Stellar®TMP16160 Owner’s Manual | Page iii

Table of Contents

Introduction.............................................................................................................................. iv

Chapter 1 - Specifications........................................................................................................... 1

Model TM16160 Capacity ....................................................................................................... 1

Model TM16160 Specifications................................................................................................ 2

TM16160 Dimensional Layout .................................................................................................. 3

Chapter 2 - Installation ................................................................................................................ 5

General Installation .................................................................................................................. 5

Installer Notice........................................................................................................................ 5

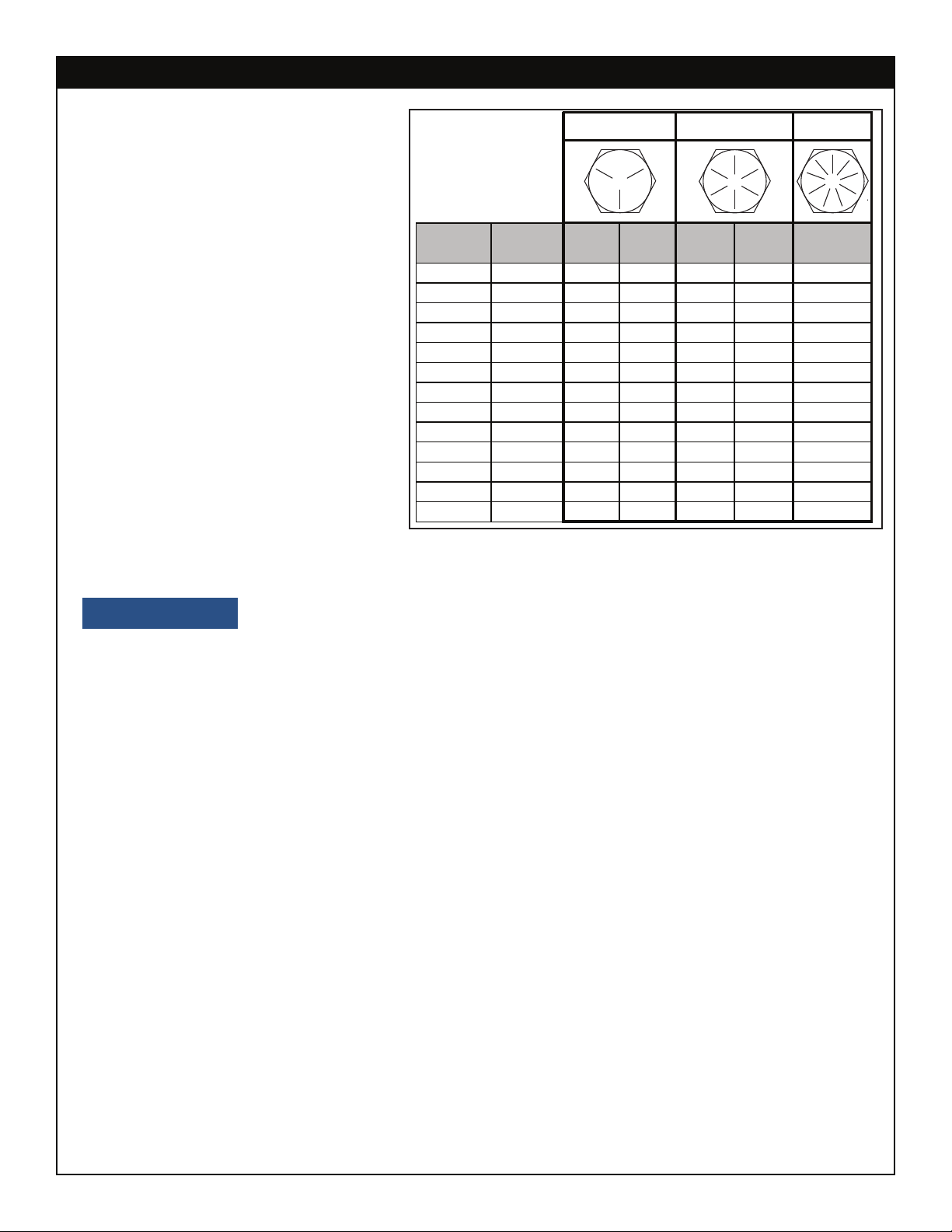

Torque Data Chart................................................................................................................. 6

Installation Overview ............................................................................................................. 7

Mounting Kit Drawing ............................................................................................................ 7

Hydraulic Installation ................................................................................................................ 8

Hydraulic Pressure Settings ...................................................................................................... 9

Face Seal/O-Ring Size Chart ................................................................................................... 9

Main Hydraulic Kit - PN 69197................................................................................................ 10

TireMan Hydraulic Kit - PN 68660........................................................................................... 11

Control Kit - PN 92667 ............................................................................................................. 12

Grease Kit - PN 68798 ............................................................................................................. 13

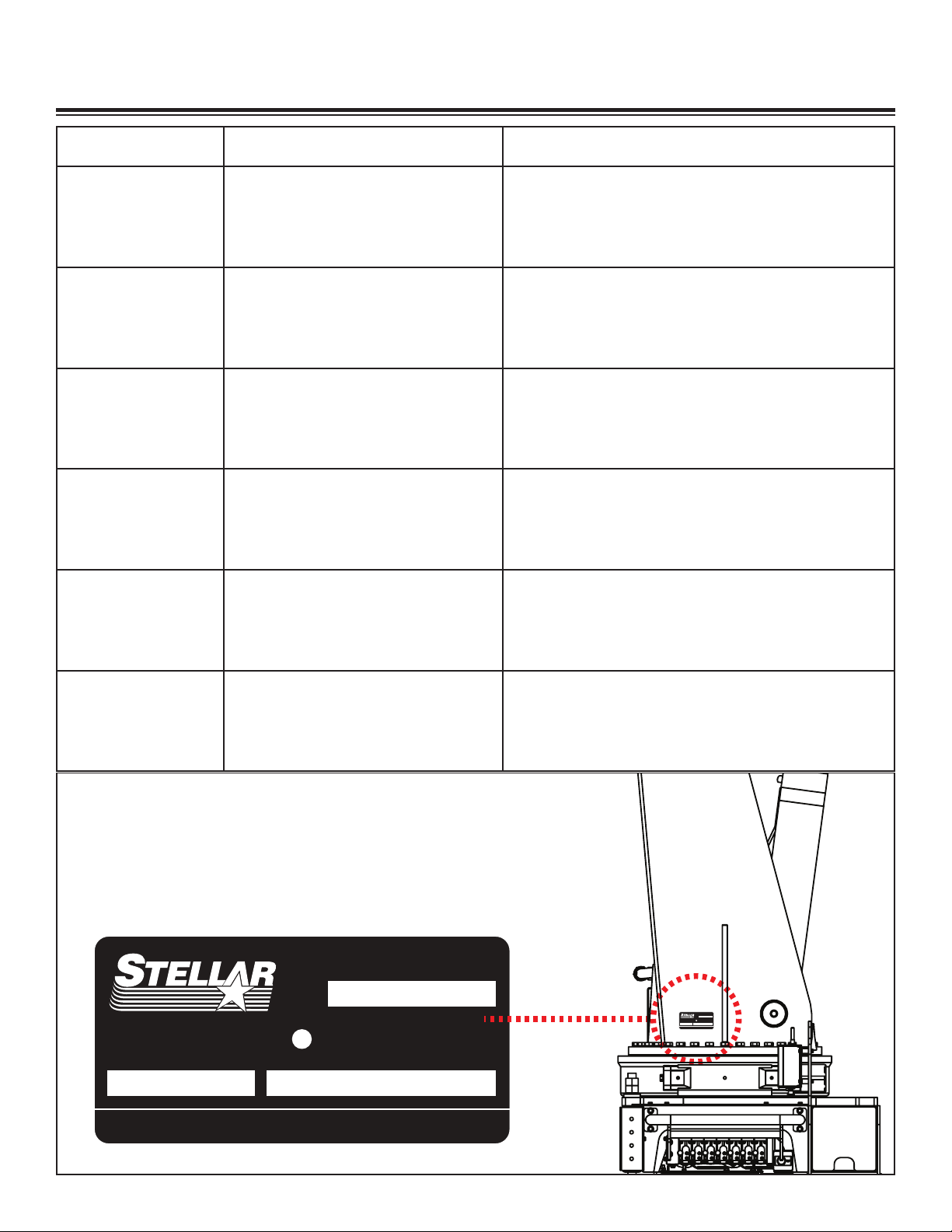

Main Decal Placement - PN 98664....................................................................................... 14

TireMan Decal Placement - PN 37845.................................................................................. 15

Chapter 3 - Assembly Drawings ............................................................................................... 17

Base Assembly - PN 47880 ..................................................................................................... 17

Optional Load Sensor Base - PN 67062 ................................................................................ 18

Stabilizer Assembly - PN 48689............................................................................................... 19

Bearing Assembly - PN 18471 ................................................................................................ 20

Gearbox - PN 60505 ............................................................................................................... 21

Valve Bank - PN 42802............................................................................................................ 22

Mast Assembly - PN 18073 ..................................................................................................... 23

Main Boom Assembly - PN 68021.......................................................................................... 24

Main Cylinder Assembly - PN 20694...................................................................................... 25

Outer Cylinder Assembly - PN 50628 .................................................................................... 26

Extension Boom Assembly - PN 70661 .................................................................................. 27

TireMan Assembly - PN 67861 ................................................................................................ 28

TireMan Assembly (cont.) - PN 67861 ................................................................................... 29

Stabilizer Cylinder Assembly - PN 48383 ............................................................................... 30

Reservoir Assembly - PN 86356 .............................................................................................. 31

Optional 15 Ton Hook Kit - PN 55138..................................................................................... 32

Radio Transmitter - PN 89149/93084...................................................................................... 33

Chapter 4 - Replacement Parts ................................................................................................ 35