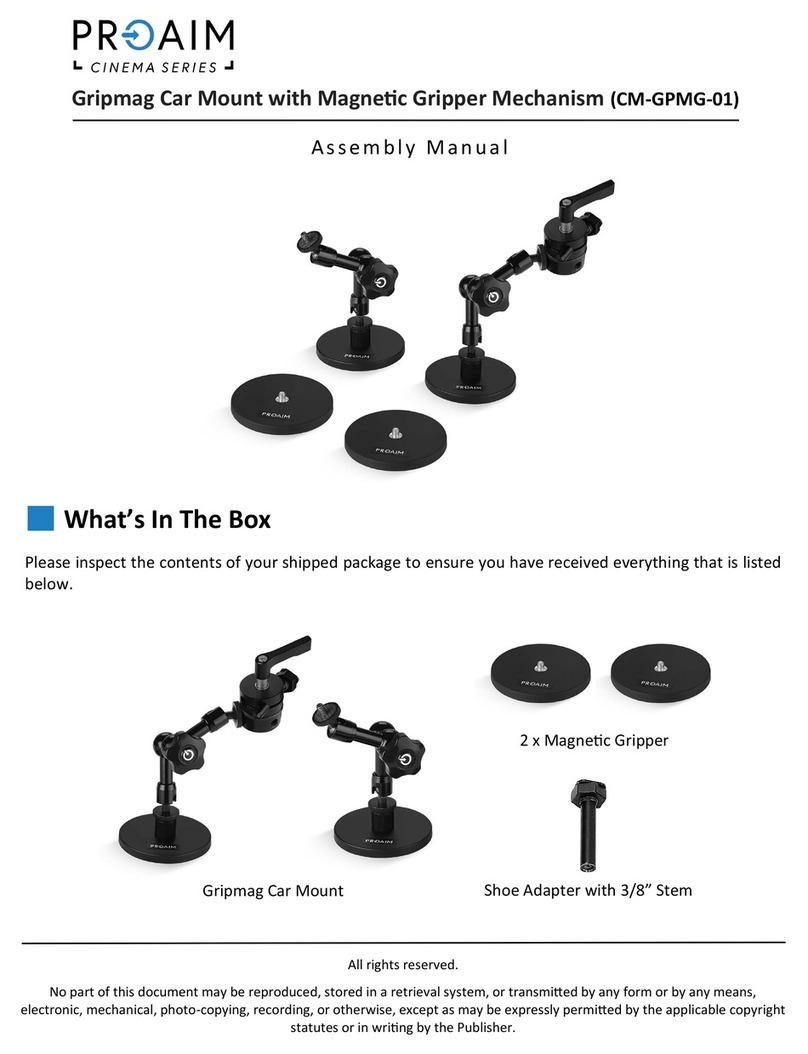

Vest Mount

Quick Release

Fits Exovest

Vest Mount Clamps

Two lock knobs

X3 Link

Width adjustment holes Quick Release Pins (4)

For storage, adjusting width and switching sides

Side to Side Adjusters (2)

Upper Fore-Aft Adjuster

Pivot Screws (2)

Arm Section

Half of a G-70X

Titanium springs

18-70Lbs payload

Lower Fore-Aft Adjuster

Ride Adjuster

Lift Adjuster

Socket Block

Standard size

The patented design of the X3

utilizes the symmetrical rods of

the Exovest to attach like a back-

mounted vest. No changes are

required to mount any standard

arm. Once the X3 is set to your

preferred side and width, it

is quickly added or removed

from the vest, without tools.

The operator can adjust arm

alignment as well as adjust the

lift and ride settings of all three

arm sections without need of

assistance.

Best of all, you are now free

to place the camera anywhere

within an expanded range and

create shots that were previously

difcult or impossible.

Caution: the unloaded arm is

shipped and stored under tension

when held by the arm lock.

NEVER place ngers or objects

within the arm sections in case

the arm releases unexpectedly.

Arm Lock

Holds unloaded arm horizontal

Shown here unlocked

X

3 4

Tighten both clamp knobs by hand with

enough torque that the mount won’t

slide.

With the waist latch of your vest closed,

check that the inside of the arm section

lines up just OUTSIDE of the waist pads.

The closer it is, the narrower your entire

setup will be, but you don’t want the X3

to contact the vest.

If it’s either too wide or too narrow, pull

the two vest mount quick release pins

and choose another set of holes in the

link so the arm is ideally positioned. Re-

install the pins.

Remove the Exovest bridge plate to

improve clearance and reduce weight.

Like the bridge plate, separate the X3 rod

clamps and place them around the REAR

rods of the vest with the arm section on

the right side.

If you prefer to y goofy, check page 11

to ip the X3 and then come back here.

Note: the vest mount is not symmetrical

top to bottom. The THIN end goes up,

tilting the X3 slightly downward.

Installation

Putting it all together:

Before you go any further, make sure you have your traditional kit set up. Your 2-section

arm front-mounted on the Exovest, arm dialed in for lift and ride (if applicable) and the rig

precisely balanced. This will make adding the X3 much easier, since you will only have to

make adjustments to the 3rd arm section once it’s on the vest.

Attaching the X3 to the Exovest is a tools free affair. And once you nd your settings,

switching from front-mount to X3 should take less than 5 minutes in the eld.

X

X

X

X

5 6

Cinch down the vest like normal. It

should not need to be adjusted from your

usual setup despite the added weight.

Add your 2-section arm at the socket

block and lock it in with the side-to-side

adjusters.

If this is your initial setup, you’ll need

to set the lift and ride, plus nd your

threads.

If you already know your threads, set

them before hoisting the rig.

Pick up your sled and ip open the arm

lock to free up the 3rd section.

Make sure the arm is locked horizontal

and the fore-aft adjusters are not loose

before putting on the vest.

The vest will be heavy, so placing it on a

cart or lift-gate can help entry.

An assistant can be a big help the rst

few times you climb in.

Hold onto the arm section with your right

hand as you climb in, lifting the shoulders

into place with your left. Secure the

shoulder dovetail and then move on to

the waist.

Caution: the unloaded arm is under

tension when held by the arm lock.

NEVER place ngers or objects within the

arm sections in case the arm releases

unexpectedly.

Climbing in Add your arm

X

7 8

Like any G-series arm, Lift is only

adjustable with the arm slightly above

horizontal. You’ll need to raise or lower

the sled to nd that sweet spot.

A normal lift setting will allow all THREE

arm sections to move together with a

slight tendency to remain horizontal.

The side-to-side adjustment rotates

the socket block similar to the fore-aft

adjustment on a traditional mount.

However, we must adjust the side-to-side

threads without the rig on board.

Wear the rig and observe which direction

it tends to pull, then dock.

With the X3 held just above horizontal,

you’ll feel the knob unlock. Adjust the X3

lift to support your rig and 2-section arm.

Lift and threads Lift and threads

To make a side-to-side adjustment,

loosen the top knob, make your

adjustment with the lower knob and re-

snug the top.

Test and repeat until the rig is centered.

Remember, these screws lock the

2-section arm socket to the X3 socket

block, so make sure they’re snug.

The fore-aft adjustment uses the pair of

knobs facing forward to rotate the entire

socket block around the pivot screws.

Similar to the side-to-side adjustment,

we’ll have to turn the knobs without the

rig on board.

Wear the rig and decide which direction

you need to adjust the fore-aft knobs,

then dock.

To make a fore-aft adjustment, loosen the

top knob, make your adjustment with the

lower knob and re-snug the top.

Test with the rig on board and repeat if

necessary.

If you run out of adjustment range on X3

fore-aft, reach for your 1/4” Allen wrench

and make adjustments to your 2-section

arm rod-ends.

X

9 10

Ride adjustment

Fly the rig and take note of how the X3

responds to booming.

Does it follow your 2-section arm?

Does X3 lock at the top or bottom?

If it’s perfect, great, go to work. If it’s not

perfect, take a few minutes to dial it in.

To make an adjustment, dock the rig

WITHOUT using the arm lock. It will be

awkward, but will allow you to dial the

ride knob by yourself.

If you have an assistant, you can boom

all the way up and have them make the

adjustment for you. Just ask nicely.

Make your adjustment and then re-test

with the rig.

If the X3 is locking at the top of the

travel, skip to the next step.

Otherwise, turn the ride knob counter-

clockwise (more ISO) until the arm

segment begins to “lock” up or down

when boomed.

Then, turn the ride knob clockwise a turn

or two until the arm ceases to lock up.

The X3 will typically require LESS ISO

than a G-70X attached to it. Fewer

threads will be showing behind the ride

knob on your X3.

Test and micro adjust the lift and ride as

necessary so all three arm sections follow

each other.

All three sections should move at the

same time, at the same angles and not

require much force.

For more details about lift and ride

adjustments, see the G-70X manual

online at:

https://tiffen.com/steadicam/product-

literature/

Nice ride:

Next we move on to the ride setting, or the ISO-elastic behavior of the arm. If you’re not

familiar with this process, don’t worry. The goal is to make all three arm sections work

together and be as ISO-elastic as possible for your payload.

Note: like any G-series arm, the X3 ride is only adjustable with the arm at the TOP of its

travel. Due to the tremendous boom range of the combined three arm sections, you may

want the help of an assistant, or you’ll want to dock without the arm lock just while setting

the ride adjustments.

Ride adjustment

X

11 12

Remove the two pivot screws and set

them aside.

Remove and ip the socket block 180˚

so the side-to-side adjusters are facing

INWARD, toward the operator.

Reinstall the two pivot screws and center

the fore-aft adjuster screws to get you

started.

Remember to check the overall width

once you attach the X3 to your vest.

Pull all four quick release pins (they’re

identical) and separate the 3 main

components of the X3.

Reassemble the pieces with the link and

the arm to the LEFT of the vest mount, as

shown.

Note: the vest mount is not symmetrical

top to bottom. The THIN end goes up,

tilting the X3 slightly downward.

Goofy setup

If you’re feeling goofy:

Flipping the X3 to the left side only takes a couple of minutes. Most of it is accomplished by

removing the quick release pins, but you’ll need a at-head screwdriver to remove the pivot

screws and ip the socket block. In a pinch, you could run your arm socket on the “regular”

side and leave the X3 regular as well. But let’s do it right this time.

X

X

13 14

Clean the X3 with a lint-free cloth misted

with household window cleaner.

The steel and aluminum nishes are

extremely durable and may be cleaned

with isopropyl alcohol, in case you need

to remove serious gunk.

Check the arm section after each shoot

for smooth, silent operation.

Make sure all hardware is maintained and

contact Tiffen for spares or repairs.

Note: DO NOT lubricate anything on the

X3, including the bearings or spring ends.

Make sure the X3 is completely dry before

storage and transport.

And be careful never to place ngers or

objects inside the arm sections when the

X3 is under tension, held by the arm lock.

Store the X3 in the included soft bag.

Always use the arm lock on the X3 before

docking and decoupling your 2-section

arm. It is nearly impossible to force the

arm down without the weight of a sled.

It IS possible to use the X3 without

engaging the arm lock, but it makes

joining your arm more difcult.

And who wants that?

Consider leaving the vest mount on the

back rods at all times and simply use the

QR pins to add the X3 in seconds.

You might use high-low-mode more

than normal. Build your sled extra short

in order to get maximum lens height

indoors.

Experiment with that expanded boom

range!

Other considerations Maintenance

X

X

X

X

15

The Tiffen Company

90 Oser Avenue

Hauppauge, NY 11788

Phone: (631) 273-2500 or 1(800) 645-2522

Fax: (631) 273-2557

Tiffen-Steadicam

2815 Winona Avenue

Burbank, CA 91504

Phone: (818) 843-4600 or 1(800) 593-3331

Fax: (818) 843-8321

Tiffen International Ltd.

Pinewood Studios

Pinewood Road

Iver Heath SL0 0NH

United Kingdom

Phone: (44) 870-1001220

Fax: (44) 1869-321766

Email:

techsupport@tiffen.com

Web:

tiffen.com/steadicam

Contact Tiffen

Designed and manufactured in the United States of America.

Patents pending. Tiffen reserves the right to change specications, accessories, etc. without prior notice. There is

no implied or expressed warranty regarding this material.

STEADICAM®, Exovest®, G-70X™ and Iso-elastic are trademarks of the Tiffen Company, LLC.

© 2017 Tiffen Company, LLC. Written by E. Barthelman

Table of contents

Other Steadicam Camera Accessories manuals

Steadicam

Steadicam ARCHER2 User manual

Steadicam

Steadicam Steadimate-S User manual

Steadicam

Steadicam Merlin Manual instruction

Steadicam

Steadicam G-70x Arm User manual

Steadicam

Steadicam MERLIN2 User manual

Steadicam

Steadicam Ultra2 User manual

Steadicam

Steadicam Ultra2 User manual

Steadicam

Steadicam M-1 User manual

Steadicam

Steadicam Merlin Arm & Vest Technical manual

Steadicam

Steadicam Merlin 2 Manual instruction