Stereotaxis Niobe PM3.1 User manual

EXHIBIT G

Stereotaxis Installation Checklists

985-006001 REV. G Effective Date: 03 June 2008

WARNING: This is a revision controlled document. Verify revision is correct prior to use.

Niobe®

MNS Installation Verification and Testing

for PM3.1 Conversion to PM3.2

and for PM3.2 Conversion to PM3.1

4320 Forest Park Avenue, Suite 100

St. Louis, MO 63108

USA

1-866-646-2346

1-314-678-6100 Manual P.N.: 985-006001

www.stereotaxis.com Revision: G

Effective Date: 03 June 2008

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page ii

REVISION HISTORY

Rev

Description

Author

Date

ECO#

-

Initial release for conversion of 1st system

S. Burgett

10-20-04

04-948

A

Remove all references to the joystick (gaming

option) and the printer; added Pivot

Force Verification.

D. Beecher

S. Burgett 06/15/05 05-432

B

Revised Pivot Force Verification

R. Ratliff

06/29/05

05-512

C

Inclusion of Note for verification that a

currently valid version of X-ray Simulator is

used.

S. Ali 08/01/05 05-594

D

Added line to X-ray Simulator compatibility

table

J. Hulsey

12/13/05

05-751

E

Updated per Field Service markups.

J. Thebeau

03/14/06

05-970

F

Update for -22 Niobe software release;

Update per Field Service markups;

Add PM3.2 to PM3.1 conversion steps

C. Hayen

J. Thebeau

07/24/06

06-379

G

Update X-ray Simulator compatibility table

C. Hayen

03 June 2008

08-193

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page iii

Table of Contents

Introduction...................................................................................................................................... 4

1. Site Information and Document Instructions........................................................................... 5

2. System Conversion................................................................................................................. 6

2.1. Convert from PM3.1 (001-005000-1) to PM3.2 (001-006000-1).................................... 6

2.2. Convert from PM3.2 (001-006000-1) to PM3.1 (001-005000-1).................................... 6

3. Verification of Conversion from PM3.1 to PM3.2.................................................................... 7

3.1. Mechanical Alignment.................................................................................................... 7

3.2. System Power On/Off and Emergency Stop.................................................................. 9

3.3. System Homing............................................................................................................ 11

3.4. PM3.2 System Movements, Stowed, Retracted, Navigate AP, Navigate RAO, Navigate

LAO and Navigate with Offset................................................................................................... 11

3.5. Image Transfer from X-ray companion System ........................................................... 17

3.6. System Connectivity..................................................................................................... 17

3.7. Image Brightness and Contrast Adjustments............................................................... 19

3.8. Drawing Vectors, Apply Field, Reduce Field................................................................ 19

3.9. Verification of Movement Ranges and Limit Switches................................................. 21

3.10. Niobe®and X-Ray companion e-stop Verification Procedure...................................... 21

3.11. L-Arm Lock Test (Philips Allura Only).......................................................................... 22

3.12. System Labeling & Cosmetic Covers........................................................................... 23

3.13. Cover Scrape Tests...................................................................................................... 23

3.14. Post Installation Magnetic Survey................................................................................ 24

4. Verification of Conversion from PM3.2 to PM3.1.................................................................. 25

4.1. System Power On/Off and Emergency Stop................................................................ 25

4.2. PM3.1 System Movements, Stowed, Retracted and Navigate.................................... 27

4.3. Image Transfer from X-ray Companion System .......................................................... 32

4.4. System Connectivity..................................................................................................... 33

4.5. Drawing Vectors, Apply Field, Reduce Field................................................................ 33

4.6. System Labeling & Cosmetic Covers........................................................................... 35

4.7. Niobe®and X-Ray companion e-stop Verification Procedure...................................... 35

5. NavigantTM System Functionality.......................................................................................... 37

6. Cardiodrive®System Verification Testing (Partial) ............................................................... 39

6.1. Cardiodrive®Installation Completion Checklist............................................................ 41

7. Installation Completion Checklist.......................................................................................... 42

Table of Figures

Figure 1 – System Control / Remote Stop**.................................................................................... 9

Figure 2 – Table Side Controller with Graphics (PM3.2 Version: 001-006000-1)**...................... 10

Figure 6 System Control / Remote Stop (Siemens PM3.1 Version)......................................... 26

Figure 7 Table Side Controller (Siemens PM3.1 Version)........................................................ 27

Figure 3 – Cardiodrive®User Interface.......................................................................................... 39

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 4 of 43

Introduction

This document is intended to verify system functionality of the Niobe and its optional equipment.

Completion of this document will require a functional companion X-ray system, or the use of a X-

ray system simulator.

The simulator will be used in cases where the X-ray system is not yet installed, or has not

completed installation. The need for the companion X-ray system or the X-ray system simulator

is called out during specific sections as required through out this document.

It is required to use the version of X-ray Simulator that is currently valid to avoid compatibility

issues with the PM3CTRL software.

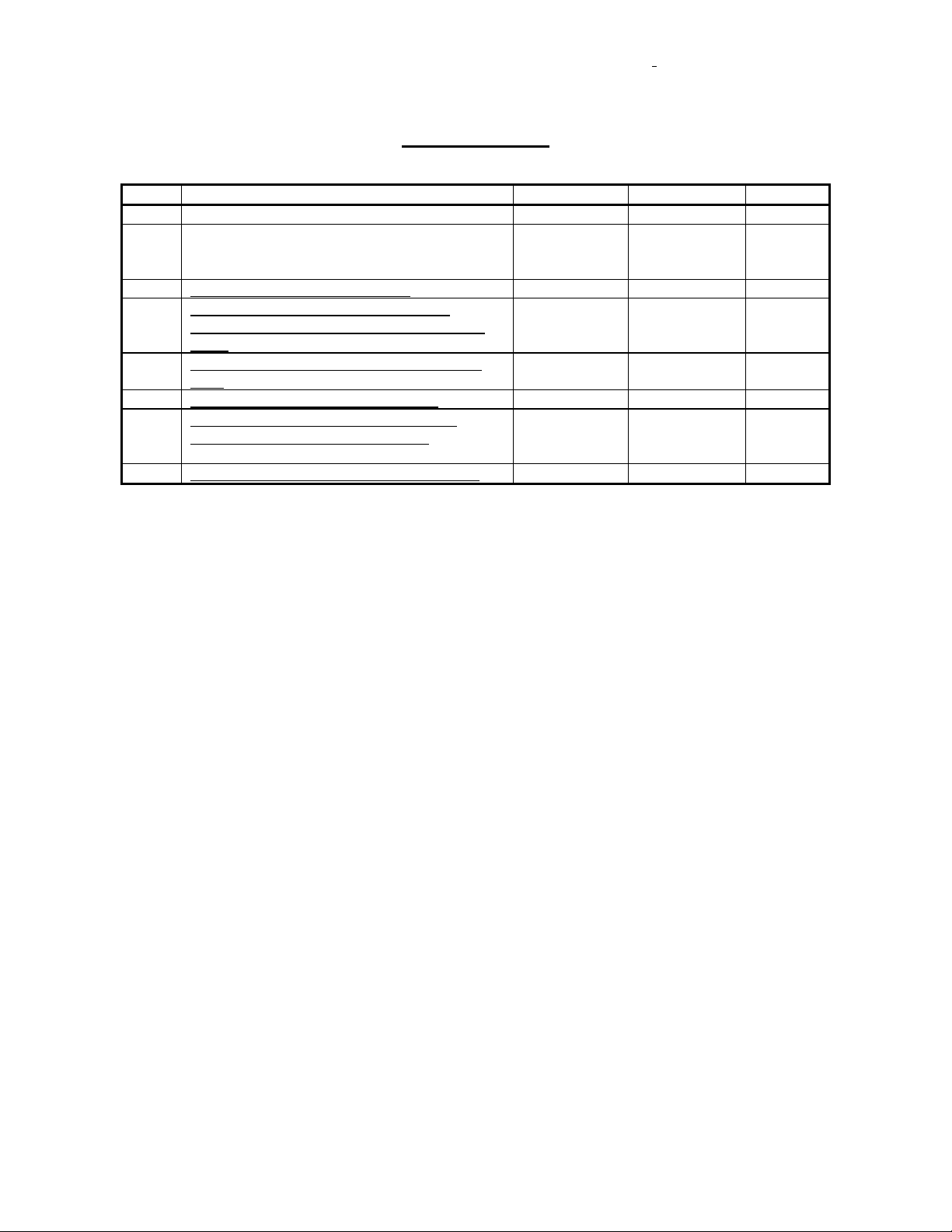

Compatibility Table for PM3CTRL and X-ray Simulator

X-ray Simulator

PM3CTRL

VERSION

S/W P/N

VERSION

S/W P/N

V 2.10 Build 0

860-004466-10

V 3.32 and up

860-003000-25 and up

V 2.9 Build 0

860-004466-9

V 3.31 and up

860-003000-24 and up

V 2.8 Build 0

860-004466-8

V 3.30 and up

860-003000-22 and up

V 2.7 Build 0

860-004466-7

V 3.23

860-003000-21

V 2.6 Build 0

860-004466-6

Up to V 3.22

860-003000-15 → -20

V 2.5 Build 0

860-004466-5

Up to V 3.16

860-003000-15 → -17

* It is required that all versions of X-ray Simulator older than the ones stated above be

updated to the latest released version.

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 5 of 43

1. Site Information and Document Instructions

System Part Number

System Serial Number

Facility Name

Facility Street Address

Facility City, State, Zip

Facility Contact Name

Phone Number for Contact

This document should be completed in the following manner:

•Use black or blue ink pens only.

•Circle P, F, or N/A in the Pass/Fail column for each bulleted step in the test.

•For each bulleted step in the test enter the tester’s initials in the Initials column adjacent to

the entry in the Pass/Fail column.

•Record software version numbers in the boxes provided.

•Sign, date, and print your name in the appropriate spaces on signoff forms.

•Check the appropriate boxes for this site in the table below.

System Configuration

YES

NO

NIOBE®

NWS

(If NO skip section 5)

CARDIODRIVE®

(If NO skip section 6)

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 6 of 43

2. System Conversion

2.1. Convert from PM3.1 (001-005000-1) to PM3.2 (001-006000-1)

Material Required

•Refer to system conversion kit (020-005451-1)

Procedure

1. Turn off system power.

2. Replace existing tableside controller (030-003972-1) with 030-003972-3 controller.

System power should be turned off prior to switching controllers.

3. Upgrade Niobe system software to 860-003000-X (refer to system conversion kit for

appropriate software version) using procedure 985-005173.

Note: To upgrade software from PM3.1 configuration to PM3.2, run the setup.exe file as

directed in 985-005173 and choose PM3.2 as system type.

4. Replace/upgrade all existing system documents with the system documents included in

the system conversion kit.

5. Replace existing system nameplate labeling on cabinet and pods with nameplates

included in system conversion kit.

6. Perform verification tests in section 3, 5, and 6.

2.2. Convert from PM3.2 (001-006000-1) to PM3.1 (001-005000-1)

Material Required

•Refer to system conversion kit (020-005451-2)

Procedure

1. Turn off system power.

2. Replace existing tableside controller (030-003972-3) with 030-003972-1 controller.

System power should be turned off prior to switching controllers.

3. Upgrade Niobe system software to 860-003000-X (refer to system conversion kit for

appropriate software version) using procedure 985-005173.

Note: To upgrade software from PM3.2 configuration to PM3.1, run the setup.exe file as

directed in 985-005173 and choose PM3.1 as system type.

4. Replace/upgrade all existing system documents with the system documents included in

the system conversion kit.

5. Replace existing system nameplate labeling on cabinet and pods with nameplates

included in system conversion kit.

6. Perform verification tests in section 4, 5, and 6.

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 7 of 43

3. Verification of Conversion from PM3.1 to PM3.2

This section includes all of the verification and testing for the base Niobe® system.

Niobe®Software Version Number

3.1. Mechanical Alignment

NIOBE®ALIGNMENT REPORT MP1

Date/Time: ____________________

Location: ____________________

Positioner P/N: ____________________

Positioner S/N: ____________________

Magnet S/N: ____________________

Alignment Fixture P/N: ____________________

Alignment Fixture S/N: ____________________

Calibration Certifier (name): ____________________

Calibration Certifier (signature): ____________________

Measured angles should be within 0.5°of commanded value

Tilt Axis:

0°Value: ____________________

+15°Value: ____________________

-15°Value: ____________________

Cover Distance (0°, +15°, -15°):

Distance to Reference (247.65mm+5/-1.5 mm): ______/_______/_______

Distance to Reference (457.2mm+5/-1.5 mm): ______/_______/_______

NIOBE®ALIGNMENT REPORT MP2

Date/Time: ____________________

Location: ____________________

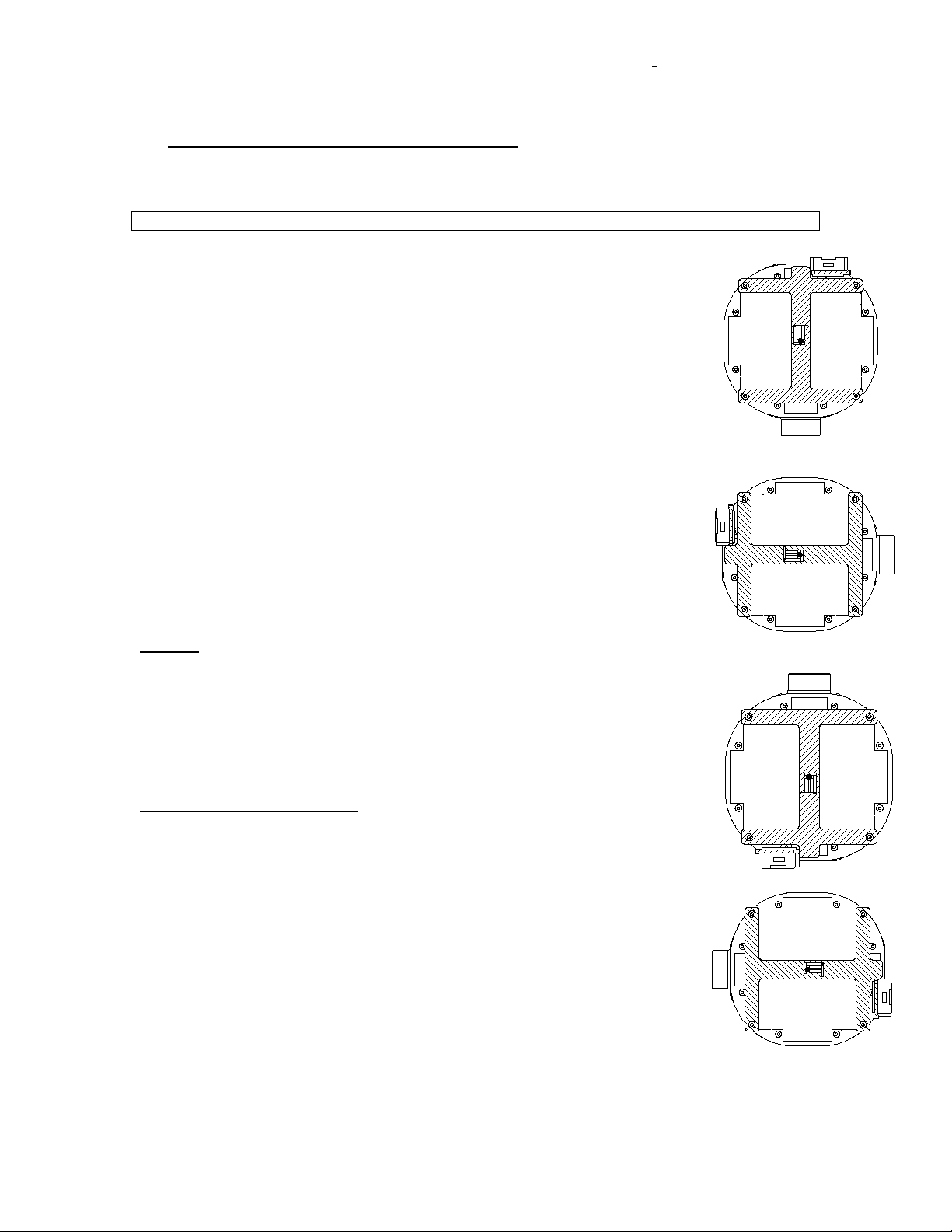

0°Theta Position

90°Theta Position

180°Theta Position

270° Theta Position

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 8 of 43

Positioner P/N: ____________________

Positioner S/N: ____________________

Magnet S/N: ____________________

Alignment Fixture P/N: ____________________

Alignment Fixture S/N: ____________________

Calibration Certifier (name): ____________________

Calibration Certifier (signature): ____________________

Tilt Axis:

0°Value: ____________________

+15°Value: ____________________

-15°Value: ____________________

Cover Distance (0°, +15°, -15°):

Distance to Reference (247.65mm+5/-1.5 mm): ______/_______/_______

Distance to Reference (457.2mm+5/-1.5 mm): ______/_______/_______

Overall Alignment / Calibration Set-Up Pass: Fail:

Test Performed by:

Signature:___________________________________Date:____________

Print Name:_______________________________________

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 9 of 43

3.2. System Power On/Off and Emergency Stop

NOTE

If an X-ray system is not available at this time use the X-ray simulator for testing purposes.

No.

Test Description

Pass/Fail

Initials

1 Verify that the Emergency Stop buttons function

•While the system is powered on and operational depress the

emergency stop button in the control area and verify that the

red light labeled “E Stop Active” behind the left hand front door

of the Control cabinet illuminates and all motion of the MPs is

inhibited.

•While the system is powered on and operational depress the

emergency stop button on a tableside controller and verify that

the red light labeled “E Stop Active” behind the left hand front

door of the Control cabinet illuminates and all motion of the

MPs is inhibited.

P F

P F

2

Verify that the System/Positioner power on/off button functions

•While the system is powered on (the system/Positioner power

on light is lit) actuate the on/off switch by holding the button in

the OFF position (approx. 3 sec) until power is removed.

Verify that the on/off light is no longer lit, the red light labeled

“E Stop Active” behind the right hand front door of the Control

cabinet and the System Control/Remote Stop Unit** are

extinguished, and all motion of the MPs is inhibited.

•While the system is powered off (the system/Positioner power

on light is not lit) actuate the on/off switch to the on position.

Verify that the on/off light illuminates, the red light labeled “E

Stop Active” behind the right hand front door of the Control

cabinet and the System Control/Remote Stop Unit** are

extinguished, motion of the MPs is restored.

P F

P F

System/Positioner

power on when

illuminated (Green)

System/Positioner

power on/off

Emergency Stop

is activated when

illuminated (Red)

Emergency Stop

(E-Stop). Press to

halt all mechanical

motion.

Figure 1 – System Control / Remote Stop**

(001-005000-1 and 001-006000-1 configuration shown)

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 10 of 43

Figure 2 – Table Side Controller with Graphics (PM3.2 Version: 001-006000-1)**

** NOTE: E-Stop Button and/or E-Stop Light are not present on 001-005100-1 and 001-006100-1

configurations of Power Box or Table Side Controller.

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 11 of 43

3.3. System Homing

No.

Test Description

Pass/Fail

Initials

3

Verify that Homing of the system completes normally.

•Force a request for homing by powering off the system.

•Turn the system power back on and observe the message:

“The System Needs Homing – Press and Hold the Navigate

AP Button”.

•Press and hold the Navigate AP button on the tableside

controller until homing completes.

•Verify that the following icons are displayed during the Homing

process and all three yellow areas are blinking on right icon.

and

•Verify that the homing command completes normally by

observing the “Homing Complete” message on the monitors.

P F

P F

P F

P F

P F

3.4. PM3.2 System Movements, Stowed, Retracted, Navigate AP, Navigate RAO,

Navigate LAO and Navigate with Offset.

No.

Test Description

Pass/Fail

Initials

4

Verify the system will move to Navigate AP position from the Stowed

position.

•While the Positioner is in the Stowed position press and hold

Navigate AP position button:

on the tableside controller until the Positioner

reaches the Navigate position.

•Verify that the Navigate AP Position indicator:

is displayed on the control room and

procedure room monitors.

•Verify that while the Positioner is moving the green indicator

for the location the Positioner has been requested to move to

blinks during the move.

•Verify that the total time to move to Navigate position does

not exceed 60 seconds.

P F

P F

P F

P F

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 12 of 43

5

Verify the system will move to Stowed position from Navigate.

•While the Positioner is in the Navigate position press and

hold the stowed position button:

on the tableside controller until the Positioner

reaches the stowed position.

•Verify that the Stowed Position indicator:

is displayed on the control room and

procedure room monitors.

•Verify that while the Positioner is moving the green indicator

for the location the Positioner has been requested to move to

blinks during the move.

•Verify that the total time to move from Navigate to Stowed

does not exceed 30 seconds.

•Verify that the first 20oof movement, on Pivot axis, towards

stowed does not exceed 15 seconds.

P F

P F

P F

P F

P F

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 13 of 43

6

Verify the system will move to Retracted position from the Stowed

position.

•While the Positioner is in the Stowed position press and hold

the Navigate AP Button:

on the tableside controller until the Positioner

reaches the Retracted position and release Navigate AP

Button.

•Verify that the Retracted Position indicator:

is displayed on the control room and

procedure room monitors.

•Verify that while the Positioner is moving the green indicator

for the location the Positioner has been requested to move to

blinks during the move.

•Verify that the total time to move to Retracted position does

not exceed 60 seconds.

P F

P F

P F

P F

7

Verify the system will move to Navigate RAO and LAO positions from

the Retracted position.

•While the Positioner is in the Retracted position press and

hold Navigate position button:

for Navigate RAO

OR

for Navigate LAO on the tableside controller until

the Positioner reaches the Navigate position.

•Verify that the Navigate Position indicator:

for Navigate RAO

OR

for Navigate LAO is displayed on the control

room and procedure room monitors.

•Verify that while the Positioner is moving the green indicator

for the location the Positioner has been requested to move to

blinks during the move.

P F

P F

P F

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 14 of 43

8

Verify the system will move to Retracted position from the Navigate

position.

•While the Positioner is in the Navigate position press and

hold the Retracted position button:

and

on the tableside controller until the Positioner reaches the

Retracted position.

•Verify that the Retracted Position indicator:

is displayed on the control room and

procedure room monitors.

•Verify that while the Positioner is moving the green indicator

for the location the Positioner has been requested to move to

blinks during the move.

P F

P F

P F

9

•Now simultaneously hold the Image Transfer and the

appropriate Movement button to initiate the interlock override

condition and verify that the system will begin to move with

the Stow position button pressed.

+

P F

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 15 of 43

10

Verify that the C-Arm Collision Detection is operational between the

Niobe®and X-ray Systems.

•Pre-Condition: PM3CTRL not in Service Mode

•Place the Positioners in the Stowed position.

•Center Patient Table Laterally

•Move the C-Arm to RAO 35 degrees:

•Press the Navigate AP position button on the tableside

controller and verify that the system will NOT move to the

Navigate AP position (starts, but does not complete).

•Press the Navigate RAO position button on the tableside

controller and verify that the Positioner DOES move to the

Navigate RAO position.

•Press the Navigate LAO position button on the tableside

controller and verify that the Positioner does NOT move to

the Navigate LAO position (starts, but does not complete).

•Move the C-arm to the AP position.

•Press the Navigate LAO position button on the tableside

controller and verify that the Positioner DOES move to the

Navigate LAO position.

•Press the Manual Retract buttons for the Left then the Right

Pods to the Fully Retracted position.

•Now simultaneously hold the Image Transfer and any

Navigate button to initiate the interlock override condition

and verify that the system will NOT begin to move to the

Navigate position with the override buttons pressed.

•Move Table 75mm towards MP2.

•Press the Manual Advance button to for MP1 to the fully

extended position (max allowable).

•Press the Manual Advance button for MP2 until the Navigate

Position is achieved.

P F

P F

P F

P F

P F

P F

P F

P F

P F

P F

11 Verify that the system between locations Icon is displayed if the

tableside controller motion button is released prior to the movement

being completed when Pivoting.

•Verify that you observed the following icon when you release

the motion button prior to the requested position being

achieved.

P F

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 16 of 43

12

Verify that the Retracted Icon is displayed if the tableside controller

motion button is released prior to the movement being completed

when Tilting.

•Verify that you observed the following icon when you release

the motion button prior to the requested position being

achieved.

P F

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 17 of 43

3.5. Image Transfer from X-ray companion System

No.

Test Description

Pass/Fail

Initials

13

Verify that Valid Images can be transferred from the Siemens System

to the Niobe®System.

•Take one image, or use the X-ray simulator to send a file, of a

suitable phantom in the x-ray field with the RAO/LAO angle at

least 20o. Click the Transfer image button on the display.

•Verify that the system displays the image transfer in process

icon (same ICON as the transfer image, except arrow goes to

green and background goes to white)

•Verify that the images are displayed on the NavigantTM

monitor in two locations.

•Verify that the transfer time is in the range of 3-5 seconds.

•Take a second image, or use the X-ray simulator to send a

file, after moving the C-Arm through at least 40oof movement

RAO/LAO. Click the Transfer image button on the display.

•Verify that the system displays the image transfer in process

icon (same ICON as the transfer image, except arrow goes to

green and background goes to white)

•Verify that the image is displayed on the NavigantTM monitor in

two locations.

•Verify that the transfer time is in the range of 3-5 seconds.

P F

P F

P F

P F

P F

P F

P F

P F

14

Verify that the system will identify invalid images and not permit

magnetic navigation.

•Repeat test 13 but only move the RAO/LAO movement 39o,

or use the X-ray simulator to send a files, between transferring

the first image and the second image. Verify that the Images

Invalid Icon is displayed, which is a large yellow “X”.

P F

3.6. System Connectivity

No.

Test Description

Pass/Fail

Initials

15

Verify that the Niobe®system reports a loss of communication with the

X-ray System.

•With the system operational remove the Category 5 cable

from connector J2 on the Control cabinet. Verify that the

system reports a Missing Information icon.

P F

16

Verify that the Niobe®System reports a loss of communication with the

P F

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 18 of 43

Control cabinet.

•With the system operational remove the Category 5 cable

from connector on the front of each Galil motion controller in

the Control cabinet. Remove the connectors one at a time to

verify that either connector will result in lost connectivity. Verify

that the system displays the red “Cannot Communicate with

the Magnet Positioners” message.

985-006001 REV. G Effective Date: 03 June 2008

Stereotaxis, Inc. Page 19 of 43

3.7. Image Brightness and Contrast Adjustments

No.

Test Description

Pass/Fail

Initials

17

Verify that the images can be adjusted for brightness and contrast on

the NWS system.

•Ensure that an image is displayed on the NWS Monitor.

•Select the Image Brightness and Contrast Adjust button on the

display.

•Verify that the cursor takes on a different shape.

•Adjust the brightness and contrast for both the RAO image

and the LAO image. Verify operation.

P F

P F

P F

3.8. Drawing Vectors, Apply Field, Reduce Field

No.

Test Description

Pass/Fail

Initials

18

Verify that you can draw a vector on Valid Images and apply the field.

•Mount a catheter on the table in the navigation test apparatus.

Place the system in Navigate mode.

•Select device type.

•Select override

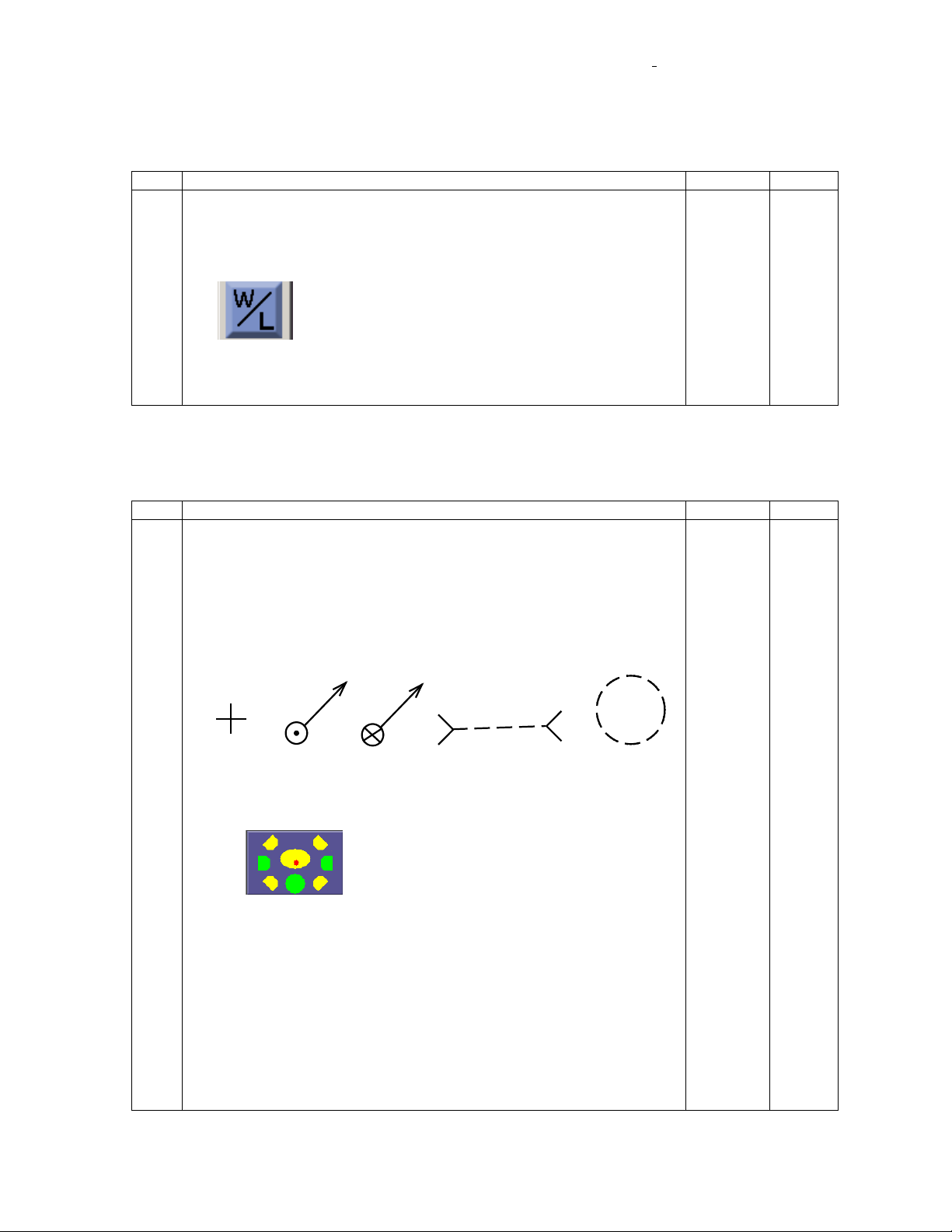

•Click on the “Direction Navigation Mode” icon.

•Acquire two valid images. Draw vectors for Cranial tip

orientation.

CURSOR VECTOR

(POINTING TOWARDS

YOU) CUE LINE

VECTOR

(POINTING AWAY

FROM YOU)

REDUCED FIELD

REGION

(APPROXIMATED)

•Click the apply field button on the display and observe the

catheter tip. Verify that the catheter tip is now in Cranial tip

orientation and the Applied Field icon is displayed.

OR appropriate Icon for Tilted Navigate position

with Field Applied.

•Verify that you observed the appropriate overlay information of

the screen while drawing vectors.

•Repeat for the following tip orientations:

oAnterior Tip Orientation

oPosterior Tip Orientation

oLeft Lateral Tip Orientation

oRight Lateral Tip Orientation

•Verify that the catheter tip orients in the expected direction.

P F

P F

P F

P F

P F

P F

P F

P F

P F

This manual suits for next models

1

Table of contents

Popular Laboratory Equipment manuals by other brands

CPAC

CPAC SteriDENT 300 operating instructions

Nepagene

Nepagene ELEPO21 instruction manual

Okolab

Okolab 158206046 installation guide

Endress+Hauser

Endress+Hauser Levelflex M FMP41C Safety instructions

Accuris

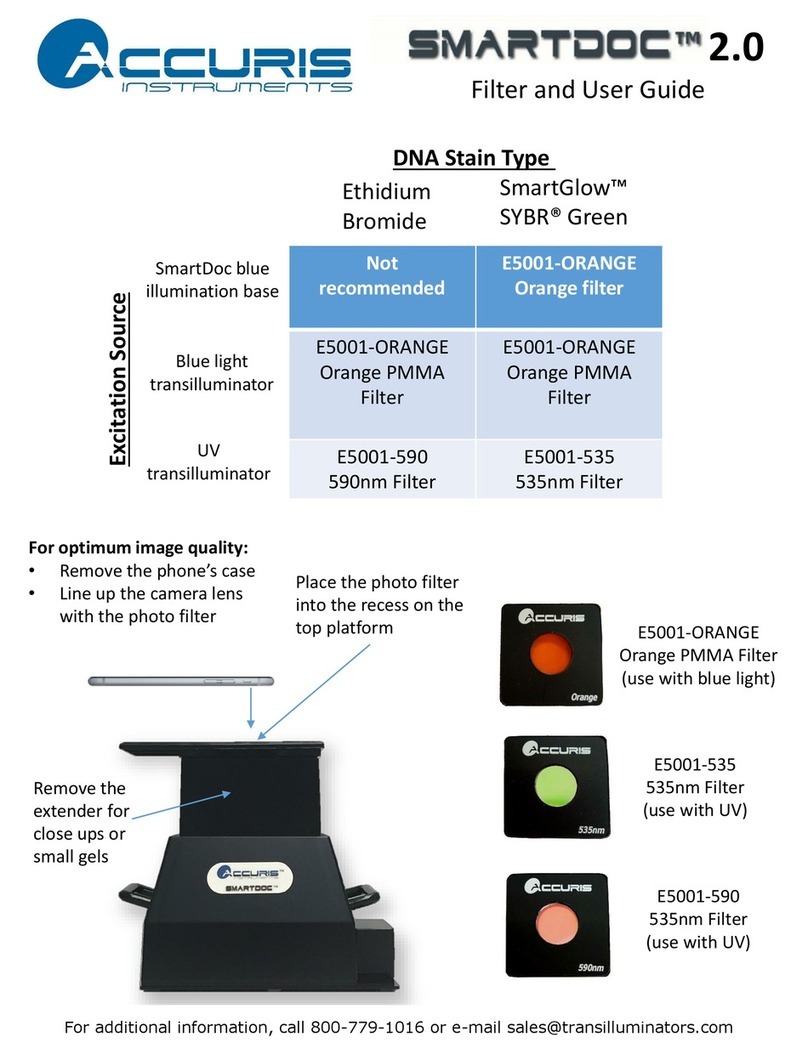

Accuris Smartdoc 2.0 Filter and user guide

Malmet

Malmet WDS1 Operation, maintenance and installation manual