Steketee EC-RIDGER 7 User manual

OPERATING INSTRUCTIONS

HOEING MACHINE

EC-RIDGER

en-GB | Item no. 17515198 | BA 00/02.2021

Ensure that these instructions are always available when using the machine

and can be accessed by all users..

●

Keep these instructions for the entire service life of the machine.

●

Pass these instructions to all users / owners.

Original instructions

©2021 | This documentation is copyright protected. All rights remain with Machinefabriek Steketee BV,

Lieve Vrouwepoldersedijk 1a, 3243 LA Stad aan ’t Haringvliet/Netherlands.

The texts, diagrams and drawings must not be duplicated, distributed or disclosed in any other way,

either in whole or in part, without express approval.

Table of contents

1 About these instructions....................................................................................................................................... 1

1.1 Introduction......................................................................................................................................................... 1

1.2 Target groups...................................................................................................................................................... 2

1.3 Applied symbols................................................................................................................................................ 2

1.3.1 Design of warning signs.............................................................................................................................. 2

1.3.2 Signal words and hazard statements...................................................................................................... 3

1.3.3 Warning of property damage.................................................................................................................... 3

1.3.4 Other notices and information.................................................................................................................. 3

1.3.5 Symbols and text markings........................................................................................................................ 4

1.3.6 Direction specications................................................................................................................................ 4

1.4 Further applicable documents..................................................................................................................... 5

2 Safety.............................................................................................................................................................................. 6

2.1 Intended use........................................................................................................................................................ 6

2.2 Personnel qualication requirements........................................................................................................ 8

2.3 Hazardous areas................................................................................................................................................. 8

2.4 Workplaces and passengers........................................................................................................................ 10

2.5 Technically perfect condition..................................................................................................................... 11

2.6 Safe handling.................................................................................................................................................... 12

2.6.1 Personal protective equipment.............................................................................................................. 12

2.6.2 Driving the tractor-machine combination......................................................................................... 13

2.7 Safety devices and labels............................................................................................................................. 13

3 Design and description........................................................................................................................................ 15

3.1 Machine overview........................................................................................................................................... 15

3.2 Machine safety................................................................................................................................................. 17

3.2.1 Meaning of the labels................................................................................................................................. 17

3.2.2 Safety devices............................................................................................................................................... 20

3.3 Type plate.......................................................................................................................................................... 21

3.4 Headstock.......................................................................................................................................................... 22

3.5 Wheels and rollers........................................................................................................................................... 22

3.6 Hoeing elements............................................................................................................................................. 24

3.7 Tools .................................................................................................................................................................... 26

4 Attaching.................................................................................................................................................................... 29

4.1 Checking suitability of the tractor............................................................................................................. 29

4.2 Preparations on the tractor......................................................................................................................... 30

4.3 Mounting the machine................................................................................................................................. 31

5 Road travel................................................................................................................................................................. 34

5.1 Information on road travel........................................................................................................................... 34

Table of contents

en-GB | Item no. 17515198 | BA 00/02.2021 I

5.2 Preparing for road travel.............................................................................................................................. 35

6 Operation................................................................................................................................................................... 36

6.1 Basic procedure............................................................................................................................................... 36

6.2 Basic operation................................................................................................................................................. 37

6.2.1 Lifting and lowering the hoeing elements mechanically............................................................. 37

6.2.2 Lifting and lowering the Combi-Element hydraulically................................................................. 39

6.3 Changing the setup state............................................................................................................................. 40

6.3.1 Replacing the toolbar - EC-Ridger 9...................................................................................................... 40

6.4 Adjusting the machine.................................................................................................................................. 43

6.4.1 Required adjustments prior to operation........................................................................................... 43

6.4.2 Aligning the hoeing machine with support wheels ...................................................................... 45

6.4.3 Aligning the hoeing machine without support wheels ............................................................... 48

6.4.4 Checking and adjusting distances of the hoeing elements......................................................... 49

6.4.5 Selecting and adjusting tools.................................................................................................................. 52

6.4.6 Adjusting the working depth of the hoeing elements.................................................................. 56

6.5 Test run............................................................................................................................................................... 57

6.6 Working with the machine.......................................................................................................................... 57

7 Cleaning and care................................................................................................................................................... 60

7.1 After working in the eld.............................................................................................................................. 60

7.2 Cleaning with high-pressure cleaner....................................................................................................... 60

8 Detaching................................................................................................................................................................... 61

8.1 Preparing detaching...................................................................................................................................... 61

8.2 Detaching the machine................................................................................................................................ 61

9 Maintenance and repair work.......................................................................................................................... 62

9.1 Maintaining the machine properly........................................................................................................... 62

9.1.1 Preparations.................................................................................................................................................. 62

9.1.2 During the maintenance and repair..................................................................................................... 62

9.2 Maintenance..................................................................................................................................................... 63

9.2.1 Maintenance schedule............................................................................................................................... 63

9.2.2 Tractor connection...................................................................................................................................... 64

9.2.3 Frame............................................................................................................................................................... 64

9.2.4 Checking safety devices............................................................................................................................ 65

9.2.5 Hydraulics....................................................................................................................................................... 65

9.2.6 Electrics............................................................................................................................................................ 66

9.2.7 Soil working tools........................................................................................................................................ 66

9.3 Lubricating......................................................................................................................................................... 67

9.3.1 Lubrication schedule.................................................................................................................................. 67

9.3.2 Lubricating components via grease nipples..................................................................................... 67

9.3.3 Grease components.................................................................................................................................... 69

Table of contents

en-GB | Item no. 17515198 | BA 00/02.2021II

10 Troubleshooting and error correction......................................................................................................... 70

10.1 Find and eliminate errors correctly........................................................................................................ 70

10.1.1 Prior to troubleshooting at the implement..................................................................................... 70

10.1.2 When troubleshooting and eliminating errors.............................................................................. 70

10.2 Error - Cause - Remedies at a glance...................................................................................................... 71

11 Shutdown and disposal....................................................................................................................................... 73

11.1 Shutdown........................................................................................................................................................ 73

11.2 Disposal............................................................................................................................................................ 73

12 Technical data.......................................................................................................................................................... 74

12.1 Dimensions..................................................................................................................................................... 74

12.2 Machine weights........................................................................................................................................... 74

12.3 Performance data......................................................................................................................................... 75

12.4 Connection data............................................................................................................................................ 76

12.4.1 Electrical connections.............................................................................................................................. 76

12.4.2 Hydraulic connections............................................................................................................................. 76

12.5 Noise, airborne sound................................................................................................................................. 76

12.6 Operating materials..................................................................................................................................... 77

12.7 Tyres and wheels........................................................................................................................................... 77

12.8 Connecting equipment at the implement.......................................................................................... 78

Index............................................................................................................................................................................. 79

Appendix.................................................................................................................................................................... 83

A Tightening torques............................................................................................................................................ 84

B Calculating the axle load and ballasting for mounted implements................................................ 86

C Cross shaft overview......................................................................................................................................... 90

Table of contents

en-GB | Item no. 17515198 | BA 00/02.2021 III

Table of contents

en-GB | Item no. 17515198 | BA 00/02.2021IV

1 About these instructions

1.1 Introduction

These operating instructions are important and belong to the

machine's scope of delivery.

These operating instructions must be available to the user at the place

of use.

nAlways read chapter "Safety" before using the machine for the rst

time.

nRead chapter "Operation - Basic operation" before using the

machine for the rst time.

nBefore starting work, also read the relevant steps in the operating

instructions.

For an unambiguous assignment of this document to the machine,

transfer the following data from the type plate of the machine

Ä

Chapter 3.3 ‘Type plate’ on page 21:

Designation on the type

plate

Enter the machine data here:

Series

Type designation

Model year

Serial number

Year of manufacture

The machines can be equipped dierently at the factory.

Standard components, special equipment or optional accessories are

not marked separately.

The contents of these operating instructions, e.g. illustrations, may

therefore dier from the equipment of the machine.

Depending on the equipment, additional documents may be required

for operation.

Observe the operating instructions

Validity range

Equipment variants

About these instructions

en-GB | Item no. 17515198 | BA 00/02.2021 1

These operating instructions do not describe initial commissioning.

INFORMATION

Prior to operation, initial commissioning and instruction

in operation, setting and maintenance must have been

carried out by the dealer.

1.2 Target groups

The target groups of these operating instructions are operators, users

and service personnel of the machine.

The target groups must meet the requirements for the qualication of

the personnel Ä, see page 8.

1.3 Applied symbols

1.3.1 Design of warning signs

The warning signs in these instructions have the following design:

WARNING

Type and source of hazard

Possible consequences of non-adherence

– Measures for hazard avoidance

The signal word indicates the risk level.

Initial commissioning

About these instructions

en-GB | Item no. 17515198 | BA 00/02.20212

1.3.2 Signal words and hazard statements

The following signal words and hazard statements are used to label

warning signs and to warn of residual risks:

DANGER

Indicates an immediate hazardous situation

If the hazardous situation is not avoided, it will result in

death or serious injury.

WARNING

Indicates a hazardous situation

If the hazardous situation is not avoided, it may result in

death or serious injury.

CAUTION

Indicates a hazardous situation

If the hazardous situation is not avoided, it may result in

moderate or minor injury.

1.3.3 Warning of property damage

ATTENTION

Indicates a situation that may result in property

damage

If the situation is not avoided, it may result in damage to

the machine or to objects in the vicinity of the machine.

1.3.4 Other notices and information

INFORMATION

Indicates tips and useful information for the user

The tips and information facilitate work. This ensures

proper use of the machine.

ENVIRONMENTAL PROTECTION

Indicates notices and special measures regarding

environmental protection

The tips and information on environmental protection

facilitate environmentally friendly use of the machine.

About these instructions

en-GB | Item no. 17515198 | BA 00/02.2021 3

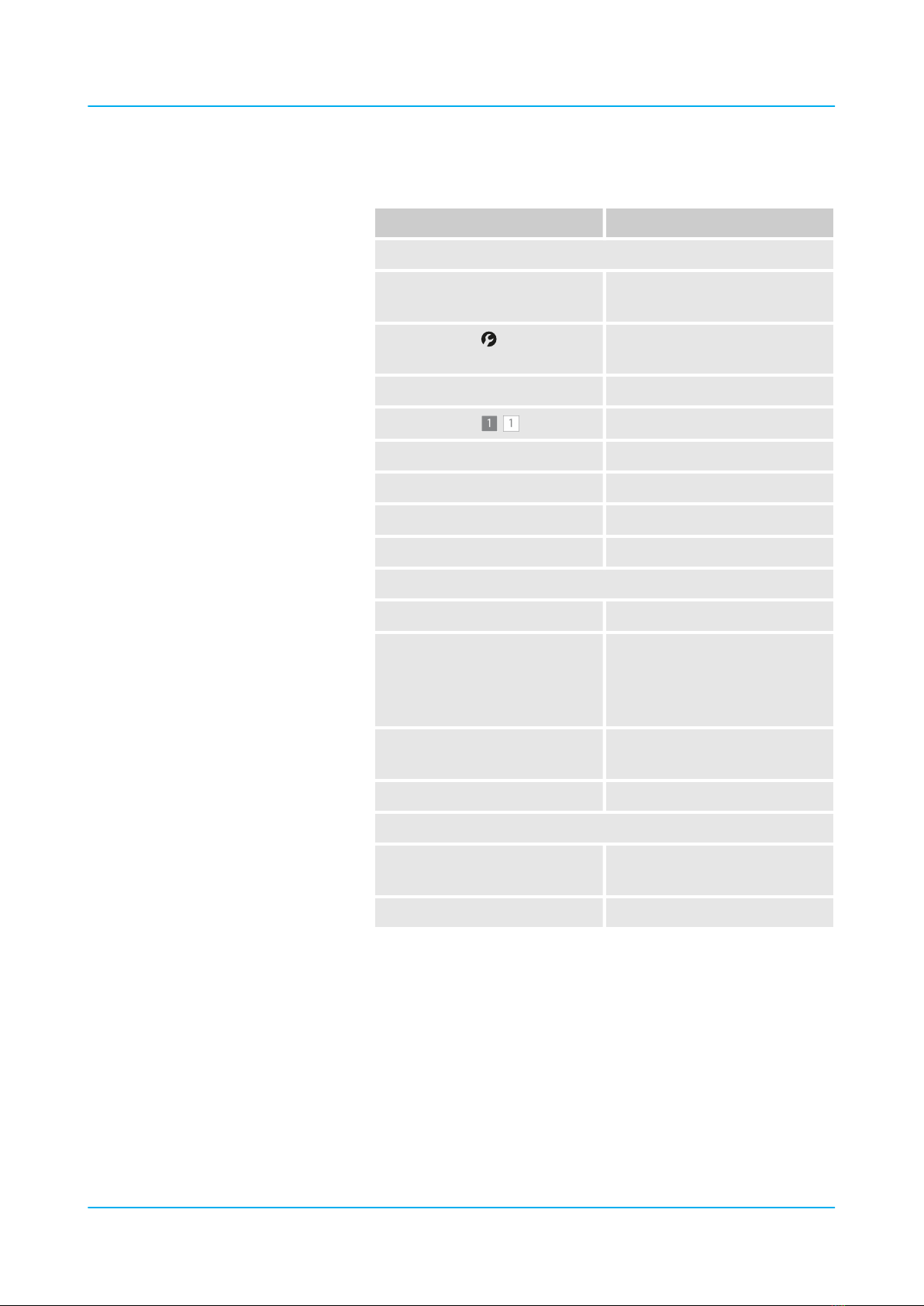

1.3.5 Symbols and text markings

Symbol, text marking Meaning

In front of and in texts

●Marking for routine maintenance

tasks

Activities that demand the help

of service sta.

nListing

[1], , Position numbers

Example: ‘Settings’ Software element

Example: [OK] Softkey, key, switch and button

[kg] Unit

ÄCross reference

In work instructions

√ Preconditions

►nWorking steps in single-step

work instructions

nMeasures for hazard avoid‐

ance in safety information

1.

2.

Working steps in multi-step work

instructions

ðResult

In illustrations

Light grey coloured components Non-relevant components, visible

to facilitate orientation

Yellow coloured components Action-relevant components

1.3.6 Direction specications

The direction specications used in the text (left, right, front and rear)

refer to the direction of travel of the tractor when moving forwards, i.e.

in normal operation.

About these instructions

en-GB | Item no. 17515198 | BA 00/02.20214

1.4 Further applicable documents

Further documents to be observed:

nOperating instructions of the tractor

nFor partially assembled or disassembled delivery:

Mounting instructions

nSpare-parts list

nOperating instructions for the combination machine

INFORMATION

In other documents and in sections of these operating

instructions, the machine is also referred to as an imple‐

ment.

About these instructions

en-GB | Item no. 17515198 | BA 00/02.2021 5

2 Safety

2.1 Intended use

The machine is used for mechanical weed control between and in rows

of crops on agricultural land.

It may only be used in accordance with the recognised rules of good

agricultural practice.

The crops must be planted in parallel and in rows. The distance

between the rows must be at least 15 cm throughout.

The ground clearance of the hoeing machine is:

n50 cm for hoeing machines with Basic-Elements (with special

design of the Basic-Element 70 or 100 cm)

n70 cm for hoeing machines with Combi-Elements

n70 cm for hoeing machines with TRS-Elements

Cultivating takes place in dry weather conditions.

►Only suciently qualied personnel may use the machine.

ÄPersonnel qualication requirements, see page 8.

►Only use the machine with a suitable tractor.

►When using the machine, observe the permitted loads and weights

for the tractor, machine and tractor-machine combination.

►Only combine the machine with suitable combination machines.

Limitations

Personnel

Tractor

Combination machine

Safety

en-GB | Item no. 17515198 | BA 00/02.20216

The operating instructions are part of the machine. The machine is

intended exclusively for use in accordance with these operating

instructions. Applications of the machine not described in these oper‐

ating instructions may result in personal injury or death or property

damage. If applications other than those described in the operating

instructions are planned, obtain the prior written consent of the manu‐

facturer. This also applies to unauthorised modications and alterations

to the machine.

►Observe the operating instructions and follow the working steps

given therein.

►Clarify questions of comprehension concerning the contents of

these operating instructions before starting work. If necessary, con‐

tact the manufacturer’s sales partner.

INFORMATION

In other documents and in sections of these operating

instructions, the machine is also referred to as an imple‐

ment.

►Operate the machine only in a technically perfect condition.

►Observe the maintenance instructions. Perform all the necessary

tests.

►Use original spare parts or parts approved by the manufacturer.

►Only use the auxiliary and operating materials listed.

►Dispose of auxiliary materials and operating materials in an envi‐

ronmentally responsible manner.

Liability and warranty are excluded if personal injury and damage to

property can be traced back to improper use or non-observance of the

operating instructions.

Operating instructions

Technically perfect condition

Liability and warranty

Safety

en-GB | Item no. 17515198 | BA 00/02.2021 7

2.2 Personnel qualication requirements

The operator is obliged to inform all the users about correct application

of the machine and the respective hazards. This can be done on the

basis of these operating instructions. The operator is responsible for

ensuring that the operating instructions are always available at the

machine and that the users observe the operating instructions. The

operator must also provide any necessary personal protective equip‐

ment.

Users are persons who drive, adjust, operate or maintain the machine.

Users must be able to use the machine safely. This means:

nUsers understand how the machine works.

nUsers know and are able to avoid dangers.

nUsers are physically capable of controlling the machine.

In order to use the machine as intended and in a professional manner,

users must have the required technical (agricultural) knowledge.

Unless otherwise indicated, users may carry out all activities described

in these operating instructions themselves.

Certain activities should only be performed by service personnel, e.g.

work on braking systems. These activities are indicated in the operating

instructions by the symbol .

Service personnel within the meaning of these instructions are all per‐

sons who maintain and repair safety-relevant components. Service per‐

sonnel are qualied for these activities based on their training and

expertise (for example agricultural machine mechanics).

2.3 Hazardous areas

If the hazardous areas are not heeded, this may result in death or

serious injury to personnel.

Only once all persons have left the hazardous areas: Switch on drives

and motors.

Any work required while the motor or drive is running in a hazardous

area requires special attention and precautions. Follow the instructions

for action in these operating instructions exactly.

Labels on the machine indicate the hazardous areas .

Operator

Users

Service personnel

Safety

en-GB | Item no. 17515198 | BA 00/02.20218

The hazardous area of the machine during operation.

b

Moving hazardous area

b

The hazardous area includes the area in the direction of travel across

the entire width

b

of the machine.

►NEVER climb out of the tractor while it is moving.

►NEVER allow other persons to board the tractor while it is moving.

►In addition, maintain a safety distance of 2 m from the machine.

►While driving on the eld, observe the entire hazardous area. Stop

if required.

When standing between the tractor and machine, there is a risk due to

tractor movements or sudden machine movements.

►Secure the tractor against rolling away.

►Before operating the linkage: Keep all persons away from the

movement area of the linkage.

Moving hazardous area

Hazardous area between the tractor

and machine

Safety

en-GB | Item no. 17515198 | BA 00/02.2021 9

The machine is equipped with components in which mechanical

energy is stored (e.g. springs, overload safety units). Uncontrolled

release of mechanical energy accelerates components like a projectile.

This may result in fatal or serious injuries.

►NEVER dismantle or open components that store mechanical

energy.

The hydraulic system is under high pressure. Leaking hydraulic oil can

penetrate through the skin into the body.

Risk of injury to body parts, face, eyes and unprotected skin areas

The hydraulic oil may be hot.

The hydraulic oil is harmful to health.

►When working on the hydraulic system:

Wear safety goggles and gloves.

►Check the condition of the hydraulic system according to the main‐

tenance schedule. Replace damaged or worn components of the

hydraulic system immediately.

►NEVER touch leaks without hand protection.

►If hydraulic oil has penetrated the body:

Seek medical attention immediately. Remove the hydraulic oil from

the body as quickly as possible. Risk of infection

2.4 Workplaces and passengers

The main workplace for working with the machine is the driver's seat in

the tractor. Further workplaces are described in the respective instruc‐

tions for action.

Dangerous situations may occur if several persons operate the machine

functions at the same time.

►Observe the hazardous areas.

►Pay attention to other persons in the vicinity of the machine.

Risk of injury due to stored mechan‐

ical energy

Risk of injury at the hydraulic system

Workplaces

Safety

en-GB | Item no. 17515198 | BA 00/02.202110

2.5 Technically perfect condition

Operational safety of the machine cannot be guaranteed without

proper preparations in accordance with these operating instructions.

This may result in fatal or serious injuries.

►Use the machine only after proper preparations.

Ä

Chapter 4.2 ‘Preparations on the tractor’ on page 30

If the technical limit values of the machine are not observed, the

machine will be damaged.

This may result in fatal or serious injuries.

►Adhere to machine-specic limit values Ä, see Technical

data page 74.

Damage to the machine can impair the operational safety of the

machine and cause accidents.

This may result in fatal or serious injuries.

To ensure that the machine is in a safe condition, carry out the fol‐

lowing measures:

►Inspect the machine according to the maintenance schedule

Ä, see page 63.

►Repair damage and eliminate causes of damage immediately.

►Remove coarse dirt.

If safety-relevant damage cannot be repaired in accordance with these

operating instructions:

►Have damage repaired by a qualied specialist workshop.

Operation only after proper prepara‐

tions

Observe the technical limit values

Danger due to damage to the

machine

Safety

en-GB | Item no. 17515198 | BA 00/02.2021 11

Structural modications and extensions can impair the functionality

and operational safety of the machine.

This may result in fatal or serious injuries.

Auxiliary equipment and spare parts that do NOT comply with the man‐

ufacturer's requirements may negatively aect the operational safety of

the machine and cause accidents.

►Modications and conversions may only be carried out with the

written consent of the manufacturer.

►Structural modications and extensions must only be carried out

by an authorised specialist workshop.

►Use original spare parts or parts approved by the manufacturer.

►Only use the auxiliary and operating materials listed

Ä, see page 77.

Improper welding work endangers the operational safety of the

machine.

This may result in fatal or serious injuries.

►Have welding work carried out by a qualied specialist workshop.

2.6 Safe handling

2.6.1 Personal protective equipment

Carrying and wearing protective equipment is an important safety

component.

Lack of or inappropriate protective equipment increases the risk of

damage to health and injury to persons.

For certain work on the machine, the following protective equipment is

required in addition to suitable workwear:

nSafety gloves

Use protective equipment as follows:

►Only use protective equipment that is in proper condition.

►Only use protective equipment that provides eective protection.

►Adapt protective equipment to the respective person, e.g. size.

Modications at the machine

Welding work

Safety

en-GB | Item no. 17515198 | BA 00/02.202112

2.6.2 Driving the tractor-machine combination

Mounted or trailed machines change the driving characteristics of the

tractor.

The driving characteristics also depend on the operating status, the

lling or loading and on the subsoil.

If the driver does not consider changed characteristics, accidents may

occur.

►Observe changed driving behaviour when driving.

Ä

Chapter 5 ‘Road travel’ on page 34

The tractor-machine combination may overturn:

nWhen folding in and out

nWhen driving on slopes

nWhen travelling around tight bends

This may result in accidents with injuries or death of persons or damage

to the machine.

►When folding in and out, make sure that the machine is standing

on a at surface.

►Observe driving behaviour when driving on a slope.

►Before travelling around tight bends: Reduce forward speed appro‐

priately.

2.7 Safety devices and labels

For the protection of the user, other persons and the machine, the

machine is equipped with special safety devices, e.g.:

nStabilisation

The actual equipment of the machine with safety devices depends on

the country-specic rules and regulations.

Ä

Chapter 3.2.2 ‘Safety devices’ on page 20

Dierent driving behaviour

Risk of tipping

Safety

en-GB | Item no. 17515198 | BA 00/02.2021 13

Existing and fully functional safety devices protect against death or

serious personal injury.

►Replace damaged safety devices.

►Install dismantled safety devices before commissioning.

►Move the safety devices to the protective position.

►In case of doubt whether all safety devices are properly installed

and fully functional: Commission a specialist workshop.

Labels on the machine warn of dangers at danger points and belong to

the safety equipment of the machine.

Missing labels increase the risk of fatal and serious injury.

►Clean dirty labels.

►Replace damaged, illegible or lost labels immediately.

►Provide spare parts with the provided labels.

Ä

Chapter 3.2.1 ‘Meaning of the labels’ on page 17

Keeping the safety devices fully func‐

tional

Keeping the labels legible

Safety

en-GB | Item no. 17515198 | BA 00/02.202114

This manual suits for next models

1

Table of contents

Other Steketee Farm Equipment manuals

Popular Farm Equipment manuals by other brands

McHale

McHale 991B Series Operator's instruction manual

Claydon

Claydon TERRABLADE Operator's manual

Arrowquip

Arrowquip Q-CATCH 86 Series product manual

AGROdeviate

AGROdeviate Hawkins StripCat owner's manual

Roto-Mix

Roto-Mix Roto-Spread 532-16B Operation and parts manual

Vicon

Vicon Andex 714 T Vario operating manual