Language: English

WARNING

Activities using this type of equipment are inherently dangerous. It is not possible to cover every eventuality relating to the use

of this equipment. Purchasers and users of this device should seek professional training from a fully qualified and competent

instructor prior to engaging in any activity. If you are not able, or not in a position to assume this responsibility, do not use this

product. The manufacturer its distributors and retailers do not accept any liability if users do not follow the instructions correctly.

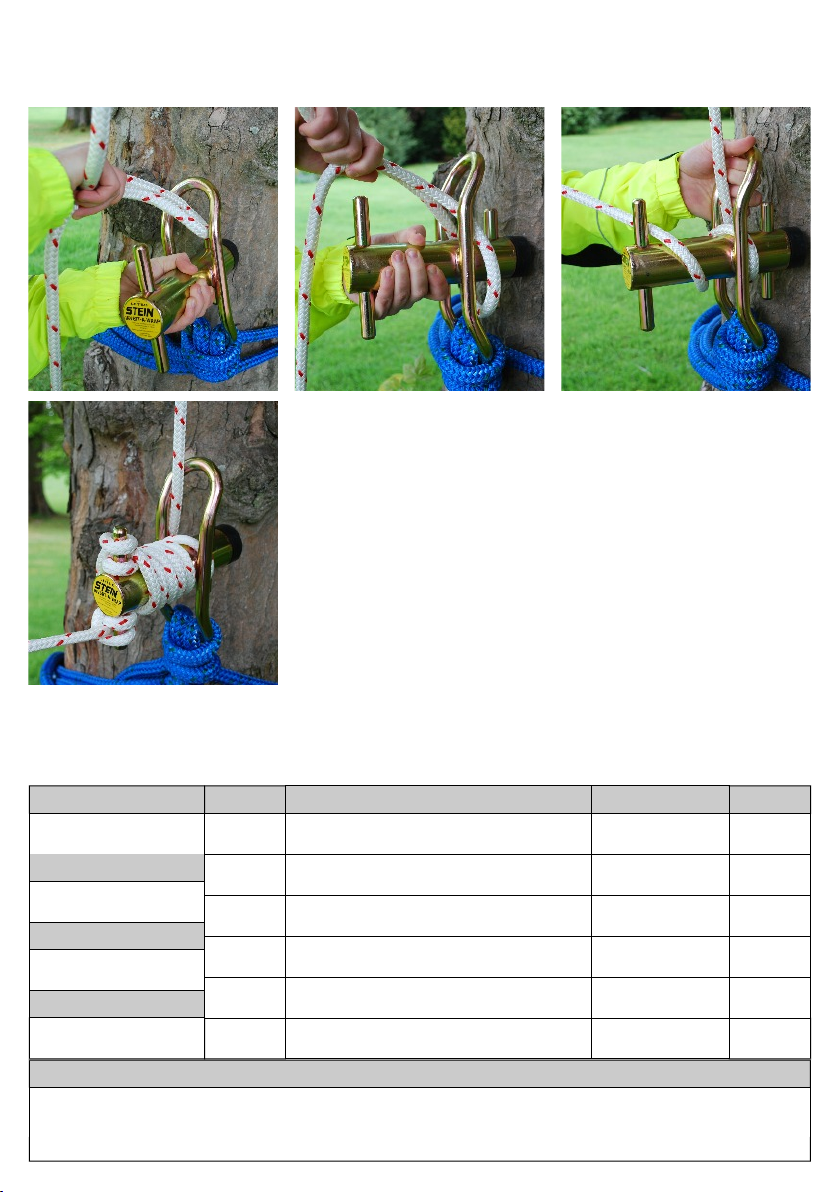

Only the techniques shown in the diagrams are authorised. Any other use deviating from those shown may result in serious

injury or death.

Prior to each use a complete risk assessment must be carried out to ascertain that the device chosen configures with and is

appropriate to the work being undertaken. The device chosen must also be compatible with all the other components within the

system.

Users must always ensure that all components of the work system are suitable for the foreseeable loadings that may be applied

during use. Poor technique and shock loading may cause catastrophic failure of this equipment and should be avoided. Where

a failure of the product may occur a suitable backup system must be installed and used. All components of the system used with

the device must be inspected before and after each lowering/lifting operation. Retire the device from use if there are any tactile

or visual signs of wear or damage. The retention devices must also be inspected & checked for both tension and wear after each

lowering or lifting operation to ensure they are securely attached to the device and the mounting point.

The Lowering Device should only ever be used with the correct diameter of rope, You must never exceed the recommended

maximum diameters. Each device has a Working Load Limit (WLL) – This is the maximum load allowed to be applied to the

device either for lifting or lowering above which catastrophic failure will occur. These values are based on a vertical load being

applied and used as specified within these instructions.

This device has been issued with a Working Load Limit (WLL) it is your responsibility to ensure that all the components used in

conjunction with the device are matched equally with their Working Load Limit (WLL) or Safety Factor (SF) or Safe Working Load

(SWL). If you are unsure on a products individual specifications you should contact the manufacturer. You should never exceed

the lowest rated section or component within a rigging system. When calculating any rigging system the strength of the anchor

and attachment points must also be taken into account. The Working Load Limit is based on using a sufficiently rated Anchor

Sling

·This device must never be used for lifting or lowering people. They are not intended or rated for use as Personal Protective

Equipment. (PPE)

·Always keep body parts, loose clothing, and debris away from the device when in use.

·Always use appropriate hand protection when operating the device.

·When holding the working line NEVER wrap the line around your hands or other body parts. Always ensure it can run freely

in case you need to release the line in an emergency.

·Do not stand or allow others to stand directly under the load being lowered or under the work being performed above.

Ensure users and other persons are working and operating the device from a safe distance.

·Any potential shock loading must always be kept to an absolute minimum when using the device as with all rigging

equipment.

·All connecting devices or components must be retired from use if they are subjected to impact loading.

·To avoid damage to the device you must minimise all if any free fall distance.

·Always maintain control of any lowered load.

·Products covered under these instructions should never be resold or used by a third party after it has been used by the

original purchaser.

·The manufacturer recommends this product should be inspected prior to use along with periodically independent inspection

in line with UK LOLER 1998.

Model Maximum Rope Diameter Working Load Limit (WLL)

LD750 13mm 750kg

Manufacturer Details

Fletcher Stewart (Stockport) Limited

Newby Road Industrial Estate

Hazel Grove, Stockport Cheshire SK7 5DA

United Kingdom

Tel: +44 (0)161 483 5542 Fax: +44 (0)161 483 5569

The manufacturer reserve the right to change specifications or modify

these instructions without prior notification. E & O E

As part of any method statement we recommend that all

users of this equipment must be given a copy of these

instructions. They must read them, understand them and

explicitly follow all instructions and cautions attached.

Any person using this equipment should be fully trained

and competent in its use before carrying out any rigging

operations.