THERMELECT INSTALLATION 3.10

AIR CONDITIONER/HEAT PUMP INTERFACE

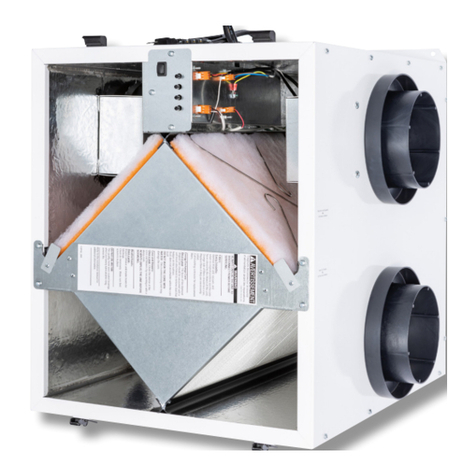

The system can accommodate most heat pump or air conditioner indoor

coils up to a 7.5-ton capacity provided the heat pump or air conditioner is

sized in accordance to supply air delivery rates of the system. Refer to the

System Air Delivery Matrix for information on air delivery rates of the

supply air blower with regard to the blower’s speed, To ensure that ad-

equate air flow is provided for the heat pump or air conditioner system

beinginstalled.

When interfacing the system with a heat pump, the indoor coil MUST be

placed on the return side of the system in a position that provides even air

flow through the coil. The installer needs to make provisions in the plenum

to accommodate the coil and air filter.When interfacing with an air condi-

tioner, the indoor coil can be placed on either the supply air or return air

side. The condensate drain trap, in a heat pump or air conditioner installa-

tion, should be designed for the vacuum in which the system is operating. Typically, taller traps are better suited

for these types of applications.

Refer to the Room Thermostat Connections Diagrams for more information on interfacing the system with a

heat pump or air conditioner. Refer to Location 46 and 47 in the Supplemental Installer's Guide for information

on compressor control from the ThermElect system using outdoor temperature lockout.

Installation

WARNING

Risk of fire. Any one ducting

system MUST NOT contain more

than one air handling (blower)

system. If the application

requires multiple systems or it is

necessary to have multiple air

handlers share the same

ductwork, you MUST contact

Steffes Corporation. There are

special installation require-

ments that MUST be performed.

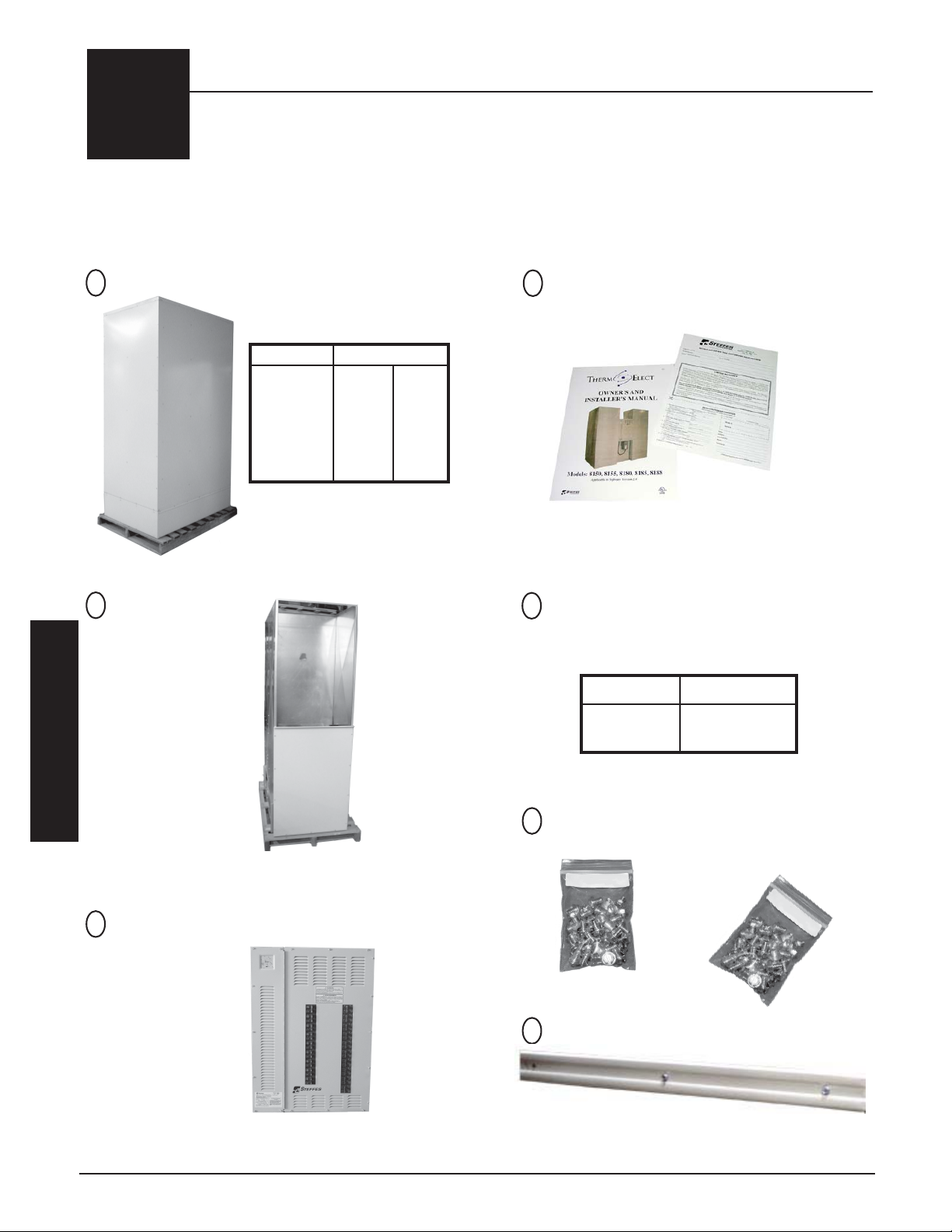

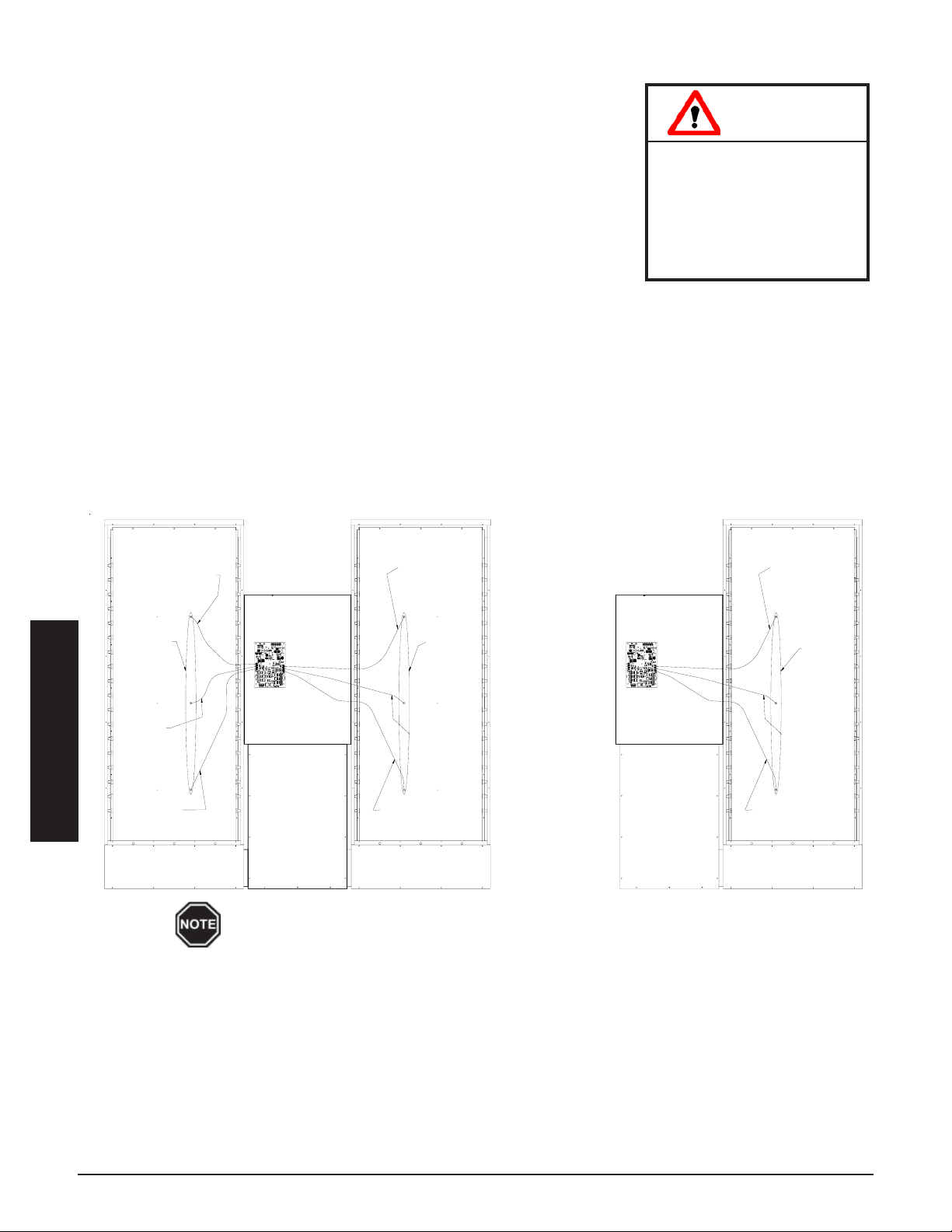

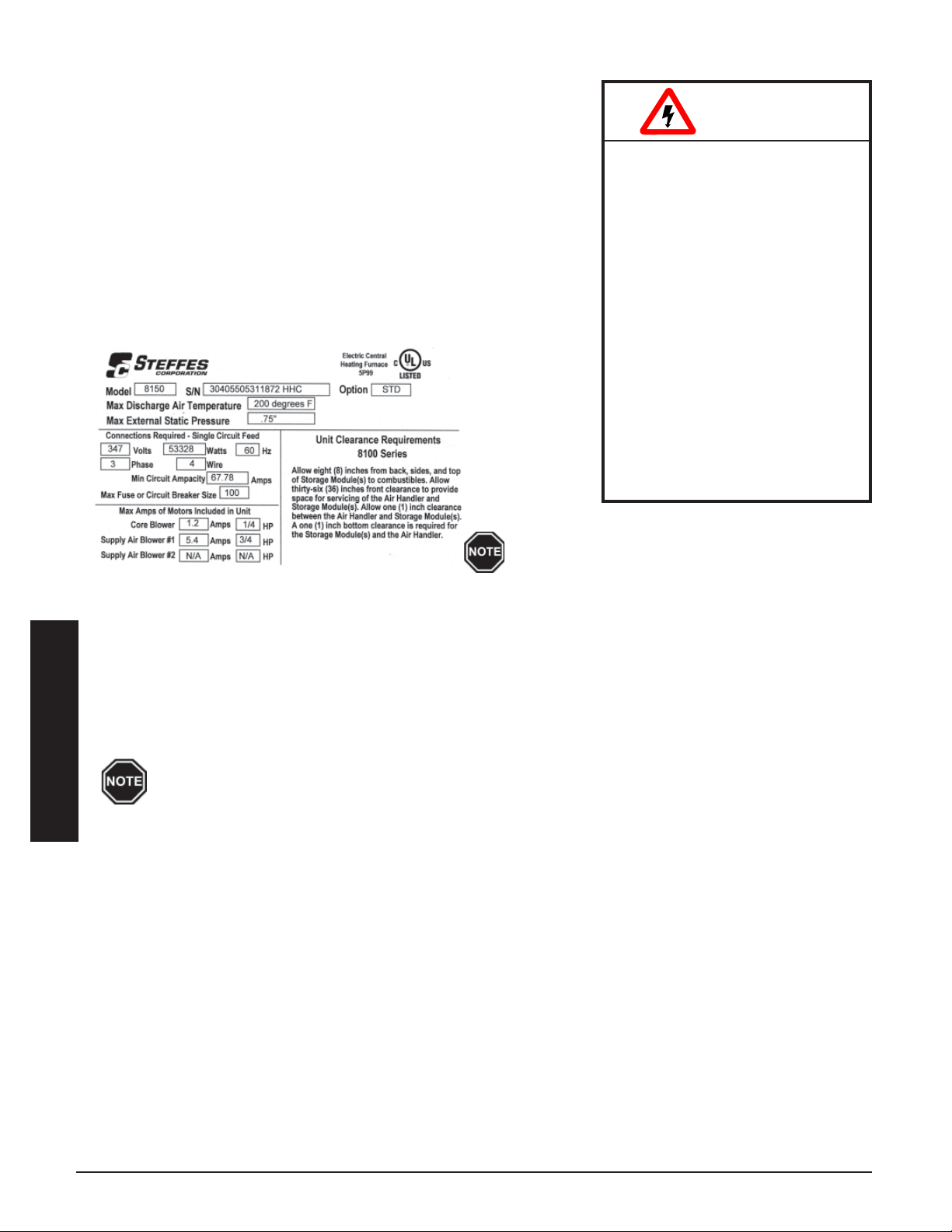

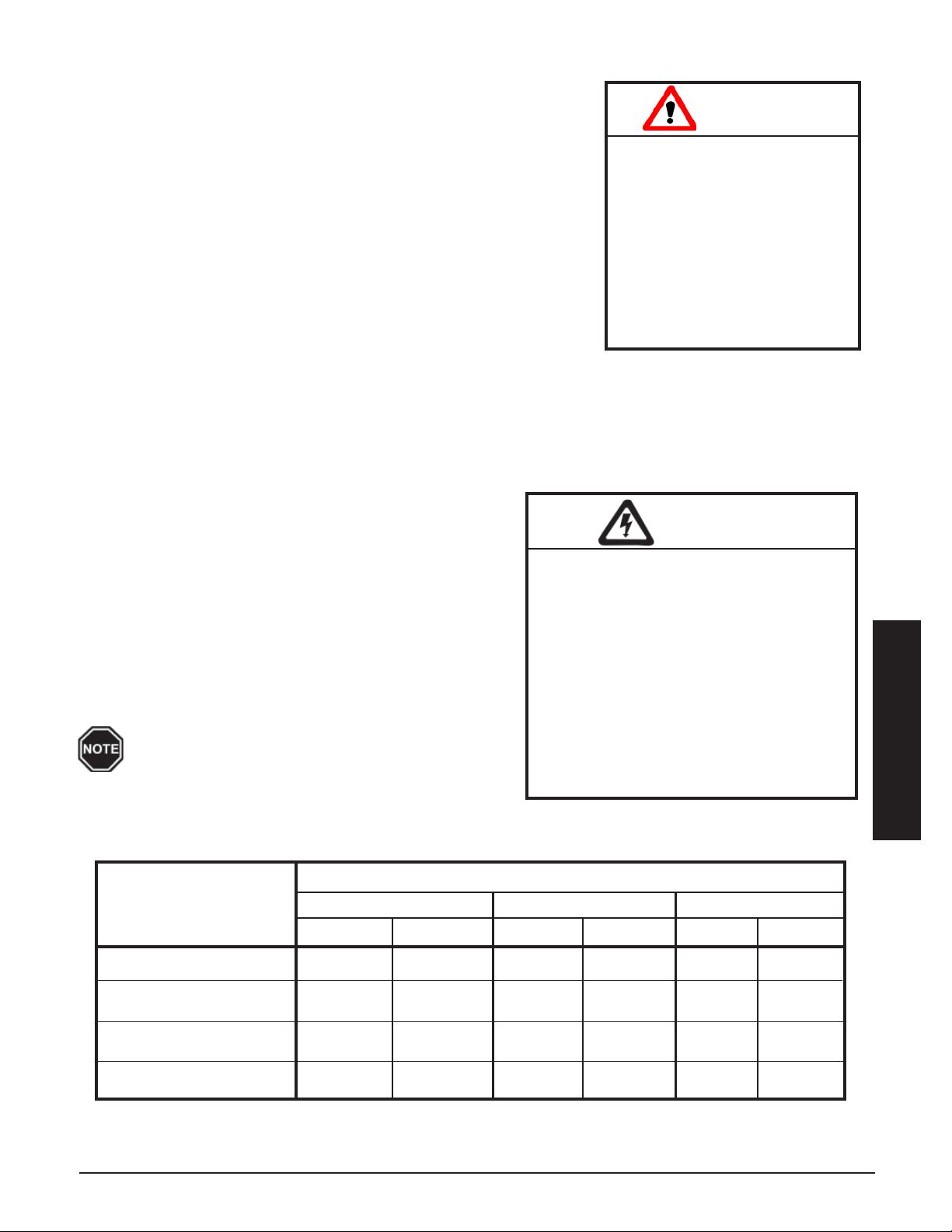

SYSTEM AIR DELIVERY MATRIX

.25" .50" .75"

2000 3000* 2000 3000* 2000 3000*

High(CFM) 2050 2950 1900 2490 1540 2160

Medium High (CFM) 1990 2850 1890 2350 1535 1980

Medium Low (CFM) 1870 2520 1670 2270 1450 N/A

Low (CFM) N/A 1920 N/A N/A N/A N/A

(External static pressure should not exceed .75 inches water column for all models)

*An optional 3000 CFM Air Handler is available. The 3000 CFM Air Handler is equipped with two 4-speed

supply air blowers.

SupplyAir

Blower Speed

DUCTING

SUPPLY AIR BLOWER SPEED

For air delivery, the system is equipped with a 2000 CFM Air

Handler containing a 3-speed supply air blower. The system is

factory wired to operate in medium speed for “heating” and in

high speed for “cooling” or a “fan only” thermostat setting.

Blower speed selection is made at the supply air blower. To

change blower speed for either "heating" or "cooling" modes,

detach the quick disconnect terminals at the supply air blower.

Select the blower speed and connect the corresponding wires.

When interfacing the system with a heat pump,

the blower speed connected to the high speed

relay is used for both heating and cooling.

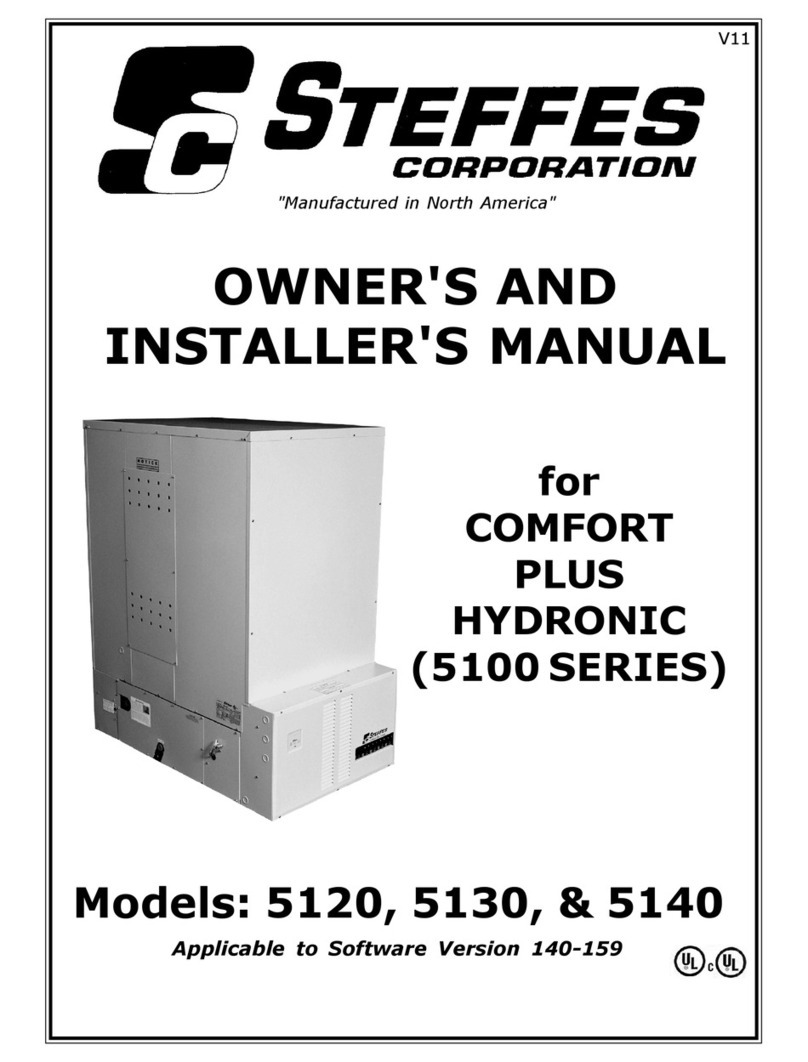

WARNING

HAZARDOUSVOLTAGE:Riskof

electric shock, injury or death. DO

NOT operate the system without

ducting installed to both the air

inlet and outlet.

EQUIPMENT DAMAGE: Risk of

equipment damage or improper

operation. On 3000 CFM systems

where there are multiple supply air

blowers, both blowers MUST be

connected to the same blower

speed to avoid equipment damage.