STEIN300_Radius Circuit_06_GB.doc / 01.2020 3

Contents

1Abbreviations and symbols ............................................................................................................................4

1.1 Explanation of safety and warning notices .......................................................................................... 4

2Introduction ......................................................................................................................................................5

2.1 Short description................................................................................................................................ 6

2.2 Initial inspection................................................................................................................................. 7

2.3 Complaints......................................................................................................................................... 7

2.4 Warranty ............................................................................................................................................ 7

3Safety instructions...........................................................................................................................................8

3.1 General safety information ................................................................................................................. 8

3.2 Appropriate use and liability exclusions .............................................................................................. 8

3.3 Residual danger ................................................................................................................................. 9

3.4 Safety information for installation and repair work............................................................................ 10

4Technical description ................................................................................................................................... 11

4.1 Scope of delivery.............................................................................................................................. 11

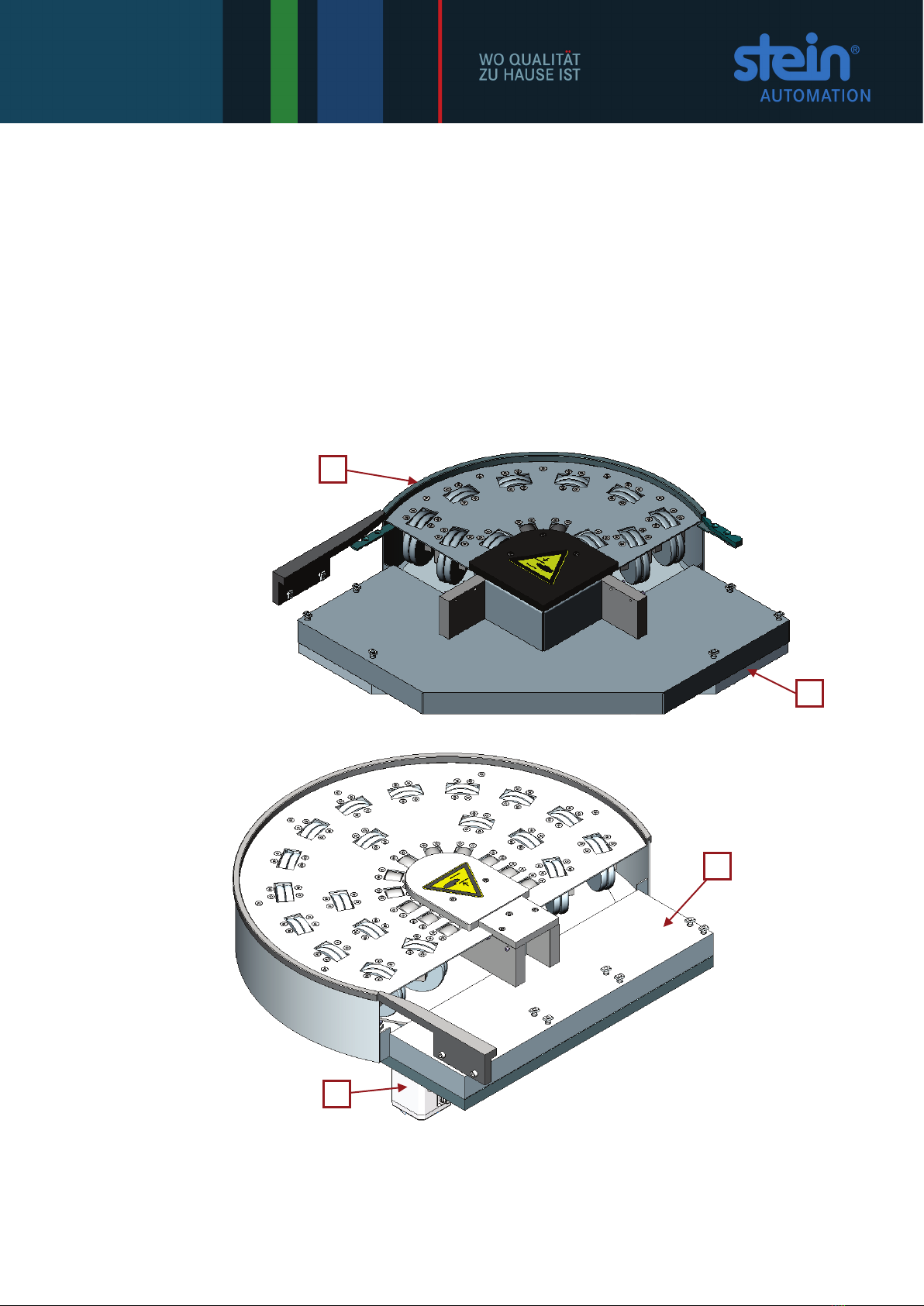

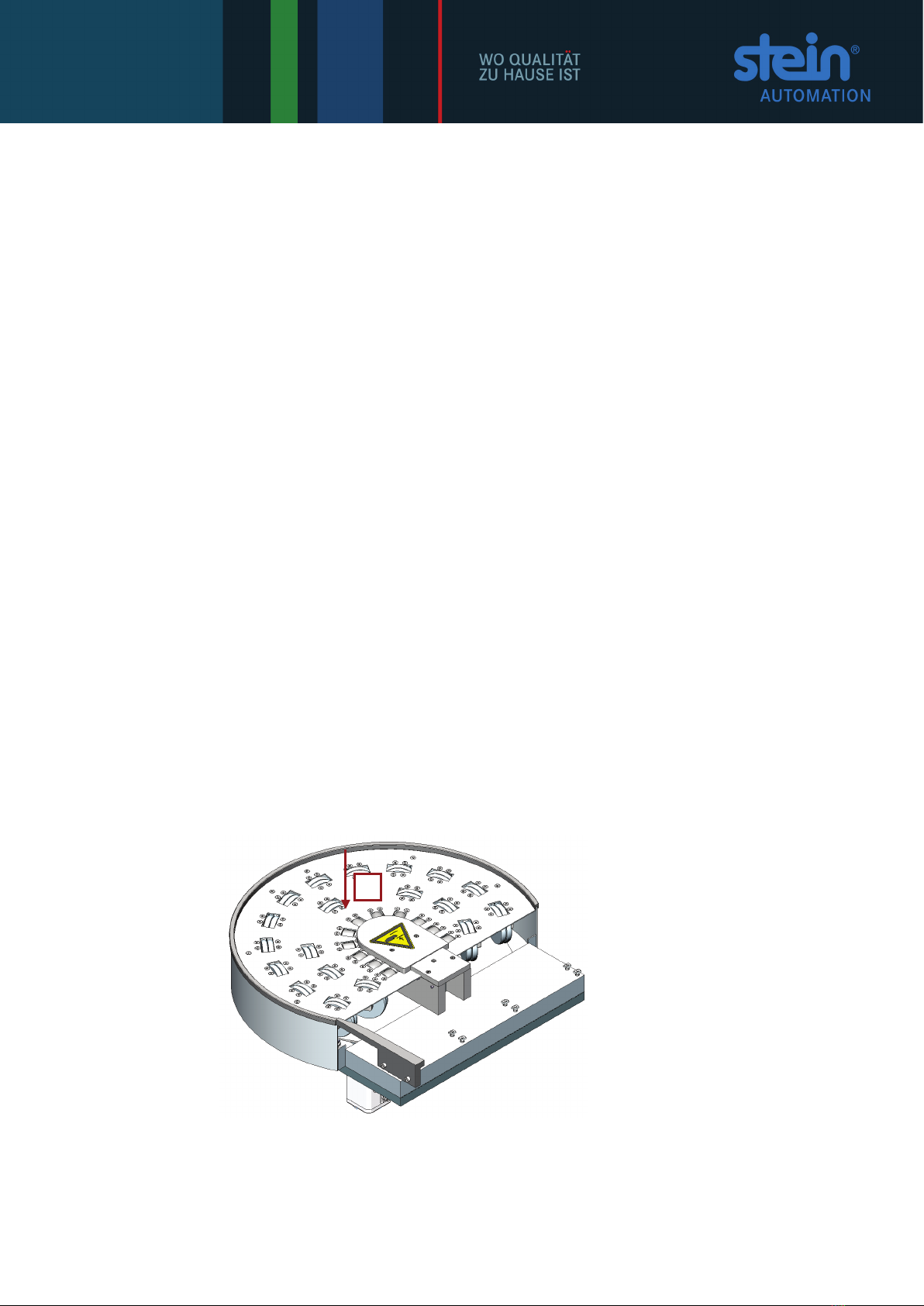

4.2 WT orientation.................................................................................................................................. 12

4.3 Sub-assemblies ................................................................................................................................ 12

5Radius circuit installation ............................................................................................................................ 13

5.1 Procedure ........................................................................................................................................ 13

5.2 Preparation ...................................................................................................................................... 13

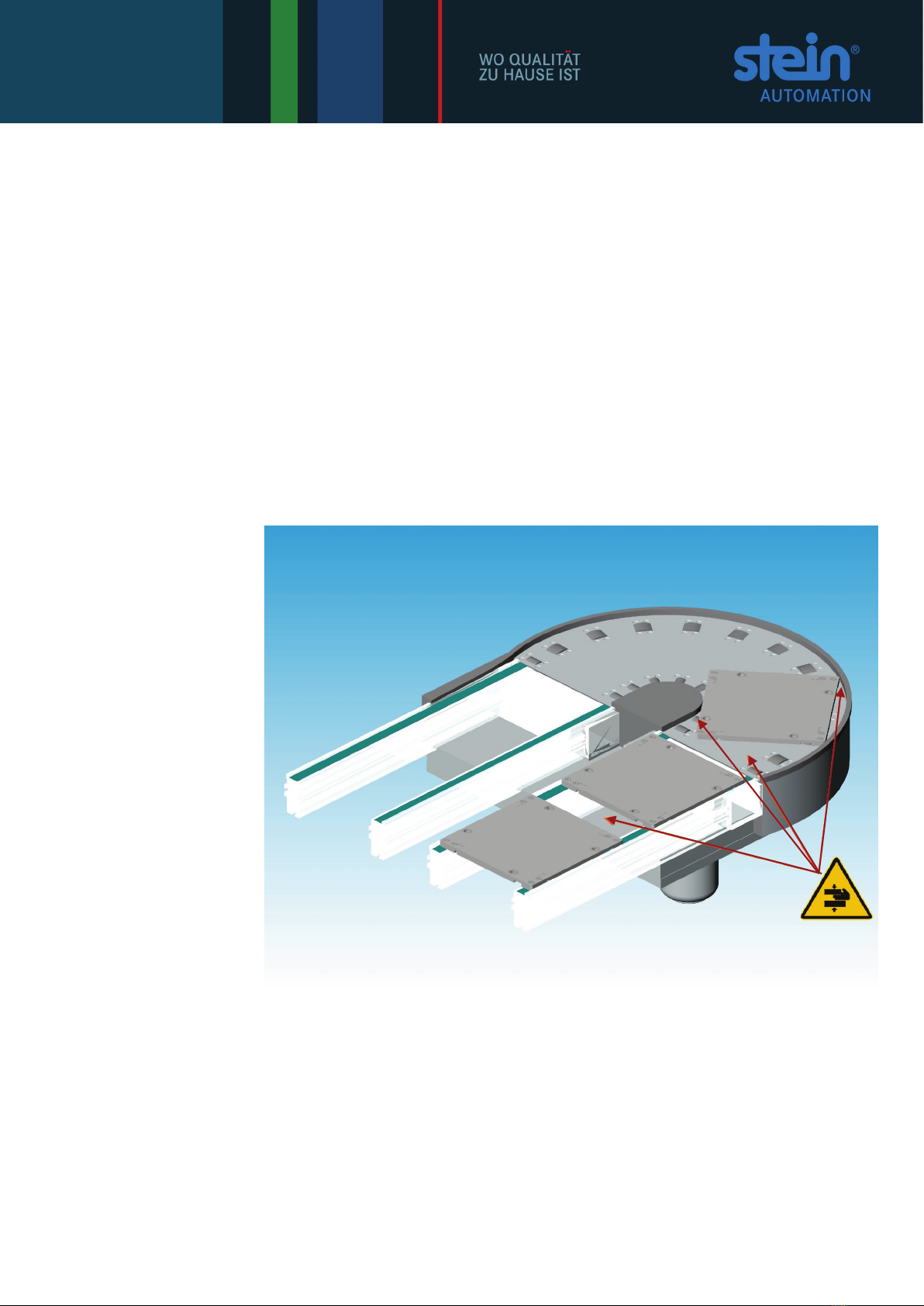

5.3 Radius circuit installation and de-installation .................................................................................... 14

5.4 Connection of the radius circuit to the mains supply ........................................................................ 17

5.5 Pile-up separator installation ............................................................................................................ 17

6Initial operation ............................................................................................................................................. 18

7Radius circuit operation ............................................................................................................................... 19

8Faults.............................................................................................................................................................. 20

8.1 Causes of faults and troubleshooting problems ................................................................................ 20

9Cleaning, inspection, maintenance............................................................................................................. 21

9.1 Cleaning........................................................................................................................................... 21

9.2 Inspection ........................................................................................................................................ 22

9.3 Maintenance .................................................................................................................................... 22

10 Dimensions sheet.......................................................................................................................................... 23

11 Spare parts..................................................................................................................................................... 24

11.1 300 095 001 Radius circuit 90° - PB 160x160 ................................................................................. 24

11.2 300 093 001 Radius circuit 90° - PB 240x240 ................................................................................. 27

11.3 300 151 001 Radius circuit 90° - PB 320x320 ................................................................................. 30

11.4 300 102 001 Radius circuit 90° - PB 400x400 ................................................................................. 33

11.5 300 089 001 Radius circuit 180° - PB 160x160............................................................................... 36

11.6 300 104 001 Radius circuit 180° - PB 240x240............................................................................... 39

11.7 300 098 001 Radius circuit 180° - PB 320x320............................................................................... 42

11.8 300 096 001 Radius circuit 180° - PB 400x400............................................................................... 45

11.9 300 789 001 Stand for radius circuit STRB....................................................................................... 48

11.10 300 790 001 Double column stand for radius circuit DSTRB ............................................................ 49

11.11 930 001 001 F1 Stand for radius circuit RBF1.................................................................................. 50

11.12 930 002 001 F2 Stand for radius circuit RBF2.................................................................................. 51