STEP ST550 User manual

MB

Installation manual

STEP Motor lock ST550/551

Edition 1 2021

When it has to work.

Stendals El AB, Signalistgatan 17, 721 31 Västerås, Sweden

+46 (0)21-18 97 50 | info@steplock.se | www.steplock.se

Article number

Accessories

Specications

Dimensional drawing

Control unit overview

Features control unit

Open - Open signal

External door sensor - External door magnet signal

Exit reset - Reset alarm

AUX in - Re-entry / Panic locking

Lock - Communication and voltage

OSDP signal

Electric lock - Electric strike signal

GND

15-30V AC / DC - Supply voltage

Bolt locked - Bolt out and locked

Bolt open - Bolt in

Lock alarm - Communication alarm

Door open / closed - Magnetic contact

Exit alarm - Manual unlocking

AUX 1 - Programmable function

AUX 2 - Programmable function

AUX 3 - Programmable function

AUX 4 / Tamper - Programmable function

Technical data

Power consumption

Complete set

Installation instructions

Turn the latch bolt

Attach the drill protection

Connection of ST550 / ST551 with STEP cable

Connection of ST550 / ST551 with separate cable

Activation of active signal

Cable dimensions

Initiation

Location of the strike plate

Content

Menu structure overview

1: Time & Date

2: Sync Mode

3: Door sensor

4: Timers Setup

5. Re-entry setup

6: Input setup

7: Relay setup

8: AUX Rel Menu

9: SSF3522

10: Service Due

11: FW ver menu

12: Factory Reset

13: Log Menu

14: Debug menu

Dimensions

Evacuation and re-entry

STEP Exit emergency device

Troubleshooting

Performance specications

Maintenance

Important information

Note of selected settings

Notes

Contact

3

3

3

4

5

6

6

6

6

6

7

7

7

7

8

8

8

8

8

9

9

9

9

9

10

10

11

12

12

12

13

14

15

15

15

16

17

18

18

18

19

19

20

21

22

23

23

24

24

24

24

25

26

26

27

27

28

28

29

30

31

3

ARTICLE NUMBER

ACCESSORIES

Accessories for ST550 and ST551

Art no. Description

ST500C STEP Control unit

ST1283 STEP Lead cover

ST0916 10 m cable 0,25 mm2 with 8 leaders.

ST0917 20 cm cable with adapter

ST1192 Skrew and magnet set.

ST1199 Drill protection

ST0918-1 Reinforcement plate with recess for cylinder. In polished stainless steel.

ST0918-2 Reinforcement plate with recess for cylinder. In brushed stainless steel.

ST0919-1 Reinforcement plate without recess for cylinder. In polished stainless steel.

ST0919-2 Reinforcement plate without recess for cylinder. In brushed stainless steel.

ST0910 Magnet

ST17999-70 Spindle 70 mm

ST17999-105 Spindle 105 mm

ST17999-140 Spindle 140 mm

ST17988-70 Cylinder spindle 70 mm

ST9009-15 Strike plate

Art no. Description

ST550 STEP 550 Motor lock. With modern bolt placement and latch lock. 50 mm back set.

ST550 KPL STEP 550 complete set. Incl. ST550, STEP Control unit, STEP Lead cover, 10 m cable, mechanical strike plate,

skrew and magnet set.

ST550 LB STEP 550 Lock and Control unit set. Incl. ST550, STEP Control unit, 20 cm cable and skrew set.

ST551 STEP 551 Motor lock. With modern bolt placement and latch lock. 50 mm back set.

ST551 KPL STEP 551 complete set. Incl. ST551, STEP Control unit, STEP Lead cover, 10 m cable, mechanical strike plate,

skrew and magnet set.

ST551 LB STEP 551 Lock and Control unit set. Incl. ST550, STEP Control unit, 20 cm cable and skrew set.

SPECIFICATIONS

Motor lock ST550 and ST551 certied according to SS-EN 14846:2008

1 2 3 4 5 6 7 8 9

Category

of use Durability and

load on latchbolt Door mass and

closing force

Suitability for

use on re/smoke

doors Safety Corrosion resistance,

temperature and humidity Security and

drill resistance

Security

electrical

function

Security

electrical

manipulation

3 X 9 F L 7 1 3

SSF 3522

Motor lock ST550 and ST551 certied

according to Class 5 SSF 3522 Edition. 2. CERTIFIERAD

Certicate C900547 | edition 1 | 2021

4

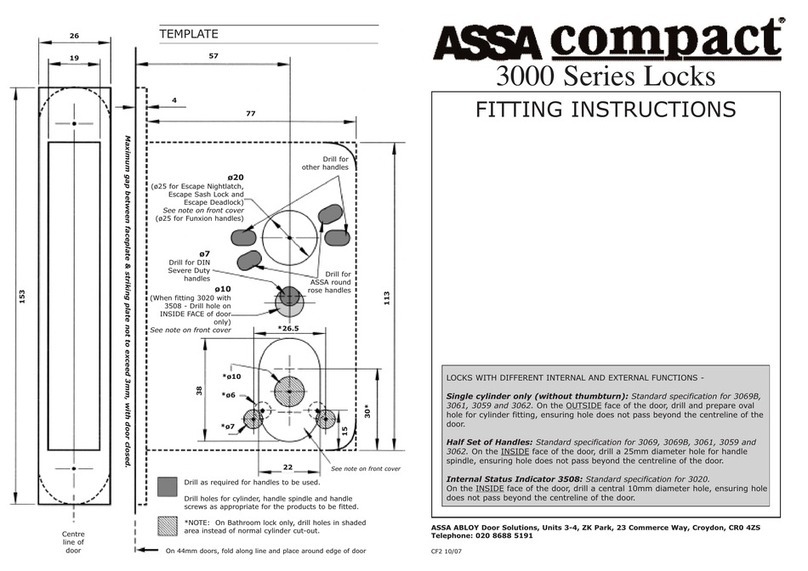

DIMENSIONAL DRAWING 550

DIMENSIONAL DRAWING 551

50

63

37

105

150

15,5

127

1666,5

75

19,5

22

14

203

225

50

63

37

150

15,5

127

75 19,5

22

203

225

54

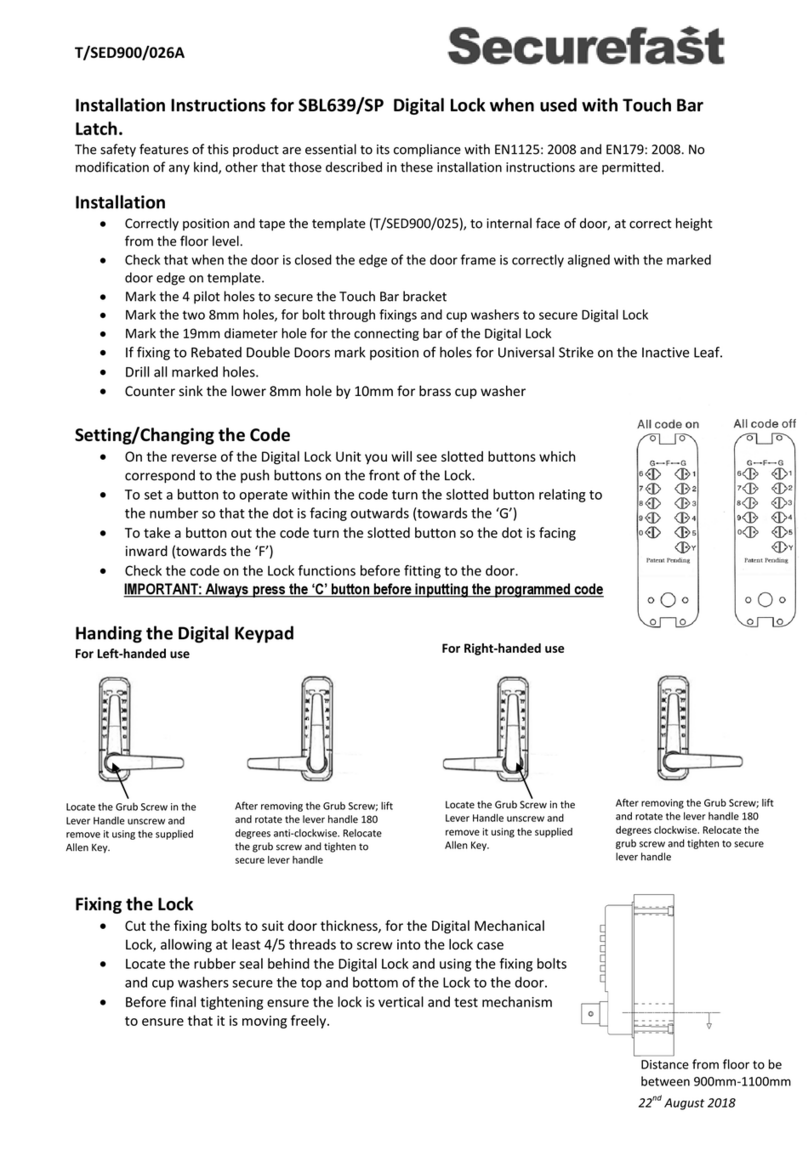

CONTROL UNIT OVERVIEW ST500C

BOLT #1

LOCKED BOLT #1 OPEN BOLT #2

LOCKED BOLT #2 OPEN DOOR

OPEN/

CLOSED

LOCK

ALARM EXIT

ALARM AUX 4/

TAMPER

AUX 1 AUX 2 AUX 3

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NO

COM

NO

COM

NO

COM

NO

COM

NO

COM

NO

COM

IN#1-

IN#1+

IN#2-

IN#2+

IN#3-

IN#3+

IN#5-

IN#5+

A+

B-

VCC

GND

IN#4-

IN#4+

A+

B-

VCC

GND

A+

B-

GND

OPEN#1 OPEN#2 EXT

DOOR

SENSOR

EXIT

RESET Electric

Lock 15-30V

AC/DC

AUX IN LOCK#1 LOCK#2 OSDP

-

GND

+

1 2 3 4 5 6 7 8 9 11

10

Input signal Description Function

IN#1 OPEN#1 Open signal lock 1

IN#2 OPEN#2 Open signal lock 2

IN#3 EXT DOOR SENSOR Extern door sensor

IN#4 EXIT RESET Reset alarm

IN#5 AUX IN Re-entry/Panic locking

LOCK#1 LOCK#1 Communication and voltage Lock 1

LOCK#2 LOCK#2 Communication and voltage Lock 2

OSDP OSDP OSDP-signal

Electric Lock Electric Lock Electric strike signal

GND GND Ground

AC/DC 15-30V AC/DC Supply voltage

Output signal Description Function

Relay #1 BOLT #1 LOCKED Bolt out and locked, Lock 1

Relay #2 BOLT #1 OPEN Bolt open, Lock 1

Relay #3 LOCK ALARM Communication alarm

Relay #4 BOLT #2 LOCKED Bolt out and locked, Lock 2

Relay #5 BOLT #2 OPEN Bolt open, Lock 2

Relay #6 DOOR OPEN/CLOSED Magnet

Relay #7 EXIT ALARM Manual unlocking

Relay #8 AUX 1 Programmable function

Relay #9 AUX 2 Programmable function

Relay #10 AUX 3 Programmable function

Relay #11 AUX 4/TAMPER Programmable function/Tamper

6

IN#1 OPEN#1 Öppnasignal lås 1

IN#2 OPEN#2 Öppnasignal lås 2

IN#3 EXT DOOR SENSOR Extern dörrmagnetsignal

IN#4 EXIT RESET Återställning larm

IN#5 AUX IN Re-entry/Paniklåsning

Open - Open signal

Activated by potential-free closing (default).

Can be changed to active.

OPEN # 1 Used to open lock 1 or lock 1 and

lock 2 in synchronized mode.

Open # 2 is only used to open

lock 2 in unsynchronized mode.

External door sensor - External door

magnet

Connection of external magnetic sensor for

door sensing. Can replace or be

combined with the internal door magnet.

Exit reset

For resetting the re-entry function. Used to

return to normal operation of the lock after

evacuation.

Reset can also be done via mechanical

cylinder.

AUX in - Re-entry function/Panic lock

Relay connection for re alarm or panic lock.

In the event of a re alarm, re-entry is

activated after passage. Applies to both

mechanical and electrical exit.

Panic lock function locks an unlocked door

and blocks unlocking. This feature overrides

the opening signal.

FEATURES CONTROL UNIT

76

LOCK#1

LOCK#1

Kommunikation och spänning Lås 1

LOCK#2

LOCK#2

Kommunikation och spänning Lås 2

OSDP

OSDP

OSDP signal

Electric Lock

Electric Lock

Elslutblecksignal

GND

GND

Jord

Lock - Communication and voltage

Connection of STEP motor lock

LOCK # 1 is used to connect lock 1.

LOCK # 2 is used to connect lock 2.

(It is possible to connect both locks

to LOCK # 1)

OSDP signal

Prepared for connection of OSDP signal.

Electric lock - Electrical end plate signal

Connection of STEP electric lock / electric

strike.

Controlled by OPEN # 1 and is activated as

long as the bolt is in.

The supply voltage to the control unit

also controls voltage to electrical strike.

GND

Connection of shielded cable.

8

Relay #1 BOLT #1 LOCKED Regel ute och förreglad, Lås 1

Relay #4 BOLT #2 LOCKED Regel ute och förreglad, Lås 2

Relay #2 BOLT #1 OPEN Regel inne, Lås 1

Relay #5 BOLT #2 OPEN Regel inne, Lås 2

Relay #3 LOCK ALARM Kommunikationslarm

Relay #6 DOOR OPEN/CLOSED Magnetkontakt

AC/DC 15-30V AC/DC Supply voltage

15-30V AC / DC - Supply voltage

Connection of supply voltage. The terminal is

potential-free and can be supplied with

15-30V AC / DC.

Bolt locked - Bolt out and locked

BOLT LOCKED activates relay when

the door is locked (bolt out and

locked).

BOLT # 1 LOCKED activates relay

from lock 1.

BOLT # 2 LOCKED activates relay

from lock 2.

Bolt open - Bolt in

BOLT OPEN activates relay when

the door is unlocked (Bolt in).

BOLT # 1 OPEN activates relay from

lock 1.

BOLT # 2 OPEN activates relay from

lock 2.

Lock alarm - Alarm in the event of a

malfunction

LOCK ALARM is activated at:

• Broken door

• Communication error / cable tampering

Prevented locking / unlocking

Restore to normal operation by repairing

the cause of the alarm or via EXIT RESET.

Door open / closed - Magnetic contact

DOOR OPEN / CLOSED activates the relay

for magnetic contact when the door is closed.

98

Relay #7 EXIT ALARM Manuell upplåsning

Relay #8 AUX 1 Programerbar funktion

Relay #9 AUX 2 Programerbar funktion

Relay #10 AUX 3

Programerbar funktion

Relay #11 AUX 4/TAMPER Programerbar funktion/Styrenhet öppnad

Exit alarm - Indication of mechanical unlocking

EXIT ALARM activates relay for unlocking via

key, cylinder knob or evacuation accessory

AUX 1 - Selectable function

AUX 1 activates the relay depending on func-

tion selection. The default is Vital

Closed (the door is closed and locked).

Selectable functions can be found on page

22 (8. AUX Rel menu)

AUX 2 - Selectable function

AUX 2 activates the relay depending on

function selection. The default is Vital open

(the lock is unlocked).

Selectable functions can be found on page

22 (8. AUX Rel menu)

AUX 3 - Selectable function

AUX 3 activates the relay depending on

function selection. The default is Service Due.

Selectable functions can be found on page

22 (8. AUX Rel menu)

AUX 4 / Tamper - Selectable function

AUX 4 / Tamper activates the relay depending

on function selection. The default is Tamper

(Sabotage contact control unit cover).

Selectable functions can be found on page

22 (8. AUX Rel menu)

10

TECHNICAL DATA

Security:

Grade 7 SS-EN 14846.

Class 5 SSF-3522.

Factory tested:

1 700 000 cycles

Fire approved:

E/EI 120 (ST550)

Certied according to:

SS-EN 179:2008

Certicate

• Certied in class 5 per SSF 3522.

• Certied in Grade 7 per SS-EN 14846.

• Certied in Grade M for corrosion, temperatures and humidity, which

corresponds to high requirements according to SS-EN 14846.

• Certied for re rated doors in Grade F (120 min) per SS-EN 14846: 2008.

Product characteristics

• Unlocks in less than 0.1 second.

• Modern bolt placement.

• The control unit handles day locking.

• Durable material choises with lock case in stainless steel.

• FreeDrive® technology.

• Manipulation-protected barrier technology.

• Back set 50 mm.

• Encrypted communication AES-128.

• Power consumption: 32 mA at rest, max 255 mA for about 20 ms.

• Guarantees opening even if the door is subjected to pressure of up to 5 kg.

• Connection to the motor lock is via RS-485.

• Prepared for OSDP.

• Evacuation and re-entry are ensured together with STEP Exit emergency exit

devices adapted for motor locks. Certied according to SS-EN 179:2008.

Environment

• The control unit can handle temperatures from -5 to +70 degrees.

• The lock can withstand temperatures from -20 to +70 degrees.

POWER CONSUMPTION

Power consumption

Voltage: 15-30 V AC/DC

Power consumption: 32 mA i vila, max 255 mA i ca 20 ms.

1110

COMPLETE SET

Picture no. Art no. Description

1 ST550 Motor lock

2 ST500C STEP Control unit

3 ST9009-15 Strike plate

4 ST0910 Magnet

5 ST1199 Drill protection

6 ST0917 20 cm cable with adapter

7 ST1192 Skrew and magnet set.

8 ST1283 STEP Lead cover

9 ST0916 10 m cable 0,25 mm2 with 8 leaders.

6

1

7

2

3

8

9

5

4

12

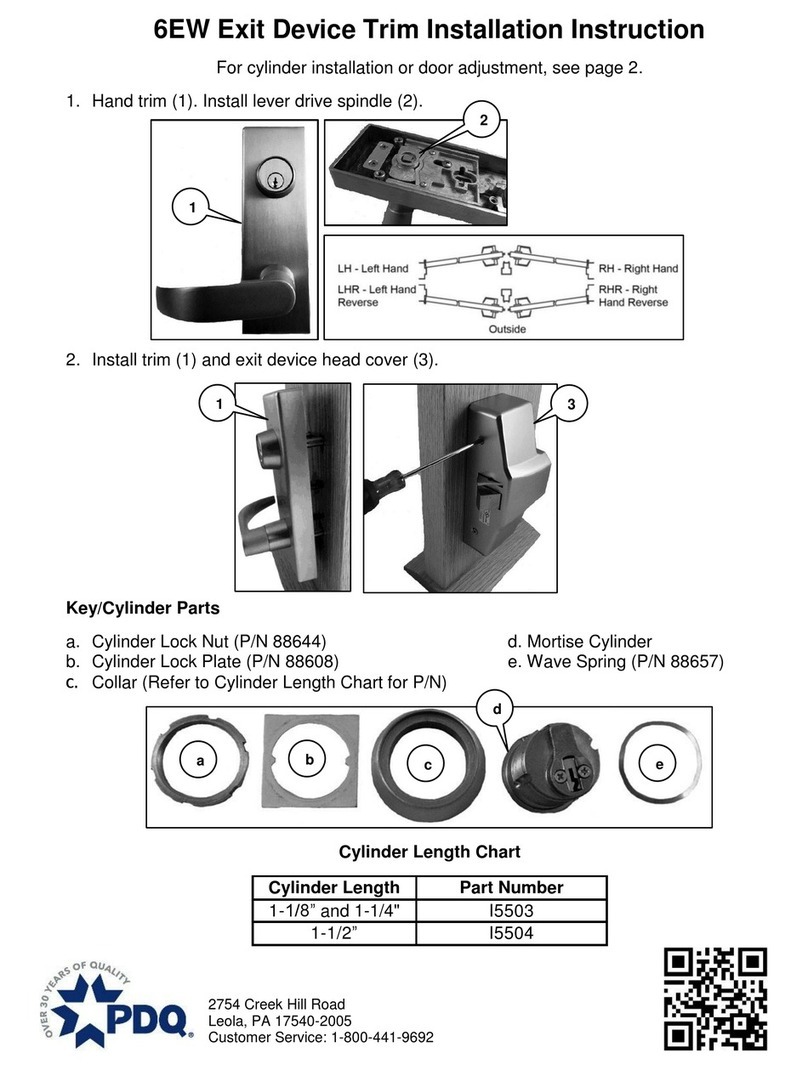

INSTALLATION INSTRUCTIONS

The latch bolt position

in a right handed door.

1. Pusch the latch bolt in.

2. Loosen the screw completely so that

the latch bolt is released.

1. Pull out and turn the latch bolt.

2. Put the latch bolt back. The latch bolt position

in a left handed door.

1. Pusch the latch bolt in.

2. Screw back the screw.

Turn the latch bolt for left handed doors (ST550)

The ST550 motor lock is delivered with the latch bolt mounted for a right handed door. If the lock

is going to be installed in a left handed door, the latch bolt must be turned.

Picture 1 Picture 2 Picture 3 Picture 4 Picture 5

Attach the drill

protection

Attach the drill protection with

included mounting pads.

Outside

1312

Connection of ST550 / ST551 with STEP cable (ST0916)

Connect supply voltage

Supply voltage must be connected to 15-30 V AC / DC. The terminal is polarity-free.

Connect opening signal

Open signal connects to OPEN # 1.

Art no. Description

ST550 STEP 550 Motor lock

ST0916 10 m cable 0,25 mm2 with 8 leaders.

ST500C STEP Control unit

Connect the pre-connected end of the cable to the back of

the lock. See picture.

Connect the other end of the cable to LOCK # 1 in the

control unit (lock 2 is connected to LOCK # 2). Check that

the leaders is connected as instructed.

Check that the switch on the back of the lock is set in its

upper position for lock 1 and its lower position for lock 2.

Switch Lock 1

Lock 2

1. Brown B-

2. White A+

3. Green VCC

4. Yellow GND

1. White A+

2. Brown B-

3. Green VCC

4. Yellow GND

1. IN#1-

2. IN#1+

OPEN #1

LOCK #1

15-30 V

AC/DC

Switch

Lock 1

Lock 2

Lock 1 Lock 2

14

Connect the connector of the cable adapter to the

back of the lock. See picture.

Pin and connect a separate extension cable.

Connect the cable to the white cable adapter.

Connect the other end of the cable to LOCK # 1 in the

control unit (lock 2 is connected to LOCK # 2). Check that

the leaders is connected as instructed.

Check that the switch on the back of the lock is set to

its upper position for lock 1 and its lower position for lock 2.

Connection of ST550 / ST551 with separate cable and adapter (ST0917)

Art no. Description

ST500C STEP Control unit

ST1283 STEP Lead cover

ST0916 10 m cable 0,25 mm2 with 8 leaders.

ST0917 20 cm cable with adapter

ST1192 Skrew and magnet set.

1. Brown B-

2. White A+

3. Green VCC

4. Yellow GND

1. White A+

2. Brown B-

3. Green VCC

4. Yellow GND

1. IN#1-

2. IN#1+

6. White A+

5. Brown B-

4. Green VCC

3. Yellow GND

OPEN #1

LOCK #1

15-30 V

AC/DC

Switch Lock 1

Lock 2

Lock 1

Connect supply voltage

Supply voltage must be connected to 15-30 V AC / DC. The terminal is polarity-free.

Connect opening signal

Open signal connects to OPEN # 1.

1514

ACTIVATION OF ACTIVE SIGNAL

The open signal inputs (IN # 1 and IN # 2) can be programmed to be activated by an active signal

or potential-free closing. Maximum voltage at active signal 30V, minimum 10V.

Potential-free closure is defult selected. See instructions on page 20.

INITIATION

Motor lock and control unit needs to be initialized. Follow these steps.

1. Connect the motor lock to ”LOCK # 1” on the

control unit. (If you have 2 locks the second lock is

connected to ”LOCK # 2”.)

2. Check that the switch in each lock is set to lock 1

and lock 2. Install lock in the door.

3. Power the control box.

4. Open the door, lock out the bolt via the cylinder.

(See Picture 1)

5. Press button . Connected locks are now initiated.

Picture 1

1

1

Display after pairing.

Display before pairing.

2

Drag in the bolt

Pull in the bolt manually via the cylinder or via the opening signal.

Close the door

Close the door and check that the latch bolt locks out again (default delay 0.5 sec). If the door is not

opened after the opening signal has been given, the motor lock re-locks again after a preset delay

of 3 sec. (Delay times can be adjusted in the ”time setup” menu).

The display will show ”searching” for 5

min. When lock 1 and the control unit

are paired , appears at the

bottom left of the display. The search

can be canceled by pressing

button again.

When lock 2 and the control unit are

paired , appears at the bottom

right of the display.

2

1

CABLE DIMENSIONS

Cable length Cable area at 24V

20 m 0,3 mm2

30 m 0,4 mm2

40 m 0,5 mm2

50 m 0,6 mm2

Squeeze the connector to

release the cable.

Disassembly of cable

Safe mode

1

16

Applies when using the motor lock’s internal magnetic contact.

LOCATION OF THE STRIKE PLATE

The motor locks’s door monitor is placed behind the plate at the sensor marking:

1. Install the supplied magnetic contact in the strike plate. It is important that the

magnetic contact in the strike plate and the sensor marking on the plate is placed

at the same height.

2. Make sure that there is no preload on the hook bolt.

1716

MENU STRUCTURE OVERVIEW

Settings

13: Log Menu

1: Time & Date

5. Re-entry setup

4: Timers Setup

3: Door sensor

7: Relay setup

6: Input setup

2: Sync Mode

12: Factory Reset

14: Debug menu

11: FW ver menu

9: SSF3522

8: AUX Rel Menu

10: Service Due

13.1: Record #1-10

1.1: Date

1.2: Time

5.1: Re-entry Mode

3.1: Mode: Internal/External

7.1: Relay #1-11

4.1: Open timer

4.2: Deadbolt

4.3: Door alarm

6.1: Input 1-5

2.1: Sync Mode: ON/OFF

12.1: Delete settings

9.1: Timer Mode

8.1: AUX 1-4 Relay

10.1: Mode

10.1.1: Cycles

10.1.2: Date

18

3: Door sensor

Setting for which door sensor or magnetic contact that is useed.

3.1: Mode: Internal/External (Default Internal)

Choose between internal, external or both

internal and external door magnet.

Change with .

Internal

External

Door

sensor

Internal & External

1: Time & Date

Time is preset to GMT + 1. Time and date can

be changed in separate submenus.

1.1: Date

Current date (DD.MM.YYYY).

Change date: press , change with .

Conrm with .

1.2: Time

Current time, 24 hours (HH: MM).

Change time: press , change with .

Conrm with .

Date

Time

Time & Date DD.MM.YYYY

HH:MM

2: Sync Mode

Activate synchronization mode for 2 locks where

both locks are controlled by OPEN # 1. Change with

2.1: Sync Mode: ON/OFF (förinställt OFF)

ON: Aktivera synkronisering

OFF: Avaktivera synkronisering

ON

OFF

Sync Mode

1918

4: Timers Setup

Settings for operating times.

4.1: Open timer (Default 3 s)

Setting for unlocked time. The opening time can

be set between 3-30 seconds.

Change setting: press , change with .

Conrm with .

4.2: Deadbolt (Default 3 s)

Time setting for delay of locking out

the deadbolt after contact with the door

magnet. Can be set between 0-10 seconds.

Change setting: press , change with .

Conrm with .

4.3: Door alarm (Default OFF)

Time setting for a door buzzer function.

Can be set between OFF / 15-180 seconds.

Change setting: press , change with .

Conrm with .

(Must be supplemented with AUX setting,

8: AUX Rel Menu, page 22).

Open timer

Deadbolt

Timer

setup

Door open

3-30 s

0-10s

OFF/15-180s

5. Re-entry setup

Settings for evacuation and re-entry.

5.1: Re-entry Mode (Default OFF)

Enable or disable re-entry.

Re-entry is activated (ON), deactivated

(OFF) or time activated (3-60 min).

Select mode with .

Change the setting to time: press , change

with . Conrm with .

ON

OFF

Escape

Mode

3-60 min

20

6.1: Input 1-5

6: Input setup

Input settings.

Scroll between inputs with .

Change the setting with .

Mode relay or AC/DC

Choose passive (Relay) or active (AC/DC).

Potential

Relay no. Description Programming

IN #1 polarity OPEN #1 HIGH or LOW

IN #2 polarity OPEN #2 HIGH or LOW

IN #3 polarity DOOR SENSOR HIGH or LOW

IN #4 polarity EXIT RESET HIGH or LOW

IN #5 polarity AUX IN HIGH or LOW

Relay no. Description Programming

IN #1 mode OPEN #1 RELAY or AC/DC 10-48V

IN #2 mode OPEN #2 RELAY or AC/DC 10-48V

IN #3 mode DOOR SENSOR RELAY

IN #4 mode EXIT RESET RELAY

IN #5 mode AUX IN RELAY

Polarity: HIGH/LOW

Choose closed or open. Potential free.

IN #1 polarity HIGH

LOW

Input #1 mode Relay

AC/DC

IN #2 polarity HIGH

LOW

Input #2 mode Relay

AC/DC

IN #3 polarity HIGH

LOW

Input #3 mode Relay

IN #4 polarity HIGH

LOW

Input #4 mode Relay

IN #5 polarity HIGH

LOW

Input #5 mode Relay

Input #5 Role Fire

Panic

Input

setup

This manual suits for next models

1

Table of contents